Académique Documents

Professionnel Documents

Culture Documents

Mechanical Engineering, Course Descriptions Autumn 2013-2014

Transféré par

Shah Jehan HanifCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mechanical Engineering, Course Descriptions Autumn 2013-2014

Transféré par

Shah Jehan HanifDroits d'auteur :

Formats disponibles

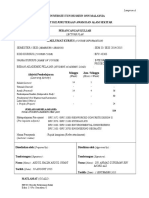

15.4.

2013/VM

SCHOOL OF TECHNOLOGY / Mechanical Engineering

AUTUMN SEMESTER 2013

Period 1

August 26 - October 11

Exam week

October 14-18

Period 2

Exam weeks

SPRING SEMESTER 2014

Period 3

January 7 - February 21

Exam week

February 24-28

Period 4

Exam weeks

March 3 - April 25

April 28 - May 23

ECTS cr

Course

Course

number

BK50A0701

BK20A2200

Basics of Welding Technology

NOTE!

Attendance

required in both

semesters

Course number

changed on 15.4.

Attendance

required in both

semesters

*)

Semester

Period

Autumn 2013

1-2

Study

level

Master

*)

October 21 - December 5

December 9-20

Advanced Production Engineering

Autumn 2013

Master

Autumn 2013

and Spring

2014

Autumn 2013

1-3

Master

BK50A2500

Coating and Lamination of Fibre Based Packaging

Materials

1-2

Master

BK60A1000

Control of Mechatronic Machines

Autumn 2013

1-2

Master

BK50A1300

Autumn 2013

1-2

Master

BK50A2200

Autumn 2013

1-2

Master

BK30A0801

Autumn 2013

1-2

Master

10-30

BK10A1100

Autumn 2013

1-2

Master

BK30A0700

Converting and Forming of Fibre Based

Packaging

Design Methodologies and Applications of

Machine Element Design

Laboratory Course of Laser Processing

Technology

Laboratory Work Course in Mechanical

Engineering

Laser Materials Processing

Autumn 2013

1-2

Master

BK70A0500

Machine Dynamics

Autumn 2013

1-2

Master

BK20A0101

Materials Engineering

Autumn 2013

1-2

Master

BK20A0400

Modern Welding Technology

Autumn 2013

1-2

Master

BK50A2400

Packaging Materials

Autumn 2013

and Spring

2014

Autumn 2013

1-4

Master

BK50A2600

Principles of Chemistry, Paper Technology and

Food Technology

1-2

Master

BK50A2100

Printing and Package Design

Autumn 2013

1-2

Master

BK10A1200

Research Methods and Methodologies

Autumn 2013

1-2

Master

BK60A0301

Servo Control Engineering

Autumn 2013

1-2

Master

BK70A0000

Simulation of a Mechatronic Machine

*)

*)

*)

rd

suitable for 3 year Bachelor level student

Course descriptions on pages 2 - 11

Learning agreement is created in Mobility-Online system during application process. More information about

applying, i.e. Guide for Applicants, is available on www.lut.fi/exchange > Apply to LUT > Exchange studies

Course registration is done online before the semesters start. Methods of registration and deadlines are announced

to the accepted students.

Course schedules are available in Uni portal and they are published in summer 2013.

1(11)

Subject to alterations

15.4.2013/VM

SCHOOL OF TECHNOLOGY / Mechanical Engineering

BK50A0701

ADVANCED PRODUCTION ENGINEERING

6 ECTS cr

Replaces the course BK50A0700 Advanced Production Engineering

Year and Period

Teacher(s)

Aims

Content

Modes of Study

Evaluation

Study materials

Further Information

M.Sc. (Tech.) 1, Period 1-2

Professor, D.Sc. (Tech.) Juha Varis

Docent, D.Sc. (Tech.) Harri Eskelinen

Researcher, D.Sc. (Tech.) Mika Lohtander

Doctoral Student, M.Sc. (Tech.) Ville Leminen

University Lecturer, M.Sc. (Tech.) Merja Huhtala

Development Manager, M.Sc. (Tech.), M.Sc. (Econ. & Bus. Adm.) Mika Kainusalmi

After having completed this course module the student should be able to:

- compare and evaluate the most advanced design and production methods, equipment, equipment

systems and modern product facilities used especially in the manufacture of thin and rough sheet

metal products especially in the manufacturing of solid parts and sheet metal products

- justify the role of manufacturing as a part of the companys strategy

- understand the duties of factory management and development as well as in research in the field.

Manufacturing methods for modern metal cutting, sheet metal production and basics of paperboard

forming. Advanced production methods for punching, folding and mechanical joining of sheet metal

products. Production control systems of flexible automatic (FMS, IMS) production facilities. The

significance and technologies of product design as well as of production (CAD, CAP, PPS, CAM). DFMA

and cost functions of products, production control and simulation. The operation of a factory as part

of a principal-supplier network. The technology and methods for improving production. Material

handling, production and information systems of a workshop.

Development of workshop operations and quality control.

Lectures 28 h, 1st-2nd period.

Seminar lecture 2 h, 1st period.

Seminars 18 h, 2nd period.

Seminar work (pair work) and working as an opponent 65 h, 1st-2nd period.

Independent study 30 h.

Industry visit 12 h in 1st or 2nd period.

Total workload 155 h.

0-5, examination 65%, seminar 35%.

Intermediate seminar presentation, final presentation and working as an opponent. Adequate

participation in seminars.

Materials to be announced during the introductory lecture.

Moodle.

This course has 1-5 places for open university students. More information on the web site for open

university instruction.

BK20A2200

BASICS OF WELDING TECHNOLOGY

Year and Period

Teacher(s)

Aims

M.Sc. (Tech.) 1, Period 2

University Lecturer, Lic.Sc. (Tech.) Raimo Suoranta

After having passed this course module the student is able to:

- identify and define the special features of quality management in production of welded

constructions and

- evaluate the influence of welding to material properties.

