Académique Documents

Professionnel Documents

Culture Documents

Steering Initialization

Transféré par

omanstar12Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Steering Initialization

Transféré par

omanstar12Droits d'auteur :

Formats disponibles

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

2006 Lexus GS 300 3.0L Eng

VARIABLE GEAR RATIO STEERING SYSTEM

PRECAUTION

CAUTION: If the negative (-) battery cable has been

disconnected, initialize the following systems when the

cable is reconnected.

VARIABLE GEAR RATIO STEERING SYSTEM

System

See procedure

Clearance Sonar System

INITIALIZATION

Power Window Control System

INITIALIZATION

Sliding Roof System

INITIALIZATION

Variable Gear Ratio Steering System

INITIALIZATION

1. TROUBLESHOOTING PRECAUTIONS

a. If the problem is caused by a poor connection of a terminal or poor installation of a part,

reconnecting the terminal, or removing and reinstalling the part may solve the problem, or may

temporarily return the system to normal.

b. To specify the cause of the problem, check for DTCs or confirm vehicle operating conditions

when the problem occurred and note them down before disconnecting connectors or removing

parts.

c. Be sure to check for DTCs in other systems as the problem may be caused by a malfunction in

another system.

d. DTCs may be stored in the EPS and/or ECB systems due to VGRS system inspections. Check

for DTCs in the EPS and ECB systems and clear any output codes after inspecting the VGRS

system.

e. When the engine switch is turned on/off, system start-up/stop operation is performed. At this

time, a small operating sound can be heard and the steering wheel slightly moves in a turning

direction.

f. If "INVALID" is displayed for "STRAIGHT ANG FLG" in the data list, the VGRS system does not

operate.

g. If the steering wheel is turned left and right with the engine switch off, a noise can be heard.

However, this is not a malfunction.

2. HANDLING AND OPERATIONAL PRECAUTIONS

a. Removal and installation of the steering control ECU, steering actuator, and each sensor must

be performed with the engine switch off unless specified.

b. If the steering control ECU, steering actuator, or a sensor is removed and installed, perform the

test mode inspection, check for DTCs, and confirm that the normal system code is output.

c. If the engine switch is turned on (IG) with the steering control ECU connector disconnected,

DTCs may be stored in the EPS and/or ECB systems. Check for DTCs in those systems and

clear any output codes after completing repair.

3. PRECAUTIONS FOR REPLACEMENT OF STEERING SYSTEM PARTS

a. If the steering control ECU or steering actuator is replaced, perform actuator angle neutral point

calibration and initialization.

b. The steering control ECU cannot be disassembled or repaired. If there is any problem with the

1 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

steering control ECU, replace with a new one.

4. PRECAUTIONS FOR STEERING WHEEL OFF-CENTER

NOTE: If the steering wheel is still off-center

after completing steering angle sensor initialization

(See INITIALIZATION ), perform VGRS system

calibration (See INITIALIZATION ).

HINT:

The steering wheel may become off-center under any of the following conditions.

These conditions do not indicate a malfunction.

1. The steering wheel is turned when the engine switch is off.

2. The steering wheel is turned quickly.

3. The steering wheel is turned to the left or right lock position.

If the steering wheel is off-center, drive the vehicle at 35 km/h (22 mph) or more for 5 seconds

or more, or turn the steering wheel to the left and right with the vehicle stopped or while driving

at low speeds. This may center the steering wheel.

5. CONDITIONS UNDER WHICH VGRS SYSTEM DOES NOT OPERATE

a. The VGRS system does not operate under any of the following conditions:

a. Power supply voltage is low or too high.

b. A fail-safe function is operating to protect the system from overheating. (System control

is suspended to prevent the motor in the steering actuator and the steering control

ECU from overheating. If the temperatures of the motor and ECU drop, the system will

return to normal.)

c. The vehicle is exposed to extremely low temperatures. (If the ambient temperature

becomes approximately -30C, system control will be suspended.)

NOTE: If any of the above occurs,

perform steering angle sensor initialization

(See INITIALIZATION ).

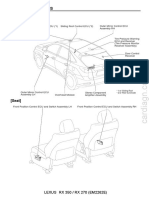

PARTS LOCATION

2 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 1: Identifying Steering Column Parts Location

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

SYSTEM DIAGRAM

3 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 2: System Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

COMMUNICATION METHOD SPECIFICATION

Transmitting ECU

(Transmitter)

Steering Angle

Receiving ECU

Sensor Steering

Control ECU

Signals

Steering wheel angle signal

Communication

method

CAN

Tire angle (during straight

ahead driving) signal

4 of 87

Steering Angle

Sensor

Steering Control

ECU

Steering wheel angle signal

ECM

Steering Control

ECU

Engine speed signal

Deceleration

Sensor

Steering Control

ECU

Deceleration sensor signal

Yaw Rate Sensor

Steering Control

ECU

Yaw rate signal

Serial

communication

CAN

CAN

CAN

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Skid Control ECU

Steering Control

ECU

Vehicle speed signal

CAN

Steering cooperative

control level signal

Steering Control

ECU

Skid Control ECU

Steering Control

ECU

Power Steering

ECU

Steering actuator operating

angle signal

Steering actuator operating

angle signal

CAN

CAN

Steering cooperative

control level signal

Steering Control

ECU (*1)

Combination Meter

Warning information signal

CAN - BEAN

HINT:

*1: Warning information signals are transmitted via the following route:

Steering control ECU --> (CAN) --> Power steering ECU --> (CAN) --> Gateway ECU --> (BEAN) --> Combination

meter

SYSTEM DESCRIPTION

1. GENERAL DESCRIPTION

a. The VGRS (Variable Gear Ratio Steering) system controls the steering angle in accordance with

vehicle speed. The system is controlled by the steering control ECU which operates the steering

actuator mounted on the steering intermediate shaft. The operating angle of the steering actuator

is added to the steering angle of the intermediate shaft in order to vary the turning angle of the

front wheels in accordance with vehicle speed.

b. When the VGRS system is operating normally, the steering wheel can be turned approximately

2.7 turns from lock to lock, with the engine running and the vehicle stopped.

c. If a malfunction occurs in the VGRS system, steering actuator operation will immediately stop

and the input and output shafts will be directly connected to enable the conventional steering

mechanism to operate, maintaining steering function (fail-safe). At the same time, the master

warning light (VGRS) will come on to inform the driver of the malfunction.

2. FUNCTIONS OF COMPONENTS

a. Functions of VGRS system components

FUNCTIONS OF COMPONENTS

Component

5 of 87

Function

Steering

Control ECU

Calculates the steering gear ratio based on tire angle signals and vehicle

speed signals. Drives the steering actuator based on calculation results of

steering cooperative control received from the skid control ECU, and of

steering gear ratio control.

Steering

Actuator

Drives the motor using the output current from the steering control ECU to

change the output shaft angle.

Rotation Angle

Sensor

Outputs the motor rotation angle to the steering control ECU.

Steering Angle

Sensor

Outputs the steering wheel angle to the steering control ECU.

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Master

Warning Light

Multiinformation

Display

Located on the combination meter ECU. Comes on or blinks in accordance

with system conditions to inform the driver of system malfunctions.

Located on the combination meter ECU. Displays a warning message to inform

the driver of system malfunctions.

HOW TO PROCEED WITH TROUBLESHOOTING

HINT:

The intelligent tester can be used in steps 3, 4, 5, 7 and 11.

1. VEHICLE BROUGHT TO WORKSHOP

NEXT

2. CUSTOMER PROBLEM ANALYSIS

a. Confirm problem symptoms.

NEXT

3. CHECK MULTIPLEX COMMUNICATION SYSTEM

a. Check for DTCs.

MULTIPLEX COMMUNICATION SPECIFICATION

DTC is not output.

DTC is output.

B : GO TO MULTIPLEX COMMUNICATION SYSTEM

A : GO TO NEXT STEP

4. CHECK CAN COMMUNICATION SYSTEM

a. Check for DTCs.

