Académique Documents

Professionnel Documents

Culture Documents

Excellium Project - Standby Pump and Stainless Steel Tanks - NJD

Transféré par

musewejamesoumaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Excellium Project - Standby Pump and Stainless Steel Tanks - NJD

Transféré par

musewejamesoumaDroits d'auteur :

Formats disponibles

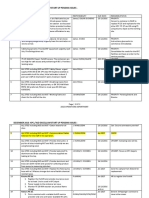

TOTAL KENYA LTD.

Bills of

Quantities

P.O. BOX 30736

NAIROBI, KENYA

TASK: SUPPLY AND INSTALLATION OF STANDBY PUMP AND ADDITIVE TANKS

LOCATION: NJD - WOD

CONTRACTOR

ELECTROMAG ENGINEERING

DATE:30/12/2016

Item

Description

Unit

Quantity

XL1.25 Blackmer vane Standby additive

dosing pump c/w Ex plosion proof

motor(ATEX rating , CE Ex II 2G Ex d IIA

T4 Gb, with IP67 Enclosure), coupling,

guard and baseplate. DN 32( 1 1/4 ")

Suction and delivery ports. NB: Skid frame

fabricated from 2" by 4" by 6mm Channel

section c/w bolting holes and anchor bolts.

No.

Pump START - STOP Switch in All

weather Explosion proof (ATEX rating , CE

Ex II 2G Ex d IIA T4 Gb, with IP67

Enclosure)

No.

DOL Starter control panel for pump in all

weather enclosure at NJD Power house.

No.

Rate

( Kshs)

Amount

( Kshs)

NB: Contractor MUST confirm all

dimensions on site and on attached site

layout drawing before commencing any

work. Project valuation will be on "AsBuilt" basis.

A)

SCOPE OF WORKS:

Standby Dosing pump

Supply and install

1.1)

1.2)

1.3)

409,500.00

409,500

65,400.00

65,400

65,400.00

65,400

1.4)

1.5)

1.6)

Supply and lay 1.5mm SWA cable for

control circuit between pump flame proof

switch and control panel through existing

cable trays and ducts

LM

Supply and lay 2.5mm SWA cable for

power circuit between pump motor and

control panel through existing cable ducts

and trays

LM

150

37,500.00

250

417,000.00

150

2,780

Allow for tie in as standby to either PMS or

AGO dosing system by supplying and

installing the following:-

1.6.1)

1.6.2)

1.6.3)

1.6.4)

1.6.5)

1.6.6)

1.6.7)

1.6.8)

1.6.9)

1 1/4" Sch 40, ASTM A 312M / A 312,

bevelled, Seamless and welded austenetic

stainless steel line pipe

LM

1" Sch 40, ASTM A 312M / A 312,

bevelled, Seamless and welded austenetic

stainless steel line pipe

LM

1 1/4" Sch 40, bevelled, Seamless,

stainless steel, 90 degree Elbows

No.

1" Sch 40, bevelled, Seamless, stainless

steel, 90 degree Elbows

No.

1 1/4" NPT, ANSI Class 150, Cast, A

316L, Stainless steel Ball valves

No.

1" NPT, ANSI Class 150, Cast, A 316L,

Stainless steel Ball valves

No.

1/2" NPT, ANSI Class 150, Cast, A 316L,

Stainless steel Ball valves

No.

1" NPT, ANSI Class 150, Cast, A 316L,

Stainless steel Check valves

No.

1 1/4" NPT, ANSI Class 150, Cast, A 316L

, Y strainer

No.

23,640.00

7,880

24,480.00

4,080

8,400.00

4,200

14,850.00

1,650

9,720.00

9,720

9,720.00

4,860

2,430.00

2,430

2,700.00

2,700

4,470.00

4,470

1.6.10) 1 1/4" NPT, Sch 40, bevelled, Seamless,

stainless steel sockets

No.

1.6.11) 1" NPT, Sch 40, bevelled, Seamless,

stainless steel sockets

No.

1.6.12) 1 1/4" NPT, Sch 40, Seamless, stainless

steel Nipples

No.

1.6.13) 1 1/4" NPT, Sch 40, stainless steel Unions

No.

4,130.00

4,130

1,275.00

1,275

3,000.00

3,000

4,500.00

4,500

1.6.14) 1" NPT, Sch 40, stainless steel Unions

No.

4,500.00

2,250

1.6.15) 1" Sch 40, bevelled, Seamless, stainless

steel, 90 degree Tees

No.

1.6.16) 1" NPT, Sch 40, Seamless, stainless steel

Nipples

No.

1.6.16) 1/2" NPT, Sch 40, Seamless, stainless

steel Nipples

No.

1.6.17) Supply and install 4" Dial Wika, oil filled

bottom process connection pressure

guage to pump discharge

No.

