Académique Documents

Professionnel Documents

Culture Documents

ASME Target Stress Values

Transféré par

shazanDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ASME Target Stress Values

Transféré par

shazanDroits d'auteur :

Formats disponibles

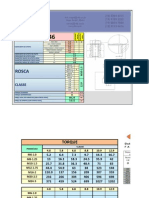

Table 1M Reference Values for Calculating Target Torque Values for Low-Alloy

Steel Bolting Based on Target Prestress of 345 MPa (Root Area) (SI Units)

(See section 12 for instructions on how to use this table.)

Target Torque, Nm

Basic Thread Designation

Noncoated Bolts [Note (1)]

Coated Bolts [Notes (1), (2), and (3)]

M14-2

M16-2

M20-2.5

M24-3

M27-3

M30-3

M33-3

M36-3

M39-3

M42-3

M45-3

M48-3

M52-3

M56-3

M64-3

M70-3

M76-3

M82-3

M90-3

M95-3

M100-3

110

160

350

550

800

1 150

1 550

2 050

2 650

3 350

4 200

5 100

6 600

8 200

12 400

16 100

20 900

26 400

35 100

41 600

48 500

85

130

250

450

650

900

1 200

1 600

2 050

2 550

3 200

3 900

5 000

6 300

9 400

12 200

15 800

20 000

26 500

31 500

36 700

GENERAL NOTE: The values shown are based on a Target Prestress of 345 MPa (root area). See section 12

(Target Torque Determination). The root areas are based on coarse-thread series for sizes M27 and smaller,

and 3 mm pitch thread series for sizes M30 and larger.

NOTES:

(1) Computed values are based on working surfaces that comply with section 4 (Cleaning and

Examination of Flange and Fastener Contact Surfaces) and section 7 (Lubrication of Working

Surfaces), and the following coefficients of friction: 0.16 for noncoated surfaces and 0.12 for new

coated surfaces. These coefficients were selected to make the computed Target Torques consistent

with that needed for a Target Prestress of 345 MPa as independently verified by accurate bolt

elongation measurements by several users. (See Appendix K for equivalent nut factors.)

(2) The coating on coated bolts is polyimide/amide and is considered to be the sole source of

working surface lubrication; the application of a lubricant to the coated surfaces can result in a

considerable reduction in the assumed coefficient of friction of 0.12. (See Appendix K for

equivalent nut factor.)

(3) Coated torque values apply only for initial tightening of new, coated bolts using the torqueincrement rounds shown in Table 2. For second and subsequent tightening by torquing methods,

use of lubricants and torque values as specified for noncoated bolts is recommended.

Vous aimerez peut-être aussi

- Torque ValuesDocument1 pageTorque Valuesakhilsyam21Pas encore d'évaluation

- Torque GuideDocument1 pageTorque GuideAlvinHoPas encore d'évaluation

- Torque Value For FastenersDocument1 pageTorque Value For Fastenersboracul2kPas encore d'évaluation

- ICEF2006-1566 PistonFriction Mahle-Brasil 2006Document7 pagesICEF2006-1566 PistonFriction Mahle-Brasil 2006Bogdan NeagoePas encore d'évaluation

- Mahindra StandardDocument6 pagesMahindra StandardSuresh Shinde67% (3)

- Torque Tension ControlDocument5 pagesTorque Tension ControlLéia FernandesPas encore d'évaluation

- Torque CalculatorDocument2 pagesTorque CalculatorDanhHoPas encore d'évaluation

- Bevel Gear PaperDocument6 pagesBevel Gear PaperIsmail IbrahimPas encore d'évaluation

- 01 - 50 - 912 - BDocument27 pages01 - 50 - 912 - Bh_eijy2743Pas encore d'évaluation

- 3012en PDFDocument560 pages3012en PDFmgualdiPas encore d'évaluation

- Bolted Connections: 1.1 Range and Class of The Screw FastenersDocument8 pagesBolted Connections: 1.1 Range and Class of The Screw FastenersksPas encore d'évaluation

- PDFDocument9 pagesPDFTimmyJuriPas encore d'évaluation

- Fasteners To AISC and BS449Document11 pagesFasteners To AISC and BS449bgmenotmanPas encore d'évaluation

- VDI2230 Review Design GuidelineDocument15 pagesVDI2230 Review Design GuidelinebreeeeezzzzzePas encore d'évaluation

