Académique Documents

Professionnel Documents

Culture Documents

8 99 Leaflet Transition Joints A4

Transféré par

cluaudiopolis2Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

8 99 Leaflet Transition Joints A4

Transféré par

cluaudiopolis2Droits d'auteur :

Formats disponibles

YOUR ENERGY... OUR SYSTEMS...

ANYWHERE

Product

range

Compact design

The transition between single core cables with different

designs up to a Umax of 170 kV is performed by using a

compact joint.

The dry design concept is used on the extruded cable

side to allow the connection of a polymeric cable while

on the paper insulated side crepe paper is applied to

complete the necessary stress relief cone.

The hydraulic separation between the different cables

is ensured by utilising an epoxy resin insulator that is

manufactured through a strictly controlled production

process to guarantee its full reliabilty under any

service condition.

Back-to-back design

For EHV applications, up to Umax 420 kV, the traditional

BACK-TO-BACK configuration (based on standard oil

immersed transformer termination designs) is still

preferred because of its unsurpassed reliability.

> Three cores transition joints

When the transition between a three-core paper

insulated cable and three single core extruded cables is

required, a very specific jointing solution has to be used.

Such a solution is designed to ensure the proper

connection between the different cable designs and

to guarantee an adequate sealing to avoid any leakage

from the paper insulated side.

The connection between the cable conductors

(compression method for copper and welding for

aluminum) is made by using specifically designed epoxy

resin bushings with embedded electrodes that are

manufactured under controlled and monitored conditions.

A highly specific manufacturing process has been finetuned for many years and routine tests on the

bushings include high voltage tests and ultrasonic

measurements. Premoulded sleeves, one for each core,

are used on the extruded cable side whereas on the

paper insulated cable side the stress control is carried

out by using crepe paper tapes.

A wide range of three-core transition joints is

available depending on the specific circuit requirements.

3/C gas compression cable - to 3 single core polymeric cables

3/C pipe type cable - to 3 single core polymeric cables

HONG KONG

Prysmian Cable Systems Pte. Ltd.

Unit A, 18/F, China Overseas Building,

139 Hennessy Road, Wanchai, Hong Kong

tel. +85 2 2827 8308

fax +85 2 2827 7212

ROMANIA

Prysmian Cabluri si Sisteme SA

Soseaua Draganesti, Km. 4,

0500 Slatina

tel. +40 49 435 699

fax +40 49 433 484

AUSTRALIA

Prysmian Power Cables & Systems

Australia PTY LTD

1 Heathcote Road, Locked Bag 7042,

Liverpool Business Centre 1871, NSW

tel. +61 2 9600 0777

fax +61 2 9600 0747

HUNGARY

Prysmian MKM Magyar Hungarian Cable

Works Co. Ltd.

Barzda u. 38, H-1116 Budapest

tel. +36 1 3822 222

fax +36 1 3822 202

RUSSIA

Prysmian Cables and Systems

4-th str. Vosmogo Marta 6

building 1, 9-th floor,

Moscow, 125167

tel. +7 495 933-7036

fax +7 495 933-7035

AUSTRIA

Prysmian OEKW GmbH

Lembockgasse 47A,

1230 Wien

tel. +43 1 8667 70

fax +43 1 8667 7109

INDONESIA

PT. Prysmian Cables Indonesia

Gedung BRI II, Suite 1502,

Jln. Jend Sudirman No 44-46,

Jakarta 10210

tel. +62 264 351 222

fax +62 264 351 780

SINGAPORE

Prysmian Cable Systems Pte. Ltd.

No 4 Tuas Avenue 12. 3rd Storey,

639047 Singapore

tel. +65 6862 9866

fax +65 6862 9877

BRAZIL

Prysmian Energia Cabos e Sistemas do Brasil S. A.

Av. Alexandre de Gusmao 145,

09110-900 Santo Andr SP

tel. +55 11 4998 4000

fax +55 11 4998 4811

ITALY

Prysmian Cavi e Sistemi Energia Srl

Viale Sarca 222,

20126 Milano

tel. +39 02 6449 9492

fax +39 02 6449 5035

SLOVAKIA

Prysmian Kablo Bratislava

Tovarenska 11,

812 61 Bratislava

tel. +421 7 50211111

fax +421 7 52961773

CHINA

Prysmian Cables & Systems

1505-06, Tower A, City Center of Shanghai,

No. 100 ZunYi Road, Shanghai 200051

tel. +86 21 6237 1411

fax +86 21 6237 1195

KUWAIT

Prysmian Cables & Systems Kuwait Office

Villa No 4 (next to Hyatt Regency Hotel),

Bidda - KUWAIT

tel. +965 575 7704

fax +965 572 5780

SPAIN

Prysmian Cables y Sistemas S.L.

Carretera C-15, Km. 2,

08800 Vilanova i la Geltr (Barcelona),

tel. +34 93 811 6181

fax +34 93 811 6011

EGYPT

Prysmian Cables & Systems

8 Abd El Azim Aoudallah st. Hegaz sq.,

Heliopolis - Cairo

tel. +20 2 2418 557

fax +20 2 6381 327

MALAYSIA

Prysmian Cable Systems Pte. Ltd.

Lot 2 Jalan Kawat 15/18,

40702 Shah Alam, Selangor Darul Ehsan

tel. +60 3 5518 4575

fax +60 3 5511 9590

THAILAND

Prysmian Cable Systems Pte. Ltd.