Productivity, economy and quality in welding. Welding costs. Weldability of the most common

materials. Basics of mechanization and robotization of welding. Basics of design of welded structures.

Quality management.

Lectures 14 h, 2nd period.

Independent study 64 h.

Content

Modes of Study

2(11)

Subject to alterations

3 ECTS cr

15.4.2013/VM

SCHOOL OF TECHNOLOGY / Mechanical Engineering

Evaluation

Study materials

Further Information

Total workload 78 h.

0-5, examination 100%.

Lecture notes.

This course has 1-5 places for open university students. More information on the web site for open

university instruction.

BK50A2500

COATING AND LAMINATION OF FIBRE BASED PACKAGING MATERIALS

5 ECTS cr

Replaces the course BK20A1400 Coating and Lamination of Fibre Based

Packaging Materials

Year and Period

Teacher(s)

Aims

Content

Modes of Study

Evaluation

Study materials

M.Sc. (Tech.) 1, Period 1-3

Visiting lecturer, Professor, Jurkka Kuusipalo

Professor, Ph.D. Henry Lindell

After having passed this course module the student is able to:

- compare various ways to combine materials with paper and board and

- compare and evaluate their properties in different packaging applications.

Raw materials, for main coating and laminating methods. Main properties (including pronting) of the

finished products. Focus in extrusion coating process.

The main applications of paper based packaging materials in packaging sector.

Combined packaging structures and their manufacturing techniques.

Capability to run extrusion coating line and utilize fibre materials on the packaging solutions.

Lectures total 18 h, 1st-3rd period.

Exercises total 8 h, 1st-3rd period.

Seminars 24 h, 1st-3rd period.

Independent study 80 h.

Total workload 130 h.

0-5, examination 70%, exercises 30%.

Course material. Handouts.

Lecturers' comments.

Kuusipalo, J. ed., Paper and Paperboard Converting. In series of books: Papermaking Science and

Technology, part 12, 2nd edition, Fapet, Helsinki.

Moodle.

BK50A1300

CONVERTING AND FORMING OF FIBRE BASED PACKAGING

Year and Period

Teacher(s)

M.Sc. (Tech.) 2, Period 1-2

Professor, Ph.D. Henry Lindell

Professor, D.Sc. (Tech.) Juha Varis

Researcher, M.Sc. (Tech.) Panu Tanninen

Laboratory Engineer, M.Sc. (Tech.) Jari Selesvuo

After having passed this course module the student is able to:

- choose and evaluate various paper and board converting technologies and

- compare and analyze their developments in package production.

The main technologies of carton forming: die cutting, scoring, folding of blanks and other forming

technologies. Tool design (3D-systems) and tool manufacturing technologies in modern workshops.

Machines and equipment for listed converting processes, and their integration into effective

production systems.

Sealing, gluing and closing technologies of fibre based packaging materials. The special requirements

various paper based materials for converting processes.

Features to be considered in multimaterial converting.

Knowledge of the main paper package forming technologies. The requirements of various paper and

board grades set for the processes.

Aims

Content

3(11)

Subject to alterations

5 ECTS cr

15.4.2013/VM

SCHOOL OF TECHNOLOGY / Mechanical Engineering

Modes of Study

Evaluation

Study materials

Lectures 28 h.

Independent study 102 h.

Total workload 130 h.

Written examination 100%.

Lecture handouts.

Moodle.

BK60A1000

CONTROL OF MECHATRONIC MACHINES

Year and Period

Teacher(s)

Aims

M.Sc. (Tech.) 1, Period 1-2

Associate Professor, D.Sc. (Tech.) Huapeng Wu

The aim of this course is to develop the theoretical and practical expertise in the analysis and design

of control systems as well as programming and control of robotic machines.

The application of control system strategies covers a wide area and the course provides a sound base

for the study of both classical and modern techniques.

After having passed this course module, the student is able to:

- model and simulate the control of mechatronic machines

- design servo control systems for hydraulic, pneumatic and electro-machines e.g., by utilizing the

frequency- and time-domain methods

- programming and control mechatronic machines e.g., a robotic machine

This course introduces common industrial servo control systems: hydraulic, pneumatic, and electromechanic systems. The dynamic analysis of these servo systems is studied in both time- and

frequency-domain. Different control strategies are introduced, mainly classical with some concepts of

modern control. Design and analysis of digital control will be introduced. During this course, the

design, analysis and simulation using Matlab/Simulink are conducted. Suitable also for postgraduate

studies.

Lectures 42 h, 1st-2nd period.

Tutorials 42 h, 1st-2nd period.

Exercises 30 h, 2nd period.

Laboratory work 10 h.

Independent study 50 h.

Total loading 174 h.

0-5, examination 100%.

Lecture notes.

Selected chapters from the following text books:

1) Shinners: "Modern control system theory and application".

2) Gene F. Franklin, J. David Prowell: "Feedback control of dynamic systems".

3) Jelali Mohieddine: "Hydraulic servo-systems, modeling, identification and control".

This course has 6-10 places for open university students. More information on the web site for open

university instruction.

Content

Modes of Study

Evaluation

Study materials

Further Information

BK50A2200

DESIGN METHODOLOGIES AND APPLICATIONS OF MACHINE ELEMENT

DESIGN

6 ECTS cr

5 ECTS cr

Replaces the course BK50A1201 Machine Design for Packaging Technology.

Year and Period

Teacher(s)

Aims

M.Sc. (Tech.) 1, Period 1-2

Docent, D.Sc. (Tech.) Harri Eskelinen

After having passed the course student knows:

- how to dimension the most essential machine elements according to the requirements of their

strength, reliability, lifetime and wear

- how to carry out mechanisms synthesis and analysis for typical engineering applications

- how to handle the design process of a simple machine or mechanism and means to estimate

4(11)

Subject to alterations

15.4.2013/VM

SCHOOL OF TECHNOLOGY / Mechanical Engineering

Content

Modes of Study

Evaluation

Study materials

Further Information

BK30A0801

functional aspects of applied technology.

