Académique Documents

Professionnel Documents

Culture Documents

CE470MidExam Solutions

Transféré par

Tefera TemesgenCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CE470MidExam Solutions

Transféré par

Tefera TemesgenDroits d'auteur :

Formats disponibles

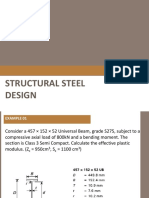

CE 470 Mid-term Exam

Student Name: ____________________________

Problem No. 1

Total points = 50

Determine the design tensile strength of the C10 x 25 channel section made from A36 steel. The

member end connection is made using bolts that are in. in diameter made from A325 steel. The

bolt connection layout is shown below.

(1) Determine the design tensile strength:

(45 pts)

(a) Consider only the limit states of gross yielding and net section fracture.

(b) For net section fracture, check all fracture paths (at least 3) you deem appropriate.

(c) Calculate U (shear lag factor) using the equation U=1-x/L0.9

(2) Answer the following questions qualitatively, i.e., without any calculations.

(5 pts)

(a) What will be the block shear failure path for the member?

(b) Can the block shear strength be computed using the standard AISC equations, or will

you need to modify them? If so, How?

Solution

(5) getting material properties right + (5) for gross yielding strength

Fy 36 ksi

Fu 58 ksi

db 0.75 in

Ag 7.34

in

tw 0.526

Part 1

Gross Yielding

Pny 0.9 Fy Ag

Pny 237.816 kips

(8) for computing U correctly

x 0.617

in

L 5.5

in

U 1

x

L

U 0.888

Less than 0.9

in

CE 470 Mid-term Exam

Student Name: ____________________________

(9) points for each of three net fracture cases = 9 x 3 = 27

For each case: Assumption of correct path (2)

Calculation of correct net width = (5)

Calculation of correct fracture strength = (2)

3 2.5

Fracture Path

C10x25

3

2

Net Fracture Case 2

An Ag 3 db

Pnf2 0.75 Fu Ae

2

2

3

3

tw

8

7

5

An 5.959 in

Ae U An

Pnf2 322.205 kips

3 2.5

Fracture Path

C10x25

Ae 5.291

in

CE 470 Mid-term Exam

Student Name: ____________________________

3 2.5

2

2

Af/2

Fracture Path

Aredg

C10x25

Af/2

Additional (more than three) cases to be considered for no points

Net Fracture Case 4

T 8 in

Aredg T tw

Aredg 4.208

Af Ag Aredg

Af 3.132

wn T 3 db

An Af wn tw

Pnf3 0.75 Fu Ae

( AISC)

g 3 in

in

in

4 g

wn 5.896

An 6.233 in

7

s 2.5 in

in

Ae U An

Ae 5.534

in

Pnf3 280.848 kips

3 2.5

Af/2

Fracture Path

C10x25

Aredg

Af/2

This is obviously (5) points

Part 2

By examining the results in Part 1, the block shear failure path would be as follows:

2

2

3

3

3 2.5

Fracture Path

C10x25

In this case, no modifications to the AISC equation is required. However, if the results in Part 1

indicate that Path 2 governs, then the AISC equations would have to be modified as follows:

CE 470 Mid-term Exam

4 g

Agt tw 6 2

Ant Agt db

Student Name: ____________________________

tw

Ultimately, the equation for the gross area is computed as follows:

s2

Where g is the vertical spacing.

Agt t w g

4g

CE 470 Mid-term Exam

Student Name: ____________________________

Problem No. 2

Total points=50

(a)

Using the tension member design Tables in the AISC manual, select a double angle

tension member (with equal legs) to carry a factored design load of 150 kips.

(b)

Is the net section fracture strength noted in Table 3-7 correct? If not, then where does the

approximation appear in this Table?

(c)

Assuming in. diameter A325 bolts in shear/bearing for the connection system, how

many such bolts do you need for the connection?

(d)

Assuming Le=2 in., s=3.0 in., sketch a reasonable bolt layout, what is the actual net

section fracture design strength?