555 RASA Tower 11th floor,

Phaholyothin Road, Lardyao, Chatuchak,

Bangkok 10900

tel. +66 2 9370 316

fax +66 2 9370 318

FINLAND

Prysmian Cables & Systems Oy

P.O. Box 13,

FIN-02401 Kirkkonummi

tel. +358 10 77551

fax +358 9 2982204

NETHERLANDS

Prysmian Cables and Systems B.V.

Schieweg 9, 2627 AN Delft

P.O. Box 495, 2600 AL Delft

The Netherlands

tel. +31 15 260 5260

fax +31 15 261 3808

TURKEY

Turk Prysmian Kablo ve Sistemleri A.S.

Buyukdere Caddesi No 117,

34394 Gayrettepe, Istanbul

tel. +90 212 3551 500

fax +90 212 2175 810

FRANCE

Prysmian Energie Cables et Systmes

France s.a.

Zone Industrielle du PORT AU VIN,

GRON, 89 100 SENS

tel. +33 3 8695 7769

fax +33 3 8695 7781

NEW ZEALAND

Prysmian Cables & Systems

71 Hugi Johnson Drice, P.O. Box 12162,

Penrose, Auckland

tel. +64 9 5251 260

fax +64 9 5251 262

U.A.E. (Dubai)

Prysmian Cabels and Systems Middle East

P.O. Box 72125,

Dubai

tel. +971 4 345 7870

fax +971 4 345 7101

GERMANY

Prysmian Kabel und Systeme GmbH

Gartenfelder Str. 28,

D 13599 Berlin

tel. +49 30 3675 40

fax +49 30 3675 4640

NORTH AMERICA

Prysmian Cables & Systems North America

700 Industrial Drive,

Lexington, SC 29072 - USA

tel. +1 803 9511 171

fax +1 803 9511 092

UK

Prysmian Cables & Systems Limited

P. O. Box 6, Leigh Road,

Eastleigh, Hampshire, SO50 9YE

tel. +44 2380 2955 55

fax +44 2380 2951 11

Transition

Joints

p cnet

network components

dega design group

> Single core transition joints

ARGENTINA

Prysmian Energa Cables y Sistemas de Argentina S. A.

Fbrica La Rosa, Av.da Argentina 6784,

1439 Capital Federal

tel. +54 11 4630 2000

fax +54 11 4630 2100

3/C fluid filled cable - to 3 single core polymeric cables

Prysmian Cavi e Sistemi Energia Srl

Viale Sarca 222, 20126 Milano, Italy - tel. +39 02 6449 1, fax +39 02 6449 2931 - www.prysmian.com

Accessories for high voltage

polymeric cables

TRANSITION JOINTS

About us

Prysmian Cables & Systems is a world-class

multinational company. Founded in 1872 as Ditta

Pirelli & C., it has achieved a leading position for

more than a century of operations in its two key

international markets - Energy Cables and Systems

and Telecom Cables & Systems.

Prysmian Cables and Systems is the worlds largest

manufacturer of power and telecommunications cables,

with 52 manufacturing facilities in 21 countries in five

continents and a market share in excess of 10%.

Prysmian Energy Cables and Systems is a global

solutions provider, offering a wide range of integrated

solutions, such as cable systems, system design

and engineering, project management, installation

and post-sale services.

Prysmian Energy Cables and Systems concentrates

on continuous product innovation and on achieving

a competitive edge by focusing on research and

development. This is done through Prysmians own

R&D centres and by co-operating with universities,

scientific institutions and above all, our customers.

Prysmians world-wide organisation makes and

delivers advanced technological solutions to

customers anywhere in the world.

YOUR ENERGY... OUR SYSTEMS... ANYWHERE

Joint

Transition joints

core basics

availble from 72,5 kV up to 420 kV

The origin of the current product range of accessories

for HV polymeric cables dates back to 1978 when

Prysmian, strong of its very long and successful experience

in Fluid Filled cable systems developed its first generation

of accessories for extruded cable systems.

These accessories are based on pre-moulded electrical

components, i.e. stress cones for terminations and

one-piece sleeves for joints.

Pre-moulded sleeves and stress cones are currently

available for HV polymeric cables from 72.5 kV up to

525 kV and adopt the same design at all voltage classes.

> Additional features

THREE-CORE DESIGN

available for 72,5 - 123 - 145 kV

Following the latest cable design developments and in

view of a full system approach, upon specific request

Prysmian joints can include:

>

>

>

Legend

1

2

3

4

5

6

7

Optical fibres management

Partial discharge sensor

Connection between conductors made by different materials

JOINTING SOLUTIONS

FOR THREE-CORE

PIPE TYPE CABLES

AVAILABLE

Thanks to its outstanding electrical and mechanical

properties, ethylene-propylene rubber (EPR) has been

favoured for the rubber mouldings manufacture. After a

thorough research on rubber compounds properties,

Prysmian developed a proprietary formulation with superior

characteristics that is manufactured in-house, which

guarantees an unsurpassed reliability of the products.

POLYMERIC

CABLE SIDE

Connection bushing

Single core extruded cable

Three-core paper insulated cable

One piece premoulded sleeve

Paper stress core

Separation flange (steel)

Outer casing (steel)

4

2

1

FLUID FILLED

CABLE SIDE

POLYMERIC

CABLE SIDE

The mechanical properties of Prysmian special compounds

ensure a constant pressure at the cable/moulding

interface during the entire lifetime of the accessories,

whilst the electrical design has been optimised to minimise

the electrical stress concentration in the same area.

Prysmian one-piece pre-moulded sleeves and stress

cones are completely manufactured in-house.