MULTIPLEX COMMUNICATION SPECIFICATION

DTC is not output.

DTC is output.

B : GO TO CAN COMMUNICATION SYSTEM

A : GO TO NEXT STEP

5. CHECK DTC

a. Check for DTCs.

a. Record the DTCs.

b. Clear the DTCs.

c. Recheck for DTCs.

a. Simulate the malfunction and check if the DTCs are output again (See TERMINALS

OF ECU ).

TERMINALS OF ECU SPECIFICATION

6 of 87

DTC is output.

DTC is not output.

DTCs are not output, and the malfunction can not be simulated or

checked.

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

B : GO TO STEP 10

C : SYMPTOM SIMULATION

A : GO TO NEXT STEP

6. DTC CHART

NEXT

7. CIRCUIT INSPECTION

NEXT

8. REPAIR

NEXT

9. CONFIRMATION TEST

NEXT

END

10. PROBLEM SYMPTOMS TABLE

NEXT

11. CIRCUIT INSPECTION

NEXT

12. CONFIRMATION TEST

NEXT

END

INITIALIZATION

1. STEERING ANGLE SENSOR INITIALIZATION (to obtain a tire angle (during straight-ahead driving)

signal)

a. Turn the engine switch on (IG), and check that the master warning light and VSC/ABS warning

lights illuminate for a few seconds.

NOTE: If the warning lights remain on or

blink, repair he applicable system.

b. Drive the vehicle on a straight road at 35 km/h (22 mph) or more for 5 seconds or longer.

HINT:

a. At this point, the steering wheel will still remain off-center by 5 to 10 degrees.

b. In this step, the neutral position of the steering wheel is restored from the steering

control ECU memory.

c. Confirm that steering angle sensor initialization is completed (when using the intelligent tester).

a. Enter the VGRS menu using the intelligent tester. Select "STRAIGHT ANG FLG" from

"DATA LIST". Check if the steering angle sensor has obtained a tire angle (during

straight-ahead driving) signal.

Standard:

"VALID" is displayed on the tester screen.

d. Confirm that steering angle sensor initialization is completed (when not using the intelligent

tester).

7 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

a. Drive the vehicle on a straight road at 60 km/h (37 mph) or more for 30 seconds or

longer.

b. Stop the vehicle (engine running).

c. Slowly turn the steering wheel from lock to lock.

d. If it turns approximately 2.7 turns, steering angle sensor initialization is completed. If it

turns approximately 3.2 turns, steering angle sensor initialization is not completed.

NOTE: If the steering wheel turns

approximately 3.2 turns, perform step (b)

again.

Fig 3: Identifying Master Warning Light

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

CALIBRATION

NOTE: Use this procedure to center the steering

wheel if:

The steering actuator has been replaced,

The steering control ECU has been replaced,

The steering column or gear has been

disconnected,

or

The steering wheel is still off-center after

completing the steering angle sensor

initialization.

8 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

1. VGRS SYSTEM CALIBRATION PROCEDURE (USING SST CHECK WIRE)

1. FACE TIRES STRAIGHT AHEAD

NOTE: Drive the vehicle to confirm that the

steering wheel is centered.

NEXT

2. CHECK DTCs

a. Check for DTCs (See TERMINALS OF ECU ).

Result

RESULT SPECIFICATION

Result

Proceed to

DTC C1591/51 is not output.

DTC C1591/51 is output.

B : Go to step 4

A : GO TO NEXT STEP

3. PERFORM ACTUATOR ANGLE INITIALIZATION

NOTE: Complete steps (d) to (h) within 1

minute.

a. Turn the engine switch on (IG).

b. Start the engine.

c. Center the steering wheel.

d. Using SST check wire, connect terminals TS and CG, and TC and CG of the DLC3.

SST 09843-18040

e. Disconnect the SST check wire from terminal TS of the DLC3, and turn the steering

wheel to the left 180 or more.

f. Connect the SST check wire to terminal TS of the DLC3.

g. Disconnect the SST check wire from terminal TC of the DLC3, and turn the steering

wheel to the right 180 or more.

h. Connect the SST check wire to terminal TC of the DLC3.

9 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 4: Identifying DLC3 Connector

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

When the master warning light (VGRS) comes on, DTC C1591/51 is memorized.

i. Disconnect the SST check wire from the DLC3.

j. Turn the engine switch off.

NEXT

Go to step 1

4. FACE TIRES STRAIGHT AHEAD

a. Confirm that the steering wheel is centered when facing the tires straight ahead.

NOTE: Drive the vehicle to confirm that

is steering wheel is centered.

Result

RESULT SPECIFICATION

Result

Proceed to

Steering wheel is off-center.

Steering wheel is centered.

B : Go to step 8

10 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

A : GO TO NEXT STEP

5. UNLOCK STEERING ACTUATOR

NOTE: Do not start the engine.

a. Turn the engine switch off.

b. Disconnect the negative (-) terminal cable from the battery.

c. Disconnect the K26 connector from the steering actuator.

d. Connect a jumper wire from terminal LV+ to the positive (+) battery terminal and

another jumper wire from terminal LG+ to the negative (-) battery terminal.

NOTE: Do not apply voltage for more

than 3 minutes.

Fig 5: Identifying K26 Connector From Steering Actuator

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NEXT

6. STEERING CENTER ADJUSTMENT

a. Center the steering wheel.

NOTE: If the spiral cable of the airbags

and VGRS system is not centered when

the steering wheel is installed, release the

system lock and center the spiral cable

(See SPIRAL CABLE ). Slowly turn the

steering wheel to the left. Turn it to the right

11 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

approximately 2 turns from the point where

resistance begins to be felt (the end of the

spiral cable) while steering. This will center

the spiral cable. (If excessive force is

applied to the end of the spiral cable, the

cable may break.)

NEXT

7. LOCK STEERING ACTUATOR

a. Disconnect the positive (+) and negative (-) battery terminal cables from the steering

actuator.

b. Connect the K26 connector to the steering actuator.

c. Connect the negative (-) terminal cable to the battery.

d. Turn the steering wheel approximately 3 to the left and right. Confirm that the reaction

force can be felt.

NOTE:

a. If the above procedures are not

followed correctly, a DTC will be

detected. If a DTC is detected,

perform the above procedures

again and then check for DTCs.

b. Perform these procedures with

the engine switch off.

NEXT : Go to step 1

8. ADJUST ACTUATOR ANGLE

HINT:

Activating and ending test mode will complete actuator angle adjustment.

a. Make sure the engine switch is off.

NOTE: Do not touch the steering

wheel during these procedures.

b. Using SST check wire, connect terminals TS and CG of the DLC3.

SST 09843-18040

c. Turn the engine switch on (IG).

d. Confirm that the "VGRS TEST MODE" is displayed on the multi-information display

when test mode is activated.

e. Turn the engine switch off.

f. Disconnect the SST check wire from terminals TS and CG of the DLC3.

12 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 6: Identifying DLC3 Connector

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

g. Turn the engine switch on (IG) again.

NEXT

9. CHECK MASTER WARNING LIGHT

a. Confirm that the master warning light (VGRS) off.

b. Turn the engine switch off.

c. Confirm that master warning light (VGRS) operating normally.

NEXT

10. CHECK STEERING WHEEL OPERATION

a. Start the engine.

b. Perform the steering angle sensor initialization (See INITIALIZATION ).

c. Turn the steering wheel from lock to lock to check that it rotates approximately 2.7

turns.

d. Drive vehicle to confirm steering wheel is centered.

NEXT

END

2. VGRS SYSTEM CALIBRATION PROCEDURE (USING INTELLIGENT TESTER)

1. FACE TIRES STRAIGHT AHEAD

13 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

NOTE: Drive the vehicle to confirm that the

steering wheel is centered.

NEXT

2. PERFORM VGRS SYSTEM CALIBRATION

a. Connect the intelligent tester to the DLC3.

b. Turn the engine switch on (IG) and turn the intelligent tester on.

c. Select and perform "STEERING ANGLE ADJ" from the VGRS menu on the intelligent

tester display.

