Académique Documents

Professionnel Documents

Culture Documents

How Chin Engineering: Job Safety Analysis

Transféré par

How Chin Engineering Sdn BhdTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

How Chin Engineering: Job Safety Analysis

Transféré par

How Chin Engineering Sdn BhdDroits d'auteur :

Formats disponibles

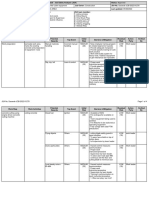

HOW CHIN ENGINEERING

Job Safety Analysis

JOB DESCRIPTION

TYPES OF WORK

: Oxy Cutting

LOCATION OF WORK: Tank 513

REQUIRED PERSONAL PROTECTIVE EQUIPMENT

x

x

x

Safety Helmet

Safety Shoes / Boots

Safety Glasses

Face / Welding Shield

Goggles

Life Jackets

Cotton Glove

Rubber Glove

Leather Gloves

Leather Apron

Gauntlets

Dust Mask

Work Vest

Safety Vest

Safety Harness / Belt

Face Mask

Ear Protection

Others (Specify): _________________

OTHER SAFETY EQUIPMENT / REQUIREMENTS

Fire Extinguisher

Gas Detector

Safety Signs

Barricades

Lifeline

N

o

Activity

( Job Steps )

1.

Work permit

from Client to

be obtained.

Tag Out / Lock Out

Work Permit

Competency Certificate

Respirator

First Aid Equipment

Potential Hazard

Unauthorized

commencement of

works may result in

exposing workers

and or potential to

Control/ Recovery Measures

Authorized lead-operator / in-charge shall ensure obtaining and

maintaining valid work permit.

The worksite supervisor responsible for this activity has to

check the PPE of his staff to ensure that all required items are

available and properly used.

Responsib

le/ Action

By

Leadoperator

Supervisor

HOW CHIN ENGINEERING

harm or danger

Pre-task

briefing

toolbox talks.

The work force does

not understand the

pre task briefing

therefore does not

understand the

potential dangers

and control

measures to be

implemented. Some

of the workers could

be lacking PPE or

using defective PPE.

Ensure that adequate shaded areas are provided.

Heat stress to the

Provide proper ventilation and drink plenty of water even if

labour working on

this task.

you are not thirst.

Wear loose fitting full length clothing that can breathe.

Markers are not

clearly visible

Ensure that all markers and signage are of a suitable height to be

creating a risk of

clearly seen and sufficient lighting is placed to identify the area

others coming into

at night.

the area.

Set out

boundary

markers for the

work site area.

Break the job

down into

steps.

Inform all workers regarding permit condition before work

starts.

Worksite supervisor shall conduct toolbox talks about nature of

works and associated potential hazards and their essential

precautionary measure.

Follow mobilization schedule and arrange the required

documents to avoid any cause of delay.

Ensure that the pre task briefing is given out in a language

understood by the work force, have it translated.

Ask question regarding the briefing to get feedback from the

staff, this ensures full comprehension.

Issue required appropriate PPE and replace PPE that has signs

of defect.

Identify the hazards

associated with

each step.

Supervisor

Workers

Supervisor

Workers

Supervisor

Specify what action/procedures will be taken to eliminate or

minimise the hazards, the risk of injury/damage, and/or

potential severity factors. Including the measure to be taken to Workers

HOW CHIN ENGINEERING

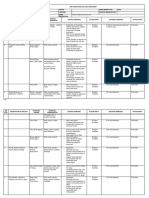

Each step

should

accomplish

some major

task and be in a

logical

sequence

Using power

tools

Drills

Authorised

Personnel

Noise

Vibration

Dust

Electrical hazards.

Using hand

tools

Screw driver

Scrapper

Hammer

Cuts

Tears sprains

Position oxy

acetylene

equipment and

materials for

use.

Manually Handling,

potential sprain

and strain injuries

Slip, trip and fall.

Cylinders falling

over, potential

projectile and/or

explosion

ensure the proposed control

Examine each to

find possibilities

that could lead top

an accident

Wear appropriate personal protective equipment

Ensure all tools are appropriately guarded and electrical

appliances are protected by means of a residual current

device.

