Académique Documents

Professionnel Documents

Culture Documents

Din 6930 2 PDF

Transféré par

Eduardo Perez0 évaluation0% ont trouvé ce document utile (0 vote)

794 vues9 pagesTitre original

155925598-DIN-6930-2 (1).pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

794 vues9 pagesDin 6930 2 PDF

Transféré par

Eduardo PerezDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 9

POC 669.14-411.13:621.96:621.753.1_ DEUTSCHE NORM April 1989

Steel stampings

General tolerances

Stanzteile aus Stahl; Allgemeintoleranzen ‘Supersedes Jenuary 1983 edition,

{a keeping with current practice in standards published by the International ‘Orgenization for Staniardizetion (180),

2 comma has been used throughout as the decimal marker.

Dimensions in mm.

1 Scope

{us Standard is intended to simplify drawings. It specifies general tolerances on linear and angular dimensions and on

Seely and symmetry in four sccuracy grades comprising # fine), m tedium). oeoeras on 9 (very coarse). When

‘electing a defined accuracy grade, the respective workshop accuracy isto be tater fone account,

{f smaller tolerances are required or if larger tolerances are permitted and more economical, these shall be indicated

adjacent to the relevant basic siz

2. Field of application

conditions).

General tolerances for parts

If, by way of exception, it is

finer then fat products, or fom materials other than see, ths shall be particulsly agregn

It is recommended that ths standard be applied in conjunction withthe specifications given in DIN 6932,

Zhe technioal delivery conditions for stampings are coverd by DIN 6930 Part 1.

Guidelines relating to general tolerances indicated on existing drawings are given in clause 6,

a

thot the pion permision of DIN Devtecha na

guage origina should bo conauod

3 General tolerances

3.1. General

Ge Seneral tolerances specified inthis standard take accountof the particular conditions. of stamping practice including

allowance for die wear.

{n the case of blanked stampings, the tolerances apply to the cut band (eee figure 1),

sheared face.

‘Actual size: length or diameter

Figure 1. Determination of actual size

Note. Where the position and sizeof the draw.in band, break band and burr may affect the functioning of the stamping,

tered ie ag 2areement shall be reached between manufacturer and purchaser, details of nich re ere

‘Depth of burr

y tieedin hese

2 EB] In the caso of stampings produced by nibbling (ef. DIN 8588), the actual size is the dimension measured over: the

Be ca| sentsot he unseen peerage

SBE] Ficwe 2. dotermination of actual size of stampings 3

= 3 Produced by nit 3

5 SS] The actual size of a stamping may p< ly be influenced by the tolerance on ‘thickness of the flat product used. In this

1 DE | connection, itis to be considered that the thickness of ae’ flat product may alter when subjected to bending or deep

= § drawing, Continued on pages 2 to 9

538

eu Yarieg Gb Bertin ha the exclusive ah of sat for Gorman Sananrds DuPNomonT DIN 6930 Part 2 Engl. Price group 9

03.90 Sates No, 0109

Page 2. DIN 6930 Part 2

3.2. General tolerances for flat stampings

Flat stampings are to be made exclusively from flat products by cutting (using @ shear or blanking tool). Cf. DIN 8588

for definition of cutting processes.

3.2.1 General tolerances for linear dimensions of flat stampings

‘The limit deviations specified in table 1 shall apply to al i ensions including the diameters of flat stampings

except for the radii of curvature, which are specified in subclause 3.2.2.

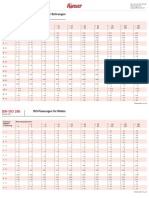

Table 1. Limit deviations for linear dimensions of flat stampings excluding radii of curvature

