Académique Documents

Professionnel Documents

Culture Documents

,, Packoff / Seal: 8 SEP 2015 8 SEP 2015 03

Transféré par

Arjun PrajapatiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

,, Packoff / Seal: 8 SEP 2015 8 SEP 2015 03

Transféré par

Arjun PrajapatiDroits d'auteur :

Formats disponibles

PROPERTY OF

DWN BY

DWN DATE

APVD BY

APVD DATE

SHEET

REVISION

LENA CHNG

8 SEP 2015

TANG, NAI AN

8 SEP 2015

1 OF 4

03

QP-022211-03-21

QUALITY PLAN DESCRIPTION:

RAW MATERIAL (FORGING, BARSTOCK, TUBING) FOR PRESSURE CONTAINING COMPONENTS (EXCEPT STEMS) , MANDREL HANGERS, PACKOFF / SEAL:

API 6A PSL 3, ALL PRESSURES, ALL TEMPERATURES RATINGS, ALL MATERIAL CLASS, WITH VOLUMETRIC NDE

CUSTOMER:

BP (SP-007057)

INSPECTION/

TEST ACTIVITY

STANDARD (1)

PROCEDURE AND ACCEPTANCE CRITERIA

NONCONFORMANCE

(NC)

CAMERON SP /

CUSTOMER

REQUIREMENT

NON-CONFORMANCE REPORT (NCR) SHALL BE PRODUCED WHEN A FORGING, PART OR ASSEMBLY HAS

PASSED THE POINT OF MANUFACTURE WHERE THE NON-CONFORMANCE OCCURRED. RAISING,

IDENTIFYING, DISPOSITION AND CONTROL OF NON-CONFORMANCE SHALL FOLLOW THE REQUIREMENT IN

SP-007057.

CUSTOMER

DEVIATION /

CONCESSION

REQUEST

CAMERON SP /

CUSTOMER

REQUIREMENT

DEVIATION AND CONCESSION REQUEST SHALL FOLLOW THE REQUIREMENT IN SP-007057.

DEVIATION REQUEST

A WRITTEN APPLICATION BY CAMERON, REQUESTING BP TO ACCEPT A CHANGE FROM AGREED

REQUIREMENTS THAT APPLIED AT THE TIME OF MAKING THE REQUEST. A DEVIATION REQUEST IS NOT A

RESULT OF A NON-CONFORMANCE. CAMERON IS TO USE BP DEVIATION REQUEST FORM IN SP-007057.

DOC

Y/N (2)

SAMPLE

SIZE (3)

CUSTOMER

INSPECTION

YES

100%

YES

100%

HOLD FOR

APPROVAL

YES

100%

HOLD FOR

APPROVAL

YES

100%

DEVIATION REQUEST SHALL BE SUBMITTED TO BP APPROVAL:

WHERE CAMERON WISHED TO DEVIATE FROM ORIGINALLY SPECIFIED REQUIREMENTS AND AN

ASSOCIATED NON-CONFORMANCE HAS NOT OCCURRED.

CONCESSION REQUEST

A WRITTEN APPLICATION BY CAMERON, REQUESTING BP TO ACCEPT AT LEAST ONE ACTION OR ITEM THAT

DEVIATES FROM AGREED SPECIFICATIONS AS A CONSEQUENCES OF NON-CONFORMANCE. CAMERON IS

TO USE BP CONCESSION REQUEST FORM IN SP-007057.

CONCESSION REQUEST SHALL BE SUBMITTED TO BP FOR APPROVAL WHICH

LIMITED TO, THE FOLLOWING NON-CONFORMANCES:

DAC VIOLATIONS

INCLUDE, BUT ARE NOT

NOTE: REQUEST FOR CONCESSION COVERING MULTIPLE ISSUES SHALL NOT BE COMBINED ON THE SAME

FORM.

RECEIVING

INSPECTION FOR

INTER-COMPANY

EQUIPMENT

CUSTOMER

REQUIREMENT

FACILITY

PROCEDURE

THIS INSPECTION APPLIES ONLY TO CAMERON FACILITY.

PERFORM RECEIVING INSPECTION PER FACILITY PROCEDURE.

ACCEPTANCE CRITERIA:

CAMERON BOM

(1) REVISION LEVEL IS CURRENT REVISION UNLESS OTHERWISE NOTED OR NOT COVERED BY API/ ISO.

(2) VERIFYING / INSPECTION RECORDS FOR THE INSPECTION/TEST ACTIVITY

(3) EQUIPMENT SAMPLE SIZE REQUIRED FOR THE INSPECTION/TEST ACTIVITY

(4) DOCUMENTS SHALL COMPLY WITH EN10204 (DIN 50049) AS DESIGNATED.