Ensure all extension leads are in a safe condition with plugs

and connections

Use tools in a manner that will not cause jamming or seizing.

Wear appropriate PPE.

Immediately inform supervisor or in-charge to get first aid if

there cut/tears sprains.

Supervisor

Park work vehicle and deliver materials as close as

possible to the work area to reduce the travel distance to

carry the equipment / materials.

When lifting, keep the object as close to the body as

possible, bend with your knees, rather than your back and

keep your back straight.

Organise mechanical lifting aids (crane, forklift, trolley,

hand jack, etc) to be available for handling heavy and/or

awkward materials.

Seek assistance and utilize share lifting when handling

heavy and/or awkward materials.

Supervisor

Workers

Supervisor

Workers

Workers

Authorised

Personnel

HOW CHIN ENGINEERING

Lighting and

adjusting of

flame

Cut steel

materials

Burns

Burns

Fire

Ensure the travel path and set down area is clear of slip

and trip hazards.

Avoid laying hoses across walkways to prevent trip hazards

to other site workers.

All cylinders (empty and full) must be secured at all times

to prevent them from moving and falling over.

Only use appropriate flint to light torch.

Adjust acetylene first, and then adjust the oxygen to suit.

Ensure appropriate PPE is worn, including a welding shield,

leather gauntlets, steel capped boots, long sleeved cotton

shirt and long pants.

Ensure there are no workers below the work area. If workers

do enter the area below, work is to stop immediately. If

necessary, the area below should be barricaded and warning

signs displayed.

Erect signs CAUTION OXY CUTTING IN PROGRESS or have a

designated Spotter available for short term activities at the

entrances to the welding work area.

Care is needed when handling hot materials to prevent the

risk of burns.

Where practical, a water supply should be available to cool

cut steel.

Be aware of other workers in the area and ensure they are not

at risk of burns.

Where required, a Hot Work Permit must be completed prior

to Oxy/Acetylene work.

Supervisor

Workers

Authorised

Personnel

Supervisor

Workers

Authorised

Personnel

HOW CHIN ENGINEERING

1

0

Shut down,

clean area and

pack up

equipment

Burns

1

2

Work during

extreme

weather/

climate

conditions.

Over exposure to

heat

Move or cover any combustible materials or flammable

substances clear of the work area.

Ensure a suitable fire extinguisher is available in the

immediate area.

The work area should be inspected 1 hour after finishing to

identify any smoldering embers.

Always turn off acetylene first, then the oxygen, ensure hoses

are drained of all gas.

When finished, both cylinder regulators must be turned off

and hoses, hand piece and torch tips inspected for damage.

Cylinders must always be securely stored to prevent them

from moving during storage and transportation.

Any waste materials cleaned up and placed in the bin.

Any after work requirements as specified in the Hot Work

Permit must be completed prior to leaving the work area.

Become acclimated to the heat gradually before working in hot

temperatures for a long time;

Ensure 100% availability of cold water and always drink plenty

of cool water;

Wear hats and sunglasses to help stay cool;

Take frequent breaks in a cool place, if possible;

Wear loose clothing that allows the skin to breathe, such as

cotton;

Protect your skin from the sun. Keep as much of it covered with

clothing as possible. Wearing long-sleeved shirts will help;

Field supervision/ supervisor shall closely monitor the condition

of workers, intervene as the need arises.

Supervisor

Workers

Authorised

Personnel

Supervisor

Workers

HOW CHIN ENGINEERING

Prepared By :

2016

Contractor / Contractor Representative

Jayammohan Balachandaram

Reviewed By :

Lead-operator / In-charge

Date : 28 March

Vous aimerez peut-être aussi

- Jsa Copper Grounding at Fire PumpDocument5 pagesJsa Copper Grounding at Fire PumpHow Chin Engineering Sdn BhdPas encore d'évaluation

- 3.jsa - Arc Welding-NDocument5 pages3.jsa - Arc Welding-NVivek NaikPas encore d'évaluation

- Jsa PolypipeDocument2 pagesJsa PolypipeHow Chin Engineering Sdn BhdPas encore d'évaluation

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- HSE-RA-011 Manual Handling - Rev 0Document11 pagesHSE-RA-011 Manual Handling - Rev 0عمروPas encore d'évaluation