(e)

What is the block shear strength assuming that the shear fracture strength dominates, i.e.,

Rn = 0.75 [0.6FuAnv + FyAgt] 0.75 [0.6FuAnv + FuAnt]

(f) Is the original selected member still valid? Do not re-design, just state what needs to be

changed to make it valid.

Solution

(4) points for selecting a reasonable section. No deduction for not picking the lightest section.

Just a warning. Sections in the neighborhood of the lightest section are OK.

(a) The most economical section from Table 3-7 is a 2L3 x 3 x 3/8 Py = 150 k, Pn = 151 k

(4) points for this

(b) When Ae < 0.75 Ag, tabulated values of design tension rupture cannot be used. Tables assume

Ae = 0.75 Ag

(12 points) for this calculation (4 for bearing and 8 for bolt shear strength)

(c) For bearing strength, assuming Le Lefull and s sfull Rn = 78.3 kips/in (Table 7-12)

Rn = 78.3 kips/in

Rn 78.3 t 2 Rn 58.725

kips of 1 bolt

Pu

Rn

n 2.554

bolts

CE 470 Mid-term Exam

Student Name: ____________________________

Shear Strength 1 bolt: Rn 31.8 kips (Table 7-10)

n 5 bolts

Make

Rn 58.725 n

Bearing

Shear

31.8

n

Rn

78.3Rn Rn

78.3

Rn 78.3 t

Rn 293.625

kips

Rn 159

in

Rn 29.362

Pu

Rn

n 4.717

bolts

kips

kips

kips of 1 bolt

Pu

Rn

n 5.109

bolts

KK: The bearing strength will be 78.3 x t x 2 = 58.6 kips because there are two angles, and each

shares half the load. If they dont do this step and use the shear strength of the bolt directly,

deduct only a few points (max. 5).

Shear Strength 1 bolt: Rn 31.8 kips (Table 7-10)

n 6 bolts

Make

Bearing

Rn 29.362 6

Rn 176.172

kips

Shear

Rn 31.8 6

Rn 190.8

kips

Pu

Rn

n 4.717

bolts

(10) points for this calculation (net area calculation =3, U calculation =4, strength calc. = 3)

(d) Bolt layout shown below. Path shown for block shear in Part (e).

32

CE 470 Mid-term Exam

Ag 2.32

in

An Ag

x 0.823

An 1.992 in

L 15 in

in

Ae An U

Student Name: ____________________________

Ae 3.585

U 1

Pn 0.75 Fu Ae

in

2 Angles

An 2 An

U 0.945

U 0.9

x

L

Pn 155.964 kips

((18 points for this calculation)

Path = 3, Anv=5, Agt=2, Ant=5, Final strength = 3

(e) Path shown above in (d).

1 3

Anv t 14 4.5

8 4

Anv 3.773

in

Agt t 2

Agt 0.75

in

Ant 0.586

in

1 3

Ant t 2 0.5

8 4

Fy Agt 27

Fu Ant 33.984

kips

Rn 0.75 ( 0.6 Fu Anv Fy Agt )

2 Angles

Use Equation Below:

Rn 118.737

kips

2 Rn 237.473 kips

Anv t 17 5.5

1

8

Agt t 2

1 3

Ant t 2 0.5

8 4

Fy Agt 27

kips

Fu Ant 33.984

Rn 0.75 ( 0.6 Fu Anv Fy Agt )

2 Angles

kips

2 Rn 279.07

Anv 4.57

in

Agt 0.75

in

Ant 0.586

in

kips

Use Equation Below:

Rn 139.535

kips

kips

(2) points for this conclusion

(f) Section is adequate.

An 3.984 in

CE 470 Mid-term Exam

Student Name: ____________________________

Problem No. 3

(Total points=50)

Design the welded connection (only) for the member shown below. The given loads are service

loads. Assume Fy=50 ksi for the angle tension member, and Fy=36 ksi for the gusset plate. Show

the connection design on a sketch complete with all dimensions.

Note: You will have to consider both (angle and gusset) base metal strengths to compare with the

fillet weld strength.