SUITABLE FOR FEEDING

FLUID FILLED DUCT

3

4 3

Prysmian started manufacturing insulated cables

for electric power distribution around 1880 and

soon afterwards initiated the development of the

first cable accessories.

Prysmians very long and successful experience in HV

and EHV cable systems have lead to the development

of a comprehensive range of accessories for extruded

dielectric cables.

A relentless R&D effort focused on rubber compounds

as well as on electrical design has created accessories

for all applications, based on pre-moulded and factory

tested joint sleeves and termination stress cones

that are recognised worldwide for their unsurpassed

reliability.

Three cores Transition Joint - paper insulated side

The moulding process has been refined thanks to the

long-standing presence of Prysmian in the rubber

industry; each single moulding is mechanically and

electrically tested in the factory (the applied electrical

test parameters are stricter than those established by

the international standards) and certified individually.

Prysmian HV Accessories quality system complies with

both ISO 9001 and ISO 14001 standards. Prysmian HV

accessories based on EPR mouldings represent a highly

reliable solution that is considered a key component in

the safe operation of a HV cable system.

The reliability of its HV accessories has made Prysmian the

worldwide market leader in terms of design and quality and

all major power Utilities consider Prysmian products the

benchmark in terms of performance and service.

FLUID FILLED

CABLE SIDE

DRY DESIGN ON

POLYMERIC CABLE SIDE

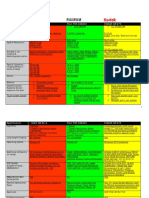

SINGLE CORE

COMPACT DESIGN

SINGLE CORE

BACK-TO-BACK DESIGN

available for voltage classes

available for 123 - 145 - 170 kV

Legend

Legend

1

2

3

4

5

6

7

Conductor connection

Extruded cable

Paper insulated cable

One piece premoulded stress cone (rubber)

Paper stress cone

Epoxy resin bushing

Outer casing (steel)

FLUID FILLED

CABLE SIDE

1

2

3

4

5

6

7

8

Multi-contact connection (copper) )

Corona shield (copper)

Insulator (epoxy resin)

Casing (steel)

Earthing lug (copper)

Filling material (insulating oil)

Paper stress cone

One piece premoulded stress cone

POLYMERIC

CABLE SIDE

YOUR ENERGY... OUR SYSTEMS... ANYWHERE

Product

range

Compact design

The transition between single core cables with different

designs up to a Umax of 170 kV is performed by using a

compact joint.

The dry design concept is used on the extruded cable

side to allow the connection of a polymeric cable while

on the paper insulated side crepe paper is applied to

complete the necessary stress relief cone.

The hydraulic separation between the different cables

is ensured by utilising an epoxy resin insulator that is

manufactured through a strictly controlled production

process to guarantee its full reliabilty under any

service condition.

Back-to-back design

For EHV applications, up to Umax 420 kV, the traditional

BACK-TO-BACK configuration (based on standard oil

immersed transformer termination designs) is still

preferred because of its unsurpassed reliability.

> Three cores transition joints

When the transition between a three-core paper

insulated cable and three single core extruded cables is

required, a very specific jointing solution has to be used.

Such a solution is designed to ensure the proper

connection between the different cable designs and

to guarantee an adequate sealing to avoid any leakage

from the paper insulated side.

The connection between the cable conductors

(compression method for copper and welding for

aluminum) is made by using specifically designed epoxy

resin bushings with embedded electrodes that are

manufactured under controlled and monitored conditions.

A highly specific manufacturing process has been finetuned for many years and routine tests on the

bushings include high voltage tests and ultrasonic

measurements. Premoulded sleeves, one for each core,

are used on the extruded cable side whereas on the

paper insulated cable side the stress control is carried

out by using crepe paper tapes.

A wide range of three-core transition joints is

available depending on the specific circuit requirements.

3/C gas compression cable - to 3 single core polymeric cables

3/C pipe type cable - to 3 single core polymeric cables

HONG KONG

Prysmian Cable Systems Pte. Ltd.

Unit A, 18/F, China Overseas Building,

139 Hennessy Road, Wanchai, Hong Kong

tel. +85 2 2827 8308

fax +85 2 2827 7212

ROMANIA

Prysmian Cabluri si Sisteme SA

Soseaua Draganesti, Km. 4,

0500 Slatina

tel. +40 49 435 699

fax +40 49 433 484

AUSTRALIA

Prysmian Power Cables & Systems

Australia PTY LTD

1 Heathcote Road, Locked Bag 7042,

Liverpool Business Centre 1871, NSW

tel. +61 2 9600 0777

fax +61 2 9600 0747

HUNGARY

Prysmian MKM Magyar Hungarian Cable

Works Co. Ltd.

Barzda u. 38, H-1116 Budapest

tel. +36 1 3822 222

fax +36 1 3822 202

RUSSIA

Prysmian Cables and Systems

4-th str. Vosmogo Marta 6

building 1, 9-th floor,

Moscow, 125167

tel. +7 495 933-7036

fax +7 495 933-7035

AUSTRIA

Prysmian OEKW GmbH

Lembockgasse 47A,

1230 Wien

tel. +43 1 8667 70

fax +43 1 8667 7109

INDONESIA

PT. Prysmian Cables Indonesia

Gedung BRI II, Suite 1502,

Jln. Jend Sudirman No 44-46,

Jakarta 10210

tel. +62 264 351 222

fax +62 264 351 780

SINGAPORE

Prysmian Cable Systems Pte. Ltd.

No 4 Tuas Avenue 12. 3rd Storey,

639047 Singapore

tel. +65 6862 9866

fax +65 6862 9877

BRAZIL

Prysmian Energia Cabos e Sistemas do Brasil S. A.