QP-022211-03-21

PROPERTY OF

DWN BY

DWN DATE

APVD BY

APVD DATE

SHEET

REVISION

LENA CHNG

8 SEP 2015

TANG, NAI AN

8 SEP 2015

2 OF 4

03

QP-022211-03-21

QUALITY PLAN DESCRIPTION:

RAW MATERIAL (FORGING, BARSTOCK, TUBING) FOR PRESSURE CONTAINING COMPONENTS (EXCEPT STEMS) , MANDREL HANGERS, PACKOFF / SEAL:

API 6A PSL 3, ALL PRESSURES, ALL TEMPERATURES RATINGS, ALL MATERIAL CLASS, WITH VOLUMETRIC NDE

CUSTOMER:

BP (SP-007057)

INSPECTION/

TEST ACTIVITY

MECHANICAL

TESTING

PROCEDURE AND ACCEPTANCE CRITERIA

DOC

Y/N (2)

SAMPLE

SIZE (3)

CUSTOMER

INSPECTION

VERIFICATION OF EACH HEAT TO CAMERON MATERIAL SPECIFICATION FOR QTC MECHANICAL PROPERTIES,

HARDNESS, AND IMPACTS, AS APPLICABLE.

YES

3.1(4)

PER

HEAT

NUMBER

YES

3.1(4)

PER

HEAT

NUMBER

YES

PER

HEAT

TREAT

LOAD

YES

100%

STANDARD (1)

API 6A/ISO 10423

CAMERON BOM

ASTM A370

DOCUMENT QTC RESULTS FOR MECHANICAL PROPERTIES, IMPACTS AND HARDNESS, INCLUDING A

STATEMENT OF COMPLIANCE TO THE CAMERON MATERIAL SPECIFICATION.

CHEMICAL

ANALYSIS

API 6A/ISO 10423

CAMERON BOM

VERIFY THE CHEMICAL COMPOSITION TO THE CAMERON MATERIAL SPECIFICATION.

DOCUMENT ACTUAL WEIGHT % OF ELEMENTS LISTED BY THE MATERIAL SPECIFICATION.

HEAT TREAT

CONTROL

API 6A/ISO 10423

CAMERON BOM

HEAT TREATS TO CAMERON MATERIAL SPECIFICATION.

HEAT TREATMENT CERTIFICATION OF COMPLIANCE (FOR PARTS AND QTC) TO INCLUDE ACTUAL TIMES,

TEMPERATURES, METHODS OF COOLING AND FURNACE CALIBRATION DETAILS (CALIBRATED TO API 6A

ANNEX M OR EQUIVALENT INDUSTRY STANDARD).

TRACEABILITY/

MARKING

API 6A/ISO 10423

CAMERON BOM

X-043764-01

PURCHASE ORDER NUMBER, PART NUMBER, HEAT NUMBER, HEAT TREAT LOAD NUMBER OR SERIAL

NUMBER TRACEABLE TO HEAT NUMBER AND HEAT TREAT LOAD NUMBER.

METHOD:

FORGINGS: INFORMATION TO BE HOT STAMPED OR LOW STRESS STEEL STAMPED. THE PURCHASE

ORDER NUMBER MAY BE MARKED ON THE FORGING USING PAINT STENCILLING OR PAINT STICKS OR

MARKED ON EACH CONTAINER FOR FORGINGS SHIPPED.

BARSTOCK AND TUBING: INFORMATION TO BE LOW STRESS STEEL STAMPED. THE PURCHASE ORDER

AND PART NUMBERS MAY BE MARKED USING PAINT STENCILLING OR PAINT STICKS PROVIDED MARKING

REMAINS LEGIBLE AFTER EXTENDED STORAGE.

LOCATIONS:

FORGINGS: MARK AT LOCATIONS SPECIFIED BY THE DRAWING OR AT READILY VISIBLE LOCATION WHEN

NOT SPECIFIED BY A DRAWING.

BARSTOCK AND TUBING: MARK ON EACH END

(1) REVISION LEVEL IS CURRENT REVISION UNLESS OTHERWISE NOTED OR NOT COVERED BY API/ ISO.

(2) VERIFYING / INSPECTION RECORDS FOR THE INSPECTION/TEST ACTIVITY

(3) EQUIPMENT SAMPLE SIZE REQUIRED FOR THE INSPECTION/TEST ACTIVITY

(4) DOCUMENTS SHALL COMPLY WITH EN10204 (DIN 50049) AS DESIGNATED.