1.7)

Hack pump floor a depth not exceeding

200mm, fabricate appropriate sawn

formwork, and cast reinforced concrete

plinths for dosing pumps. NB:

Reinforcement schedule to be determined

as per pump specifications with reference

to Eurocode 2 code.

5,250.00

2,625

3,000.00

750

1,350.00

675

14,000.00

14,000

Item

38,000.00

38,000

Stainless steel additive tanks

2.1)

2.2)

2.3)

Fabricate and install Welded stainless

steel tank measuring 1.2m by 1.2m by

1.5m for PMS additive storage c/w 2"

Outlet nozzle c/w 22 outlet ball valve ,

breather vent, 1 1/2" return line top nozzle,

6" top manhole, 2" top filling nozzle and

level gauge ( In graduations of 5 litres) on

existing concrete plinth. NB: 6mm shell

plate of A 316L, Stainless steel.

No.

Fabricate and install Welded stainless

steel tank measuring 1.2m by 1.2m by

1.5m for AGO additive storage c/w 2"

Outlet nozzle c/w 22 outlet ball valve ,

breather vent, 1 1/2" return line top nozzle,

6" top manhole, 2" top filling nozzle and

level gauge ( In graduations of 5 litres) on

existing concrete plinth. NB: 6mm shell

plate of A 316L, Stainless steel.

No.

Supply and install Corossion resistant

flexible hoses for additive transfer from

navicube to tank using existing client rotary

transfer pumps.

No.

SUB-TOTAL 1

Add VAT @ 16%

GRAND TOTAL

ENG. PAUL MAKAU:

768,000.00

768,000

768,000.00

768,000

48,700.00

48,700

2,758,915.00

441,426.40

3,200,341.40

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- 3 - Hdpe - Itp Pipe WeldingDocument2 pages3 - Hdpe - Itp Pipe Weldingasif712100% (6)

- Heat Treatment ProcessesDocument61 pagesHeat Treatment ProcessesMadhubalan100% (1)

- MARITIME COMMERCE (Arts. 573-869) : R.A. 6106 P.D. 1521Document10 pagesMARITIME COMMERCE (Arts. 573-869) : R.A. 6106 P.D. 1521JuliannaMendozaMalePas encore d'évaluation

- Fasteners1 PDFDocument3 pagesFasteners1 PDFmanishjain@live.inPas encore d'évaluation

- Boeing 727 Tech DetailsDocument6 pagesBoeing 727 Tech DetailsPourya100% (1)

- Anchor Bolt Design PhilosophyDocument6 pagesAnchor Bolt Design PhilosophyjiokoijikoPas encore d'évaluation

- 747-400 Vs 747-800 DifferencesDocument2 pages747-400 Vs 747-800 DifferencesJoão MiguelPas encore d'évaluation

- MSC Building Services EngineeringDocument7 pagesMSC Building Services EngineeringmusewejamesoumaPas encore d'évaluation

- Burhani Contract - Rev 1-16.11.8Document27 pagesBurhani Contract - Rev 1-16.11.8musewejamesoumaPas encore d'évaluation

- Bucket Elevator ManualDocument37 pagesBucket Elevator ManualEdwin MarsigliaPas encore d'évaluation

- PETRONASDocument29 pagesPETRONASAisyah RashidPas encore d'évaluation

- Textile and Apparel Supply ChainDocument30 pagesTextile and Apparel Supply ChainPawan KumarPas encore d'évaluation

- Inv04a-Lhc Detection enDocument2 pagesInv04a-Lhc Detection enmusewejamesoumaPas encore d'évaluation

- 00569420181106140644Document1 page00569420181106140644musewejamesoumaPas encore d'évaluation

- Air CompressorsDocument8 pagesAir CompressorsmusewejamesoumaPas encore d'évaluation

- Gapco Terminal InspectionDocument18 pagesGapco Terminal InspectionmusewejamesoumaPas encore d'évaluation

- Car and General Contract Servicing of Generators 2016 2019Document20 pagesCar and General Contract Servicing of Generators 2016 2019musewejamesoumaPas encore d'évaluation

- As Built Valuation For Fire Drill Ramp Works - 1.11.18Document1 pageAs Built Valuation For Fire Drill Ramp Works - 1.11.18musewejamesoumaPas encore d'évaluation

- Access Controls Cost Estimates - A1-3d37dDocument5 pagesAccess Controls Cost Estimates - A1-3d37dmusewejamesoumaPas encore d'évaluation

- List of Critical Safety Barriers: NO.s Code LocationsDocument2 pagesList of Critical Safety Barriers: NO.s Code LocationsmusewejamesoumaPas encore d'évaluation

- List of Critical Safety Barriers: NO.s Code LocationsDocument2 pagesList of Critical Safety Barriers: NO.s Code LocationsmusewejamesoumaPas encore d'évaluation

- Diploma HseDocument1 pageDiploma HsemusewejamesoumaPas encore d'évaluation

- Chain Link Fencing at Nrs - FinancialDocument1 pageChain Link Fencing at Nrs - FinancialmusewejamesoumaPas encore d'évaluation