- Steel BS Parameter PDFDocument8 pagesSteel BS Parameter PDFdpkPas encore d'évaluation

- TSB1503G 9 P 1 PDFDocument18 pagesTSB1503G 9 P 1 PDFHatada Felipe100% (1)

- Mechanical Seals Optimization DesignDocument8 pagesMechanical Seals Optimization DesigneduardogcarvalhoPas encore d'évaluation

- OPTIMIZATION IN MECHANICAL SEAL DESIGN FOR API 682 CATEGORY 1 APPLICATIONS Ijariie1505 PDFDocument8 pagesOPTIMIZATION IN MECHANICAL SEAL DESIGN FOR API 682 CATEGORY 1 APPLICATIONS Ijariie1505 PDFChetan The game changerPas encore d'évaluation

- Analysis of Bolt TorquingDocument7 pagesAnalysis of Bolt TorquingAlessandro Serafini100% (1)

- JisDocument23 pagesJisĐào_hải_10100% (1)

- Maryland Metrics Acabado SuperficialDocument1 pageMaryland Metrics Acabado SuperficialalviarezalvarezPas encore d'évaluation

- Resistance Spot Welding Parameters Optimal Selection For Automotive Steel PlateDocument6 pagesResistance Spot Welding Parameters Optimal Selection For Automotive Steel PlateMahmoud SingerPas encore d'évaluation

- Indian Codes - Concrete Design PerDocument7 pagesIndian Codes - Concrete Design Peribrahim100% (1)

- Is 10143 1995Document23 pagesIs 10143 1995Arjuna ReddyPas encore d'évaluation

- Calculo de Torque X Forca AxialDocument4 pagesCalculo de Torque X Forca Axialmajonas77Pas encore d'évaluation

- Informative Annex 2 - Surface FinishDocument10 pagesInformative Annex 2 - Surface FinishzaheerPas encore d'évaluation

- Chassis ModificationDocument46 pagesChassis ModificationJawahar Raj0% (1)

- Mounting Instruction For M254 Package (V-Series Dualxt Module)Document9 pagesMounting Instruction For M254 Package (V-Series Dualxt Module)Manikanta SwamyPas encore d'évaluation

- 4.2. Consumable Consumption and Welding Time 4.2.1 Calculation of Electrode ConsumptionDocument9 pages4.2. Consumable Consumption and Welding Time 4.2.1 Calculation of Electrode ConsumptionNejat Ababay50% (2)

- An Approach To Optimize MIG Welding Parameters by Using Design of ExperimentsDocument14 pagesAn Approach To Optimize MIG Welding Parameters by Using Design of ExperimentsRadhe shamPas encore d'évaluation

- 07 Assembly HP - ENDocument67 pages07 Assembly HP - ENandersson benito herreraPas encore d'évaluation

- 07 Assembly CS - ENDocument90 pages07 Assembly CS - ENandersson benito herreraPas encore d'évaluation

- TSB1503G 9 P 1Document18 pagesTSB1503G 9 P 1kk_pammu_915176926Pas encore d'évaluation

- SF 0010 0 Metco 320NS PDFDocument8 pagesSF 0010 0 Metco 320NS PDFMehdi KoneshlouPas encore d'évaluation

- XV 1700 Supplement Service Manual (ENG) 2002-2003Document36 pagesXV 1700 Supplement Service Manual (ENG) 2002-2003broddie1230% (1)

- AA01042A Fisura Horse CollarDocument5 pagesAA01042A Fisura Horse CollarSebastiánRodrigoPérezHenríquezPas encore d'évaluation

- Design of Machine Members - IDocument8 pagesDesign of Machine Members - IPradeepkumarKatgiPas encore d'évaluation

- Is 1367 Part 8Document24 pagesIs 1367 Part 8Otavio1230% (2)

- Belt Conveyor Pulley DesignDocument11 pagesBelt Conveyor Pulley Designthakur_raghab100% (1)

- Is 14394 1996 PDFDocument10 pagesIs 14394 1996 PDFSantosh KumarPas encore d'évaluation

- 20ME0314 - Design of Machine Elements-IDocument7 pages20ME0314 - Design of Machine Elements-IAbdalmalek ShamsanPas encore d'évaluation

- 07 Assembly CP - ENDocument104 pages07 Assembly CP - ENandersson benito herreraPas encore d'évaluation