Basic mechanisms types, mechanisms analysis and synthesis, reliability-based machine design, wear

phenomena and lifetime analysis of selected machine parts and elements. Different methodologies

of DFM(A) and means to apply them in mechanical engineering. Knowledge about how to design a

simple machine or mechanisms for special application areas of mechanical engineering and means to

estimate functional aspects of applied technology.

Lectures total 28 h, 1st-2nd period.

Exercises total 28 h, 1st-2nd period.

Seminar 16 h, 1st-2nd period.

Independent study 58 h.

Total workload 130 h.

0-5, examination 50%, exercises and seminar 50%.

Erdman A.G., Mechanism Design.

Norton R.L., Design of Machinery.

This course has 6-10 places for open university students. More information on the web site for open

university instruction.

LABORATORY COURSE OF LASER PROCESSING TECHNOLOGY

4 ECTS cr

Replaces the course BK30A0800 Laboratory Course of Laser Materials

Processing.

Year and Period

Teacher(s)

Aims

Content

Modes of Study

Evaluation

Study materials

BK10A1100

M.Sc. (Tech.) 1, Period 1-2

M.Sc. (Tech.) Tuomas Purtonen

Person in Charge: Researcher, Lic.Sc. (Tech.) Heidi Piili

After having passed the course module the student is able to:

- describe, specify and compare the special features and practical aspects of laser materials

processing practices of different materials and

- classify them for different processes.

Basics of laser processes, systems and equipment. Processability of common engineering materials

with different processes. Practical using of laser processes.

Lectures for this course are similar to BK30A0000 Sdetyst.

Lectures 10 h, 1st period.

Laboratory practices 14 h, 1st-2nd period.

Individual work 80 h.

Total work load 104 h.

0-5, written exam 50%, reports of laboratory practices 50%. Both have to be passed for course

completion.

Lecture notes.

Steen, W., Laser Material Processing.

LABORATORY WORK COURSE IN MECHANICAL ENGINEERING

10 - 30 ECTS cr

The course is mainly intended for foreign visiting students. The students

register for the course by contacting the supervisor.

Teacher(s)

Aims

Content

N. N.

Person in Charge: Head of the Laboratory

To give the student a deeper understanding on mechanical engineering in a specialized area.

A specific project which is done in one of the laboratories of the department. The project is planned

together with the supervisor(s) and consists mainly of laboratory work, literature work and report

writing. The course may contain lectures and seminars. The project may also be planned together

with industry and then carried out at some industrial location.

5(11)

Subject to alterations

15.4.2013/VM

SCHOOL OF TECHNOLOGY / Mechanical Engineering

Modes of Study

Evaluation

Further Information

The amount of work hours in the project will determine the amount of credits, e.g. three months of

work would give 15 ECTS cr. Credits will be granted when the final report is delivered. Extra credits

can be received if specific examinations are made.

0-5 or pass/fail, depending on the project carried out.

This course has 1-5 places for open university students. More information on the web site for open

university instruction.

BK30A0700

LASER MATERIALS PROCESSING

Year and Period

Teacher(s)

M.Sc. (Tech.) 2, Period 1-2

Researcher, Lic.Sc. (Tech.) Heidi Piili

M.Sc. (Tech.) Tuomas Purtonen

Docent, D.Sc. (Tech.) Veli Kujanp

Person in Charge: Professor, D.Sc. (Tech.) Antti Salminen

After having passed the course module the student:

- is able to compare and select the special features of laser materials processing processes

- knows how to select and optimize proper process and processing procedure for different materials

- is able to develop processes for different applications.

Laser beam material interaction, transmission, reflection, absorption. The features of different

materials and laser beams on phenomena. Heating, melting, vaporizing, ablating material with laser

beam. Behaviour of molten material, heat transfer mechanisms. Formation of keyhole and

phenomena connected. Knowledge on existing ways to process material with laser beam and the

effect of laser beam material interaction on that. Knowledge on most common laser processes like

laser welding, cutting, marking, drilling, scribing, micro processing additive manufacturing and

surface treatment. Practical cases, applications will be combined to theory.

Lectures 28 h, 1st-2nd period.

Seminar 14 h, 1st-2nd period.

Individual work 88 h.

Total workload 130 h.

0-5, written exam 80%, seminar 20%.

Steen W., Laser Material Processing.

Ion, J., Laser Processing of Engineering Materials.

Moodle.

Obligatory BK30A0000 Sdetyst or BK30A0801 Laboratory Course of Laser Processing Technology

accepted.

This course has 1-5 places for open university students. More information on the web site for open

university instruction.

Aims

Content

Modes of Study

Evaluation

Study materials

Prerequisites

Further Information

5 ECTS cr

BK70A0500

MACHINE DYNAMICS

Year and Period

Teacher(s)

Aims

M.Sc. (Tech.) 2, Period 1-2

Professor, D.Sc. (Tech.) Jussi Sopanen

After having passed the course student knows:

- theory of structural dynamics design and how to apply the knowledge in the design of machine

systems (especially electromechanical systems)

- how to model dynamic machine systems, solve the equations of motion in frequency and time

domains and analyze the results

- basics of vibration measurements and experimental modal analysis

Multiple degree-of-freedom vibrations, solution and interpretation of natural frequencies and

modes. Response to the harmonic and general force excitation. Derivation of the equations of

motion of the system and solution in frequency and time domain. Vibration measurements and

experimental modal analysis. Basics of Rotor Dynamics. Torsion vibrations. Vibrations of

electromechanical systems.

Content

6 ECTS cr

6(11)

Subject to alterations

15.4.2013/VM

SCHOOL OF TECHNOLOGY / Mechanical Engineering

Modes of Study

Evaluation

Study materials

Prerequisites

Further Information

Lectures 28 h, 1st-2nd period.

Supervised tutorials 20 h, 1st-2nd period.

Laboratory work 6 h.

Independent study 72 h, 1st-2nd period.

Teamwork in multi-cultural working environment 30 h, 1st-2nd period.

Total workload 156 h.