QP-022211-03-21

PROPERTY OF

DWN BY

DWN DATE

APVD BY

APVD DATE

SHEET

REVISION

LENA CHNG

8 SEP 2015

TANG, NAI AN

8 SEP 2015

3 OF 4

03

QP-022211-03-21

QUALITY PLAN DESCRIPTION:

RAW MATERIAL (FORGING, BARSTOCK, TUBING) FOR PRESSURE CONTAINING COMPONENTS (EXCEPT STEMS) , MANDREL HANGERS, PACKOFF / SEAL:

API 6A PSL 3, ALL PRESSURES, ALL TEMPERATURES RATINGS, ALL MATERIAL CLASS, WITH VOLUMETRIC NDE

CUSTOMER:

BP (SP-007057)

INSPECTION/

TEST ACTIVITY

VOLUMETRIC NDE

(BASE MATERIAL)

VOLUMETRIC NDE

ACCEPTANCE

CRITERIA

(BASE MATERIAL)

STANDARD (1)

PROCEDURE AND ACCEPTANCE CRITERIA

API 6A/ISO 10423

CAMERON BOM

ASTM A-388/E-428

X-8064

ASTM E-94/ E-747

X-8063

PERFORM 100% VOLUMETRIC EXAMINATION (AS PRACTICAL) BY ULTRASONIC FLAT BOTTOM HOLE

TECHNIQUE (IMMERSION METHOD MAY BE USED) OR 2% AND A 2-2T QUALITY LEVEL EQUIVALENT

SENSITIVITY RADIOGRAPHIC METHOD AFTER HEAT TREAT EXCLUSIVE OF STRESS RELIEF TREATMENTS

AND PRIOR TO MACHINING AFFECTING THE EXAM.

API 6A/ISO 10423

UT ACCEPTANCE CRITERIA FORGINGS (WROUGHT MATERIAL)

NOTE: CASTINGS NOT PERMITTED

DOC

Y/N (2)

SAMPLE

SIZE (3)

CUSTOMER

INSPECTION

YES

100%

ACCEPTANCE CRITERIA

SEE VOLUMETRIC NDE ACCEPTANCE CRITERIA SECTION.

DISTANCE AMPLITUDE CURVE (DAC) SHALL BE BASED ON THE FOLLOWING:

WALL THICKNESS (T)

T TO 38 MM (1.5 IN) INCLUSIVE

T FROM 38 TO 150 MM (1.5 TO 6 IN) INCLUSIVE

T OVER 150 MM (6 IN)

DAC

1.6 MM (1/16 IN)

3.2 MM (1/8 IN)

6.4 MM (1/4IN)

1. NO SINGLE INDICATION GREATER THAN THE REFERENCE DAC.

2. TWO OR MORE INDICATIONS EXCEEDING 50% DAC WITHIN 13 MM (1/2 IN) OF EACH OTHER IN ANY

DIRECTION ARE UNACCEPTABLE.

CUSTOMER

REQUIREMENT

IN ADDITION, THE FOLLOWING INDICATIONS SHALL BE INCLUDED ON THE NDE REPORT:

INDICATIONS EXCEEDING 50% OF THE DAC

SINGLE INDICATION AT A DISTANCE GREATER THAN 1/2 INCH (12.7 MM) APART, IN ANY DIRECTION

RT ACCEPTANCE CRITERIA FORGINGS (WROUGHT MATERIAL):

NOTE: CASTINGS NOT PERMITTED

1. NO TYPE OF CRACK, LAP, OR BURST.

2. NO ELONGATED INDICATIONS WITH LENGTH GREATER THAN:

WALL THICKNESS (T)

LESS THAN 19 MM (0.75 IN)

19 TO 57 MM (0.75 TO 2.25 IN)

GREATER THAN 57 MM (2.25 IN)

INCLUSION LENGTH

6.4 MM (0.25 IN)

1/3T (0.33 T)

19 MM (0.75 IN)

3. NO GROUP OF INDICATIONS IN A LINE THAT HAVE AN AGGREGATE LENGTH GREATER THAN T IN A

LENGTH OF 12T (WHERE T IS PRESSURE VESSEL WALL THICKNESS).

(1) REVISION LEVEL IS CURRENT REVISION UNLESS OTHERWISE NOTED OR NOT COVERED BY API/ ISO.

(2) VERIFYING / INSPECTION RECORDS FOR THE INSPECTION/TEST ACTIVITY

(3) EQUIPMENT SAMPLE SIZE REQUIRED FOR THE INSPECTION/TEST ACTIVITY

(4) DOCUMENTS SHALL COMPLY WITH EN10204 (DIN 50049) AS DESIGNATED.