inal Limit deviations for thicknesses

stornge | A076 | 50, toot upte Somer up tower upto] ovr 10

t Hops | #008 | ot £02 £04

From 4 m £0 fos | #02 £08 04

= ® 9 £02 £08 £04 £06 £08

*0 £05 #05 ‘£08 #12 #15

t #008 | #04 £015 £02 £04

ovr 6 m ‘015 | #02 #025 #os #04

Seta io, 9° +03 £04 £05 £08 £08

9 £08 et #1 £15 £18

t £04 ot E018 £02 £04

Over 10 a 02 tos | x08 Hoa £06

meee 2 fos £05 £06 £08 at

9 Ht et E16 £15 #2

f fos tots | £02 £08 £04

terete = 028 | £08 £04 £05 #08

wo 68 ® ‘£05 £06 Pr at #12

30 #t Ht E15 #2 #8

t fos | sors | +02 #08 £04

over 63 m £03 tos £05 x06 |- +08

upto 160 ° £08 £08 at #12 #18

39 is #18 #2 #8 #8

t eon £03 £08 E04 £05

over 160 = £05 £06 £08 £08 E10

ee 100 @ et #12 Par Ete #2

30 #15 #2 £25 #8 #8

t £04 £04 £05 £08 £08

Over 400 m £08 ‘£08 #1 #1 218

E00: 2 216 £16 22 #2 zs

6 £25 £25 #3 #4 za

t E08 £08 £08 at Ht

Over 1000 ™ #12 E15 £18 #2 22

upto 6300 a £28 +25 +3 #4 #4

sa Fz] Pz Fz] Ht =A

fa)

oO

DIN 6930 Part 2. Page 3

3.2.2 General tolerances for radii of curvature of flat stampings

See table 2.

Table 2. Limit deviations for radii of curvature

sei aah ed Limit deviation for thicknesses

ius ie {from 0,1 to 1 forer 1 up to 3jover 3 up to Gover 6up to 10] over 10

aaaeaet tm £02 £03 £08 - -

wo 6

980 +04 £06 £10 - -

eee tm, £08 £04 £08 £08 -

upto 10

oe a9 £06 £08 £10 £12 -

eee aa tm, £04 £08 £06 £08 £10

wr 2

3.80 0p £10 £12 £18 £20

Paneer tm, £05 £08 £08 £10 #12

upto 6

‘ 3.0 £10 #12 #18 £20 per

ia tm, +08 £10 £12 £4 £18

upto 160

et 0.59 £18 £20 £24 £28 292

oaeteg tm, £10 #12 £18 £18 £20

eet 9.80 £20 #24 £30 £38 40

tm, £18 £20 #22 £25 £30

over 400

°0 £92 £40 a4 #50 £60

3.23 General tolerances for angular dimensions of flat stampings

‘General tolerances for angular dimensions of fat stampings shall apply irrespective of the actual linear dimensions, ie. the

“angulor deviations ore permitted both for workpieces with maximum material sizes and for those with minimum material

Sizes. The limit deviations do not affect the tolerances of form of the legs or faces enclosing an angle.

Table 3. Limit deviations for angular dimensions of flat stampings

Limit deviations for a nominal size of the shorter leg, in angular units

‘Accuracy

ease’ | From1 | Over 6 | Over 10 | Over 25 | Over 63 | Over 160 | Over 400] Over 1000

to 6 | upto10 | upto25 | upto63 | upto 160 | up to400 | up to 1000| up to 2500)

' ze ae | so | co | zo | so | ts | 28

m avo | avo | sso | sev | ta | tw | tt | 2

LL 99 +e £9 ae £P ar £0 £20 £20

3.2.4 General tolerances on coaxiality and symmetry of flat stampings

‘See ISO 1101 for the definitions of ‘coaxiality tolerance’ and ‘symmetry tolerance’ and the corresponding indications on

drawings.

3.2.4.1 Coaxiality

‘The nominal size of the largest of the related form elements is the size to be considered for the coaxiality tolerance. On

the basis of this nominal size, the coaxiality tolerance results from the difference between the upper and lower deviations

specified in table 1 for the accuracy grade concerned and the given thickness of the flat product.

Page 4 DIN 6930 Part 2

Example:

Concentric arrangement of outer and inner contours of a pierced disc (see figure 3).