- Lifting Equipment PDFDocument2 pagesLifting Equipment PDFcityofdarwingisPas encore d'évaluation

- 4.cutting Grinding WeldingDocument5 pages4.cutting Grinding WeldingMohammad Fazal KhanPas encore d'évaluation

- Jacks and Vehicle Stands PDFDocument1 pageJacks and Vehicle Stands PDFcityofdarwingisPas encore d'évaluation

- RMDJV-PJ74-HIRADC-SUBE 03 (Installation of Outdoor Equipment)Document2 pagesRMDJV-PJ74-HIRADC-SUBE 03 (Installation of Outdoor Equipment)myn maliQuePas encore d'évaluation

- 001 - JHA Survey Setting Out - REV000Document5 pages001 - JHA Survey Setting Out - REV000Venkadesh Periathambi100% (2)

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDocument2 pagesJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemPas encore d'évaluation

- TieDocument5 pagesTieshinto LawrencePas encore d'évaluation

- 09 JSA For Excavation and Blinding at Pump House 1 & 3Document4 pages09 JSA For Excavation and Blinding at Pump House 1 & 3Hilbrecht De Pedro100% (1)

- JHA Blowing PressDocument5 pagesJHA Blowing PressLuqman OsmanPas encore d'évaluation

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaPas encore d'évaluation

- Job Safety Analysis For Civil WorkDocument9 pagesJob Safety Analysis For Civil Worksakthi venkatPas encore d'évaluation

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDocument2 pagesAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640Pas encore d'évaluation

- Warehouse Job Hazard AssessmentDocument2 pagesWarehouse Job Hazard AssessmentAnonymous cuHV7lTPas encore d'évaluation

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajPas encore d'évaluation

- Job HazardDocument2 pagesJob HazardBre WirabumiPas encore d'évaluation

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechPas encore d'évaluation

- RA Templates ElectricalDocument17 pagesRA Templates ElectricalAbid MujtabaPas encore d'évaluation

- Concrete Cutting JsaDocument4 pagesConcrete Cutting JsaMohammad Irfan Kiki IsmailPas encore d'évaluation

- JSA Formet New Structural Steel FabricationDocument7 pagesJSA Formet New Structural Steel Fabricationsakthi venkatPas encore d'évaluation

- Daily HSE ReportDocument5 pagesDaily HSE ReportSayeed MalikPas encore d'évaluation

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelPas encore d'évaluation

- Job Safety Analysis: S.No Activities Hazard Risk Control MeasuresDocument2 pagesJob Safety Analysis: S.No Activities Hazard Risk Control Measureskhaja asifuddinPas encore d'évaluation

- JHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDocument4 pagesJHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDarmawan OnradPas encore d'évaluation

- PCC & ConcDocument4 pagesPCC & Concprasanna okPas encore d'évaluation

- 07 - JSA Compaction and BackfillingDocument4 pages07 - JSA Compaction and Backfillingsatti100% (2)

- JSA Scaffolding Erection and Dismentling New 2021Document5 pagesJSA Scaffolding Erection and Dismentling New 2021Captain ChickenPas encore d'évaluation

- Rock BreakingDocument1 pageRock BreakingGyanendra Narayan NayakPas encore d'évaluation

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdPas encore d'évaluation

- HSE-RA-053 Floor Screed - Rev 0Document9 pagesHSE-RA-053 Floor Screed - Rev 0عمروPas encore d'évaluation

- SWP Air CompressorDocument2 pagesSWP Air Compressormyn maliQuePas encore d'évaluation

- Steel Erection JSADocument5 pagesSteel Erection JSASalah Abd Eldayem100% (1)

- HIRARC Work at HeightDocument2 pagesHIRARC Work at HeightPanchdev KumarPas encore d'évaluation

- Job Safety Analysis Erection SiloDocument3 pagesJob Safety Analysis Erection SiloDanangPas encore d'évaluation

- JSA For Ship Repairing Welding Cutting and Grinding Activity 21.08.2023Document7 pagesJSA For Ship Repairing Welding Cutting and Grinding Activity 21.08.2023Sebin VarghesePas encore d'évaluation