Fig 7: Connecting Intelligent Tester To DLC3

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

d. Press the "ENTER" key.

NOTE: Press the "ENTER" key even if

DTC C15B4/71 is output.

14 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 8: Intelligent Tester Display - Press "ENTER" Key

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

e. Press the "ENTER" key.

NOTE: Ensure that the engine switch

is off.

15 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 9: Intelligent Tester Display - Press "ENTER" Key

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

f. Press the "YES" key.

Fig 10: Intelligent Tester Display - Press "YES" Key

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

g. Press the "ENTER" key.

16 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

NOTE: If the spiral cable of the airbags

and VGRS system is not centered when

the steering wheel is installed, release the

system lock and center the spiral cable

(See SPIRAL CABLE ). Slowly turn the

steering wheel to the left. Turn it to the right

approximately 2 turns from the point where

resistance begins to be felt (the end of the

spiral cable) while steering. This will center

the spiral cable. (If excessive force is

applied to the end of the spiral cable, the

cable may break.)

Fig 11: Intelligent Tester Display - Press "ENTER" Key

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

h. Press the "ENTER" key.

NOTE: Do not touch the steering

wheel during these procedures.

17 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 12: Intelligent Tester Display - Press "ENTER" Key

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

i. Press the "ENTER" key.

Fig 13: Intelligent Tester Display - Press "ENTER" Key

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

18 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

j. Press the "ENTER" key.

NOTE: Do not touch the steering

wheel during these procedures.

Fig 14: Intelligent Tester Display - Press "ENTER" Key

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

k. The remaining time is displayed and the display switches automatically to the next

screen.

NOTE: Do not touch the steering

wheel during these procedures.

19 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 15: Intelligent Tester Display - VGRS System Calibration

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

l. Check that VGRS system calibration is completed normally.

m. Select "ENTER" to return the display to the "MENU" screen.

Fig 16: Intelligent Tester Display - Steering Angle

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

20 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

NEXT

3. CHECK MASTER WARNING LIGHT

a. Confirm that the master warning light (VGRS) off.

b. Turn the engine switch off.

c. Disconnect the intelligent tester from the DLC3.

d. Confirm that master warning light (VGRS) operating normally.

NEXT

4. CHECK STEERING WHEEL OPERATION

a. Start the engine.

b. Perform the steering angle sensor initialization (See INITIALIZATION ).

c. Turn the steering wheel from lock to lock to check that it rotates approximately 2.7

turns.

d. Drive vehicle to confirm steering wheel is centered.

NEXT

END

PROBLEM SYMPTOMS TABLE

HINT:

If a normal system code is displayed during the DTC check but the problem still occurs, check the circuits for each

problem symptom in the order given in the table below and proceed to the relevant troubleshooting page.

Variable Gear Ratio Steering System

PROBLEM SYMPTOMS CHART

Symptom

See

Steering wheel is off-center or

deviates from neutral position

DTC U0100/56 LOST

COMMUNICATION WITH ECM / PCM

"A"

Only if the following (1 to 4) is all

normal and the problem is still

occurring, replace the steering

control ECU.

REMOVAL

1. Actuator temperature is

abnormal

DTC U0123/56 LOST

COMMUNICATION WITH YAW RATE

(DECELERATION) SENSOR

MODULE

2. IG power source circuit

DTC C15B4/71 ECU MALFUNCTION

3. IG or PIG power supply circuit

WIRING DIAGRAM

4. Power steering system (check

steering effort)

ON-VEHICLE INSPECTION

Steering angle differs

between left and right

Steering angle differs between left

and right

STEERING ANGLE DIFFERS

BETWEEN LEFT AND RIGHT

Steering wheel vibrates

or abnormal noise is

heard from steering

wheel

Steering wheel vibrates or

abnormal noise is heard from

steering wheel

STEERING WHEEL VIBRATES OR

ABNORMAL NOISE IS HEARD FROM

STEERING WHEEL

Steering wheel is

off-center

VGRS system stops or

does not operate

21 of 87

Suspected area

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Master warning light

(VGRS) malfunction

Master warning light circuit

MASTER WARNING LIGHT

MALFUNCTION

TERMINALS OF ECU

HINT:

Inspect the connectors from the back side while they are connected.

Fig 17: Identifying Terminals Of ECU

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

TERMINAL DESCRIPTION SPECIFIED CONDITION CHART

Symbols

(Terminal No.)

22 of 87

Wiring Color

Terminal Description

Condition

Specified

Condition

AFS+ (A40-2)

- PGND

(A40-7)

L - W-B

CAN communication line (to AFS

system)

Engine switch on

(IG)

Pulse

generation

IG (A40-3) PGND (A40-7)

B-Y - W-B

Power supply (ECU-IG fuse)

Engine switch on

(IG)

10 to 14 V

CAN+ (A40-4)

- CAN(A40-9)

B-W

Local CAN communication

Engine switch on

(IG)

Pulse

generation

AFS- (A40-5) PGND (A40-7)

Y - W-B

CAN communication line (to AFS

system)

Engine switch on

(IG)

Pulse

generation

PGND (A40-7)

- Body ground

W-B -

Body Ground

Always

Below 1

PIG (A40-8) PGND (A40-7)

R - W-B

Power supply (VGRS fuse)

Engine switch on

(IG)

10 to 14 V

+BI (A40-10) PGND (A40-7)

GR - W-B

Power supply (ECU-B fuse)

Always

10 to 14 V

BMV (K69-1) PGND (A40-7)

W - W-B

Steering actuator motor signal (V

phase)

Engine start

Sine wave

BMU (K69-2) PGND (A40-7)

B - W-B

Steering actuator motor signal (U

phase)

Engine start

Sine wave

BMW (K69-3)

- PGND

(A40-7)

R - W-B

Steering actuator motor signal (W

phase)

Engine start

Sine wave

SG (K69-6) PGD2 (K69-8)

BR - W-B

Steering actuator motor signal shield

ground

Always

Below 1

PGD2 (K69-8)

- Body ground

W-B Body

ground

Steering control ECU ground

Always

Below 1

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

+BO (K70-1) PGND (A40-7)

LG - W-B

Steering sensor power supply line

Always

10 to 14 V

LV (K70-3) PGND (A40-7)

Y - W-B

Power source for steering actuator

lock

Engine switch on

(IG)

10 to 14 V

S1 (K70-41) PGND (A40-7)

W - W-B

Steering actuator motor rotation

angle sensor signal

Engine switch on

(IG)

Sine wave

RV (K70-6) PGND (A40-7)

B - W-B

Steering actuator resolver excitation

output voltage

Engine switch on

(IG)

Sine wave

SIL (K70-7) PGND (A40-7)

R - W-B

Diagnostic communication signal

Engine switch on

(IG)

Pulse

generation

CANH (K70-9)

- CANL

(K70-20)

P-V

Global CAN communication

Engine switch on

(IG)

Pulse

generation

SS1- (K70-10)

- PGND

(A40-7)

L - W-B

Steering angle sensor signal

Engine switch on

(IG), turn the

steering wheel

Pulse

generation

LG (K70-12) PGND (A40-7)

L - W-B

Steering actuator lock ground

Engine start

Pulse

generation

S2 (K70-14) PGND (A40-7)

R - W-B

Steering actuator motor rotation

angle sensor signal

Engine switch on

(IG)

Sine wave

RG (K70-15) PGND (A40-7)

G - W-B

Steering actuator resolver common

ground

Always

Below 1

SS2+

(K70-16) PGND (A40-7)

Shielded W-B

Ground for steering actuator motor

rotation angle sensor signal wire and

control signal wire shield wire

Engine switch on

(IG)

Pulse

generation

SS1+

(K70-19) PGND (A40-7)

LG - W-B

Steering angle sensor signal

Engine switch on

(IG), turn the

steering wheel

3 to 4 V

DIAGNOSIS SYSTEM

1. DIAGNOSTIC SYSTEM

a. Inspect the battery voltage.