Nominal size to be considered

to be considered for the coaxility tolerance

ickness of 2mm and accuracy grade m, the coaxi

Figure 3. Nominal si

‘Assuming a product

0.8mm.

ity tolerance is found from table 1 to be

3.2.4.2 Symmetry

‘The nominal size of the largest of the related form elements is the size to be considered for the symmetry tolerance. On

the basis of this nominal size, the symmetry tolerance results from the difference between the upper and lower deviations

specified in table 1 for the accuracy grade concerned and the given thickness of the flat product.

Example: ; EEE

‘Symmetrical arrangement of two notches and of a hole relative tothe sides of a rectangular strip (see figure 4).

4 48

3

KN 7

| e s

t + 04 + 06 + 08 a4 -

Dugg m + 08 a4 £12 15 -

eee ° #12 #2 £ 26 - -

2a + 16 £2 + 26 - -

‘ + 08 £ 08 at #12 £48

meee m 4 + 12 +15 £2 £28

peers 9 $2 £28 £4 - -

sa + 28 24 +4 - -

t + 08 a1 £12 £15 £2

loathe m £12 18 +2 #25 £4

eres. ° £28 £4 +6 - -

89 £4 26 26 - -

t £1 + 12 +18 £2 + 28

Over 63 m £15 £2 £28 24 £6

eee 8 £4 +6 £10 £15; £25

sa £6 +10 £10 £15 £25

t 412 £18 +2 ‘£25 £3

Over 160 m #2 + 28 #4 £6 £10

Pe earn a 46 £10 £15 £25 £40

30 £10 £15 £15 £25 £40

' 2 18 £2 + 28 +3 £4

Over 400 m + 28 24 £6 £10 218

pee tie ° £10 £15 425 £40 x)

89 £15 £25 $25 £40 £60

a

DIN 6930 Part 2 Page 7

3.3.3 General tolerances for angulsr dimensions of stampings manufactured by forming

General tolerances for angular dimensions of stampings manufactured by forming shall apply irrespective of the actual

linear dimensions, i.e. the angular deviations are permitted both for workpieces with maximum material sizes and those

with minimum material sizes. The limit deviations do not affect the tolerances of form of the legs of faces enclosing an

angle.

For angles produced by bending, the limit deviations specified in DIN 6936 for cold bent angles shall apply to all accuracy

‘grades.

Note. Since the present standard also covers hot formed stampings, the angular deviations specified in DIN 6935 apply to

‘these products as well.

3.3.4 General tolerances on cosxiality and symmotry of stampings manufactured by forming

‘The nominal size of the lergest of the related form elements is the size to be considered for the coaxiality and symmetry

tolerances. On the basis of this nominal size, the coaxiality and symmetry tolerances result from the difference between

the upper and lower deviations specified in table 4 for the accuracy grade concerned and the given thickness of the flat,

product.

Example:

‘Symmetrical arrangement of a hole

a bent channel (see figure 6)

100,

Nominal size to be conch d

Figure S. Nominal sizes to be considered for the symmetry tolerance

Assuming a product thickness of Smm and accuracy grade g, the symmetry tolerances for the hole axis are found

from table 4 to be 0,8mm in the longitudinal direction and 4,0.mm in the transverse direction.

Table 4 does not apply if the form elements for which a coaxial or symmetrical position is required are located in

different planes of the stamping.

4 Indication on drawings

Whenever general tolerances as specified in this standard are to be applied, the followir

drawing in the box provided for the purpose, e.g., when accuracy grade ‘medium (mn) is choser

General tolerance DIN 6930 — m

5 General tolerances in existing drawings

General tolerances as specified in this standard shall apply to new drawings. It is recommended that existing drawings be

amended by substituting previous tolerance indications by those specified in standard, If this is not possible and if

‘the previous indication ‘Tolerance as in DIN 6930’ is retained, then the limit deviations specified in the previous. ions

of DIN 6930 Parts 2 to4 shal apply.

Page 8 DIN 6930 Part 2

6 Special cases

“The specifications made in this clause shall apply to ail accuracy grades.

6.1 Straightness tolerance for strip and sections

For strip cut by shears and for sections bent from strip, the straightness tolerance shall not exceed the values spe

in table 6, this requirement being bated on a minimum ratio of strip width, b, to flat product thickness, 5, of 25 : 1. For

sections bent from strip, the tolerance given in table 6 shall apply for each longitudinal axis of the section.