Av. Alexandre de Gusmao 145,

09110-900 Santo Andr SP

tel. +55 11 4998 4000

fax +55 11 4998 4811

ITALY

Prysmian Cavi e Sistemi Energia Srl

Viale Sarca 222,

20126 Milano

tel. +39 02 6449 9492

fax +39 02 6449 5035

SLOVAKIA

Prysmian Kablo Bratislava

Tovarenska 11,

812 61 Bratislava

tel. +421 7 50211111

fax +421 7 52961773

CHINA

Prysmian Cables & Systems

1505-06, Tower A, City Center of Shanghai,

No. 100 ZunYi Road, Shanghai 200051

tel. +86 21 6237 1411

fax +86 21 6237 1195

KUWAIT

Prysmian Cables & Systems Kuwait Office

Villa No 4 (next to Hyatt Regency Hotel),

Bidda - KUWAIT

tel. +965 575 7704

fax +965 572 5780

SPAIN

Prysmian Cables y Sistemas S.L.

Carretera C-15, Km. 2,

08800 Vilanova i la Geltr (Barcelona),

tel. +34 93 811 6181

fax +34 93 811 6011

EGYPT

Prysmian Cables & Systems

8 Abd El Azim Aoudallah st. Hegaz sq.,

Heliopolis - Cairo

tel. +20 2 2418 557

fax +20 2 6381 327

MALAYSIA

Prysmian Cable Systems Pte. Ltd.

Lot 2 Jalan Kawat 15/18,

40702 Shah Alam, Selangor Darul Ehsan

tel. +60 3 5518 4575

fax +60 3 5511 9590

THAILAND

Prysmian Cable Systems Pte. Ltd.

555 RASA Tower 11th floor,

Phaholyothin Road, Lardyao, Chatuchak,

Bangkok 10900

tel. +66 2 9370 316

fax +66 2 9370 318

FINLAND

Prysmian Cables & Systems Oy

P.O. Box 13,

FIN-02401 Kirkkonummi

tel. +358 10 77551

fax +358 9 2982204

NETHERLANDS

Prysmian Cables and Systems B.V.

Schieweg 9, 2627 AN Delft

P.O. Box 495, 2600 AL Delft

The Netherlands

tel. +31 15 260 5260

fax +31 15 261 3808

TURKEY

Turk Prysmian Kablo ve Sistemleri A.S.

Buyukdere Caddesi No 117,

34394 Gayrettepe, Istanbul

tel. +90 212 3551 500

fax +90 212 2175 810

FRANCE

Prysmian Energie Cables et Systmes

France s.a.

Zone Industrielle du PORT AU VIN,

GRON, 89 100 SENS

tel. +33 3 8695 7769

fax +33 3 8695 7781

NEW ZEALAND

Prysmian Cables & Systems

71 Hugi Johnson Drice, P.O. Box 12162,

Penrose, Auckland

tel. +64 9 5251 260

fax +64 9 5251 262

U.A.E. (Dubai)

Prysmian Cabels and Systems Middle East

P.O. Box 72125,

Dubai

tel. +971 4 345 7870

fax +971 4 345 7101

GERMANY

Prysmian Kabel und Systeme GmbH

Gartenfelder Str. 28,

D 13599 Berlin

tel. +49 30 3675 40

fax +49 30 3675 4640

NORTH AMERICA

Prysmian Cables & Systems North America

700 Industrial Drive,

Lexington, SC 29072 - USA

tel. +1 803 9511 171

fax +1 803 9511 092

UK

Prysmian Cables & Systems Limited

P. O. Box 6, Leigh Road,

Eastleigh, Hampshire, SO50 9YE

tel. +44 2380 2955 55

fax +44 2380 2951 11

Transition

Joints

p cnet

network components

dega design group

> Single core transition joints

ARGENTINA

Prysmian Energa Cables y Sistemas de Argentina S. A.

Fbrica La Rosa, Av.da Argentina 6784,

1439 Capital Federal

tel. +54 11 4630 2000

fax +54 11 4630 2100

3/C fluid filled cable - to 3 single core polymeric cables

Prysmian Cavi e Sistemi Energia Srl

Viale Sarca 222, 20126 Milano, Italy - tel. +39 02 6449 1, fax +39 02 6449 2931 - www.prysmian.com

Accessories for high voltage

polymeric cables

TRANSITION JOINTS

About us

Prysmian Cables & Systems is a world-class

multinational company. Founded in 1872 as Ditta

Pirelli & C., it has achieved a leading position for

more than a century of operations in its two key

international markets - Energy Cables and Systems

and Telecom Cables & Systems.

Prysmian Cables and Systems is the worlds largest

manufacturer of power and telecommunications cables,

with 52 manufacturing facilities in 21 countries in five

continents and a market share in excess of 10%.

Prysmian Energy Cables and Systems is a global

solutions provider, offering a wide range of integrated

solutions, such as cable systems, system design

and engineering, project management, installation

and post-sale services.

Prysmian Energy Cables and Systems concentrates

on continuous product innovation and on achieving

a competitive edge by focusing on research and

development. This is done through Prysmians own

R&D centres and by co-operating with universities,

scientific institutions and above all, our customers.

Prysmians world-wide organisation makes and

delivers advanced technological solutions to

customers anywhere in the world.

YOUR ENERGY... OUR SYSTEMS... ANYWHERE

Joint

Transition joints

core basics

availble from 72,5 kV up to 420 kV

The origin of the current product range of accessories

for HV polymeric cables dates back to 1978 when

Prysmian, strong of its very long and successful experience

in Fluid Filled cable systems developed its first generation

of accessories for extruded cable systems.