Solution

Calculation of factored load = 2 points

Amin = 4 points

A max = 4 points

Selecting correct a = 2 points

Lmin= 4 points

Lmax=4 points

Implementing Lmax=2 points

Weld metal strength = 8 points

Base metal strength = 6 + 6 points

Required weld length = 3 points

Figure showing detail layout = 5 points

CE 470 Mid-term Exam

Fya 50 ksi

Fyg 36 ksi

Pu 1.2 D 1.6 L

tmin

5

16

Student Name: ____________________________

in

D 45 kips

Pu 271.6

tmax

3

8

in

L 136

kips

ta

5

16

in

tg

kips

amax tmin

1

16

amax 0.25

in

3

Table J2.4 Make

in

a 0.25 in

Fexx 70 ksi

16

Strength Weld Metal Rn ( Lw) 0.75 0.6 Fexx 0.707 a Lw 5.56762500 Lw

amin

Base Strenght Gusset Rn ( Lw) 0.9 0.6 Fyg tg Lw 7.2900000000000000000 Lw

Base Strenght Angle

Rn ( Lw) 0.9 0.6 Fya ta Lw 8.4375000000000000000 Lw

Strength Weld Metal Governs

Lw

271.6

5.56762500

Lwmin 4 a 1.00

Lw 48.782

in

in

Lwmax 100 a 25.00

in

Therefore, in one strip, the effective length of the

weld can't be greater than 25 in.

22 in.

5 in.

22 in.

3

8

in

CE 470 Mid-term Exam

Student Name: ____________________________

25 in.

0.5 in.

0.5 in.

25 in.

0.25 in.

0.25 in.

25 in.

25 in.

10

CE 470 Mid-term Exam

Student Name: ____________________________

Problem No. 4.

Total points = 50

Design a bolted splice connection for a single angle tension member. The service loads acting on

the member are 50 kips dead load + 30 kips live load.

The splice must be slip-critical for service loads, and have adequate shear/bearing strength for

factored loads. Assume 7/8 in. diameter A325 bolts.

(1) Design and check the splice to be slip-critical at service loads

(2) Design and check the shear/bearing strength of splice at ultimate loads.

(3) Design the thickness and width of the gusset plate

(4) Provide a sketch of the splice detail.

There is no need to check the design strength of the angle at ultimate loads. Assume that the

angle design works.

Solution

D 50 kips

L 30 kips

db

7

8

in

t 0.5 in

Part 1

SL D L 80

kips

Rn 10.2

For Slip Critical, One Bolt from Table 7-16

Rn 10.2 n

kips

Rn 81.6

kips

(12 points for slip critical design)

11

Use 8 bolts

n 8

CE 470 Mid-term Exam

Student Name: ____________________________

(18 points for shear bearing design) 8 for shear, and 10 for bearing.

Part 2

Pu 1.2 D 1.6 L

Pu 108

Shear (Table 7-10)

Rn 21.6 n

kips

Rn 172.8 kips ok

Bearing

Lemin 1.125 Table J3.4

Make Le 1.25 in

smin 2.6667 db

smin 2.333 in

spref 3 db

spref 2.625 in

For Edge:

Rn 40.8 t

For Interior Spacing:

Rn 20.4

Rn 91.3 t

s 3 in

Use

kips

Rn 45.65 kips

Rn 45.65 7 20.4 Rn 339.95 kips ok

Note Assume Gusset Plate has same thickness

(15 points for gusset plate design) 5 points for getting 0.85 factor

Part 3

Make U=0.85

Ag

From AISC 16.1-178 U 0.85

Pu

Ag 3.333 in

0.9 36

width

Ag

width 6.667

0.5

Ag b 0.5

Ag 3.5

in

Gross Yielding

Py Ag 0.9 36

Net Fracture

b 7

in

in

An Ag db

Make

0.5

Pn 0.75 U An 58

Py 113.4

kips

Pn 110.925 kips

Part 4

(5 points for pretty picture)

1.25

3 3 3

3 3

1.25

12

Vous aimerez peut-être aussi

- Fsi GreekBasicCourse Volume1 StudentTextDocument344 pagesFsi GreekBasicCourse Volume1 StudentTextbudapest1Pas encore d'évaluation