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- JSA Pipeworks - UEM - RAPID PETRONAS - Common FacilitiesDocument10 pagesJSA Pipeworks - UEM - RAPID PETRONAS - Common FacilitiesNazreen AzriPas encore d'évaluation

- Risk Asses 53-GPR Fitting AssemblyDocument6 pagesRisk Asses 53-GPR Fitting AssemblyRochdi BahiriPas encore d'évaluation

- Guillotine (Metal) PDFDocument1 pageGuillotine (Metal) PDFcityofdarwingisPas encore d'évaluation

- 42-JSA-Construction of Fence (Excavation, Installation of Fence Posts and Accessories) PDFDocument11 pages42-JSA-Construction of Fence (Excavation, Installation of Fence Posts and Accessories) PDFFarhan MPas encore d'évaluation

- Risk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Document2 pagesRisk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Danny100% (1)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelPas encore d'évaluation

- Building De-Dusting JSADocument3 pagesBuilding De-Dusting JSAJayesh J PillaiPas encore d'évaluation

- 19.hydro Pressure Testing.Document8 pages19.hydro Pressure Testing.Mohammad Fazal KhanPas encore d'évaluation

- Job Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Document5 pagesJob Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Madhan KannanPas encore d'évaluation

- PTW JHA Electrical Wiring Installation Work at Air Dryer RoomDocument4 pagesPTW JHA Electrical Wiring Installation Work at Air Dryer RoomPHH9834Pas encore d'évaluation

- 5.confined Space EntryDocument6 pages5.confined Space EntryMohammad Fazal KhanPas encore d'évaluation

- Project JHA For Grading Compacting WorksDocument27 pagesProject JHA For Grading Compacting WorksBasker Balu100% (1)

- JHA-Mechanical Lifting1Document2 pagesJHA-Mechanical Lifting1john jaycoh veranoPas encore d'évaluation

- Cranes and HoistsDocument3 pagesCranes and HoistsAditya Raj MishraPas encore d'évaluation

- Hot Work Procedure, WHSPRO-010 CMDocument3 pagesHot Work Procedure, WHSPRO-010 CMmyo lwinPas encore d'évaluation

- 05 LiftingDocument6 pages05 LiftingabdulhalimbinamrinPas encore d'évaluation

- Nasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetDocument2 pagesNasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetRaza Muhammad SoomroPas encore d'évaluation

- Job Safety Analysis Work Sheet: Arabian Pipeline & Services Company WR # K002849Document20 pagesJob Safety Analysis Work Sheet: Arabian Pipeline & Services Company WR # K002849Barkat Ullah50% (2)

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdPas encore d'évaluation

- 7 Electrical PDFDocument6 pages7 Electrical PDFMohammed AtefPas encore d'évaluation

- Skylift CHECKLISTDocument1 pageSkylift CHECKLISTEmmie Van Halen100% (2)

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdPas encore d'évaluation

- Gas TestingDocument1 pageGas TestingHow Chin Engineering Sdn BhdPas encore d'évaluation

- Skylift CHECKLISTDocument1 pageSkylift CHECKLISTEmmie Van Halen100% (2)

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdPas encore d'évaluation

- Jsa Dismantling The Wooden Framework-NewDocument3 pagesJsa Dismantling The Wooden Framework-NewHow Chin Engineering Sdn BhdPas encore d'évaluation

- Jsa Installing BracketDocument3 pagesJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdPas encore d'évaluation

- JSA Teflon - U BoltDocument3 pagesJSA Teflon - U BoltHow Chin Engineering Sdn BhdPas encore d'évaluation

- JSA Concereting and PaintingDocument4 pagesJSA Concereting and PaintingHow Chin Engineering Sdn BhdPas encore d'évaluation

- Jsa General HousekeepingDocument2 pagesJsa General HousekeepingHow Chin Engineering Sdn Bhd44% (9)

- JSA Ceiling Access by LadderDocument3 pagesJSA Ceiling Access by LadderHow Chin Engineering Sdn BhdPas encore d'évaluation

- Jsa Welding Diesel PipelineDocument3 pagesJsa Welding Diesel PipelineHow Chin Engineering Sdn BhdPas encore d'évaluation