These accessories are based on pre-moulded electrical

components, i.e. stress cones for terminations and

one-piece sleeves for joints.

Pre-moulded sleeves and stress cones are currently

available for HV polymeric cables from 72.5 kV up to

525 kV and adopt the same design at all voltage classes.

> Additional features

THREE-CORE DESIGN

available for 72,5 - 123 - 145 kV

Following the latest cable design developments and in

view of a full system approach, upon specific request

Prysmian joints can include:

>

>

>

Legend

1

2

3

4

5

6

7

Optical fibres management

Partial discharge sensor

Connection between conductors made by different materials

JOINTING SOLUTIONS

FOR THREE-CORE

PIPE TYPE CABLES

AVAILABLE

Thanks to its outstanding electrical and mechanical

properties, ethylene-propylene rubber (EPR) has been

favoured for the rubber mouldings manufacture. After a

thorough research on rubber compounds properties,

Prysmian developed a proprietary formulation with superior

characteristics that is manufactured in-house, which

guarantees an unsurpassed reliability of the products.

POLYMERIC

CABLE SIDE

Connection bushing

Single core extruded cable

Three-core paper insulated cable

One piece premoulded sleeve

Paper stress core

Separation flange (steel)

Outer casing (steel)

4

2

1

FLUID FILLED

CABLE SIDE

POLYMERIC

CABLE SIDE

The mechanical properties of Prysmian special compounds

ensure a constant pressure at the cable/moulding

interface during the entire lifetime of the accessories,

whilst the electrical design has been optimised to minimise

the electrical stress concentration in the same area.

Prysmian one-piece pre-moulded sleeves and stress

cones are completely manufactured in-house.

SUITABLE FOR FEEDING

FLUID FILLED DUCT

3

4 3

Prysmian started manufacturing insulated cables

for electric power distribution around 1880 and

soon afterwards initiated the development of the

first cable accessories.

Prysmians very long and successful experience in HV

and EHV cable systems have lead to the development

of a comprehensive range of accessories for extruded

dielectric cables.

A relentless R&D effort focused on rubber compounds

as well as on electrical design has created accessories

for all applications, based on pre-moulded and factory

tested joint sleeves and termination stress cones

that are recognised worldwide for their unsurpassed

reliability.

Three cores Transition Joint - paper insulated side

The moulding process has been refined thanks to the

long-standing presence of Prysmian in the rubber

industry; each single moulding is mechanically and

electrically tested in the factory (the applied electrical

test parameters are stricter than those established by

the international standards) and certified individually.

Prysmian HV Accessories quality system complies with

both ISO 9001 and ISO 14001 standards. Prysmian HV

accessories based on EPR mouldings represent a highly

reliable solution that is considered a key component in

the safe operation of a HV cable system.

The reliability of its HV accessories has made Prysmian the

worldwide market leader in terms of design and quality and

all major power Utilities consider Prysmian products the

benchmark in terms of performance and service.

FLUID FILLED

CABLE SIDE

DRY DESIGN ON

POLYMERIC CABLE SIDE

SINGLE CORE

COMPACT DESIGN

SINGLE CORE

BACK-TO-BACK DESIGN

available for voltage classes

available for 123 - 145 - 170 kV

Legend

Legend

1

2

3

4

5

6

7

Conductor connection

Extruded cable

Paper insulated cable

One piece premoulded stress cone (rubber)

Paper stress cone

Epoxy resin bushing

Outer casing (steel)

FLUID FILLED

CABLE SIDE

1

2

3

4

5

6

7

8

Multi-contact connection (copper) )

Corona shield (copper)

Insulator (epoxy resin)

Casing (steel)

Earthing lug (copper)

Filling material (insulating oil)

Paper stress cone

One piece premoulded stress cone

POLYMERIC

CABLE SIDE

TRANSITION JOINTS

About us

Prysmian Cables & Systems is a world-class

multinational company. Founded in 1872 as Ditta

Pirelli & C., it has achieved a leading position for

more than a century of operations in its two key

international markets - Energy Cables and Systems

and Telecom Cables & Systems.

Prysmian Cables and Systems is the worlds largest

manufacturer of power and telecommunications cables,

with 52 manufacturing facilities in 21 countries in five

continents and a market share in excess of 10%.

Prysmian Energy Cables and Systems is a global

solutions provider, offering a wide range of integrated

solutions, such as cable systems, system design

and engineering, project management, installation

and post-sale services.

Prysmian Energy Cables and Systems concentrates

on continuous product innovation and on achieving

a competitive edge by focusing on research and

development. This is done through Prysmians own

R&D centres and by co-operating with universities,

scientific institutions and above all, our customers.

Prysmians world-wide organisation makes and

delivers advanced technological solutions to

customers anywhere in the world.

YOUR ENERGY... OUR SYSTEMS... ANYWHERE

Joint

Transition joints

core basics

availble from 72,5 kV up to 420 kV

The origin of the current product range of accessories

for HV polymeric cables dates back to 1978 when

Prysmian, strong of its very long and successful experience

in Fluid Filled cable systems developed its first generation

of accessories for extruded cable systems.

These accessories are based on pre-moulded electrical

components, i.e. stress cones for terminations and

one-piece sleeves for joints.

Pre-moulded sleeves and stress cones are currently

available for HV polymeric cables from 72.5 kV up to

525 kV and adopt the same design at all voltage classes.