QP-022211-03-21

PROPERTY OF

DWN BY

DWN DATE

APVD BY

APVD DATE

SHEET

REVISION

LENA CHNG

8 SEP 2015

TANG, NAI AN

8 SEP 2015

4 OF 4

03

QP-022211-03-21

QUALITY PLAN DESCRIPTION:

RAW MATERIAL (FORGING, BARSTOCK, TUBING) FOR PRESSURE CONTAINING COMPONENTS (EXCEPT STEMS) , MANDREL HANGERS, PACKOFF / SEAL:

API 6A PSL 3, ALL PRESSURES, ALL TEMPERATURES RATINGS, ALL MATERIAL CLASS, WITH VOLUMETRIC NDE

CUSTOMER:

BP (SP-007057)

INSPECTION/

TEST ACTIVITY

PART HARDNESS

(IF APPLICABLE)

STANDARD (1)

API 6A/ ISO 10423

CAMERON BOM

ASTM E-10/ E-18

X-8065

PROCEDURE AND ACCEPTANCE CRITERIA

VERIFY HARDNESS TO CAMERON MATERIAL SPECIFICATION AFTER HEAT TREATMENT AT LOCATIONS

SPECIFIED BY DRAWING.

LOCATIONS: HARDNESS TEST FORGINGS AT LOCATION SPECIFIED BY THE DRAWING

HARDNESS TEST BARSTOCK AND TUBING ON EACH END

DOC

Y/N (2)

SAMPLE

SIZE (3)

CUSTOMER

INSPECTION

YES

100%

YES

100%

HARDNESS VALUE TO BE STAMPED ON MATERIAL NEXT TO TEST LOCATION USING LOW STRESS STEEL

STAMPING.

VISUAL

EXAMINATION

API 6A/ ISO 10423

CAMERON BOM

X-8060

CUSTOMER

REQUIREMENT

PERFORM VISUAL EXAMINATION PER CAMERON BILL OF MATERIAL

ACCEPTANCE CRITERIA

SHALL BE FREE OF BURST, PIPES, LAPS, SEAMS, CRACKS, POROSITY, AND ANY OTHER DEFECTS WHICH

ARE DETRIMENTAL TO MECHANICAL OR MACHINING PROPERTIES OF THE MATERIAL

STATEMENT STATING VISUAL ACCEPTANCE CAN BE INCLUDED IN NDE REPORT.

REPAIR WELDS

CAMERON ENG

REPAIR WELDS ARE NOT PERMITTED

DIMENSIONAL

VERIFICATION

API 6A/ ISO 10423

CAMERON BOM

PERFORM DIMENSIONAL INSPECTION PER SPECIFIED DRAWING.

NO

100%

DOCUMENTATION

API 6A/ISO 10423

CAMERON BOM

PROVIDE RECORDS IN ACCORDANCE WITH MATERIAL SPECIFICATION WHICH INCLUDE:

IDENTIFICATION OF PURCHASE ORDER, PART NUMBER, QUANTITY, HEAT NUMBER, AND HEAT TREAT

LOAD NUMBER OR SERIAL NUMBER TRACEABLE TO HEAT NUMBER AND HEAT TREAT LOAD NUMBER

STATEMENT OF COMPLIANCE TO CAMERON MATERIAL SPECIFICATION

MATERIAL TEST RECORDS (MTR'S)

* CHEMICAL ANALYSIS

* IMPACT TEST (QTC)

* TENSILE TEST (QTC)

* HARDNESS TEST (QTC)

HEAT TREATMENT CERTIFICATE OF COMPLIANCE

VOLUMETRIC NDE RECORDS

YES

100%

(1) REVISION LEVEL IS CURRENT REVISION UNLESS OTHERWISE NOTED OR NOT COVERED BY API/ ISO.

(2) VERIFYING / INSPECTION RECORDS FOR THE INSPECTION/TEST ACTIVITY

(3) EQUIPMENT SAMPLE SIZE REQUIRED FOR THE INSPECTION/TEST ACTIVITY

(4) DOCUMENTS SHALL COMPLY WITH EN10204 (DIN 50049) AS DESIGNATED.

QP-022211-03-21

Vous aimerez peut-être aussi

- Onan Service Manual MDJA MDJB MDJC MDJE MDJF Marine Diesel Genset Engines 974-0750Document92 pagesOnan Service Manual MDJA MDJB MDJC MDJE MDJF Marine Diesel Genset Engines 974-0750GreenMountainGenerators80% (10)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- API 510 Data SheetsDocument11 pagesAPI 510 Data SheetshahahPas encore d'évaluation

- ITP-Pressure Vessel Repair, Modification, AlterationDocument5 pagesITP-Pressure Vessel Repair, Modification, Alterationyosafateden67% (3)

- Sample QAPDocument3 pagesSample QAPsniperiPas encore d'évaluation

- Inspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusDocument18 pagesInspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusoberaiPas encore d'évaluation

- Itp For Main SteelaaaaaaDocument4 pagesItp For Main SteelaaaaaaaymanmalahPas encore d'évaluation