- Manual of Engineering Drawing: British and International StandardsD'EverandManual of Engineering Drawing: British and International StandardsÉvaluation : 3.5 sur 5 étoiles3.5/5 (4)

- The Christian Life ProgramDocument28 pagesThe Christian Life ProgramRalph Christer MaderazoPas encore d'évaluation

- Chapter-2 Design For Tension MemberDocument14 pagesChapter-2 Design For Tension Memberzakai zakiPas encore d'évaluation

- The EagleDocument4 pagesThe EagleJunkoPas encore d'évaluation

- JointDocument8 pagesJointTefera TemesgenPas encore d'évaluation

- Rebar Unit RateDocument10 pagesRebar Unit RateTefera TemesgenPas encore d'évaluation

- 1 - API 570 Exam A (150 Q&A)Document46 pages1 - API 570 Exam A (150 Q&A)Tashrif Yusuf100% (4)

- 1 - API 570 Exam A (150 Q&A)Document33 pages1 - API 570 Exam A (150 Q&A)Shaalan AliPas encore d'évaluation

- 343 3khbDocument35 pages343 3khbshimic32000100% (1)

- 425 Serviceability CHP 6 S11Document76 pages425 Serviceability CHP 6 S11aomareltayeb100% (1)

- Aisi Example II-7Document24 pagesAisi Example II-7LauraMilenaHernándezTorresPas encore d'évaluation

- Structural Steel Design to Eurocode 3 and AISC SpecificationsD'EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsPas encore d'évaluation

- General FormulaDocument53 pagesGeneral FormulaTsegawbezto97% (32)

- 425-Doubly Reinforced Beam Design-S11Document45 pages425-Doubly Reinforced Beam Design-S11Kaye MamisaoPas encore d'évaluation

- Knuckle Joints DesignDocument10 pagesKnuckle Joints DesignKvrd Prasad100% (1)

- Beam DeflectionDocument59 pagesBeam DeflectionmkbijuPas encore d'évaluation

- Strut and Time MethodDocument30 pagesStrut and Time MethodkrishPas encore d'évaluation

- API 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsDocument6 pagesAPI 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsIbtehaj ManiPas encore d'évaluation

- Extracts From Ec3 For Students 2012Document6 pagesExtracts From Ec3 For Students 2012Alexandru MarincuPas encore d'évaluation

- 2 - API 570 Exam B (150 Q&A)Document33 pages2 - API 570 Exam B (150 Q&A)Dabbar Taher100% (1)

- Design For RC Flat SlabsDocument70 pagesDesign For RC Flat SlabsAil AafaaqPas encore d'évaluation

- Lecture 4 - Flexure: June 9, 2003 CVEN 444Document48 pagesLecture 4 - Flexure: June 9, 2003 CVEN 444chiranjeevi02Pas encore d'évaluation

- BAA 3223 Steel & Timber Design Final Exam PaperDocument11 pagesBAA 3223 Steel & Timber Design Final Exam PaperAzil14100% (4)

- 171-178 EurocodeDocument8 pages171-178 EurocodeDeana WhitePas encore d'évaluation

- Mathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsD'EverandMathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsRoderick MelnikPas encore d'évaluation

- Chapter 3 Example of Compression ColumnDocument9 pagesChapter 3 Example of Compression ColumnMesfin100% (2)

- Strut and Tie ModelDocument30 pagesStrut and Tie ModelRoya Abn100% (2)

- Stair Case DesignDocument4 pagesStair Case DesignTefera TemesgenPas encore d'évaluation

- New Building Height Regulation ManualDocument70 pagesNew Building Height Regulation ManualTefera Temesgen58% (12)

- 7 Critical Reading StrategiesDocument1 page7 Critical Reading StrategiesWilliam Holt100% (2)

- Chapter 1 - Yield Line Analysis For SlabsDocument52 pagesChapter 1 - Yield Line Analysis For SlabsTefera Temesgen100% (1)

- CE470MidExam SolutionsDocument12 pagesCE470MidExam SolutionsJavier CaballeroPas encore d'évaluation