Standard:

11 to 14 V

HINT:

If the voltage is below 11 V, recharge the battery before proceeding.

23 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 18: Identifying DLC3 Connector

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Check the DLC3.

a. The steering control ECU uses CAN and ISO 9141-2 as its communication protocol.

The terminal arrangement of the DLC3 complies with SAE J1962 and matches the ISO

9141-2 format. Verify the conditions listed in the table below.

TERMINAL DESCRIPTION SPECIFIED CONDITION CHART

24 of 87

Symbols (Terminals

No.)

Terminal

description

Condition

Specified

condition

SIL (7) - SG (5)

Bus "+" line

During

transmission

Pulse

generation

CG (4) - Body

ground

Chassis ground

Always

Below 1

SG (5) - Body

ground

Signal ground

Always

Below 1

BAT (16) - Body

ground

Battery positive

Always

11 to 14 V

CANH (6) - CANL

(14)

HIGH-level CAN

bus line

Engine switch

off

54 to 67

CANH (6) - Battery

positive

HIGH-level CAN

bus line

Engine switch

off

1 M or

higher

CANH (6) - CG (4)

HIGH-level CAN

bus line

Engine switch

off

3 k or higher

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

CANL (14) Battery positive

LOW-level CAN

bus line

Engine switch

off

1 M or

higher

CANL (14) - CG (4)

LOW-level CAN

bus line

Engine switch

off

3 k or higher

HINT:

If the display shows a communication error message when you connect the cable of

the intelligent tester to the DLC3, turn the engine switch on (IG) and operate the

intelligent tester, there is a problem on either the vehicle side or the tool side.

a. If communication is normal when the tool is connected to another vehicle,

inspect the DLC3 on the original vehicle.

b. If communication is still not possible when the tool is connected to another

vehicle, the problem is probably in the tool itself. Consult the Service

Department listed in the tool's instruction manual.

c. If the problem still occurs after the above inspection is performed, there may

be a problem with the DLC3 connector.

2. FUNCTION OF WARNING LIGHT AND MESSAGE

a. If a malfunction occurs during system operation, the master warning light (VGRS) on the

combination meter assembly will come on and "CHECK VGRS" will be displayed on the multiinformation display to inform the driver of the system malfunction.

Fig 19: VGRS Screen Display

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3. DTCs

a. Normal mode.

a. DTCs are memorized in the steering control ECU and read by using the intelligent

tester (See TERMINALS OF ECU ).

b. Test mode.

a. By switching from normal mode to test mode, the steering angle sensor can be

inspected (See DTC CHECK / CLEAR ).

HINT:

25 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Whether the system is in diagnostic mode or test mode can be checked from the

indication on the multi-information display. For details of the indication and how to

check, refer to "DTC CHECK / CLEAR" (see DTC CHECK / CLEAR ).

Fig 20: Connecting Intelligent Tester To DLC3

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

4. CHECK MASTER WARNING LIGHT

a. Turn the engine switch on (IG).

b. Check that the master warning light (VGRS) comes on for 2 seconds.

HINT:

If the master warning light (VGRS) check result is not normal, proceed to troubleshooting of the

warning light circuit.

TROUBLE AREA CHART

Trouble Area

Master warning light circuit

26 of 87

See procedure

MASTER WARNING LIGHT MALFUNCTION

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 21: Identifying Master Warning Light

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

DTC CHECK / CLEAR

1. DTC CHECK (USING INTELLIGENT TESTER)

HINT:

If the DTC check/clear is performed using the intelligent tester, 2-digit codes will also be displayed on the

multi information display.

a. Check for DTCs.

a. Connect the intelligent tester to the DLC3.

b. Turn the engine switch on (IG) and turn the intelligent tester on.

c. Check the DTCs by following the prompts on the tester screen. (5-digit DTCs only will

be displayed.)

HINT:

Refer to the intelligent tester's operator's manual for further details.

b. Clear the DTCs.

a. Connect the intelligent tester to the DLC3.

b. Turn the engine switch on (IG).

c. Clear the DTCs by following the prompts on the tester screen.

HINT:

Refer to the intelligent tester's operator's manual for further details.

27 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 22: Connecting Intelligent Tester To DLC3

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

2. DTC CHECK (USING SST CHECK WIRE)

HINT:

The master warning light comes on in diagnostic mode.

a. Check for DTCs.

a. Using SST check wire, connect terminals TC and CG of the DLC3.

SST 09843-18040

b. Turn the engine switch on (IG).

c. "DIAG VGRS" is displayed on the multi information display and the system starts

searching for a malfunction.

28 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 23: Identifying DLC3 Connector

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

d. If the system is normal, "DIAG VGRS OK" is displayed.

Fig 24: DIAG VGRS OK Screen Display

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

e. If the system has a malfunction, "DIAG VGRS xx" is displayed. ("xx" is a 2-digit DTC.)

b. Clear the DTCs.

29 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

a. Turn the engine switch on (IG).

Fig 25: DIAG VGRS xx Screen Display

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Using SST check wire, connect and disconnect terminals TC and CG of the DLC3 4

times within 8 seconds.

SST 09843-18040

c. Disconnect SST check wire from the DLC3.

NOTE: The stored yaw rate sensor

value will be cleared by the above

operation. Obtain the yaw rate sensor zero

point.

d. Turn the engine switch off.

HINT:

If the problem still exists, DTCs may not be cleared (See INITIALIZATION ).

e. Obtain the yaw rate sensor zero point.

30 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 26: Identifying DLC3 Connector

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

FREEZE FRAME DATA

HINT:

The VGRS system stores data when a trouble code is set and can be viewed using the intelligent tester.

1. FREEZE FRAME DATA OF STEERING CONTROL ECU

a. Connect the intelligent tester to the DLC3.

b. Turn the engine switch on (IG) and turn the intelligent tester on.

c. Select "FREEZE FRAME DATA" from the display on the tester.

INTELLIGENT TESTER DISPLAY CHART

Intelligent Tester

Display

SPD (VSC)

Vehicle speed (VSC ECU)

Value (Unit)

Speed indicated on

speedometer (km/h)

ENGINE REV

(RPM)

Engine revolution (RPM)

MTR SOURCE

CUR

Motor power source actual

current

0 to 127.5 (A)

PIG SOURCE

VOL

PIG power source voltage

0 to 25.5 (V)

IG power source voltage

0 to 25.5 (V)

IG SOURCE VOL

31 of 87

Measurement Item

Less than 300 or more then

300 (RPM)

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

LOCK OUTPUT

VOL

LOCK motor output voltage

0 to 25.5 (V)

Command value DUTY for PVM

control

0 to 100 (%)

Command value DUTY for

actuator lock control

0 to 100 (%)

RES OFFSET

(SIN)

Resolver offset (SIN)

0 to 25.5 (V)

RES OFFSET

(COS)

Resolver offset (COS)

0 to 25.5 (V)

MOTOR

CURRENT U

Motor current U

-63 to 64.5 (A)

MOTOR

CURRENT V

Motor current V

-63 to 64.5 (A)

MOTOR

CURRENT W

Motor current W

-63 to 64.5 (A)

DUTY VAL

LOCK DUTY VAL

MOTOR

VOLTAGE

Motor power supply voltage

0 to 51 (V)

STEERING POS1

Steering position1

-2047 to 2048.9375 (deg)

ACTUATOR POS

Actuator position

-2047 to 2048.9375 (deg)

STR ANGL VEL

Steering wheel angle velocity

-2047 to 2048.9375

(deg/sec)

ACT TARGET

ANG1

Actuator target angle1

-2047 to 2048.9375 (deg)

ACT TARGET

ANG2

Actuator target angle2

-2047 to 2048.9375 (deg)

ACT REV SPD

Actuator revolution speed

-2047 to 2048.9375 (deg)

CHECK MODE PROCEDURE

1. TEST MODE (VGRS SENSOR SIGNAL CHECK)

HINT:

1. When the system enters test mode, "VGRS TEST MODE" is displayed on the multi-information

display.