0-5, examination or mid-course examinations 70%, simulation work 20%, laboratory exercises 10%.

Lecture notes.

Inman, D. J.: Engineering vibration, 3rd ed., Pearson Education Inc., New Jersey, 2007. ISBN 0-13228173-2.

Moodle

Students are recommended to have completed BK80A0100 Dynamiikka I, BK80A2500 Dynamiikka II

(not required form students of Master's Degree Programme in Mechanical Engineering) and

BK80A1100 FE-analyysin peruskurssi or BK80A1200 FE-analysis Course.

This course has 6-10 places for open university students. More information on the web site for open

university instruction.

BK20A0101

MATERIALS ENGINEERING

Year and Period

Teacher(s)

M.Sc. (Tech.) 1, Period 1-2

University Lecturer, Lic.Sc. (Tech.) Raimo Suoranta

Post-Doctoral Researcher, D.Sc. (Tech.) Paul Kah

After having passed this course module the student is able to:

- utilize the basics of physical metallurgy and is able to explain the relationship between physical

metallurgy and material properties

- select proper material according to functionality and economics.

The structure of steel, plastic deformation, restoration, hardening, heat treatment methods.

Selecting materials according to strength, toughness, corrosion resistance, wear resistance.

Manufacturability. Light metals and non-metallic materials. LCC. Systems for selecting materials.

Lectures 24 h, 1st-2nd period.

Independent study 132 h, 1st-2nd period.

Total workload 156 h.

0-5, examination 80%, tutorials 20%.

Moodle.

This course has 1-5 places for open university students. More information on the web site for open

university instruction.

Aims

Content

Modes of Study

Evaluation

Study materials

Further Information

6 ECTS cr

BK20A0400

MODERN WELDING TECHNOLOGY

Year and Period

Teacher(s)

M.Sc. (Tech.) 1, Period 1-2

University Lecturer, Lic.Sc. (Tech.) Raimo Suoranta

M.Sc. (Tech.) Paul Kah

After having passed this course module the student is able to:

- identify and define the special features welding in production and product design

- select proper processes and welding procedures for different materials.

Productivity, economy and quality in welding. Welding costs. Productive and efficient new welding

processes. Weldability of the most common materials. Mechanization and robotization of welding.

Basics of design of welded structures. Bevelling methods. The quality, environmental and safety in

welding workshop.

Lectures 28 h, 1st-2nd period.

Tutorials 14 h, seminar, 1st-2nd period.

Independent study 140 h.

Total workload 182 h.

Aims

Content

Modes of Study

7(11)

Subject to alterations

7 ECTS cr

15.4.2013/VM

SCHOOL OF TECHNOLOGY / Mechanical Engineering

Evaluation

Study materials

Further Information

BK50A2400

0-5, examination 80%, seminar 20%.

Lecture notes.

Moodle.

This course has 1-5 places for open university students. More information on the web site for open

university instruction.

PACKAGING MATERIALS

5 ECTS cr

Replaces the course BK20A1301 Packaging Materials

Year and Period

Teacher(s)

Aims

Content

Modes of Study

Evaluation

Study materials

Further Information

BK50A2600

M.Sc. (Tech.) 1, Period 1-2

Professor, Ph.D. Henry Lindell

After having passed this course module the student is able to:

- compare the packaging related properties of various packaging materials

- choose appropriate packaging materials for typical packaging applications.

The manufacture, physical and chemical properties (relevant for packaging) of the major packaging

materials: paper, paperboard, corrugated board, wood, glass, metals, polymers including

biopolymers and adhesives. Foreseeable future development of each material.

Material composite possibilities and their use.

Capability to select material alternatives or combinations for specific packaging solutions based on

their possible performance characteristics.

Lectures total 16 h, 1st-2nd period.

Exercises total 8 h, 1st-2nd period.

Independent study 80 h.

Total workload 104 h.

0-5, examination 70%, exercises 30%.

Course material. Handouts. Moodle.

This course has 6-10 places for open university students. More information on the web site for open

university instruction.

PRINCIPLES OF CHEMISTRY, PAPER TECHNOLOGY AND FOOD

TECHNOLOGY

5 ECTS cr

Replaces the course BK20A1500 Principles of Chemistry, Paper Technology

and Food Technology. Belongs only to complementary studies and minor

subject in Packaging Technology. Course registrations during 1st period.

Year and Period

Teacher(s)

Aims

Content

Modes of Study

Evaluation

Study materials

M.Sc. (Tech.) 1, Period 1-4

Professor, Ph.D. Henry Lindell

After having passed this course module the student is able to:

- explain basic general, organic and biochemical phenomena

- explain and categorize basics of paper technology and products

- define packaging related features of processed food.

Basic phenomena of general, organic and biochemistry.

Main fibre grades and other raw materials and their role in paper products, the main part processes

of paper production, typical properties of the main paper and board grades.

The basic principles of foods and processing theory, the main food processes and their effect on

foods considering packaging.

Essays with specific instruction.

Independent study 130 h.

Total work load 130 h.

Pass/Fail.

Smook G.A., Handbook for Pulp & Paper Technologists, 2nd edition, p 1-7, 36-44,194-324 or

8(11)

Subject to alterations

15.4.2013/VM

SCHOOL OF TECHNOLOGY / Mechanical Engineering

Smook G.A., Handbook for Pulp & Paper Technologists, 3rd edition, p 1-9, 37-45, 190-324 or

Herbert Holik, Handbook of Paper and Board, Wiley-VCH Verlag GmbH & Co. KgaA, Wennheim,

Germany.

Bettelheim & March, Introduction to General, Organic and Biochemistry Saunders College Publishing

Fellows P., Food processing technology - Principles and Practice, 2nd edition, Part I p 7-62, III and IV,

p 229-452.

Moodle.