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdPas encore d'évaluation

- MC DuroDesign EDocument8 pagesMC DuroDesign Epetronela.12Pas encore d'évaluation

- Social Media As An Effective Tool To Promote BusinessDocument5 pagesSocial Media As An Effective Tool To Promote BusinessHannah Gwyneth BalaPas encore d'évaluation

- A Multivariate Model For Analyzing Crime Scene InformationDocument26 pagesA Multivariate Model For Analyzing Crime Scene InformationNorberth Ioan OkrosPas encore d'évaluation

- Isomers: Constitutional Isomers Stereoisomers Conformational IsomersDocument6 pagesIsomers: Constitutional Isomers Stereoisomers Conformational IsomersJules BrunoPas encore d'évaluation

- Structuralism From Bsa 2D PDFDocument57 pagesStructuralism From Bsa 2D PDFPrincess AlegrePas encore d'évaluation

- PizzaOrder Assignment Working CodingDocument3 pagesPizzaOrder Assignment Working CodinginpreetkPas encore d'évaluation

- 02 Clemente V CADocument8 pages02 Clemente V CAATRPas encore d'évaluation

- Cambridge Igcse Literature in English Teacher S Resource CD Rom Cambridge Education Cambridge U Samples PDFDocument14 pagesCambridge Igcse Literature in English Teacher S Resource CD Rom Cambridge Education Cambridge U Samples PDFMorshedHumayunPas encore d'évaluation

- Cold SandwichesDocument7 pagesCold SandwichesLea Galano ManarpaacPas encore d'évaluation

- LP Understanding The Writing ProcessDocument8 pagesLP Understanding The Writing Processargus.dump11Pas encore d'évaluation

- Paper-CutoutDocument5 pagesPaper-CutoutmauricioPas encore d'évaluation

- Night EssayDocument4 pagesNight Essayapi-386640809Pas encore d'évaluation

- Dot Net TricksDocument101 pagesDot Net TrickssathishmnmPas encore d'évaluation

- Chraj 1Document6 pagesChraj 1The Independent GhanaPas encore d'évaluation

- DerivativeDocument29 pagesDerivativeMohit AggarwalPas encore d'évaluation

- Writing Kafani or AlfiDocument5 pagesWriting Kafani or AlfisahebjuPas encore d'évaluation

- C Programming UnionsDocument3 pagesC Programming UnionsslspaPas encore d'évaluation

- Impact of Government Policy and Regulations in BankingDocument65 pagesImpact of Government Policy and Regulations in BankingNiraj ThapaPas encore d'évaluation

- Lesson Plan 1 (Types of Industries)Document3 pagesLesson Plan 1 (Types of Industries)Chonie VillanuevaPas encore d'évaluation

- Science Revision Sheet Year 7 Periodic 2Document5 pagesScience Revision Sheet Year 7 Periodic 2malknabih699Pas encore d'évaluation

- SUMMATIVE Entrep Q1Document2 pagesSUMMATIVE Entrep Q1ocsapwaketsPas encore d'évaluation

- CONTEXTUALIZED DLP Q1 W1 Day1Document6 pagesCONTEXTUALIZED DLP Q1 W1 Day1QUEENIE BUTALIDPas encore d'évaluation

- Organization of Preschool Education in SwedenDocument2 pagesOrganization of Preschool Education in SwedenNelumi PereraPas encore d'évaluation

- Cristoforo BuondelmontiDocument15 pagesCristoforo BuondelmontiAnna AchiolaPas encore d'évaluation

- Diss PDFDocument321 pagesDiss PDFAbdullah GhannamPas encore d'évaluation

- Motor-Catalog English 2013 PDFDocument80 pagesMotor-Catalog English 2013 PDFILham Dwi PutraPas encore d'évaluation

- Financial Proposal: Cost Summaries For Installation of PV Power SystemsDocument16 pagesFinancial Proposal: Cost Summaries For Installation of PV Power SystemsSamuel AbebawPas encore d'évaluation

- Mao InoueDocument9 pagesMao InoueNemanja IlicPas encore d'évaluation

- 1CKCDocument44 pages1CKCsema2210100% (1)

- Daftar PustakaDocument2 pagesDaftar PustakaBang UsopPas encore d'évaluation