2. Before entering test mode, check and repair any malfunctions indicated by the present DTCs of

the VGRS system.

3. By switching from normal mode to test mode, the steering angle sensor can be read.

4. When entering test mode, the steering control ECU sets all the test mode DTCs first.

5. When the mode is switched from test mode to normal mode, all the test mode DTCs will be

erased.

a. Check the test mode DTCs (using the intelligent tester).

a. Turn the engine switch off.

32 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 27: VGRS TEST MODE Screen Display

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Connect the intelligent tester to the DLC3.

c. Turn the engine switch on (IG) and turn the intelligent tester on.

d. Read the test mode DTCs by following the prompts on the tester screen.

HINT:

Refer to the intelligent tester's operator's manual for further details.

b. Clear the test mode DTCs (using the intelligent tester).

33 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 28: Connecting Intelligent Tester To DLC3

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Turn the engine switch off.

b. Connect the intelligent tester to the DLC3.

c. Turn the engine switch on (IG) and turn the intelligent tester on.

d. Switch the system from test mode to normal mode by following the directions on the

tester screen.

HINT:

Refer to the intelligent tester's operator's manual for further details.

c. Check the test mode DTCs (using SST check wire).

a. Turn the engine switch off.

34 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 29: Connecting Intelligent Tester To DLC3

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Using SST check wire, connect terminals TS (TC) and CG of the DLC3.

SST 09843-18040

c. Turn the engine switch on (IG).

d. Read 2-digit test mode DTCs from the multi information display.

NOTE: Perform these procedures with

the vehicle stopped.

d. Clear the test mode DTCs (using SST check wire).

a. Turn the engine switch off.

b. Disconnect the SST check wire from the DLC3.

SST 09843-18040

c. Turn the engine switch on (IG).

HINT:

If the engine switch is turned on (IG) with terminals TS and CG short-circuited, the

system remains in test mode.

35 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 30: Identifying DLC3 Connector

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

2. TEST MODE DTC

a. If a trouble code is displayed during the DTC check, check the circuit indicated by the DTC. For

details of each code, proceed to DTC chart.

DTC DETECTION ITEM CHART

DTC No.

C15C4/74

C15C5/75

Detection Item

A steering signal indicating a tire angle of 36or

more (to the left or right) is input after transfer to

test mode. (*1)

A steering signal indicating a motor rotation

angle of 36or more (to the left or right) is input

after transfer to test mode. (*1)

Trouble Area

a. Steering

angle sensor

b. Steering

control ECU

a. Steering

angle sensor

b. Steering

control ECU

HINT:

*1: A tire angle of 36and a motor rotation angle of 36correspond to the steering wheel angle

respectively. The amount of change in tire angle and motor rotation angle is from when the mode

is changed to test mode.

DATA LIST / ACTIVE TEST

HINT:

By accessing the DATA LIST displayed on the intelligent tester, the values of switches and sensors can be read

36 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

without removing any parts. Reading the DATA LIST is the first step of troubleshooting and is one method to shorten

labor time.

1. STEERING CONTROL ECU

a. Connect the intelligent tester to the DLC3.

b. Turn the engine switch on (IG) and turn the intelligent tester on.

c. Following the display on the tester, select "DATA LIST".

ITEM NORMAL CONDITION CHART

Item

37 of 87

Measurement Item/Range

(Display)

Normal Condition

Diagnostic Note

SPD (VSC)

Vehicle speed (VSC

ECU)/Min.: 0 km/h, Max.:

255 km/h

Actual vehicle

speed

Speed indicated on

speedometer

ENGINE REV

(RPM)

Engine revolution

(rpm)/Less 300 or More

300

Less than 300

RPM More than

300 RPM

Engine stopped

Engine running

MTR SOURCE

CUR

Motor power source

actual current/Min.: 0 A,

Max.: 127.5 A

Less than 1 A

More than 1 A

When not turning

the steering wheel

When turning the

steering wheel

PIG SOURCE

VOL

PIG power source

voltage/Min.: 0 V, Max.:

25.5 V

9 to 16 V

Engine switch on

(IG) (Engine

stopped)

IG SOURCE

VOL

IG power source

voltage/Min.: 0 V, Max.:

25.5 V

9 to 16 V

Engine switch on

(IG) (Engine

stopped)

TERMINAL

VOL U

Terminal voltage U/Min.: 0

V, Max.: 25.5 V

0 to 16 V

Turning the

steering wheel

changes the value

(with the engine

running and the

VGRS system

operating)

TERMINAL

VOL V

Terminal voltage V/Min.: 0

V, Max.: 25.5 V

0 to 16 V

Turning the

steering wheel

changes the value

(with the engine

running and the

VGRS system

operating)

TERMINAL

VOL W

Terminal voltage W/Min.:

0 V, Max.: 25.5 V

0 to 16 V

Turning the

steering wheel

changes the value

(with the engine

running and the

VGRS system

operating)

LOCK

OUTPUT VOL

Lock motor output

voltage/Min.: 0 V, Max.:

25.5 V

9 to 16 V

Engine switch on

(IG) (Engine

stopped)

THERMISTOR

TEMP

Thermistor

temperature/Min.: -50C,

Max.: 205C

-50 to 150C

When the VGRS

system operates

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

DUTY VAL

Command value DUTY

for PVM control/Min.: 0%,

Max.: 100%

0 to 100%

When the VGRS

system operates

LOCK DUTY

VAL

Command value DUTY

for actuator lock

control/Min.: 0%, Max.:

100%

Less than 10%

Engine switch on

(IG)

STRAIGHT

ANG FLG (*1)

Straight steering angle

valid flag/VALID or

INVALID

VALID or

INVALID

Immediately after

connecting the

battery terminal

ACT TEMP

EST

Actuator estimation

temperature/Min.: -50C,

Max.: 205C

-50 to 150C

When the VGRS

system operates

MTR

OVERHEAT

(*2)

Record of continuous

overheat preventive

control/Rec or Unrec

Rec or Unrec

MTR LOW

POWER (*2)

Record of low motor

power source voltage/Rec

or Unrec

Rec or Unrec

MTR HIGH

POWER (*2)

Record of high motor

power source voltage/Rec

or Unrec

Rec or Unrec

# CODE

The number of

DTCs/Max.: 0, Min.: 255

0 to 255

TEST MODE

STAT

Test mode status/Normal

mode or Test mode

Normal mode or

Test mode

MODE STATE

Mode State/00, 01, 02,

03, 04, 05, 06, 07, 08, 09,

0A, 0B, 0C, 0D, 0E, 0F,

10 00, 01, 02, 03, 04, 06,

07, 08, 09, 0A, 0B, 0C,

0D, 0E, 0F, 10

00, 01, 02, 03,

04, 05, 06, 07,

08, 09, 0A, 0B,

0C, 0D, 0E, 0F,

10 00, 01, 02,

03, 04, 06, 07,

08, 09, 0A, 0B,

0C, 0D, 0E, 0F

or 10

NOTE: *1: This data must be "VALID"

before proceeding with any steering adjustment.

If "INVALID" is displayed, perform steering

angle sensor initialization procedure.

Alternatively, if the steering actuator or steering

control ECU has been replaced, perform VGRS

system calibration (steering angle adjustment).

HINT:

*2: If "Rec" is displayed, enter the VGRS menu on the intelligent tester, select record clearance,

and follow the prompts to set to "Unrec".

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If a trouble code is displayed during the DTC check, check the circuit indicated by the DTC. For details of each

code, proceed to the page for the respective "DTC No." in the following DTC chart.

Variable Gear Ratio Steering System

DIAGNOSTIC TROUBLE CODE CHART

38 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

DTC No.