- Mech 260-Final ExamDocument3 pagesMech 260-Final ExamwerewaroPas encore d'évaluation

- Quiz 1 2.008 Design and Manufacturing II: SolutionDocument12 pagesQuiz 1 2.008 Design and Manufacturing II: SolutionLa Casita de TonyPas encore d'évaluation

- Structural Steel DesignDocument32 pagesStructural Steel DesignshalukaPas encore d'évaluation

- AME 204 Spring 2012 Midterm Exam I SolutionDocument6 pagesAME 204 Spring 2012 Midterm Exam I SolutionJack ZhaoPas encore d'évaluation

- CVEN3302 - Final Examination 2008Document5 pagesCVEN3302 - Final Examination 2008fflegendsPas encore d'évaluation

- Lec 04 - Steel - Bolt Connections (Examples)Document3 pagesLec 04 - Steel - Bolt Connections (Examples)jaffer talhaPas encore d'évaluation

- Problemario1-Diseã o Mecanico1Document4 pagesProblemario1-Diseã o Mecanico1Gerardo BocanegraPas encore d'évaluation

- Handout CE523 Lecture Week 3 Tension MembersDocument45 pagesHandout CE523 Lecture Week 3 Tension MembersehabPas encore d'évaluation

- MODULO 3 Carlo MonsalveDocument14 pagesMODULO 3 Carlo Monsalvecarlomonsalve1Pas encore d'évaluation

- Fall 2012 Test2 SolnDocument6 pagesFall 2012 Test2 SolnepsilonnaughtPas encore d'évaluation

- Compression-Tension-Bending&biaxel Bending: Sharif Haji RasulDocument19 pagesCompression-Tension-Bending&biaxel Bending: Sharif Haji RasulRekan DahoPas encore d'évaluation

- Design AidsDocument28 pagesDesign Aidsresurrection786Pas encore d'évaluation

- ENCE 455 Design of Steel StructuresDocument6 pagesENCE 455 Design of Steel StructuresTooraj RoozkhoshPas encore d'évaluation

- f13 Ce470ch4ftb CompDocument10 pagesf13 Ce470ch4ftb CompAulia Rahma AzisPas encore d'évaluation

- KSSC 3 2007 7 4 297 (C)Document13 pagesKSSC 3 2007 7 4 297 (C)ismael.lorandi623Pas encore d'évaluation

- MECH 325 - Midterm Book 1: InstructionsDocument17 pagesMECH 325 - Midterm Book 1: InstructionsRohan ThaparPas encore d'évaluation

- MMCV312 Final Exam Paper - 2022Document7 pagesMMCV312 Final Exam Paper - 2022Praveet ChandPas encore d'évaluation

- CE 8601 Internal 2 Answerkey 2021Document10 pagesCE 8601 Internal 2 Answerkey 2021ci_balaPas encore d'évaluation

- Finite Element Methods Laboratory Manual: M. Tech in Structural/ Automobile EngineeringDocument12 pagesFinite Element Methods Laboratory Manual: M. Tech in Structural/ Automobile EngineeringDeval DesaiPas encore d'évaluation

- Ci 2505 WightDocument8 pagesCi 2505 WightsshayanmehrPas encore d'évaluation

- STR BAJA 13102023 - Malika Kaylani - I0121090Document7 pagesSTR BAJA 13102023 - Malika Kaylani - I0121090Malika KaylaniPas encore d'évaluation

- Design of Tension MembersDocument11 pagesDesign of Tension MembersWilfharry billyPas encore d'évaluation

- 10CV33 Dec2012Document2 pages10CV33 Dec2012nvnrevPas encore d'évaluation

- LSDSS - TM & CM MCQSDocument26 pagesLSDSS - TM & CM MCQSravi maske100% (1)

- Bolt Pressure DistributionDocument24 pagesBolt Pressure DistributionbitconceptsPas encore d'évaluation

- Tension Member 19.3.2023Document85 pagesTension Member 19.3.2023Akib IslamPas encore d'évaluation

- Needham and Gerarads MethodsDocument3 pagesNeedham and Gerarads MethodsRaj Kumar0% (1)