> Additional features

THREE-CORE DESIGN

available for 72,5 - 123 - 145 kV

Following the latest cable design developments and in

view of a full system approach, upon specific request

Prysmian joints can include:

>

>

>

Legend

1

2

3

4

5

6

7

Optical fibres management

Partial discharge sensor

Connection between conductors made by different materials

JOINTING SOLUTIONS

FOR THREE-CORE

PIPE TYPE CABLES

AVAILABLE

Thanks to its outstanding electrical and mechanical

properties, ethylene-propylene rubber (EPR) has been

favoured for the rubber mouldings manufacture. After a

thorough research on rubber compounds properties,

Prysmian developed a proprietary formulation with superior

characteristics that is manufactured in-house, which

guarantees an unsurpassed reliability of the products.

POLYMERIC

CABLE SIDE

Connection bushing

Single core extruded cable

Three-core paper insulated cable

One piece premoulded sleeve

Paper stress core

Separation flange (steel)

Outer casing (steel)

4

2

1

FLUID FILLED

CABLE SIDE

POLYMERIC

CABLE SIDE

The mechanical properties of Prysmian special compounds

ensure a constant pressure at the cable/moulding

interface during the entire lifetime of the accessories,

whilst the electrical design has been optimised to minimise

the electrical stress concentration in the same area.

Prysmian one-piece pre-moulded sleeves and stress

cones are completely manufactured in-house.

SUITABLE FOR FEEDING

FLUID FILLED DUCT

3

4 3

Prysmian started manufacturing insulated cables

for electric power distribution around 1880 and

soon afterwards initiated the development of the

first cable accessories.

Prysmians very long and successful experience in HV

and EHV cable systems have lead to the development

of a comprehensive range of accessories for extruded

dielectric cables.

A relentless R&D effort focused on rubber compounds

as well as on electrical design has created accessories

for all applications, based on pre-moulded and factory

tested joint sleeves and termination stress cones

that are recognised worldwide for their unsurpassed

reliability.

Three cores Transition Joint - paper insulated side

The moulding process has been refined thanks to the

long-standing presence of Prysmian in the rubber

industry; each single moulding is mechanically and

electrically tested in the factory (the applied electrical

test parameters are stricter than those established by

the international standards) and certified individually.

Prysmian HV Accessories quality system complies with

both ISO 9001 and ISO 14001 standards. Prysmian HV

accessories based on EPR mouldings represent a highly

reliable solution that is considered a key component in

the safe operation of a HV cable system.

The reliability of its HV accessories has made Prysmian the

worldwide market leader in terms of design and quality and

all major power Utilities consider Prysmian products the

benchmark in terms of performance and service.

FLUID FILLED

CABLE SIDE

DRY DESIGN ON

POLYMERIC CABLE SIDE

SINGLE CORE

COMPACT DESIGN

SINGLE CORE

BACK-TO-BACK DESIGN

available for voltage classes

available for 123 - 145 - 170 kV

Legend

Legend

1

2

3

4

5

6

7

Conductor connection

Extruded cable

Paper insulated cable

One piece premoulded stress cone (rubber)

Paper stress cone

Epoxy resin bushing

Outer casing (steel)

FLUID FILLED

CABLE SIDE

1

2

3

4

5

6

7

8

Multi-contact connection (copper) )

Corona shield (copper)

Insulator (epoxy resin)

Casing (steel)

Earthing lug (copper)

Filling material (insulating oil)

Paper stress cone

One piece premoulded stress cone

POLYMERIC

CABLE SIDE

YOUR ENERGY... OUR SYSTEMS... ANYWHERE

Product

range

Compact design

The transition between single core cables with different

designs up to a Umax of 170 kV is performed by using a

compact joint.

The dry design concept is used on the extruded cable

side to allow the connection of a polymeric cable while

on the paper insulated side crepe paper is applied to

complete the necessary stress relief cone.

The hydraulic separation between the different cables

is ensured by utilising an epoxy resin insulator that is

manufactured through a strictly controlled production

process to guarantee its full reliabilty under any

service condition.

Back-to-back design

For EHV applications, up to Umax 420 kV, the traditional

BACK-TO-BACK configuration (based on standard oil

immersed transformer termination designs) is still

preferred because of its unsurpassed reliability.

> Three cores transition joints

When the transition between a three-core paper

insulated cable and three single core extruded cables is

required, a very specific jointing solution has to be used.

Such a solution is designed to ensure the proper

connection between the different cable designs and

to guarantee an adequate sealing to avoid any leakage

from the paper insulated side.

The connection between the cable conductors

(compression method for copper and welding for

aluminum) is made by using specifically designed epoxy

resin bushings with embedded electrodes that are

manufactured under controlled and monitored conditions.

A highly specific manufacturing process has been finetuned for many years and routine tests on the

bushings include high voltage tests and ultrasonic

measurements. Premoulded sleeves, one for each core,

are used on the extruded cable side whereas on the

paper insulated cable side the stress control is carried

out by using crepe paper tapes.

A wide range of three-core transition joints is

available depending on the specific circuit requirements.

3/C gas compression cable - to 3 single core polymeric cables

3/C pipe type cable - to 3 single core polymeric cables

HONG KONG

Prysmian Cable Systems Pte. Ltd.