C1591/51

Detection Item

Actuator Neutral Position Calibration Undone

Trouble Area

1. Steering actuator

2. Steering control ECU

C1592/52

Actuator Neutral Position Calibration

Incomplete

1. Steering actuator

2. Steering control ECU

C1593/53

Actuator Standard Position Malfunction

C1595/55

Lost Communication with Steering Angle

Sensor Module

1. Steering actuator

1. Steering angle sensor

2. Steering control ECU

3. Wire harness and connector

C1597/57

Lost Communication between VGRS and EPS

1. Power steering ECU

2. Steering control ECU

3. CAN communication system

(Local CAN)

C15A1/61

Actuator Malfunction

1. Wire harness and connector

2. Steering actuator

3. Steering control ECU

C15A2/62

Actuator Malfunction

1. Wire harness and connector

2. Power source circuit

3. Steering actuator

4. Steering control ECU

C15A3/63

Actuator Malfunction

1. Wire harness and connector

2. Steering actuator

3. Steering control ECU

C15A4/64

Actuator Malfunction

C15A5/65

Actuator Malfunction

1. Steering actuator

1. Steering actuator

2. Steering control ECU

C15A6/62

Actuator Malfunction

1. Power source circuit

2. Wire harness and connector

39 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

3. Steering actuator

4. Steering control ECU

C15A9/66

Lock Holder Deviation Detection

C15AA/66

Lock Mechanism Release Incomplete

C15AB/66

Lock Mechanism Insertion Malfunction

C15B1/71

ECU Malfunction

C15B2/72

ECU Malfunction

C15B3/73

ECU Malfunction

C15B4/71

ECU Malfunction

C15C1/74

Steering Angle Sensor Malfunction

1. Steering actuator

1. Steering actuator

1. Steering actuator

1. Steering control ECU

1. Steering control ECU

1. Steering control ECU

1. Steering control ECU

1. Steering angle sensor

2. CAN communication system

3. Steering control ECU

C15C2/74

Steering Angle Sensor B+ Malfunction

1. Steering angle sensor

2. CAN communication system

3. Steering control ECU

C15C3/75

Brake System Control Module Malfunction

1. Skid control ECU

2. CAN communication system

3. Steering control ECU

C15C4/74

Steering Angle Signal (Test Mode DTC)

1. Steering angle sensor

2. Steering control ECU

C15C5/75

Motor Revolution Angle Signal (Test Mode

DTC)

1. Steering angle sensor

2. Steering control ECU

C15C6/77

IG Power Supply Voltage Malfunction

1. ECU-IG fuse

2. IG circuit

3. Charging system

4. Steering control ECU

40 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

C15C7/78

DC Motor Power Source Voltage Malfunction

1. VGRS fuse

2. Power source circuit

3. Steering control ECU

C15C8/79

Power Supply Relay Failure

1. VGRS fuse

2. Steering control ECU

U0100/56

Lost Communication with ECM / PCM "A"

1. ECM

2. CAN communication system

U0122/56

Lost Communication with Vehicle Dynamics

Control Module

1. Skid control ECU

2. CAN communication system

U0123/56

Lost Communication with Yaw Rate

(Deceleration) Sensor Module

1. Yaw rate (deceleration) sensor

2. CAN communication system

U0126/56

Lost Communication with Steering Angle

Sensor Module

1. Steering position sensor

2. CAN communication system

U0131/56

Lost Communication with Power Steering

Control Module

1. Power steering ECU

2. CAN communication system

DTC C1591/51 Actuator Neutral Position Calibration Undone

DESCRIPTION

If the steering control ECU or steering actuator is replaced, or if the tie-rod ends are adjusted, VGRS system

calibration is required. If the steering control ECU detects that steering angle adjustment is incomplete, it will store

DTC C1591/51.

DTC DETECTING CONDITION CHART

DTC No.

C1591/51

DTC Detecting Condition

The steering control ECU detects that

steering angle adjustment is incomplete.

Procedure

There is no malfunction if this DTC is not output

again after performing VGRS system calibration.

1. CHECK DTC

a. Check for DTCs (See TERMINALS OF ECU ).

OK:

DTC C1591/51 only is output.

NG : REPAIR CIRCUIT INDICATED BY DTC OUTPUT

OK : GO TO NEXT STEP

2. PERFORM VGRS SYSTEM CALIBRATION

a. Perform VGRS system calibration (See INITIALIZATION ).

41 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

NEXT

3. CHECK DTC

a. Check for DTCs (See TERMINALS OF ECU ).

Result

RESULT SPECIFICATION

Result

Proceed to

DTC is not output.

DTC C1592/52 is output.

DTC C1593/53 is output.

B : GO TO DTC C1592/52

C : GO TO DTC C1593/53

A : END

DTC C1592/52 Actuator Neutral Position Calibration Incomplete

DESCRIPTION

The steering control ECU first checks the actuator angle neutral position calibration flag after entering test mode. If

the ECU detects that steering actuator angle neutral position calibration is incomplete twice, it will store DTC

C1592/52.

DTC DETECTING CONDITION CHART

DTC No.

C1592/52

DTC Detecting Condition

The steering control ECU detects that steering actuator angle

neutral position calibration is incomplete, twice.

Trouble Area

Steering

actuator

Steering

control ECU

1. CLEAR DTC

a. Clear the DTCs (See TERMINALS OF ECU ).

NEXT

2. PERFORM VGRS SYSTEM CALIBRATION

a. Perform VGRS system calibration (See INITIALIZATION ).

NEXT

3. CHECK DTC

a. Check for DTCs (See TERMINALS OF ECU ).

OK:

DTC C1592/52 is not output.

NG : Go to step 4

OK : END

4. CHECK DTC

a. Check for DTCs (See TERMINALS OF ECU ).

42 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Result

RESULT SPECIFICATION

Proceed

to

Result

DTC C15B2/72 is output.

DTC C1592/52 is output after VGRS system calibration has been performed

less than 3 times.

DTC 1592/52 is output after VGRS system calibration has been performed

3 times or more.

A : REPLACE STEERING CONTROL ECU

B : Go to step 1

C : REPLACE STEERING ACTUATOR

DTC C1593/53 Actuator Standard Position Malfunction

DESCRIPTION

If the steering control ECU detects a steering actuator standard position error, it will store DTC C1593/53.

DTC DETECTING CONDITION CHART

DTC No.

C1593/53

DTC Detecting Condition

Trouble Area

The steering control ECU detects a steering actuator standard

position error.

Steering

actuator

1. CHECK DTC

a. Check for DTCs (See TERMINALS OF ECU ).

OK:

DTC C1593/53 is not output.

NG : REPLACE STEERING ACTUATOR

OK : END

DTC C1595/55 Lost Communication With Steering Angle Sensor Module; DTC C15C4/74 Steering Angle

Signal (Test Mode DTC)

DESCRIPTION

Signal transmission between the steering control ECU and steering angle sensor is performed via serial

communication.

If an error occurs between them in serial communication, the ECU will store DTC C1595/55.

DTC DETECTING CONDITION CHART

DTC No.

DTC Detecting Condition

Trouble Area

Steering angle

sensor

C1595/55

The steering control ECU detects an error in serial

communication between the ECU and steering angle sensor.

Wire harness and

connector

Steering control

43 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

ECU

WIRING DIAGRAM

Fig 31: Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1. CHECK STEERING ANGLE SENSOR

a. Check that a steering angle sensor with the specified part number is installed.

Standard:

A steering angle sensor with the specified part number (89245-30070) is installed.

NG : REPLACE STEERING ANGLE SENSOR

OK : GO TO NEXT STEP

2. CHECK WIRE HARNESS

a. Turn the engine switch off.

b. Disconnect the connectors from the steering control ECU and the steering angle sensor.

c. Measure the resistance according to the value(s) in the table below.

Resistance

TESTER CONNECTION SPECIFIED CONDITION CHART

Tester connection

Specified condition

K70-10 (SS1-) - K19-7 (SS1-)

Below 1

K70-19 (SS1+) - K19-8 (SS1+)

Below 1

K70-19 (SS1+) - Body ground

10 k or higher

K70-10 (SS1-) - Body ground

10 k or higher

K70-19 (SS1+) - K70-10 (SS1-)

1 k or higher

NG : REPAIR OR REPLACE WIRE HARNESS

44 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 32: Identifying K70 And K19 Connectors From Steering Control ECU And Steering Angle Sensor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK : GO TO NEXT STEP

3. CHECK STEERING ANGLE SENSOR

a. Connect the connector to the steering angle sensor.

b. Adjust the shift lever to neutral.

c. Jack up the vehicle.

d. Turn the engine switch on (IG).

e. Check the signal waveform according to the condition in the table below.