- Mace 60035Document7 pagesMace 60035eng_ayman_H_MPas encore d'évaluation

- Lap Joint (Fillet Joint)Document18 pagesLap Joint (Fillet Joint)Pratik GhimirePas encore d'évaluation

- Chapter 3b - Analysis of Tension MembersDocument56 pagesChapter 3b - Analysis of Tension MembersRami DemachkiPas encore d'évaluation

- Istability of A Column - LAB MENUDocument3 pagesIstability of A Column - LAB MENUAlan LeungPas encore d'évaluation

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionD'EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionPas encore d'évaluation

- Biology Syllabus, Grade 11Document16 pagesBiology Syllabus, Grade 11Tefera TemesgenPas encore d'évaluation

- Story Beam V2 KN M3 (KN-M) DDocument2 pagesStory Beam V2 KN M3 (KN-M) DTefera TemesgenPas encore d'évaluation

- Col 1Document9 pagesCol 1Tefera TemesgenPas encore d'évaluation

- Col 1 ( 2.00 0.00m) Col 1 (0.00 3.06m) : SD Take SD SD Take SD SDX SDX Sdy SdyDocument9 pagesCol 1 ( 2.00 0.00m) Col 1 (0.00 3.06m) : SD Take SD SD Take SD SDX SDX Sdy SdyTefera TemesgenPas encore d'évaluation

- Beamttt DesignDocument1 pageBeamttt DesignTefera TemesgenPas encore d'évaluation

- Ground ADDITIONAL PANEL Layout-ModelDocument1 pageGround ADDITIONAL PANEL Layout-ModelTefera TemesgenPas encore d'évaluation

- Chapter 16 - Structural Design PDFDocument28 pagesChapter 16 - Structural Design PDFTefera TemesgenPas encore d'évaluation

- For Mezanee Floor Panel PDocument3 pagesFor Mezanee Floor Panel PTefera TemesgenPas encore d'évaluation

- 2008-02-12 Attachment2 HCB TestDocument5 pages2008-02-12 Attachment2 HCB TestTefera TemesgenPas encore d'évaluation

- Translations: Lattice SymmetryDocument1 pageTranslations: Lattice SymmetryTefera TemesgenPas encore d'évaluation

- Assignment On Urban Waste Management: Instructor: - FeyyiraDocument3 pagesAssignment On Urban Waste Management: Instructor: - FeyyiraTefera TemesgenPas encore d'évaluation

- Untitled 1Document1 pageUntitled 1Tefera TemesgenPas encore d'évaluation

- Dimension Quantity Item Description TimizingDocument14 pagesDimension Quantity Item Description TimizingTefera TemesgenPas encore d'évaluation

- BuildingsDocument2 pagesBuildingsTefera TemesgenPas encore d'évaluation

- BuildingsDocument1 pageBuildingsTefera TemesgenPas encore d'évaluation

- Flexural Compressive Flexural CompressiveDocument1 pageFlexural Compressive Flexural CompressiveTefera TemesgenPas encore d'évaluation

- BuildingsDocument2 pagesBuildingsTefera TemesgenPas encore d'évaluation

- Surface-Active Structures Such As Shells and Folded Plates, Form-Active Structures Such As Cable orDocument1 pageSurface-Active Structures Such As Shells and Folded Plates, Form-Active Structures Such As Cable orTefera TemesgenPas encore d'évaluation

- Classics and The Atlantic Triangle - Caribbean Readings of Greece and Rome Via AfricaDocument12 pagesClassics and The Atlantic Triangle - Caribbean Readings of Greece and Rome Via AfricaAleja KballeroPas encore d'évaluation

- Blue Mountain Coffee Case (ADBUDG)Document16 pagesBlue Mountain Coffee Case (ADBUDG)Nuria Sánchez Celemín100% (1)

- Unit 4 Place Value Summative RubricDocument1 pageUnit 4 Place Value Summative Rubricapi-169564125Pas encore d'évaluation

- Second ConditionalDocument1 pageSecond ConditionalSilvana MiñoPas encore d'évaluation

