Académique Documents

Professionnel Documents

Culture Documents

Tabel Katalis

Transféré par

Meissha Ayu ArdiniCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tabel Katalis

Transféré par

Meissha Ayu ArdiniDroits d'auteur :

Formats disponibles

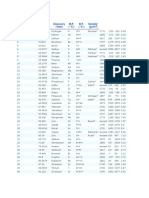

Typical Lives and Factors Determining the Life of Some Importan Industrial Catalyst (Addapted from Denny and

Twig, 1980)

Ammonia synthesis

N2 + 3H2 2NH3

Methanation (ammonia and H2 plants)

CO/CO2 + H2 CH4 + H2O

Acetylene hydrogenation (front end)

C2H2 + H2 C2H4

Sulfuric acid manufacture

2SO2 + O2 2SO3

Methanol synthesis

CO + 2H2 CH3OH

Low-Temperatur CO shift

CO + H2O CO2 + H2

Operating

Conditions

450-470 oC

200-300 atm

250-350 oC

30 atm

30-150 oC

20-30 atm

420-600 oC

1 atm

200-300 oC

50-100 atm

200-250 oC

10-30 atm

Hydrocarbon hydrodesulfurization

R2S + 2H2 H2S + R2

300-400 oC

30 atm

High-Temperatur CO shift

CO + H2O CO2 + H2

Steam reforming, natural gas

CH4 + H2O CO + 3H2

Ethylene partial oxidation

2C2H4 + O2 2C2H4O

Butane oxidation to maleic anhydride

350-500 oC

20-30 atm

500-850 oC

30 atm

200-270 oC

10-20 atm

7

C4H10 + 2 O2 C4H2O3 + 4H2O

400-520 oC

1-3 atm

Reduction of aldehydes to alcohols

RCHO + H2 RCH2OH

Ammonia oxidation

Reactions

Catalyst

Typical Life

(Years)

Process Affecting Life of Catalyst Charge

Catalyst Property

Affected

Fe with K2O promoter

and Al2O3 stabilizer

10-15

Slow sintering

Activity

Supported Nikel

5-10

Slow poisoning, S, As, K2CO3 from plants

upsets

Activity, pore blockage

Supported Palladium

5-10

Slow sintering

Activity/selectivity

Inactive compound formation, pellet fracture,

plugging by dust

Slow sintering, poisoning by S, Cl, and

carbonyls

Slow poisoning and accelerated sintering by

poisons

Activity, pressure drop

and mass transfer

1-10

Slow coking, poisoning by metals from

organometallic in residual

Activity; mass transfer;

pressure drop

1-4

Slow sintering, pellet breakage due to steam

Activity; pressure drop

1-3

Sintering, sulfur poisoning, carbon formation,

and pellet breakage due to plant upset

Activity; pressure drop

1-3

Slow sintering, poisoning by S, Cl

Activity, selectivity

Vanadium phosphorus

oxide with transition

metal additives

1-2

Loss of P; attrition or pellet breakage; S, Cl

poisoning

Activity, selectivity

220-270 oC

100-300 atm

Copper on zinc oxide

0,5-1

Slow sintering; pellet breakage (depends on

feedstock)

Activity or pressure

drop

5

2NH3 + 2 O2 2NO + 3H2O

800-900 oC

1-10 atm

Pt-Rh alloy gauze

0,1-0,5

Surface roughness, loss of platinum, fouling by

Fe

selectivity

Oxychlorination ethylene to ethylene

dichloride

2C2H4 + 4HCl + O2 2C2H4Cl2 + 2H2O

230-270 oC

1-10 atm

Copper chloride on

alumina (fluidized bed)

0,2-0,5

Loss by attrition, and other causes resulting

from plant upsets

Fluidized state, activity

Catalytic hydrocarbon reforming

460-525 oC

8-50 atm

Platinum alloys on

treated allumina

0,01-0,5

Coking, frequent regeneration

Activity, mass transfer

Vanadium and potassium

sulfates on silica

Cooper on Zinc and

Aluminium oxide

Cooper on Zinc and

Aluminium oxide

Cobalt and Molybdenum

sulfides on Aluminium

oxide

Fe3O4 on chromia

Nikel on Calcium

Alumnate or -Al2O3

Silver on -Al2O3 with

alkali metal promoters

5-10

2-5

2-4

Activity

Activity

Catalytic cracking of oils

500-560 oC

2-3 atm (fluid bad)

Synthetic zeolites

1-2 s

Very rapid coking (continuous regeneration)

poisoning by organic bases and organometallic

Activity, mass transfer

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Calculate H3O+ Concentration in Weak Acid SolutionsDocument24 pagesCalculate H3O+ Concentration in Weak Acid SolutionsMeissha Ayu ArdiniPas encore d'évaluation

- Buffer Solution pH GuideDocument15 pagesBuffer Solution pH GuideMeissha Ayu ArdiniPas encore d'évaluation

- Plan Campus Naamsesteenweg ENGDocument2 pagesPlan Campus Naamsesteenweg ENGMeissha Ayu ArdiniPas encore d'évaluation

- Livro Química Analítica Qualitativa - VogelDocument617 pagesLivro Química Analítica Qualitativa - VogelDaniel PrettiPas encore d'évaluation

- Livinginleuven 2017Document128 pagesLivinginleuven 2017Meissha Ayu ArdiniPas encore d'évaluation

- Curriculum Vitae Replace With First Name(s) Surname(s)Document2 pagesCurriculum Vitae Replace With First Name(s) Surname(s)Valentina100% (1)

- GejeDocument5 pagesGejeMeissha Ayu ArdiniPas encore d'évaluation

- Instrumen Lab QCDocument5 pagesInstrumen Lab QCMeissha Ayu ArdiniPas encore d'évaluation