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputPas encore d'évaluation

- Type Test ReportDocument17 pagesType Test ReportVaitheeswaran PalaniPas encore d'évaluation

- TBE For UG Knock Out Drum - Draft For Rev.C1Document22 pagesTBE For UG Knock Out Drum - Draft For Rev.C1pragatheeskPas encore d'évaluation

- Perma - CCC - Insulation IR04Document7 pagesPerma - CCC - Insulation IR04Amro MetwallyPas encore d'évaluation

- 10.COOPERHEAT HT ProcedureDocument16 pages10.COOPERHEAT HT Procedurethanga balanPas encore d'évaluation

- Incoming Inspection ChecklistDocument1 pageIncoming Inspection ChecklistResearch GatewayPas encore d'évaluation

- Commissioning Procedure EngrDocument11 pagesCommissioning Procedure EngrkumarPas encore d'évaluation

- Itp Non AsmeDocument7 pagesItp Non AsmeAkhilesh Kumar100% (1)

- Elm 1950001 MR Q03 1001 R6Document137 pagesElm 1950001 MR Q03 1001 R6Marwa Koubaies100% (1)

- 21Document6 pages21Dannis AnantoPas encore d'évaluation

- Contractor QAP for HT Breaker PanelDocument1 pageContractor QAP for HT Breaker Panelmadhu_bedi12Pas encore d'évaluation

- Item Inspected: CBLT-TPI-00F-186-12623Document16 pagesItem Inspected: CBLT-TPI-00F-186-12623Zulfadli RaniPas encore d'évaluation

- Stator Elastomer Evaluation ProcedureDocument7 pagesStator Elastomer Evaluation ProcedureSanjenbam SumitPas encore d'évaluation

- Ect ProDocument18 pagesEct ProAnonymous gFcnQ4go100% (2)

- Epc&C of Gas Train 5 Project at Maa Refinery: Instrument Check List Cjx31 - Instrument Junction Box InstallationDocument4 pagesEpc&C of Gas Train 5 Project at Maa Refinery: Instrument Check List Cjx31 - Instrument Junction Box InstallationSivaram KumarPas encore d'évaluation

- Dots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Document13 pagesDots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Moustafa AshrafPas encore d'évaluation

- Mil STD 870cDocument13 pagesMil STD 870cKrishnan DandapaniPas encore d'évaluation

- Op-3-26. Checklist For Static Pile Load Test Supervision: Work Instructions For EngineersDocument4 pagesOp-3-26. Checklist For Static Pile Load Test Supervision: Work Instructions For EngineersCza ManPas encore d'évaluation

- Project- Pipeline stress analysis reportDocument881 pagesProject- Pipeline stress analysis reportAnkithPas encore d'évaluation

- Projet Topping de Condensat - Skikda SC Instrument Specification For Tank Gauging SystemDocument19 pagesProjet Topping de Condensat - Skikda SC Instrument Specification For Tank Gauging SystemKARIMPas encore d'évaluation

- Inspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Document7 pagesInspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Akhilesh KumarPas encore d'évaluation

- Hardness Test Procedure: 1 of 8 DE3511.006/EDocument8 pagesHardness Test Procedure: 1 of 8 DE3511.006/Esalman1111aPas encore d'évaluation

- Inspection Test Procedure TemplateDocument8 pagesInspection Test Procedure TemplateMahesh SuthaPas encore d'évaluation

- PS 3103Document9 pagesPS 3103JayeshPas encore d'évaluation

- A Sam: Ultrasonic Inspection ProcedureDocument6 pagesA Sam: Ultrasonic Inspection ProcedureTokoKueAmelaCookis100% (1)

- AMEC Specification For Titanium 01Document9 pagesAMEC Specification For Titanium 01cenkturkerPas encore d'évaluation

- 9-Material Treacibility PDFDocument64 pages9-Material Treacibility PDFmamounsdPas encore d'évaluation

- Itp For SSDP Project Rev CDocument9 pagesItp For SSDP Project Rev CRachel FloresPas encore d'évaluation

- Cathodic Protection System MMO Grid of Tank Quality Control and Inspection Report FormDocument5 pagesCathodic Protection System MMO Grid of Tank Quality Control and Inspection Report Formjamal2877Pas encore d'évaluation

- Api 8CDocument1 pageApi 8CLeticia Lalo100% (2)

- Other Requirement: BA-0496 Refap1 Project Disengager / Stripper R-300002, R-300003Document7 pagesOther Requirement: BA-0496 Refap1 Project Disengager / Stripper R-300002, R-300003GLEDSONPas encore d'évaluation

- IS 14846 Product ManualDocument5 pagesIS 14846 Product ManualKrishna Prasad KanchojuPas encore d'évaluation