- ContainmentDocument1 pageContainmentmusewejamesoumaPas encore d'évaluation

- Euler FlowDocument9 pagesEuler FlowmusewejamesoumaPas encore d'évaluation

- Changamwe LPG HLA Recalibration of Tanks - Status 29.08.17Document1 pageChangamwe LPG HLA Recalibration of Tanks - Status 29.08.17musewejamesoumaPas encore d'évaluation

- Boarding Pass: Ouma / James MRDocument1 pageBoarding Pass: Ouma / James MRmusewejamesoumaPas encore d'évaluation

- Nesvax Email CorrespondenceDocument1 pageNesvax Email CorrespondencemusewejamesoumaPas encore d'évaluation

- Analysis+ DMA 35 EX PetroDocument2 pagesAnalysis+ DMA 35 EX PetromusewejamesoumaPas encore d'évaluation

- Boarding Pass 2Document1 pageBoarding Pass 2musewejamesoumaPas encore d'évaluation

- 05148Document1 page05148musewejamesoumaPas encore d'évaluation

- Analysis Final Revised List of Sites Weighing Scales Final ListDocument1 pageAnalysis Final Revised List of Sites Weighing Scales Final ListmusewejamesoumaPas encore d'évaluation

- Electricmotors 1Document101 pagesElectricmotors 1musewejamesoumaPas encore d'évaluation

- Par - Changamwe LPG PlantDocument2 pagesPar - Changamwe LPG PlantmusewejamesoumaPas encore d'évaluation

- 03 Fluid Flow Rev PRN (Compatibility Mode)Document38 pages03 Fluid Flow Rev PRN (Compatibility Mode)musewejamesoumaPas encore d'évaluation

- LAPESADocument16 pagesLAPESAmusewejamesoumaPas encore d'évaluation

- This Was One of FrancoDocument10 pagesThis Was One of FrancomusewejamesoumaPas encore d'évaluation

- Edoc Corrective Action Plan 2016Document2 pagesEdoc Corrective Action Plan 2016musewejamesoumaPas encore d'évaluation

- Action Items at Roll OutDocument3 pagesAction Items at Roll OutmusewejamesoumaPas encore d'évaluation

- Region 8 Jackfruit Growers PDFDocument4 pagesRegion 8 Jackfruit Growers PDFCatherine tevesPas encore d'évaluation

- Market Prices On EUROPADocument2 pagesMarket Prices On EUROPAIoana CristinaPas encore d'évaluation

- AC Maintenance Companies OmanDocument46 pagesAC Maintenance Companies OmanMohsin KhanPas encore d'évaluation

- 8 - Integrating The Supply ChainDocument31 pages8 - Integrating The Supply ChainArunkumarPas encore d'évaluation

- Kha Ya Ready Kit PresentationDocument12 pagesKha Ya Ready Kit PresentationMujjo SahbPas encore d'évaluation

- Final PresentationDocument23 pagesFinal PresentationalijinbabaPas encore d'évaluation

- SCM in Automotive IndustryDocument2 pagesSCM in Automotive IndustrySachin PanpatilPas encore d'évaluation

- ASME B16.9 InterpretationDocument13 pagesASME B16.9 Interpretationkler_kathiaPas encore d'évaluation

- 1.0425 P265GH BOILER HTTP WWW - Ccsteels.com Structural Steel 37 PDFDocument2 pages1.0425 P265GH BOILER HTTP WWW - Ccsteels.com Structural Steel 37 PDFVaibhav GuptaPas encore d'évaluation

- Abstract Post TensionDocument4 pagesAbstract Post TensionDe Silva ShmapkPas encore d'évaluation

- StandardsDocument9 pagesStandardsmutawal1100% (1)

- Final Asian Paints SCMDocument25 pagesFinal Asian Paints SCMsanju0789Pas encore d'évaluation

- Standard Specification For Copper-Zinc-Aluminum-Cobalt Alloy, Copper-Zinc-Tin-Iron Alloy Plate, Sheet, Strip, and Rolled BarDocument5 pagesStandard Specification For Copper-Zinc-Aluminum-Cobalt Alloy, Copper-Zinc-Tin-Iron Alloy Plate, Sheet, Strip, and Rolled BarLorena JimenezPas encore d'évaluation

- RetrofittingDocument36 pagesRetrofittingNagesh ChitariPas encore d'évaluation

- Beer GameDocument11 pagesBeer GameYen Foo SoonPas encore d'évaluation

- Nova LiftDocument1 pageNova LiftFloorkitPas encore d'évaluation

- Shipping Management: By: Ahmed Muztuba MainuddinDocument22 pagesShipping Management: By: Ahmed Muztuba Mainuddinsubbu2raj3372Pas encore d'évaluation

- TESDA DownloadsDocument20 pagesTESDA DownloadsSalman Ranaw33% (3)