BK50A2100

PRINTING AND PACKAGE DESIGN

Year and Period

Teacher(s)

M.Sc. (Tech.) 2, Period 1-2

Professor, Ph.D. Henry Lindell

M.Sc. (Tech.), B.Sc. (Arts) Noora Nylander

Visiting lecturer, M.Sc. (Tech.) Risto Vesanto

Industry lecturers

Person in Charge: Professor, Ph.D. Henry Lindell

After having passed this course module the student is able to:

- compare and analyze different printing methods used in packaging industry

- choose proper printing methods for a certain packaging solution

- solve printing problems and to control print quality

- justify the importance of graphic design process in packaging

- communicate with the various partners involved in a design process

- to act as a producer for a dedicated product.

Pre-press operations. The main printing technologies and their use in packaging industry. Printing of

various substrates. Composition of printing inks. Emerging printing technologies and their potential

use in packaging industry. Future trends of printing technologies. Aspects of the role of package in

the value chain. Demands set on the lay-out of a package. Various ways for idea generation of a

package lay-out.

Lectures total 20 h, 1st-2nd period.

Exercises/seminars 30 h.

Independent study 106 h.

Total work load 156 h.

0-5, examination 50%, seminar work 50%.

Handouts.

Saarelma, H., Oittinen, P., Printing. In series of books: Papermaking Science and Technology, Book 13,

Fapet, Helsinki 1989.

This course has 6-10 places for open university students. More information on the web site for open

university instruction.

Aims

Content

Modes of Study

Evaluation

Study materials

Further Information

6 ECTS cr

BK10A1200

RESEARCH METHODS AND METHODOLOGIES

Year and Period

Teacher(s)

Aims

M.Sc. (Tech.) 1, Period 1-2

Docent, D.Sc. (Tech.) Harri Eskelinen

After having passed this course module the student is able to:

- plan, lead and organize the research project according to the established scientific practices and

procedures

- compare, choose and utilize proper scientific practices to carry out research projects in industrial

environments

- write and present a scientific research plan and research report

Learning outcomes:

Criteria to evaluate scientific contribution. Scientific research projects in engineering science.

Principles of qualitative and quantitative analysis. Viewpoints of how to illustrate the results of

quantitative analysis. Different means to carry out literature reviews, interviews and surveys.

Content

9(11)

Subject to alterations

4 ECTS cr

15.4.2013/VM

SCHOOL OF TECHNOLOGY / Mechanical Engineering

Modes of Study

Evaluation

Study materials

Further Information

BK60A0301

Utilization of silent knowledge. Contents and structures of research plans and research structures

based on IMRAD-principle. Viewpoints of writing scientific articles and conference papers. Practical

advice about making a conference presentation. Guidelines of acting as an opponent in a scientific

conference or seminar.

Lectures 14 h, 1st period.

Exercises 28 h, 1st-2nd period.

Independent study 48 h, 1st-2nd period.

Seminar 14 h, 1st-2nd period.

Total workload 104 h.

0-5, exercises 30%, seminar 70%.

Lectures.

This course has 1-5 places for open university students. More information on the web site for open

university instruction.

SERVO CONTROL ENGINEERING

8 ECTS cr

Replaces the course BK60A0300 Servo Control Engineering.

Year and Period

Teacher(s)

Aims

Content

Modes of Study

Evaluation

Study materials

Prerequisites

M.Sc. (Tech.) 1, Period 1-2

Associate Professor, D.Sc. (Tech.) Huapeng Wu

The aim of this course is to develop the theoretical and practical expertise in the analysis and design

of control systems as well as modeling and simulation of such systems.

The application of control system strategies covers a wide area and the course provides a sound base

for the study of both classical and modern techniques.

After having passed this course module, the student is able to:

- model and simulate the servo control systems

- design servo control systems for hydraulic, pneumatic and electrical servo systems, e.g., by utilizing

the frequency- and time-domain methods

- construct both basic controllers and intelligent control systems, e.g., based on neural networks and

fuzzy logic

- utilize Matlab- and Simulink-software for simulation and design of servo control systems.

This course introduces common industrial servo control systems: hydraulic, pneumatic, and electromechanic systems. The dynamic analysis of these servo systems is studied in both time- and

frequency-domain. Different control strategies are introduced, mainly classical with some concepts of

modern control. Design and analysis of digital control will be introduced. During this course, the

design, analysis, and simulation using Matlab and Simulink are conducted. Suitable also for

postgraduate studies.

42 h of lectures, 1st-2nd period.

42 h of tutorials, 1st-2nd period.

30 h of exercises, 2nd period.

20 h laboratory work.

24 h team work.

50 h independent study.

Total loading 208 h.

0-5, examination 100%.

Lecture notes.

Selected chapters from the following text books:

1) Shinners: "Modern control system theory and application".

2) Gene F. Franklin, J. David Prowell: "Feedback control of dynamic systems".

3) Jelali Mohieddine: "Hydraulic servo-systems, modeling, identification and control".

Blackboard.

The student must have completed BK60A0001 Mekatroniikan peruskurssi.

Recommended BK60A0100 Hydraulitekniikka, BM20A1501 Numeeriset menetelmt I, BM20A4301

Johdatus tekniseen laskentaan, BL10A0100 Shktekniikan peruskurssi, BL40A0300 Sttekniikan

10(11)

Subject to alterations

15.4.2013/VM

SCHOOL OF TECHNOLOGY / Mechanical Engineering

Further Information

perusteet B and CT60A0200 Ohjelmoinnin perusteet (not required from students of Master's Degree

Programme in Mechanical Engineering).

This course has 6-10 places for open university students. More information on the web site for open

university instruction.

BK70A0000

SIMULATION OF A MECHATRONIC MACHINE

Year and Period

Teacher(s)

Aims

M.Sc. (Tech.) 1, Period 1-2

Professor, D.Sc. (Tech.) Aki Mikkola

The student possesses the theories and practices of mathematical modeling and computer simulation

of machine systems, which are either hydraulically, pneumatically or electronically actuated.

The student is able to utilize simulations as an integrated tool of product design and he can utilize his

skills to generalize the theories of engineering design to solve multidisciplinary design tasks.