Voltage

TESTER CONNECTION SPECIFIED CONDITION CHART

Tester connection

45 of 87

Condition

Specified condition

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

K70-19 (SS1+) K70-10 (SS1-)

Engine switch on (IG), rotate

steering wheel slowly

Pulse generation (0

--> 5 V)

HINT:

The output voltage should fluctuate up and down similarly to the diagram on the left when the

wheel is turned slowly.

NG : REPLACE STEERING ANGLE SENSOR

Fig 33: Connecting Connector To Steering Angle Sensor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK : REPLACE STEERING CONTROL ECU

DTC C1597/57 Lost Communication Between VGRS And EPS

DESCRIPTION

The steering control ECU receives signals from the power steering ECU via local CAN communication. If the

steering control ECU cannot receive signals from the power steering ECU correctly via local CAN communication, it

will store DTC C1597/57.

46 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

DTC DETECTING CONDITION CHART

DTC No.

C1597/57

DTC Detecting Condition

The steering control ECU detects a reception error of

signals from the power steering ECU via local CAN

communication.

Trouble Area

CAN communication

system (Local CAN)

Power steering ECU

Steering control ECU

WIRING DIAGRAM

Fig 34: Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1. CHECK WIRE HARNESS

a. Disconnect the connectors from the steering control ECU and the power steering ECU.

b. Measure the resistance according to the value(s) in the table below.

Resistance

TESTER CONNECTION SPECIFIED CONDITION CHART

Tester connection

Specified condition

A40-4 (CAN+) - A23-1 (CAN+)

Below 1

A40-9 (CAN-) - A23-8 (CAN-)

Below 1

A40-4 (CAN+) - A40-9 (CAN-)

10 k or higher

NG : REPAIR OR REPLACE WIRE HARNESS

47 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 35: Identifying Connectors From Steering Control ECU And Power Steering ECU

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK : GO TO NEXT STEP

2. REPLACE POWER STEERING ECU

a. Replace the power steering ECU.

b. Connect the connectors to the steering control ECU and the power steering ECU.

c. Check for DTCs in the steering control ECU (See TERMINALS OF ECU ).

OK:

DTC C1597/57 is not output.

NG : REPLACE STEERING CONTROL ECU

OK : END

DTC C15A1/61 Actuator Malfunction

DESCRIPTION

48 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

The steering control ECU drives the actuator while the steering wheel is turned to set the gear ratio. It detects the

current flowing into the actuator motor driving circuit.

If the steering control ECU detects excessive current, it will store this DTC C15A1/61, turn on the master warning

light, and stop VGRS operation.

DTC DETECTING CONDITION CHART

DTC No.

DTC Detecting Condition

Trouble Area

Wire harness and

connector

C15A1/61

Excessive current (exceeding the estimated amount) flows

due to a malfunction in the motor drive circuit.

Steering actuator

Steering control

ECU

WIRING DIAGRAM

Fig 36: Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

When DTC C15A2/62 is output, a short circuit inside the steering actuator or inside the steering control ECU is

suspected.

1. CHECK WIRE HARNESS

a. Turn the engine switch off.

b. Disconnect the connectors from the steering control ECU and the steering actuator.

c. Measure the resistance according to the value(s) in the table below.

Resistance

TESTER CONNECTION SPECIFIED CONDITION CHART

49 of 87

Tester connection

Specified condition

K69-1 (BMV) - K69-2 (BMU)

10 k or higher

K69-1 (BMV) - K69-3 (BMW)

10 k or higher

K69-2 (BMU) - K69-3 (BMW)

10 k or higher

K69-1 (BMV) - Body ground

10 k or higher

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

K69-2 (BMU) - Body ground

10 k or higher

K69-3 (BMW) - Body ground

10 k or higher

Fig 37: Identifying K69 Connector From Steering Control ECU

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG : REPAIR OR REPLACE WIRE HARNESS

OK : GO TO NEXT STEP

2. CHECK STEERING ACTUATOR

a. Connect the connector to the steering actuator.

b. Measure the resistance according to the value(s) in the table below.

Resistance

TESTER CONNECTION SPECIFIED CONDITION CHART

Tester connection

Specified condition

K69-1 (BMV) - Body ground

10 k or higher

K69-2 (BMU) - Body ground

10 k or higher

K69-3 (BMW) - Body ground

10 k or higher

NG : REPLACE STEERING ACTUATOR

50 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 38: Connecting Connector To Steering Actuator

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK : REPLACE STEERING CONTROL ECU

DTC C15A2/62 Actuator Malfunction; DTC C15A6/62 Actuator Malfunction

DESCRIPTION

The steering control ECU drives the actuator based on steering angle sensor signals and vehicle speed signals.

If the steering control ECU detects excessive current flowing into the steering actuator, or an internal malfunction, it

will turn on the master warning light, store DTC C15A2/62, and stop VGRS operation. If the steering control ECU

detects a malfunction in the pre-driver circuit, it will turn the master warning light on, store DTC C15A6/62, and stop

VGRS operation.

DTC DETECTING CONDITION CHART

DTC No.

DTC Detecting Condition

Trouble Area

Wire harness and

connector

C15A2/62

The VGRS system detects a malfunction in the motor

drive circuit.

Power source circuit

Steering actuator

Steering control ECU

Power source circuit

C15A6/62

The actual motor current value greatly differs from the

estimated value.

Wire harness and

connector

Steering actuator

Steering control ECU

51 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

WIRING DIAGRAM

Fig 39: Actuator Malfunction - Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

The actuator only can be checked in this procedure. If it is normal, the steering control ECU is faulty.

1. CHECK WIRE HARNESS (POWER SOURCE CIRCUIT)

a. Turn the engine switch off.

b. Measure the resistance according to the value(s) in the table below.

Resistance

TESTER CONNECTION SPECIFIED CONDITION CHART

Tester connection

Specified condition

A40-7 (PGND) - Body ground

Below 1

c. Turn the engine switch on (IG).

d. Measure the voltage according to the value(s) in the table below.

Voltage

TESTER CONNECTION SPECIFIED CONDITION CHART

52 of 87

Tester connection

Specified condition

A40-8 (PIG) - Body ground

10 to 14 V

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 40: Identifying Wire Harness (Power Source Circuit)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG : REPAIR OR REPLACE WIRE HARNESS

OK : GO TO NEXT STEP

2. CHECK WIRE HARNESS

a. Turn the engine switch off.

b. Disconnect the connectors from the steering control ECU and the steering actuator.

c. Measure the resistance according to the value(s) in the table below.

Resistance

TESTER CONNECTION SPECIFIED CONDITION CHART

Tester connection

Specified condition

K69-1 (BMV) - K69-2 (BMU)

10 k or higher

K69-1 (BMV) - K69-3 (BMW)

10 k or higher

K69-2 (BMU) - K69-3 (BMW)

10 k or higher

K69-1 (BMV) - K26-5 (BMV+)

Below 1

K69-2 (BMU) - K26-4 (BMU+)

Below 1

K69-3 (BMW) - K26-13 (BMW+)

Below 1

K69-1 (BMV) - Body ground

10 k or higher

K69-2 (BMU) - Body ground

10 k or higher

K69-3 (BMW) - Body ground

10 k or higher

NG : REPAIR OR REPLACE WIRE HARNESS

53 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 41: Identifying Connectors From Steering Control ECU And Steering Actuator

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK : GO TO NEXT STEP

3. CHECK STEERING ACTUATOR

a. Connect the connector to the steering actuator.

b. Measure the resistance according to the value(s) in the table below.