- Emba Sample Letters of RecommendationDocument2 pagesEmba Sample Letters of RecommendationrestuanPas encore d'évaluation

- Emba Sample Letters of RecommendationDocument2 pagesEmba Sample Letters of RecommendationrestuanPas encore d'évaluation

- IELTS Writing Answer SheetDocument4 pagesIELTS Writing Answer SheetHighPoint IELTS Preparation Services, Inc.Pas encore d'évaluation

- IELTS Calendar 2016 PDFDocument1 pageIELTS Calendar 2016 PDFMeissha Ayu ArdiniPas encore d'évaluation

- Delft MSc in Life Science and TechnologyDocument4 pagesDelft MSc in Life Science and TechnologyMeissha Ayu ArdiniPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- General Multi Choice Paper - 3Document4 pagesGeneral Multi Choice Paper - 3Chinni KrishnaPas encore d'évaluation

- Mastication Is Process During Which The Elastic Rubber Achieves Plastic PropertiesDocument1 pageMastication Is Process During Which The Elastic Rubber Achieves Plastic PropertiesBhubanDip BisWasPas encore d'évaluation

- DyeingDocument264 pagesDyeingEhsaas RifatPas encore d'évaluation

- The History of ExplosivesDocument6 pagesThe History of ExplosivesprateekpandyaPas encore d'évaluation

- NganalDocument19 pagesNganalWaleed El-azabPas encore d'évaluation

- PHPA TestDocument2 pagesPHPA TestRagha RagPas encore d'évaluation

- Natural Gums and Its Pharmaceutical ApplicationDocument10 pagesNatural Gums and Its Pharmaceutical Applicationhosam alosPas encore d'évaluation

- Miscellaneous Information: R 1.987 Cal/mole°k 8.314 J/mole°K Absolute Zero - 273.15°C 1 Joule 0.239 CaloriesDocument32 pagesMiscellaneous Information: R 1.987 Cal/mole°k 8.314 J/mole°K Absolute Zero - 273.15°C 1 Joule 0.239 CalorieswastequestPas encore d'évaluation

- Lijmproef Verslag v3.1Document27 pagesLijmproef Verslag v3.1Dominick ZeijlPas encore d'évaluation

- Carbohydrate ChemistryDocument78 pagesCarbohydrate ChemistryNikhil NathPas encore d'évaluation

- Chloride 8113Document6 pagesChloride 8113okgnosasPas encore d'évaluation

- Welding MachinesDocument53 pagesWelding MachinesDeepak Kumar Kant Kesri100% (2)

- Bio Polishing EnzymeDocument3 pagesBio Polishing Enzymefebry_yulindraPas encore d'évaluation

- MACDEMIDDocument55 pagesMACDEMIDSetyohdWPas encore d'évaluation

- Terathane: Properties, Uses, Storage and Handling of Dupont GlycolsDocument12 pagesTerathane: Properties, Uses, Storage and Handling of Dupont GlycolsA MahmoodPas encore d'évaluation

- Reductions by The Alumino - and Borohydrides in Organic SynthesisDocument236 pagesReductions by The Alumino - and Borohydrides in Organic Synthesisjfjd6889100% (1)

- Process of Production CS2 PDFDocument9 pagesProcess of Production CS2 PDFDinii Lathiifah PertiwiPas encore d'évaluation

- Lesson 2 Dna Structure and Dna ExtractionDocument8 pagesLesson 2 Dna Structure and Dna ExtractionGreatel Elijah TorregosaPas encore d'évaluation

- Wolaita Sodo University: General Chemistry (Chem.1012) Chapter FourDocument56 pagesWolaita Sodo University: General Chemistry (Chem.1012) Chapter FourAbdulmajid AbdellaPas encore d'évaluation

- Pheonwj M Spe 0025 1Document48 pagesPheonwj M Spe 0025 1Iksan Adityo Mulyo100% (1)

- SDS Hydrochloric Acid InhibitorDocument4 pagesSDS Hydrochloric Acid InhibitorJahidul IslamPas encore d'évaluation

- Effect of PH On Corrosion RateDocument8 pagesEffect of PH On Corrosion RateياسرشلالالحسنيPas encore d'évaluation

- Pacop Red Pharmaceutical ChemistryDocument109 pagesPacop Red Pharmaceutical ChemistryAstherielle GalvezPas encore d'évaluation

- School Training Report on Practice at District HospitalDocument34 pagesSchool Training Report on Practice at District Hospitalsumit sharmaPas encore d'évaluation

- Lower and Higher Heating Values of Gas Liquid and Solid FuelsDocument2 pagesLower and Higher Heating Values of Gas Liquid and Solid FuelsElwathig BakhietPas encore d'évaluation

- Symbol Hebrew תירבע Trans-literation* Discovery (Year) M.P. (°C) B.P. (°C) Density* (g/cm)Document79 pagesSymbol Hebrew תירבע Trans-literation* Discovery (Year) M.P. (°C) B.P. (°C) Density* (g/cm)Kameswar MandhataPas encore d'évaluation

- A333 - 18 PDFDocument8 pagesA333 - 18 PDFRamyMoustafaPas encore d'évaluation

- Treating Technologies of Shell Global Solutions For Natural Gas and Refinery Gas StreamsDocument19 pagesTreating Technologies of Shell Global Solutions For Natural Gas and Refinery Gas StreamsPrasad ChakkrapaniPas encore d'évaluation

- HydrocarbonsDocument7 pagesHydrocarbonsJopie ArandaPas encore d'évaluation

- Materials Selection For Corrosion PreventionDocument61 pagesMaterials Selection For Corrosion PreventionJeremy Coleman100% (1)