Table 6. Straightness tolerance, n, for

and for sections bent from strip

ip cut by shears

estonia ‘Straightness tolerance, n

Up to 2000 1

‘Over 2000 up to 3000 225

‘Over 3000 up to 4000 4

‘Over 4000 up to 5000 825

‘Over 5000 up to 6000 8

Figure 6. Straightness of strip |

6.2 Warping of strip and sections

‘The warping, e/1, of strip cut by shears and of sections bent from strip shall not exceed 0,5° per 1000 mm of length (see

figure 7), this requirement being based on a minimum ratio of strip width, b, to flat product thickness, s, of 25: 1.

Figure 7.. Warping of strip

Vous aimerez peut-être aussi

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Diseño Industrial Mecánico Con CATIA V5-6 R2015Document11 pagesDiseño Industrial Mecánico Con CATIA V5-6 R2015Eduardo Perez0% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- VW 01088 EsDocument17 pagesVW 01088 EsEduardo Perez100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Cuadro ComparativoDocument3 pagesCuadro ComparativoEduardo PerezPas encore d'évaluation

- Solicitud BajaDocument1 pageSolicitud BajaEduardo PerezPas encore d'évaluation

- 0761 Sheet 14Document1 page0761 Sheet 14Eduardo PerezPas encore d'évaluation

- h18 71740 110Document1 pageh18 71740 110Eduardo PerezPas encore d'évaluation

- LT - 03 - Lineamiento para Maquinado de Piezas - Chicas R2016 (Autosaved1)Document28 pagesLT - 03 - Lineamiento para Maquinado de Piezas - Chicas R2016 (Autosaved1)Eduardo PerezPas encore d'évaluation

- Malla Metalica IrvingDocument1 pageMalla Metalica IrvingEduardo PerezPas encore d'évaluation

- Plan de Mantenimiento Preventivo TornoDocument51 pagesPlan de Mantenimiento Preventivo TornoEduardo Perez50% (2)

- Pendiente Proyecto APDocument2 pagesPendiente Proyecto APEduardo PerezPas encore d'évaluation

- Los Siguientes Modelos Presentan Zonas en Color GrisDocument1 pageLos Siguientes Modelos Presentan Zonas en Color GrisEduardo PerezPas encore d'évaluation

- 39d 578Document11 pages39d 578Eduardo PerezPas encore d'évaluation

- 2015 02 19 MAT Tepjf4a12 CDocument21 pages2015 02 19 MAT Tepjf4a12 CjulissaPas encore d'évaluation

- Reporte DimencionalDocument13 pagesReporte DimencionalEduardo PerezPas encore d'évaluation

- Plan de Mantenimiento Preventivo TornoDocument51 pagesPlan de Mantenimiento Preventivo TornoEduardo Perez50% (2)

- 11-59D 323327Document3 pages11-59D 323327Eduardo Perez0% (1)

- Din 6930Document9 pagesDin 6930Eduardo PerezPas encore d'évaluation

- MuellesDocument15 pagesMuellesAlvaroRoncalPas encore d'évaluation

- 11-38D974714 V00a B32099868Document3 pages11-38D974714 V00a B32099868Eduardo PerezPas encore d'évaluation

- Tooling Pgs A82 99Document18 pagesTooling Pgs A82 99Eduardo PerezPas encore d'évaluation

- Reporte 11002883-02Document3 pagesReporte 11002883-02Eduardo Perez100% (1)

- VW 326 LWB - 66-96D 313780 - KBB62Document1 pageVW 326 LWB - 66-96D 313780 - KBB62Eduardo PerezPas encore d'évaluation

- 39d 20671Document4 pages39d 20671Eduardo PerezPas encore d'évaluation

- Iso 286 S 2Document1 pageIso 286 S 2Eduardo PerezPas encore d'évaluation

- Pirateria y ContrabandoDocument4 pagesPirateria y ContrabandoEduardo PerezPas encore d'évaluation