Unit A, 18/F, China Overseas Building,

139 Hennessy Road, Wanchai, Hong Kong

tel. +85 2 2827 8308

fax +85 2 2827 7212

ROMANIA

Prysmian Cabluri si Sisteme SA

Soseaua Draganesti, Km. 4,

0500 Slatina

tel. +40 49 435 699

fax +40 49 433 484

AUSTRALIA

Prysmian Power Cables & Systems

Australia PTY LTD

1 Heathcote Road, Locked Bag 7042,

Liverpool Business Centre 1871, NSW

tel. +61 2 9600 0777

fax +61 2 9600 0747

HUNGARY

Prysmian MKM Magyar Hungarian Cable

Works Co. Ltd.

Barzda u. 38, H-1116 Budapest

tel. +36 1 3822 222

fax +36 1 3822 202

RUSSIA

Prysmian Cables and Systems

4-th str. Vosmogo Marta 6

building 1, 9-th floor,

Moscow, 125167

tel. +7 495 933-7036

fax +7 495 933-7035

AUSTRIA

Prysmian OEKW GmbH

Lembockgasse 47A,

1230 Wien

tel. +43 1 8667 70

fax +43 1 8667 7109

INDONESIA

PT. Prysmian Cables Indonesia

Gedung BRI II, Suite 1502,

Jln. Jend Sudirman No 44-46,

Jakarta 10210

tel. +62 264 351 222

fax +62 264 351 780

SINGAPORE

Prysmian Cable Systems Pte. Ltd.

No 4 Tuas Avenue 12. 3rd Storey,

639047 Singapore

tel. +65 6862 9866

fax +65 6862 9877

BRAZIL

Prysmian Energia Cabos e Sistemas do Brasil S. A.

Av. Alexandre de Gusmao 145,

09110-900 Santo Andr SP

tel. +55 11 4998 4000

fax +55 11 4998 4811

ITALY

Prysmian Cavi e Sistemi Energia Srl

Viale Sarca 222,

20126 Milano

tel. +39 02 6449 9492

fax +39 02 6449 5035

SLOVAKIA

Prysmian Kablo Bratislava

Tovarenska 11,

812 61 Bratislava

tel. +421 7 50211111

fax +421 7 52961773

CHINA

Prysmian Cables & Systems

1505-06, Tower A, City Center of Shanghai,

No. 100 ZunYi Road, Shanghai 200051

tel. +86 21 6237 1411

fax +86 21 6237 1195

KUWAIT

Prysmian Cables & Systems Kuwait Office

Villa No 4 (next to Hyatt Regency Hotel),

Bidda - KUWAIT

tel. +965 575 7704

fax +965 572 5780

SPAIN

Prysmian Cables y Sistemas S.L.

Carretera C-15, Km. 2,

08800 Vilanova i la Geltr (Barcelona),

tel. +34 93 811 6181

fax +34 93 811 6011

EGYPT

Prysmian Cables & Systems

8 Abd El Azim Aoudallah st. Hegaz sq.,

Heliopolis - Cairo

tel. +20 2 2418 557

fax +20 2 6381 327

MALAYSIA

Prysmian Cable Systems Pte. Ltd.

Lot 2 Jalan Kawat 15/18,

40702 Shah Alam, Selangor Darul Ehsan

tel. +60 3 5518 4575

fax +60 3 5511 9590

THAILAND

Prysmian Cable Systems Pte. Ltd.

555 RASA Tower 11th floor,

Phaholyothin Road, Lardyao, Chatuchak,

Bangkok 10900

tel. +66 2 9370 316

fax +66 2 9370 318

FINLAND

Prysmian Cables & Systems Oy

P.O. Box 13,

FIN-02401 Kirkkonummi

tel. +358 10 77551

fax +358 9 2982204

NETHERLANDS

Prysmian Cables and Systems B.V.

Schieweg 9, 2627 AN Delft

P.O. Box 495, 2600 AL Delft

The Netherlands

tel. +31 15 260 5260

fax +31 15 261 3808

TURKEY

Turk Prysmian Kablo ve Sistemleri A.S.

Buyukdere Caddesi No 117,

34394 Gayrettepe, Istanbul

tel. +90 212 3551 500

fax +90 212 2175 810

FRANCE

Prysmian Energie Cables et Systmes

France s.a.

Zone Industrielle du PORT AU VIN,

GRON, 89 100 SENS

tel. +33 3 8695 7769

fax +33 3 8695 7781

NEW ZEALAND

Prysmian Cables & Systems

71 Hugi Johnson Drice, P.O. Box 12162,

Penrose, Auckland

tel. +64 9 5251 260

fax +64 9 5251 262

U.A.E. (Dubai)

Prysmian Cabels and Systems Middle East

P.O. Box 72125,

Dubai

tel. +971 4 345 7870

fax +971 4 345 7101

GERMANY

Prysmian Kabel und Systeme GmbH

Gartenfelder Str. 28,

D 13599 Berlin

tel. +49 30 3675 40

fax +49 30 3675 4640

NORTH AMERICA

Prysmian Cables & Systems North America

700 Industrial Drive,

Lexington, SC 29072 - USA

tel. +1 803 9511 171

fax +1 803 9511 092

UK

Prysmian Cables & Systems Limited

P. O. Box 6, Leigh Road,

Eastleigh, Hampshire, SO50 9YE

tel. +44 2380 2955 55

fax +44 2380 2951 11

Transition

Joints

p cnet

network components

dega design group

> Single core transition joints

ARGENTINA

Prysmian Energa Cables y Sistemas de Argentina S. A.