Resistance

TESTER CONNECTION SPECIFIED CONDITION CHART

54 of 87

Tester connection

Specified condition

K69-1 (BMV) - K69-2 (BMU)

Below 1

K69-1 (BMV) - K69-3 (BMW)

Below 1

K69-2 (BMU) - K69-3 (BMW)

Below 1

K69-1 (BMV) - Body ground

10 k or higher

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

K69-2 (BMU) - Body ground

10 k or higher

K69-3 (BMW) - Body ground

10 k or higher

NG : REPLACE STEERING ACTUATOR

Fig 42: Connecting Connector To Steering Actuator

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK : GO TO NEXT STEP

4. CHECK DTC

a. Connect the intelligent tester to the DLC3.

b. Turn the engine switch on (IG) and turn the intelligent tester on.

c. Check for DTCs (See TERMINALS OF ECU ).

OK:

DTC C15A1/61 is not output.

NG : REPLACE STEERING ACTUATOR

OK : REPLACE STEERING CONTROL ECU

DTC C15A3/63 Actuator Malfunction; DTC C15C5/75 Motor Revolution Angle Signal (Test Mode DTC)

DESCRIPTION

The steering actuator drives the internal motor using the current output from the steering control ECU to change the

relative angle between tire angle and steering wheel angle.

The rotation angle sensor in the steering actuator detects the motor rotation angle and outputs this information to

the steering control ECU.

If the steering control ECU detects a malfunction in the rotation angle sensor circuit, it will store DTC C15A3/63.

DTC DETECTING CONDITION CHART

55 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

DTC No.

C15A3/63

DTC Detecting Condition

The steering control ECU detects a malfunction in the

rotation angle sensor circuit.

Trouble Area

Wire harness and

connector

Steering actuator

Steering control ECU

WIRING DIAGRAM

Fig 43: Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1. CHECK WIRE HARNESS

a. Turn the engine switch off.

b. Disconnect the connectors from the steering control ECU and the steering actuator.

c. Measure the resistance according to the value(s) in the table below.

Resistance

TESTER CONNECTION SPECIFIED CONDITION CHART

56 of 87

Tester connection

Specified condition

K70-4 (S1) - K26-5 (S1+)

Below 1

K70-6 (RV) - K26-1 (RV+)

Below 1

K70-14 (S2) - K26-9 (S2+)

Below 1

K70-15 (RG) - K26-10 (RG+)

Below 1

K70-4 (S1) - K70-6 (RV)

10 k or higher

K70-4 (S1) - K70-14 (S2)

10 k or higher

K70-4 (S1) - K70-15 (RG)

10 k or higher

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

K70-6 (RV) - K70-14 (S2)

10 k or higher

K70-6 (RV) - K70-15 (RG)

10 k or higher

K70-14 (S2) - K70-15 (RG)

10 k or higher

K70-4 (S1) - Body ground

10 k or higher

K70-6 (RV) - Body ground

10 k or higher

K70-14 (S2) - Body ground

10 k or higher

K70-15 (RG) - Body ground

10 k or higher

NG : REPAIR OR REPLACE WIRE HARNESS

Fig 44: Identifying K70 And K26 Connectors From Steering Control ECU And Steering Actuator

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK : GO TO NEXT STEP

2. CHECK STEERING ACTUATOR

a. Connect the connector to the steering actuator.

57 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

b. Measure the resistance according to the value(s) in the table below.

Resistance

TESTER CONNECTION SPECIFIED CONDITION CHART

Tester connection

Specified condition

K70-4 (S1) - K70-6 (RV)

Below 100

K70-4 (S1) - K70-14 (S2)

Below 100

K70-4 (S1) - K70-15 (RG)

Below 100

K70-6 (RV) - K70-14 (S2)

Below 100

K70-6 (RV) - K70-15 (RG)

Below 100

K70-14 (S2) - K70-15 (RG)

Below 100

K70-4 (S1) - Body ground

10 k or higher

K70-6 (RV) - Body ground

10 k or higher

K70-14 (S2) - Body ground

10 k or higher

K70-15 (RG) - Body ground

10 k or higher

NG : REPLACE STEERING ACTUATOR

Fig 45: Connecting K70 Connector To Steering Actuator

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK : REPLACE STEERING CONTROL ECU

DTC C15A4/64 Actuator Malfunction; DTC C15A9/66 Lock Holder Deviation Detection; DTC C15AA/66 Lock

Mechanism Release Incomplete; DTC C15AB/66 Lock Mechanism Insertion Malfunction

DESCRIPTION

When the VGRS system is normal, the steering actuator conducts current from the steering control ECU to the

58 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

steering actuator solenoid to release the lock mechanism, enabling motor operation. The steering actuator does not

operate under either of the following conditions:

The engine is off.

The motor in the actuator is locked by the lock mechanism to prevent rotation. (Fail-safe function)

The system is being protected from overheating. (Fail-safe function)

If the steering control ECU detects a malfunction in the steering actuator lock mechanism or a motor rotation angle

error, it will store these DTCs.

DTC DETECTING CONDITION CHART

DTC No.

DTC Detecting Condition

Trouble Area

C15A4/64

The steering control ECU detects that the difference between the

actuator target angle and the actuator position is approximately 30

or more for 1 second.

Steering

actuator

C15A9/66

The steering control ECU detects that the lock pin is not aligned

with the lock holder correctly.

Steering

actuator

C15AA/66

The steering control ECU cannot operate because the actuator lock

cannot be released.

Steering

actuator

C15AB/66

The steering control ECU detects that the lock pin cannot be

inserted into the lock holder.

Steering

actuator

1. REPLACE STEERING ACTUATOR

NEXT

END

DTC C15A5/65 Actuator Malfunction

DESCRIPTION

If the steering control ECU detects a malfunction in the lock mechanism, it will turn the master warning light on, store

the DTC C15A5/65, and stop VGRS operation.

DTC DETECTING CONDITION CHART

DTC No.

C15A5/65

DTC Detecting Condition

The steering control ECU detects that the LG terminal

voltage is abnormal.

Trouble Area

Wire harness and

connector

Steering actuator

Steering control ECU

WIRING DIAGRAM

59 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 46: Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1. CHECK WIRE HARNESS

a. Turn the engine switch off.

b. Disconnect the connectors from the steering control ECU and the steering actuator.

c. Measure the resistance according to the value(s) in the table below.

Resistance

TESTER CONNECTION SPECIFIED CONDITION CHART

Tester connection

Specified condition

K70-3 (LV) - K26-7 (LV+)

Below 1

K70-12 (LG) - K26-16 (LG+)

Below 1

K70-3 (LV) - Body ground

10 k or higher

K70-12 (LG) - Body ground

10 k or higher

d. Turn the engine switch on (IG).

e. Measure the voltage according to the value(s) in the table below.

Voltage

TESTER CONNECTION SPECIFIED CONDITION CHART

Tester connection

Specified condition

K70-3 (LV) - Body ground

Below 1 V

K70-12 (LG) - Body ground

Below 1 V

NG : REPAIR OR REPLACE WIRE HARNESS

60 of 87

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

Fig 47: Identifying K70 And K26 Connectors From Steering Control ECU And Steering Actuator

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK : GO TO NEXT STEP

2. CHECK STEERING ACTUATOR

a. Turn the engine switch off.

b. Connect the connector to the steering control ECU.

c. Measure the resistance according to the value(s) in the table below.

Resistance

TESTER CONNECTION SPECIFIED CONDITION CHART

61 of 87

Tester connection

Specified condition

K26-7 (LV+) - K26-16 (LG+)

10 to 100

K26-7 (LV+) - Body ground

10 k or higher

K26-16 (LG+) - Body ground

10 k or higher

12/22/2014 1:53 PM

Printer Friendly View

http://www1.prodemand.com/Print/Index?content=article&module=...

NG : REPLACE STEERING ACTUATOR

Fig 48: Connecting K26 Connector To Steering Control ECU

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK : REPLACE STEERING CONTROL ECU

DTC C15B1/71 ECU Malfunction; DTC C15B2/72 ECU Malfunction; DTC C15B3/73 ECU Malfunction

DESCRIPTION