Académique Documents

Professionnel Documents

Culture Documents

Headfdy

Transféré par

Dulasidaran SubramanianCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Headfdy

Transféré par

Dulasidaran SubramanianDroits d'auteur :

Formats disponibles

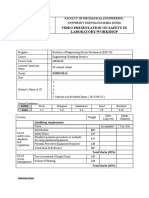

Curriculum vitae Head production/Unit Head

Steel foundry

Dulasidaran Subramanian

02-01-2017

ADDRESS FOR COMMUNICATION & PERMANENT ADDRESS

151 Kuttakarai Street, (Near GVC Teacher Training College.)

Local contact:

Arcot, Vellore District, PIN- 632 503, Tamil Nadu,

No 19 Om shakthi Nagar Madukarai market road,

Mob- +91 7845706359(personal),

Sidco Coimbatore- 21

Email: dulasidaran@yahoo.com, Skype:dulasidaran1

CORE KNOWLEDGE & STRENGTH

Steel Foundry operations

Zero tolerance for Quality variance

ISO 9001-2008, PED, API monogram

Melting/molding

WPS/PQR/WPQ

TQM, 7QC, FMEA

New alloy development

IGC and Stress corrosion test

Fixing and executing maximum target

Heat treatments

Metallurgical/Mech testing

Upgradation of new technology,

CAREER OBJECTIVE

To be a resourceful key stakeholder for the Organization in pursuing its business plan; to be diligently performing the

role through business acumen, engineering managerial excellence, professional integrity and determination in committed

tasks towards supporting the organization in fulfilling its business objectives.

EDUCATION

Basic Qualification: B.Sc- Chemistry,

B. Tech Mechanical

Additional Qualification

1. Nondestructive testing in RT, MPI, LPI - As per ASNT Level-II- IQC/Evergreen

Training Participated

Training classes were attended for TQM, Welding- WPS/PQR as per EN and ASME, Heat treatment of steels, SS, duplex

Stainless steel and FMEA in BHEL and CPC

SPECIAL SKILL

Expert in Two part- shell mold , Alpha set, three part-pep set process (Omega, IMF)

Manufacturing of castings for Valves, Auto motives , pump and defence industries

Strength in Melting, Lab, Quality , molding ,fettling , administration ,Manufacturing of any special Alloys like

Stainless Steel, PH Stainless steel , Duplex stainless steel, HAC,HAB, Inconel with cost effective. Fair knowledge

of Methoding

Focused to target, Result oriented, Good team Leader, Team Facilitator, Mentor, and good team player in

challenging moment and Very honest to management

ACHIVEMENTS

Established world class new steel foundry (Arudra Alloys Private Limited) project ,Near Chennai and entered

commercial production within 8 months and implemented good quality system to meet overseas customer

requirements

Visited Keech Castings, Australia as Quality Consultant during 2011- 1 week Achieved 1.00% overall rejection (Inclusive of customer end)

ISO certification done within 2 months after trail production in new projects from TUV

Present Employment: Head production Lakshmi Ring Travelers (CBE) Limited, Coimbatore,3000 kg/pc

Current Salary (CTC/Month) Rs 1,04800.00, Take home- 79650.00: Salary expected: Negotiable

Carrier History

DGM OPERATION- UR Castings and Alloys Pvt. Ltd, Coimbatore MAY 2010 TO Oct 2014-650 kgs /piece

Arudra Alloys Pvt.Ltd, , Chennai -Deputy General Manager operation (2007- 2010) Weight Range- upto

650Kgs

Sam Turbo Industries Limited, Coimbatore - Foundry Manager (2005 to2007)- captive foundry doing Ductile

iron, steel, Stainless steel, Exotic alloys, Gunmetal for industrial pump-weight range upto1200/ kgs

Peekay steel Pvt.Ltd,at Coimbatore ,Emirate Techno Casting Sharjah, UAE - Engineer- QA ( 2004 - 2005)

weight range upto 1600 kgs / 3000 kgs

Madura steel Pvt. Ltd, Dindugul - Manager QA in (2002- 2004) weight range upto 1200 kgs

Sanmar Alloy castings Ltd, Viralimalai Sr..ExecutiveQA(1997-2002)weight rangeupto 1500 kgs

Alagendran Steel Products Ltd., Coimbatore - Dy Manager QA (1996-1997)

Sri Ranganathar Industries Private Ltd., Coimbatore , 100% EOU -Chief Chemist (1993 - 1996)

Secals Ltd., Ranipet, Tamilnadu - Chemist .(1986-1993)

ACTIVITY INVOLVED

Company strategy planning and execution

Establish new steel foundry project as per international standard. Identification , selection , negotiation, erection and

commissioning of automated looping line steel foundry

Forecasting and avoid failures through proper Production planning, execution, Melting, molding, fettling, heat

treatment, dispatch

Preparation and approval of WPS / PQR for welding under Third party inspection as per ASME Sec IX and as per

EN standards

Establish ISO 9000-2008 procedure, QA manual, process module and Quality system procedure

Establishing and implementing PFMEA, Control plan, PFD and Operational procedure and SOP

Preparation of internal QA plan, customer QA plan and alloy development procedure.

Handling of Customers complaint and implementing suitable corrective and preventive actions to avoid re-occurrence

Coordination with third Party inspector and ISO auditors, statutory bodies.

Establish SPC to monitor monthly performance to Department objectives set in MRM

Marketing of steel casting to the various industries

Having Good negotiation skill for CG/Vendor with technical specifications

Having good knowledge of various heat treatment processes according to metallurgy

treatment, Oil quenching, Water Quenching, Tempering etc.

like Normalizing, PH

Chemical testing by Spectrometer LECO and by conventional method, mechanical testing like Tensile, impact as per

ASTM A370 and EN, Metallographic Examination of steel, stainless steel and Nickel Alloys etc using image analyzer

as per ASM Vol-9.