- Analysis On The Effect of Machining Parameters On MRR Using Different CoolantsDocument5 pagesAnalysis On The Effect of Machining Parameters On MRR Using Different Coolantsnavabnavab786Pas encore d'évaluation

- Optimization of Minimum Quantity Lubricant (MQL) Conditions in Milling of Mild SteelDocument6 pagesOptimization of Minimum Quantity Lubricant (MQL) Conditions in Milling of Mild SteelputtaPas encore d'évaluation

- Torque Vs Tension Interpretation Instructions Rev 6Document25 pagesTorque Vs Tension Interpretation Instructions Rev 6Kurt Kandora MontronePas encore d'évaluation

- PS 1804 (S)Document19 pagesPS 1804 (S)dzilioPas encore d'évaluation

- Presentation Coupler SystemDocument21 pagesPresentation Coupler SystemPralhad Kore100% (1)

- GMW 8-2008Document9 pagesGMW 8-2008Clauco Tiago Seno RoquePas encore d'évaluation

- ASME Section III Fatigue Calc ML093360330Document29 pagesASME Section III Fatigue Calc ML093360330Paldex100% (1)

- DIN 3990 MDesign 2016 Esempio Spur Gear, Gear RackDocument17 pagesDIN 3990 MDesign 2016 Esempio Spur Gear, Gear RackmgualdiPas encore d'évaluation

- IJAME - March 2018 - Vol. 15 Issue 1Document16 pagesIJAME - March 2018 - Vol. 15 Issue 1SATYAJITPas encore d'évaluation

- Winsem2015 16 Cp0409 20 Jan 2016 Rm01 Amt Unit I Question BankDocument5 pagesWinsem2015 16 Cp0409 20 Jan 2016 Rm01 Amt Unit I Question BankAnit JainPas encore d'évaluation

- 2004 - 2011 RX-8 Bodyshop Manual: General Information Construction Panel ReplacementDocument111 pages2004 - 2011 RX-8 Bodyshop Manual: General Information Construction Panel ReplacementTien Dung HoPas encore d'évaluation

- MAST CalculationDocument20 pagesMAST Calculationshamir_ahmedabad100% (2)

- Fe Analysis of Rotor Assembly: Document No: Ch/Report/Drm/109/2016-17Document37 pagesFe Analysis of Rotor Assembly: Document No: Ch/Report/Drm/109/2016-17Nishit KhuntPas encore d'évaluation

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Dynamic Damage and FragmentationD'EverandDynamic Damage and FragmentationDavid Edward LambertPas encore d'évaluation

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocument1 pageChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanPas encore d'évaluation

- Clearance CalculationDocument12 pagesClearance CalculationshazanPas encore d'évaluation

- Weld CalculationsDocument12 pagesWeld Calculationshakr5100% (1)

- Flange Details & DrawingsDocument338 pagesFlange Details & DrawingsshazanPas encore d'évaluation

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanPas encore d'évaluation

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanPas encore d'évaluation

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanPas encore d'évaluation

- Training Course ASMEDocument2 pagesTraining Course ASMEshazan100% (1)

- Seismic Calculation IS 1893 - RSMDocument3 pagesSeismic Calculation IS 1893 - RSMshazanPas encore d'évaluation

- U Stamp - KK Form - SampleDocument5 pagesU Stamp - KK Form - SampleshazanPas encore d'évaluation

- Tailing Lug - 173004-05Document1 pageTailing Lug - 173004-05shazan100% (1)

- Welding EngineeringDocument1 pageWelding EngineeringshazanPas encore d'évaluation

- Welding GuidelineDocument1 pageWelding GuidelineshazanPas encore d'évaluation

- IBR Design Calculations - FinalDocument6 pagesIBR Design Calculations - Finalshazan100% (1)

- Drawing Pressure VesselDocument1 pageDrawing Pressure VesselshazanPas encore d'évaluation

- Tailing Lug - 173004-05Document1 pageTailing Lug - 173004-05shazan100% (1)

- Bolt Torque CalculationDocument3 pagesBolt Torque Calculationshazan100% (1)

- Saddle Stresses On Shell During Transportation: Equipment NoDocument5 pagesSaddle Stresses On Shell During Transportation: Equipment NoshazanPas encore d'évaluation

- Design Planning ScheduleDocument2 pagesDesign Planning ScheduleshazanPas encore d'évaluation