- Datasheet Pompa Submersible Rev.0Document5 pagesDatasheet Pompa Submersible Rev.0NasrulSyahruddinPas encore d'évaluation

- All 24.05.16Document139 pagesAll 24.05.16Siva Prasad100% (1)

- UT Procedure NilgiriDocument16 pagesUT Procedure Nilgiriratna bomjanPas encore d'évaluation

- FQP - Civil NewDocument13 pagesFQP - Civil NewVenkatesh MudragadaPas encore d'évaluation

- Electrical Equipment QAPDocument2 pagesElectrical Equipment QAPrajkumarrakhra0% (1)

- Inspection and Test Program: Fabrication / In-Process InspectionDocument10 pagesInspection and Test Program: Fabrication / In-Process InspectionGLEDSONPas encore d'évaluation

- NDT-TEC-U115A Issue 1 Rev 0 UT Thickness Single Echo ModeDocument2 pagesNDT-TEC-U115A Issue 1 Rev 0 UT Thickness Single Echo ModekorichiPas encore d'évaluation

- C P T R F C P I: Athodic Rotection EST Eport ORM Over Age and NstructionsDocument5 pagesC P T R F C P I: Athodic Rotection EST Eport ORM Over Age and NstructionsNathanPas encore d'évaluation

- Anubar SpecDocument8 pagesAnubar SpecSHIVAJI CHOUDHURYPas encore d'évaluation

- Field Quality Plan: 2 X 520Mw TPP at VizagDocument12 pagesField Quality Plan: 2 X 520Mw TPP at Vizagryan940Pas encore d'évaluation

- Column Condenser ITP inspection planDocument2 pagesColumn Condenser ITP inspection planAshish DhokPas encore d'évaluation

- IRT For CP SystemDocument3 pagesIRT For CP SystemAnonymous i3lI9MPas encore d'évaluation

- Sunrise Process Equipments: Quality Assurance PlanDocument8 pagesSunrise Process Equipments: Quality Assurance Plansushant_jhawerPas encore d'évaluation

- Pressure Vessel RT Test: Requirements, Acceptance Criteria & Symbols ExplainedDocument3 pagesPressure Vessel RT Test: Requirements, Acceptance Criteria & Symbols ExplainedBhavani PrasadPas encore d'évaluation

- Welding Specification for Carbon and Alloy Steel PipingDocument82 pagesWelding Specification for Carbon and Alloy Steel PipingsendelkrPas encore d'évaluation

- SM 001 SRV SpecDocument5 pagesSM 001 SRV Specvardan_vardanPas encore d'évaluation

- PM IS 14399 Part 1 and 2 MAY 2020Document10 pagesPM IS 14399 Part 1 and 2 MAY 2020ishtiaqPas encore d'évaluation

- Nondestructive Test Procedure: Acceptance Criteria For Nondestructive Testing of P&H ProductDocument3 pagesNondestructive Test Procedure: Acceptance Criteria For Nondestructive Testing of P&H ProductMiguel RodriguezPas encore d'évaluation

- Inspection Test Plan Equipment - AFC Header Plug Seal Weld 1Document4 pagesInspection Test Plan Equipment - AFC Header Plug Seal Weld 1Mohd Shafuaaz KassimPas encore d'évaluation

- ITP-SV-M-FAN-CENTRIFUGAL&AXIALDocument7 pagesITP-SV-M-FAN-CENTRIFUGAL&AXIALgauravamberkarPas encore d'évaluation

- Inspection & Testing Requirements: FITTINGS: For Use in HOT TAP And/or Stopple Operations Wet &Document1 pageInspection & Testing Requirements: FITTINGS: For Use in HOT TAP And/or Stopple Operations Wet &aqisPas encore d'évaluation

- Righton LTD Stainless Steel 3S144 394Document1 pageRighton LTD Stainless Steel 3S144 394Arjun PrajapatiPas encore d'évaluation

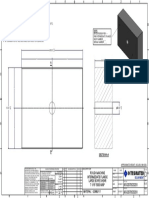

- Forged Plate: Proprietary and Confidential Unspecified ToleranceDocument1 pageForged Plate: Proprietary and Confidential Unspecified ToleranceArjun PrajapatiPas encore d'évaluation

- Packing ProcedureDocument24 pagesPacking ProcedureArjun PrajapatiPas encore d'évaluation

- Specification For Plates and Forgings PDFDocument2 pagesSpecification For Plates and Forgings PDFArjun PrajapatiPas encore d'évaluation

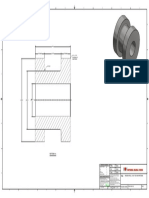

- Forged Donut: Proprietary and Confidential Unspecified ToleranceDocument1 pageForged Donut: Proprietary and Confidential Unspecified ToleranceArjun PrajapatiPas encore d'évaluation