Fbrica La Rosa, Av.da Argentina 6784,

1439 Capital Federal

tel. +54 11 4630 2000

fax +54 11 4630 2100

3/C fluid filled cable - to 3 single core polymeric cables

Prysmian Cavi e Sistemi Energia Srl

Viale Sarca 222, 20126 Milano, Italy - tel. +39 02 6449 1, fax +39 02 6449 2931 - www.prysmian.com

Accessories for high voltage

polymeric cables

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- EXTENDED PROJECT-Shoe - SalesDocument28 pagesEXTENDED PROJECT-Shoe - Salesrhea100% (5)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- State Immunity Cases With Case DigestsDocument37 pagesState Immunity Cases With Case DigestsStephanie Dawn Sibi Gok-ong100% (4)

- Expectation Vs Reality: Job Order and Contract of ServiceDocument10 pagesExpectation Vs Reality: Job Order and Contract of ServiceMikee Louise MirasolPas encore d'évaluation

- NIH Public Access: Converting Positive and Negative Symptom Scores Between Panss and Saps/SansDocument14 pagesNIH Public Access: Converting Positive and Negative Symptom Scores Between Panss and Saps/Sanscluaudiopolis2Pas encore d'évaluation

- Wire Connector T/Y+Document4 pagesWire Connector T/Y+cluaudiopolis2Pas encore d'évaluation

- Electrical Spring Connectors: Data SheetDocument4 pagesElectrical Spring Connectors: Data Sheetcluaudiopolis2Pas encore d'évaluation

- Ex-PLISSIT in Sexuality & DisabilityDocument6 pagesEx-PLISSIT in Sexuality & Disabilitycluaudiopolis2Pas encore d'évaluation

- PLISSITDocument9 pagesPLISSITcluaudiopolis2Pas encore d'évaluation

- ADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementDocument33 pagesADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementNURATIKAH BINTI ZAINOL100% (1)

- Lab 6 PicoblazeDocument6 pagesLab 6 PicoblazeMadalin NeaguPas encore d'évaluation

- Forecasting of Nonlinear Time Series Using Artificial Neural NetworkDocument9 pagesForecasting of Nonlinear Time Series Using Artificial Neural NetworkranaPas encore d'évaluation

- Sample Opposition To Motion To Strike Portions of Complaint in United States District CourtDocument2 pagesSample Opposition To Motion To Strike Portions of Complaint in United States District CourtStan Burman100% (1)

- Bajaj Allianz InsuranceDocument93 pagesBajaj Allianz InsuranceswatiPas encore d'évaluation

- Section 8 Illustrations and Parts List: Sullair CorporationDocument1 pageSection 8 Illustrations and Parts List: Sullair CorporationBisma MasoodPas encore d'évaluation

- Address MappingDocument26 pagesAddress MappingLokesh KumarPas encore d'évaluation

- Building New Boxes WorkbookDocument8 pagesBuilding New Boxes Workbookakhileshkm786Pas encore d'évaluation

- Course Specifications: Fire Investigation and Failure Analysis (E901313)Document2 pagesCourse Specifications: Fire Investigation and Failure Analysis (E901313)danateoPas encore d'évaluation

- Agfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Document3 pagesAgfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Youness Ben TibariPas encore d'évaluation

- QUIZ Group 1 Answer KeyDocument3 pagesQUIZ Group 1 Answer KeyJames MercadoPas encore d'évaluation

- Personal Best B1+ Unit 1 Reading TestDocument2 pagesPersonal Best B1+ Unit 1 Reading TestFy FyPas encore d'évaluation

- PFI High Flow Series Single Cartridge Filter Housing For CleaningDocument2 pagesPFI High Flow Series Single Cartridge Filter Housing For Cleaningbennypartono407Pas encore d'évaluation

- Asphalt Plant Technical SpecificationsDocument5 pagesAsphalt Plant Technical SpecificationsEljoy AgsamosamPas encore d'évaluation

- 3412C EMCP II For PEEC Engines Electrical System: Ac Panel DC PanelDocument4 pages3412C EMCP II For PEEC Engines Electrical System: Ac Panel DC PanelFrancisco Wilson Bezerra FranciscoPas encore d'évaluation

- How To Control A DC Motor With An ArduinoDocument7 pagesHow To Control A DC Motor With An Arduinothatchaphan norkhamPas encore d'évaluation

- Catalogo AWSDocument46 pagesCatalogo AWScesarPas encore d'évaluation

- Difference Between Mountain Bike and BMXDocument3 pagesDifference Between Mountain Bike and BMXShakirPas encore d'évaluation

- D - MMDA vs. Concerned Residents of Manila BayDocument13 pagesD - MMDA vs. Concerned Residents of Manila BayMia VinuyaPas encore d'évaluation

- Tinplate CompanyDocument32 pagesTinplate CompanysnbtccaPas encore d'évaluation

- PCDocument4 pagesPCHrithik AryaPas encore d'évaluation

- 4 Bar LinkDocument4 pages4 Bar LinkConstance Lynn'da GPas encore d'évaluation

- Research Article: Finite Element Simulation of Medium-Range Blast Loading Using LS-DYNADocument10 pagesResearch Article: Finite Element Simulation of Medium-Range Blast Loading Using LS-DYNAAnonymous cgcKzFtXPas encore d'évaluation

- Hotel Reservation SystemDocument36 pagesHotel Reservation SystemSowmi DaaluPas encore d'évaluation

- SBL - The Event - QuestionDocument9 pagesSBL - The Event - QuestionLucio Indiana WalazaPas encore d'évaluation

- Government of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Document2 pagesGovernment of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Satyaki Prasad MaitiPas encore d'évaluation

- CH 1 India Economy On The Eve of Independence QueDocument4 pagesCH 1 India Economy On The Eve of Independence QueDhruv SinghalPas encore d'évaluation