Stress corrosion and Inter granular corrosion testing of Duplex stainless steel/stainless steel as per ASTM

A262, NACE MR /TM & EN3651 etc

PERSONAL DETAILS

Name of the applicant

:

S.DULASIDARAN

Fathers name

P. Subramanian

Date of birth

7.11.1964

Nationality& Religion

Indian, Hindu

Passport No/place /valid up to

Old E8103992-Tiruchirapalli-10-02-2014

New L6186565 CHENNAI- 12-11-2023

I Assured that the above details given by me is correct to the best of my knowledge

Subramanian Dulasidaran

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Mil A 21180D PDFDocument25 pagesMil A 21180D PDFb4upalaniPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Unit I Foundry AllDocument58 pagesUnit I Foundry AllvelavansuPas encore d'évaluation

- HPDC enDocument108 pagesHPDC enmanasvi0667% (3)

- 110 KG CastingsDocument4 pages110 KG CastingsGurudutta MishraPas encore d'évaluation

- CQI-27 Casting Process Tables Stakeholder Review Final PDFDocument213 pagesCQI-27 Casting Process Tables Stakeholder Review Final PDFSelvaraj Simiyon90% (10)

- An Overview of Indian Foundry IndustryDocument2 pagesAn Overview of Indian Foundry IndustryGarima100% (1)

- Study On Strength Behaviour of Concrete Using Foundry Dust in Fine AggregateDocument60 pagesStudy On Strength Behaviour of Concrete Using Foundry Dust in Fine AggregateMourya Teja Vuddandi100% (1)

- U Said InvestmentDocument28 pagesU Said Investmentalmirb7Pas encore d'évaluation

- History CastingDocument68 pagesHistory CastingDavid SanchezPas encore d'évaluation

- Ijet 26753Document7 pagesIjet 26753kevin21790Pas encore d'évaluation

- The Effect of Gating Design on Aluminum Casting QualityDocument20 pagesThe Effect of Gating Design on Aluminum Casting Qualitybabiker mortadaPas encore d'évaluation

- CII Tech Led Solution & Fin Impact - 1'Document35 pagesCII Tech Led Solution & Fin Impact - 1'Atul SaxenaPas encore d'évaluation

- Foundry Sand Types: Green Sand (Clay Sand)Document8 pagesFoundry Sand Types: Green Sand (Clay Sand)upenderPas encore d'évaluation

- Designs in Ductile Iron: Cost Saving Design Ideas Cost Saving Design IdeasDocument14 pagesDesigns in Ductile Iron: Cost Saving Design Ideas Cost Saving Design Ideasghita_mehedintuPas encore d'évaluation

- Feedex: High Density Exothermic Feeder SleevesDocument8 pagesFeedex: High Density Exothermic Feeder SleevesBruno Eduardo CoelhoPas encore d'évaluation

- Oficial Challenges - Factory Booster Day 2023Document53 pagesOficial Challenges - Factory Booster Day 2023Gustavo Costa SilvaPas encore d'évaluation

- Automation: For The Aluminium FoundryDocument8 pagesAutomation: For The Aluminium FoundryPhúc LêPas encore d'évaluation

- Company Profile AmritDocument18 pagesCompany Profile AmritPreet Inder SinghPas encore d'évaluation

- Casting Productivity Analysis of Global Foundry Industry: M. Muralidhar and G. L. DattaDocument10 pagesCasting Productivity Analysis of Global Foundry Industry: M. Muralidhar and G. L. DattaAnonymous iztPUhIiPas encore d'évaluation

- Copper e Final PDFDocument12 pagesCopper e Final PDFLuis GuerreroPas encore d'évaluation

- Lightweight Metal Cellular Structures via 3D Printing and CastingDocument15 pagesLightweight Metal Cellular Structures via 3D Printing and CastingqualityfreekPas encore d'évaluation

- Barrels - Steerworld PDFDocument8 pagesBarrels - Steerworld PDFxy2zjgPas encore d'évaluation

- Fuel Refractories Furnaces Lecture NotesDocument50 pagesFuel Refractories Furnaces Lecture NotesKISHORE CHANDRA PATRAPas encore d'évaluation

- BS3468 Austenitic Cast Iron Material SpecificationsDocument2 pagesBS3468 Austenitic Cast Iron Material SpecificationsPanchoMiyamotoPas encore d'évaluation

- Regional HSE Manager - Pune - FOSECO India Limited - 8 To 13 Years of ExperienceDocument3 pagesRegional HSE Manager - Pune - FOSECO India Limited - 8 To 13 Years of ExperienceMuruganPas encore d'évaluation

- Reducing Casting Cooling Times 50% With Controlled AirDocument16 pagesReducing Casting Cooling Times 50% With Controlled AirRajesh PuniaPas encore d'évaluation

- Selective Laser SinteringDocument12 pagesSelective Laser SinteringMihai CitcauanPas encore d'évaluation

- Foundry Savings Divided Blast CupolaDocument7 pagesFoundry Savings Divided Blast CupolaAlly AkramPas encore d'évaluation

- MEM460 Report FoundryDocument7 pagesMEM460 Report FoundrySiti Maizatul AkmaPas encore d'évaluation

- 3D Systems Guide To Processing QuickCast PatternsDocument48 pages3D Systems Guide To Processing QuickCast Patternscgonzo100% (2)