- 0606 - s03 - 2 - 0 - QP PENTING KE 2Document8 pages0606 - s03 - 2 - 0 - QP PENTING KE 2Titin ChayankPas encore d'évaluation

- Lolita Enrico Vs Heirs of Spouses Eulogio Medinaceli and Trinidad MedinaceliDocument3 pagesLolita Enrico Vs Heirs of Spouses Eulogio Medinaceli and Trinidad Medinacelichatmche-06Pas encore d'évaluation

- Canine HyperlipidaemiaDocument11 pagesCanine Hyperlipidaemiaheidy acostaPas encore d'évaluation

- VTU Result PDFDocument2 pagesVTU Result PDFVaibhavPas encore d'évaluation

- SuratiDocument2 pagesSuratiTariq Mehmood TariqPas encore d'évaluation

- 7A Detailed Lesson Plan in Health 7 I. Content Standard: Teacher's Activity Students' ActivityDocument10 pages7A Detailed Lesson Plan in Health 7 I. Content Standard: Teacher's Activity Students' ActivityLeizel C. LeonidoPas encore d'évaluation

- Superscope, Inc. v. Brookline Corp., Etc., Robert E. Lockwood, 715 F.2d 701, 1st Cir. (1983)Document3 pagesSuperscope, Inc. v. Brookline Corp., Etc., Robert E. Lockwood, 715 F.2d 701, 1st Cir. (1983)Scribd Government DocsPas encore d'évaluation

- Journal of Cleaner Production: Kamalakanta Muduli, Kannan Govindan, Akhilesh Barve, Yong GengDocument10 pagesJournal of Cleaner Production: Kamalakanta Muduli, Kannan Govindan, Akhilesh Barve, Yong GengAnass CHERRAFIPas encore d'évaluation

- Linear Arrangement 3rdDocument30 pagesLinear Arrangement 3rdSonu BishtPas encore d'évaluation

- Pplied Hysics-Ii: Vayu Education of IndiaDocument16 pagesPplied Hysics-Ii: Vayu Education of Indiagharib mahmoudPas encore d'évaluation

- Observation: Student: Liliia Dziuda Date: 17/03/21 Topic: Movie Review Focus: Writing SkillsDocument2 pagesObservation: Student: Liliia Dziuda Date: 17/03/21 Topic: Movie Review Focus: Writing SkillsLiliaPas encore d'évaluation

- Teruhisa Morishige: Mazda Engineering StandardDocument9 pagesTeruhisa Morishige: Mazda Engineering Standardmohammad yazdanpanahPas encore d'évaluation

- Teaching Philosophy StatementDocument25 pagesTeaching Philosophy Statementtchrdale27Pas encore d'évaluation

- Human Resource Planning in Health CareDocument3 pagesHuman Resource Planning in Health CarevishalbdsPas encore d'évaluation

- Dcat2014 - Simulated Set B - Section 3 - Reading Comprehension - Final v.4.7.2014Document6 pagesDcat2014 - Simulated Set B - Section 3 - Reading Comprehension - Final v.4.7.2014Joice BobosPas encore d'évaluation

- Boxnhl MBS (Design-D) Check SheetDocument13 pagesBoxnhl MBS (Design-D) Check SheetKumari SanayaPas encore d'évaluation

- Examination of Conscience Ten Commandments PDFDocument2 pagesExamination of Conscience Ten Commandments PDFAntonioPas encore d'évaluation

- Position Paper Guns Dont Kill People Final DraftDocument6 pagesPosition Paper Guns Dont Kill People Final Draftapi-273319954Pas encore d'évaluation

- "International Finance": A Project Submitted ToDocument6 pages"International Finance": A Project Submitted ToAkshay HarekarPas encore d'évaluation

- Impact of E-Banking in India: Presented By-Shouvik Maji PGDM - 75Document11 pagesImpact of E-Banking in India: Presented By-Shouvik Maji PGDM - 75Nilanjan GhoshPas encore d'évaluation

- GK-604D Digital Inclinometer System PDFDocument111 pagesGK-604D Digital Inclinometer System PDFKael CabezasPas encore d'évaluation