- Integrated: Rough Machine Intermediate Flange Large Bore Shear 7 1/16"-5000 MWPDocument1 pageIntegrated: Rough Machine Intermediate Flange Large Bore Shear 7 1/16"-5000 MWPArjun PrajapatiPas encore d'évaluation

- ATKP362339 Revb1 111116 PDFDocument1 pageATKP362339 Revb1 111116 PDFArjun PrajapatiPas encore d'évaluation

- BU Motors and Generators: Prepared Separate Part List Title ScaleDocument1 pageBU Motors and Generators: Prepared Separate Part List Title ScaleArjun PrajapatiPas encore d'évaluation

- ATKP362341 Revb1 111116Document1 pageATKP362341 Revb1 111116Arjun PrajapatiPas encore d'évaluation

- Anov DWG 201Document1 pageAnov DWG 201Arjun PrajapatiPas encore d'évaluation

- Specification For Plates and Forgings PDFDocument2 pagesSpecification For Plates and Forgings PDFArjun PrajapatiPas encore d'évaluation

- Intermadate ShaftDocument1 pageIntermadate ShaftArjun PrajapatiPas encore d'évaluation

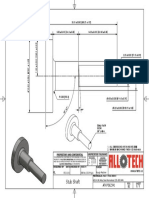

- Stub Shaft Forging: ATKP362340/ATKP302958Document1 pageStub Shaft Forging: ATKP362340/ATKP302958Arjun PrajapatiPas encore d'évaluation

- QS MS 117Document5 pagesQS MS 117Arjun PrajapatiPas encore d'évaluation

- Low Alloy Steel Spec for Forged Bars and Shaped Forgings (4130, API 6A, NACE MR0175Document4 pagesLow Alloy Steel Spec for Forged Bars and Shaped Forgings (4130, API 6A, NACE MR0175Arjun PrajapatiPas encore d'évaluation

- ATKP362339 Revb1 111116Document1 pageATKP362339 Revb1 111116Arjun PrajapatiPas encore d'évaluation

- 20inch Top Bonnet Flange PDFDocument1 page20inch Top Bonnet Flange PDFArjun PrajapatiPas encore d'évaluation

- SRNDocument1 pageSRNArjun PrajapatiPas encore d'évaluation

- Low Alloy Steel Spec for Forged Bars and Shaped Forgings (4130, API 6A, NACE MR0175Document4 pagesLow Alloy Steel Spec for Forged Bars and Shaped Forgings (4130, API 6A, NACE MR0175Arjun PrajapatiPas encore d'évaluation

- Anov DWG 201Document1 pageAnov DWG 201Arjun PrajapatiPas encore d'évaluation

- Bearing Housing: Proprietary and Confidential Unspecified ToleranceDocument1 pageBearing Housing: Proprietary and Confidential Unspecified ToleranceArjun PrajapatiPas encore d'évaluation

- Receiving Inspection Plan SummaryDocument2 pagesReceiving Inspection Plan SummaryArjun PrajapatiPas encore d'évaluation

- Specification For Plates and Forgings PDFDocument2 pagesSpecification For Plates and Forgings PDFArjun PrajapatiPas encore d'évaluation

- Bid Inv 6300011707 c1209 33 Steel TubesDocument2 pagesBid Inv 6300011707 c1209 33 Steel TubesArjun PrajapatiPas encore d'évaluation

- Chapter-I Particulars of Esi Corporation, Its Functions and DutiesDocument30 pagesChapter-I Particulars of Esi Corporation, Its Functions and DutiesArjun PrajapatiPas encore d'évaluation

- Thrust Bearing Bush Forging RMDocument1 pageThrust Bearing Bush Forging RMArjun PrajapatiPas encore d'évaluation

- High-Carbon, High Chromium Cold Work Tool Steel: Z Similar SteelsDocument3 pagesHigh-Carbon, High Chromium Cold Work Tool Steel: Z Similar Steelsjaskaran singhPas encore d'évaluation

- Technical Card Gruppo Lucefin Revision 2013 All Rights ReservedDocument1 pageTechnical Card Gruppo Lucefin Revision 2013 All Rights ReservedArjun PrajapatiPas encore d'évaluation

- Technical Annexure: EREQ No.: Split No.Document6 pagesTechnical Annexure: EREQ No.: Split No.Arjun PrajapatiPas encore d'évaluation

- 9256 1..girth FLG - DV - Ex-9256 (Final) H1828-29-34-35 R1Document2 pages9256 1..girth FLG - DV - Ex-9256 (Final) H1828-29-34-35 R1Arjun PrajapatiPas encore d'évaluation