The student is able to compare and justify the use of different constructional solutions for linear and

rotating motion mechanism based on their static, kinematic and dynamic analysis.

The student is able to individual scientific work to simulate mechatronic machines.

Principles of multibody dynamics, modelling of actuators, coupled simulation. The use of Lagrangian

equation. Constraint equations and Lagrangian multipliers. Inertia of rigid bodies. Modeling of

hydraulic components. Numerical integration of the equation of motion. Individual utilization of

simulation software, which includes also the principles of how to apply previous mentioned

mathematical theories into handling and solving abstract and multidisciplinary problems.

Lectures 28 h, 1st-2nd period.

Teamwork in multi-cultural working environment 30 h, 1st-2nd period.

Supervised tutorials 28 h, 1st-2nd period.

Independent study 70 h, 1st-2nd period.

Total loading 156 h.

0-5, examination or mid-course examinations 80%, simulation work 20%.

Lecture notes.

Shabana, A. A.: Computational Dynamics, John Wiley & Sons, Inc., 1st edition, 1994. ISBN 0-47130551-0.

Moodle.

Students are recommended to have completed BK60A0001 Mekatroniikan peruskurssi, BK80A0000

Statiikka, BK80A0100 Dynamiikka I

BK80A2500 Dynamiikka II (not required from students of Master's Degree Programme in Mechanical

Engineering).

This course has 11-15 places for open university students. More information on the web site for open

university instruction.

Enrolment to tutorial groups in WebOodi

Content

Modes of Study

Evaluation

Study materials

Prerequisites

Further Information

11(11)

Subject to alterations

6 ECTS cr

Vous aimerez peut-être aussi

- Allison - Technical Documents 157 - Cooling Test - UpdateDocument29 pagesAllison - Technical Documents 157 - Cooling Test - Updateangie michell paccini rodriguezPas encore d'évaluation

- Inspection HandbookDocument126 pagesInspection Handbooksteffy18295% (21)

- 2015 KOBELCO Defect PDFDocument25 pages2015 KOBELCO Defect PDFayushPas encore d'évaluation

- Procurement PlanDocument27 pagesProcurement PlanSheraz Tariq67% (18)

- Repair VP 44 PumpDocument11 pagesRepair VP 44 Pumpmuhamed95% (20)

- Concrete Coating of Line Pipe PDFDocument19 pagesConcrete Coating of Line Pipe PDFZadeh Norman100% (1)

- Chapters 1 To 4Document108 pagesChapters 1 To 4Andreu1287100% (1)

- ANNA UNIVERSITY AFFILIATED INSTITUTIONS PLASTIC TECHNOLOGY CURRICULADocument76 pagesANNA UNIVERSITY AFFILIATED INSTITUTIONS PLASTIC TECHNOLOGY CURRICULAThulasi NathPas encore d'évaluation

- Dyneon PTFE BrochureDocument0 pageDyneon PTFE BrochureXray UandPas encore d'évaluation

- Materials Forming and Machining: Research and DevelopmentD'EverandMaterials Forming and Machining: Research and DevelopmentÉvaluation : 3 sur 5 étoiles3/5 (1)

- Materials Science and Engineering - Stanford UniversityDocument22 pagesMaterials Science and Engineering - Stanford Universityteerth_brahmbhattPas encore d'évaluation

- Kiln Preheater Fan CoatingDocument6 pagesKiln Preheater Fan CoatingVijay Bhan100% (1)

- CHE310 Chemical Engineering Process Analysis 1Document2 pagesCHE310 Chemical Engineering Process Analysis 1BoluwatifePas encore d'évaluation

- 101 2014 3 BDocument20 pages101 2014 3 BTshepiso NthitePas encore d'évaluation

- 221 Outline-Fall 2014Document4 pages221 Outline-Fall 2014vince273Pas encore d'évaluation

- E - Fyp GuidelinesDocument71 pagesE - Fyp GuidelinesArif AzizanPas encore d'évaluation

- Module Description 2021 11Document21 pagesModule Description 2021 11PAVAN KUMAR THATAPas encore d'évaluation

- MAT 402-Syllabus-Spring2021Document2 pagesMAT 402-Syllabus-Spring2021Liang FrankPas encore d'évaluation

- Buiding Materials and Construction Msbte Manual Msbte Store 1Document102 pagesBuiding Materials and Construction Msbte Manual Msbte Store 1Neha JadhavPas encore d'évaluation

- Master's in Sustainable Materials EngineeringDocument4 pagesMaster's in Sustainable Materials Engineeringmuhammad adnanPas encore d'évaluation

- PC LAB Workbook - 17.12.2016Document71 pagesPC LAB Workbook - 17.12.2016y satishkumarPas encore d'évaluation

- Syllabus 2023Document2 pagesSyllabus 2023Morteza NikoonejadPas encore d'évaluation

- ME3450 Syllabus 2011 Fall v3Document7 pagesME3450 Syllabus 2011 Fall v3petkirstPas encore d'évaluation

- Advanced Concrete Technology MSC (Eng) - PGDip - Advanced Concrete Technology MSC (Eng) - PGDip - School of Civil Engineering - University of LeedsDocument2 pagesAdvanced Concrete Technology MSC (Eng) - PGDip - Advanced Concrete Technology MSC (Eng) - PGDip - School of Civil Engineering - University of LeedsApril IngramPas encore d'évaluation

- CAD/CAM Lab Manual for Mechanical EngineeringDocument83 pagesCAD/CAM Lab Manual for Mechanical EngineeringPasupathi KumarPas encore d'évaluation

- A Cutting Edge Program: OPCION 1. Master's Degree in Management in Polymer TechnologyDocument3 pagesA Cutting Edge Program: OPCION 1. Master's Degree in Management in Polymer TechnologyEmilio Bernal MorenoPas encore d'évaluation

- Position Optimization of Additively Manufactured Soft Magnetic CoresDocument3 pagesPosition Optimization of Additively Manufactured Soft Magnetic CoresFudo FudicPas encore d'évaluation