- HenyaDocument6 pagesHenyaKunnithi Sameunjai100% (1)

- Algorithms For Image Processing and Computer Vision: J.R. ParkerDocument8 pagesAlgorithms For Image Processing and Computer Vision: J.R. ParkerJiaqian NingPas encore d'évaluation

- Marshal HMA Mixture Design ExampleDocument2 pagesMarshal HMA Mixture Design ExampleTewodros TadessePas encore d'évaluation

- Google Dorks For PentestingDocument11 pagesGoogle Dorks For PentestingClara Elizabeth Ochoa VicentePas encore d'évaluation

- UNIT FOUR: Fundamentals of Marketing Mix: - Learning ObjectivesDocument49 pagesUNIT FOUR: Fundamentals of Marketing Mix: - Learning ObjectivesShaji ViswambharanPas encore d'évaluation

- Nama: Yetri Muliza Nim: 180101152 Bahasa Inggris V Reading Comprehension A. Read The Text Carefully and Answer The Questions! (40 Points)Document3 pagesNama: Yetri Muliza Nim: 180101152 Bahasa Inggris V Reading Comprehension A. Read The Text Carefully and Answer The Questions! (40 Points)Yetri MulizaPas encore d'évaluation

- DNA Gel Electrophoresis Lab Solves MysteryDocument8 pagesDNA Gel Electrophoresis Lab Solves MysteryAmit KumarPas encore d'évaluation

- Clark DietrichDocument110 pagesClark Dietrichikirby77Pas encore d'évaluation

- Motor Master 20000 SeriesDocument56 pagesMotor Master 20000 SeriesArnulfo Lavares100% (1)

- The European Journal of Applied Economics - Vol. 16 #2Document180 pagesThe European Journal of Applied Economics - Vol. 16 #2Aleksandar MihajlovićPas encore d'évaluation

- UAPPDocument91 pagesUAPPMassimiliano de StellaPas encore d'évaluation

- Zelev 1Document2 pagesZelev 1evansparrowPas encore d'évaluation

- Electronics Ecommerce Website: 1) Background/ Problem StatementDocument7 pagesElectronics Ecommerce Website: 1) Background/ Problem StatementdesalegnPas encore d'évaluation

- Biagioli Did Galileo Copy The TelescopeDocument28 pagesBiagioli Did Galileo Copy The TelescopeGregory HooPas encore d'évaluation

- Reflection Homophone 2Document3 pagesReflection Homophone 2api-356065858Pas encore d'évaluation

- Evaluating Sources IB Style: Social 20ib Opvl NotesDocument7 pagesEvaluating Sources IB Style: Social 20ib Opvl NotesRobert ZhangPas encore d'évaluation

- Difference Between Mark Up and MarginDocument2 pagesDifference Between Mark Up and MarginIan VinoyaPas encore d'évaluation

- ERP Complete Cycle of ERP From Order To DispatchDocument316 pagesERP Complete Cycle of ERP From Order To DispatchgynxPas encore d'évaluation

- Rounded Scoodie Bobwilson123 PDFDocument3 pagesRounded Scoodie Bobwilson123 PDFStefania MoldoveanuPas encore d'évaluation

- 2023 Test Series-1Document2 pages2023 Test Series-1Touheed AhmadPas encore d'évaluation

- 2010 - Impact of Open Spaces On Health & WellbeingDocument24 pages2010 - Impact of Open Spaces On Health & WellbeingmonsPas encore d'évaluation

- Marketing Plan for Monuro Clothing Store Expansion into CroatiaDocument35 pagesMarketing Plan for Monuro Clothing Store Expansion into CroatiaMuamer ĆimićPas encore d'évaluation

- Contact and Profile of Anam ShahidDocument1 pageContact and Profile of Anam ShahidSchengen Travel & TourismPas encore d'évaluation

- Mercedes BenzDocument56 pagesMercedes BenzRoland Joldis100% (1)

- MBO, Management by Objectives, Pooja Godiyal, Assistant ProfessorDocument20 pagesMBO, Management by Objectives, Pooja Godiyal, Assistant ProfessorPooja GodiyalPas encore d'évaluation

- Simply Put - ENT EAR LECTURE NOTESDocument48 pagesSimply Put - ENT EAR LECTURE NOTESCedric KyekyePas encore d'évaluation

- 1.each of The Solids Shown in The Diagram Has The Same MassDocument12 pages1.each of The Solids Shown in The Diagram Has The Same MassrehanPas encore d'évaluation

- Antenna VisualizationDocument4 pagesAntenna Visualizationashok_patil_1Pas encore d'évaluation

- QuickTransit SSLI Release Notes 1.1Document12 pagesQuickTransit SSLI Release Notes 1.1subhrajitm47Pas encore d'évaluation