- Mech3403 2013 Sem-1 CrawleyDocument9 pagesMech3403 2013 Sem-1 CrawleyTamsin VenterPas encore d'évaluation

- Meng Materials Science and Engineering: Ucas Code: J500Document2 pagesMeng Materials Science and Engineering: Ucas Code: J500Nazar NasserPas encore d'évaluation

- Course File 18-19 orDocument35 pagesCourse File 18-19 orAmrutha MandigaPas encore d'évaluation

- PG Programmes 2011 - 1Document3 pagesPG Programmes 2011 - 1Chaitanya MittalPas encore d'évaluation

- PhD in Mechanical Engineering at Politecnico di MilanoDocument7 pagesPhD in Mechanical Engineering at Politecnico di MilanoAshok BodaPas encore d'évaluation

- Eee SyllabusDocument264 pagesEee SyllabusJamesgerald ParimalamPas encore d'évaluation

- OutlineDocument4 pagesOutlineRajib BaruaPas encore d'évaluation

- Become What You Want To Be: Unit GuideDocument6 pagesBecome What You Want To Be: Unit GuideMq SharozPas encore d'évaluation

- Visvesvaraya Technological University, BelgaumDocument41 pagesVisvesvaraya Technological University, BelgaumBen GeorgePas encore d'évaluation

- MEC 2202 Introductory BookDocument32 pagesMEC 2202 Introductory Bookalail2002Pas encore d'évaluation

- ISE551Document3 pagesISE551MahendraMeenaPas encore d'évaluation

- Rpp04 Idp Bfc43303 - Laterst02-01Document6 pagesRpp04 Idp Bfc43303 - Laterst02-01Syamim BakriPas encore d'évaluation

- Course Syl Lab UsDocument2 pagesCourse Syl Lab UsJorge RodríguezPas encore d'évaluation

- Plas TechDocument99 pagesPlas TechsggdgdPas encore d'évaluation

- Velammal Institute of Technology Mechanical Engineering Course Outcomes Program OutcomesDocument54 pagesVelammal Institute of Technology Mechanical Engineering Course Outcomes Program OutcomesshivakeesPas encore d'évaluation

- Foundry and Forging Laboratory ManualDocument110 pagesFoundry and Forging Laboratory Manualvampiredraak2712Pas encore d'évaluation

- SMME FYP Guidelines v3p1Document15 pagesSMME FYP Guidelines v3p1Mukaram AliPas encore d'évaluation

- Faculty of Engineering and The Environment Regulations 2022 BEng MetallurDocument12 pagesFaculty of Engineering and The Environment Regulations 2022 BEng MetallurIsaiah MakurunjePas encore d'évaluation

- Ecofriendly Sweeping Machine Project ReportsDocument31 pagesEcofriendly Sweeping Machine Project Reports69 Abhishek PandeyPas encore d'évaluation

- ENGD3114 Emerging Materials ProcessesDocument13 pagesENGD3114 Emerging Materials ProcessesSam StidePas encore d'évaluation

- Peo MSFPDocument1 pagePeo MSFPsnpadhiPas encore d'évaluation

- Visvesvaraya Technological University, Belgaum: M.TECH. Tool Engineering - (Tentative) I SemesterDocument6 pagesVisvesvaraya Technological University, Belgaum: M.TECH. Tool Engineering - (Tentative) I Semesteryathin KLPas encore d'évaluation

- MECH421 Outline 2017Document5 pagesMECH421 Outline 2017mralex11Pas encore d'évaluation

- BEE-Document210 pagesBEE-th3noob8389Pas encore d'évaluation

- Academic Report 16-17 MAHAGENCODocument44 pagesAcademic Report 16-17 MAHAGENCOI am knoxPas encore d'évaluation

- Experimental Engineering CourseDocument5 pagesExperimental Engineering CourseTim NguyenPas encore d'évaluation

- MECH9420 Course-Outline S2-2017 2Document15 pagesMECH9420 Course-Outline S2-2017 2HariDuraPas encore d'évaluation

- Advanced Construction Materials and Technology: Module Specification Student and Academic ServicesDocument5 pagesAdvanced Construction Materials and Technology: Module Specification Student and Academic ServicesU.ManeeshaPas encore d'évaluation

- TYBTech Syllabus MechanicalDocument49 pagesTYBTech Syllabus MechanicalswapnillkPas encore d'évaluation

- DPUC_46411_2020-2021_v1_enDocument3 pagesDPUC_46411_2020-2021_v1_enabastosuaptPas encore d'évaluation

- Mechanics of MaterialsDocument13 pagesMechanics of MaterialsJack jacksonPas encore d'évaluation

- Advances in Welding and Joining TechnologiesDocument1 pageAdvances in Welding and Joining Technologiessmsunil12345Pas encore d'évaluation

- MEC 322 OutlineDocument3 pagesMEC 322 OutlineBob jonesPas encore d'évaluation

- FYP Briefing May 2011Document20 pagesFYP Briefing May 2011Amir MalikiPas encore d'évaluation

- MS Handout and II Unit QuestionsDocument13 pagesMS Handout and II Unit QuestionsSrinivas naidu KotyadaPas encore d'évaluation

- Fitting ManualDocument72 pagesFitting Manualayush bindalPas encore d'évaluation

- Course Outline MCTE 2311 Signal and System AnalysisDocument6 pagesCourse Outline MCTE 2311 Signal and System AnalysisnewasamPas encore d'évaluation

- MQF Level 3 Diploma in Mechanical EngineeringDocument9 pagesMQF Level 3 Diploma in Mechanical EngineeringA SPas encore d'évaluation

- Brochure Fem&Smss 2016Document2 pagesBrochure Fem&Smss 2016Karthik SubramaniPas encore d'évaluation

- Is 2379 (Color Coding of Industrial Pipelines)Document13 pagesIs 2379 (Color Coding of Industrial Pipelines)Rajbir Saini85% (26)

- Part-C Defects - Nptel PDFDocument5 pagesPart-C Defects - Nptel PDFLakhwant Singh KhalsaPas encore d'évaluation

- Pneumatic ActuatorsDocument8 pagesPneumatic ActuatorsShah Jehan HanifPas encore d'évaluation

- JD HvacDocument2 pagesJD HvacShah Jehan HanifPas encore d'évaluation

- Dunya Profile32Document32 pagesDunya Profile32Shah Jehan HanifPas encore d'évaluation

- Process Improvement Proposal (Procurement) PDFDocument21 pagesProcess Improvement Proposal (Procurement) PDFShah Jehan HanifPas encore d'évaluation

- Process Improvement Proposal (Procurement) PDFDocument21 pagesProcess Improvement Proposal (Procurement) PDFShah Jehan HanifPas encore d'évaluation

- Dua e AnasBinMalik R.ADocument17 pagesDua e AnasBinMalik R.AShah Jehan HanifPas encore d'évaluation

- S235JR ST37-2 E24-2 SS400 A283c A36Document1 pageS235JR ST37-2 E24-2 SS400 A283c A36Shah Jehan HanifPas encore d'évaluation

- Sahi Bukhari Shareef - Urdu Volume 1Document741 pagesSahi Bukhari Shareef - Urdu Volume 1humayounkabirkhan92% (62)

- Msa Booklet - 5august2015Document40 pagesMsa Booklet - 5august2015Muhammad Arsalan AshrafPas encore d'évaluation

- KhawateenKiIslamiMashratByImamNisair aUrduTranslationByShaykhMuftiShamsuddinNoorDocument313 pagesKhawateenKiIslamiMashratByImamNisair aUrduTranslationByShaykhMuftiShamsuddinNoorShah Jehan HanifPas encore d'évaluation

- Beam Bearing PlatesDocument23 pagesBeam Bearing PlatesShah Jehan HanifPas encore d'évaluation

- Industrial Materials ClassificationDocument32 pagesIndustrial Materials ClassificationShakeel AhmadPas encore d'évaluation

- Condenser Bushings 25 KVDocument8 pagesCondenser Bushings 25 KVOktafian PrabandaruPas encore d'évaluation

- Technical Data Sheet Baltoflake EcolifeDocument5 pagesTechnical Data Sheet Baltoflake EcolifeAkram AlhaddadPas encore d'évaluation

- Datasheet IC L7107Document16 pagesDatasheet IC L7107Michael HarveyPas encore d'évaluation

- MR419X6188A000Document22 pagesMR419X6188A000Ties van RaakPas encore d'évaluation

- Position Paper: Agenda:Discussing The Solutions and Repercussions of Plastic On Environment Delegate: GermanyDocument2 pagesPosition Paper: Agenda:Discussing The Solutions and Repercussions of Plastic On Environment Delegate: GermanyKatherinePas encore d'évaluation

- Mini ProjectDocument7 pagesMini ProjectSyakirin SpearsPas encore d'évaluation

- QCVN 162019BXD National Technical Regulation On Products, Goods of Building Materials (Eng)Document41 pagesQCVN 162019BXD National Technical Regulation On Products, Goods of Building Materials (Eng)lwin_oo2435Pas encore d'évaluation

- Void Content of Reinforced Plastics: Standard Test Methods ForDocument3 pagesVoid Content of Reinforced Plastics: Standard Test Methods ForStéfany Vier SteffenPas encore d'évaluation

- Fire Detector PlacementDocument32 pagesFire Detector Placementawadalmekawy100% (2)

- 2sc-Pco - Dual Solenoid Control ValveDocument3 pages2sc-Pco - Dual Solenoid Control Valveshan07011984Pas encore d'évaluation

- Multi-turn Actuator and Gear Reducer SpecificationsDocument10 pagesMulti-turn Actuator and Gear Reducer SpecificationspaulPas encore d'évaluation

- 6001 FluorescentLightFittings EK00 III en PDFDocument9 pages6001 FluorescentLightFittings EK00 III en PDFarturonc100% (1)

- UK Gate Valves Brochure High Res 02 - 2017Document20 pagesUK Gate Valves Brochure High Res 02 - 2017Sivasubramanian PalaniappanPas encore d'évaluation

- Webasto Heater Remote Control: Here Is The Climate Control Unit J255 That Is Going To Be ModifiedDocument8 pagesWebasto Heater Remote Control: Here Is The Climate Control Unit J255 That Is Going To Be ModifiedAlexanderPas encore d'évaluation

- Effects of On-Line Melt Blending of Polypropylene With Polyamide 6 On The Bulk and Strength of The Resulting BCF YarnDocument10 pagesEffects of On-Line Melt Blending of Polypropylene With Polyamide 6 On The Bulk and Strength of The Resulting BCF YarnianPas encore d'évaluation

- REPORT OF EOT CRANE EXAMINATIONDocument2 pagesREPORT OF EOT CRANE EXAMINATIONRavikant PandeyPas encore d'évaluation

- FTX-JV - GV - LR-Technical Data PDFDocument19 pagesFTX-JV - GV - LR-Technical Data PDFAndreea JitarasuPas encore d'évaluation

- KD-213 TDSDocument3 pagesKD-213 TDSalpesh.samruddhigroupPas encore d'évaluation

- ASD - Structural Code - 2016-02 PDFDocument37 pagesASD - Structural Code - 2016-02 PDFWilliam BohorquezPas encore d'évaluation

- Anchorage To Concrete - Means and MethodsDocument28 pagesAnchorage To Concrete - Means and MethodsMustafaPas encore d'évaluation

- Prelis 2012 MK en BRDocument9 pagesPrelis 2012 MK en BRDana LorePas encore d'évaluation

- Lec 6Document5 pagesLec 6Abderrahim HAMDAOUIPas encore d'évaluation

- Inject Neutralizer To CDU OVHD Wash WaterDocument1 pageInject Neutralizer To CDU OVHD Wash WaterPhuong LePas encore d'évaluation

- Ah 9315Document1 pageAh 9315scanmidiaPas encore d'évaluation