Académique Documents

Professionnel Documents

Culture Documents

Sonatrach's - Problem Well Analysis PDF

Transféré par

Armando Pinto FloresTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sonatrach's - Problem Well Analysis PDF

Transféré par

Armando Pinto FloresDroits d'auteur :

Formats disponibles

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Introduction to Hydrocarbon Exploitation

Problem Well Analysis

Pratap Thimaiah

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Prob le m Well Analysis

Problem Well Analysis

Surveillance

Getting Started

What is a problem well?

Inflow restrictions

Outflow restrictions

Reservoir Problems

Artificial Lift

Mechanical Failures

Sand Control

Re-completions

Plug and Abandonment

Workover Economics

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Surveillance

Monitoring of the asset to optimally recover the oil and gas

reserves in a timely fashion through safe and profitable

operations

Critical for the future profitability of the field

Entire Business Unit

Analysis

Reservoir A

Identification of well problems

or

field problems

Problem Definition

Pro blem We ll Analysis

Reservoir B

Problem Analysis

Reservoir C

Solutions

Generation

Reservoir D

Production and operating cost problems

Continue to produce well's) with no change,

Collect additional data,

Workover and/or stimulation,

Equipment change,

Operations procedures changes),

Re-completion,

Pressure maintenance,

Enhanced recovery operation, or

Shut-in and abandonment

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Getting Started

Essential data must be in hand like:

Plot of the bottom-hole flow rate and pressure

recorded during a drawdown test

Well test plots

Daily production plots

Wellbore diagram

Base open-hole log

Schlumberger

Production plot, oil, gas, water, and GOR. Exponential decline.

Prob le m Well Analysis

Log-log plot of two well tests shows wellbore storage

reduction with downhole shut-in

Schlumberger

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Getting Started

Typical deepwater well completion

Wellbore diagram

Pro blem We ll Analysis

Must include both the measured

and true vertical depths of

tubulars, perforations, packers,

and all subsurface equipment.

Outer diameter and internal

diameters of each item.

Tight spots

Junk in hole

Potential problem areas

Reference elevation

Type connection in the wellhead

for production logging described

Schlumberger

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Getting Started

Prob le m Well Analysis

Base Openhole Log

Open perforations must be

shown for each well.

Cased hole gamma ray

and porosity log could be

of help.

Casing collar depths and

any radioactive marker

depths should always be

shown at the proper

depths on the base log.

GOC and WOC should be

shown when available.

001) BONANZA 1

GRC

0

150

SPC

-160 MV 40

ACAL

6

16

ILDC

0.2

200

SNC

0.2

200

RHOC

DT

1.95

2.95 150 us/f 50

CNLLC

0.45 -0.15

MLLCF

0.2

200

10700

10800

10900

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Problem Well Defined

Pro blem We ll Analysis

What is a problem well?

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Problem Well Defined

What is a problem well?

Prob le m Well Analysis

Low oil or gas production

High GOR

High water cut

Mechanical problems

Should be differentiated from a reservoir

problem

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Inflow Restrictions

Potentially damaging fines

Wellbore plugging

Perforation restrictions

Formation Damage

Pro blem We ll Analysis

Scale deposit in Tubing

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Inflow Restrictions

Such damage may be indicated by:

Production well tests

Pressure build-up and drawdown tests

Comparison with offset wells

Analysis of production history Effect of wellbore damage on productivity

Prob le m Well Analysis

Difference between pressure drawdown in undamaged and

damaged reservoirs. 50% of p occurs in last 15 ft.

pressure

Damage zone

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Inflow Restrictions

Pro blem We ll Analysis

Procedure in surveillance for problem wells:

If the monthly production test rate has decreased more

than 10 percent from normal decline retest the well

immediately.

Review adjacent wells for abnormal decline. If a number of

wells in an area have significant declines, the problem may

be reservoir related.

Check the well for mechanical problems; especially if on

artificial lift.

Check for wellbore fill-up.

Check for changes in backpressure or operating procedures.

Consider the need for production logs or pressure surveys

to confirm damage.

If damage is confirmed, take corrective action.

Use caution on stimulation if near gas-oil or water-oil contacts

Recommend bold action for low rate wells

Use some restrain on high rate wells, however they may offer

the highest potential again.

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Wellbore Plugging

Flow restrictions in the wellbore is often formation fill or scale.

For flowing or gas lifted wells, provided the tubing is openended, where there is fill across the formation, a coiled tubing

unit are commonly used for cleanout.

Prob le m Well Analysis

For pumping wells it may be necessary to pull the tubing before

clean-out.

Inorganic scale in the wellbore and perforation is a common

problem that can easily reduce production.

Sodium chloride salt

Calcium carbonate

Gypsum

Barium and strontium chloride

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Perforation Restrictions

Cause by perforation plugging or inadequate perforations

Considerable effort should be made on completion to

ensure that the perforations are open and undamaged

Pro blem We ll Analysis

Avoid loss of dirty water of dirty water into the formation

which may plug both the perforations and the formation

pores.

Solutions range from re-perforation, wash the

perforations, surge the formation, or to even fracture the

formation.

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Formation Damage

Impairment of well productivity or injectivity

due to

Prob le m Well Analysis

Plugging within the perforations

Formation pores adjacent to the wellbore

Fractures communicating with the wellbore

The procedure to follow:

Determine the degree of well damage (skin)

Causes of damage

Approach to alleviate the damage

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Formation Damage

Paraffin or Asphaltene Plugging

Emulsion Blocks

Pro blem We ll Analysis

Water blocking

Fine Particles

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Outflow Restrictions

Increase the backpressure

Limit drawdown

Reduce production

Prob le m Well Analysis

Some cases:

Tubing smaller than optimum will cause extra

friction losses

Larger than optimum will increase slippage and

may cause the well to load up and die.

On a pumping well, to small a tubing may restrict

the lift equipment or cause friction, which will

increase lift energy requirements.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Outflow Restrictions

Inflow and outflow performance curves can

help determine if a tubing size change is

justified.

Pro blem We ll Analysis

Well system analysis. Node selected at perforation outlet

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Outflow Restrictions

Prob le m Well Analysis

The production well test should report the wellhead pressure. If

it is relatively high, and outflow analysis should be undertaken.

If the pressure has recently increased, then possible

plugging in the outflow system should be checked.

If the pressure is normally high, the investigate why it is

high.

Are there any gas sales pressure limitations?

Are there compressors that require a fixed suction pressure?

Can it be economically lowered?

What is the pressure drop between the wellhead and the

separator?

Is there a surface choke on the well and what is its size?

On pumping wells, is the annulus vented into the flowline?

Are there any downhole restrictions?

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Reservoir Problems

Low reservoir permeability

Low reservoir pressure

Pro blem We ll Analysis

Water production problems

Gas problems in gas wells

High Viscosity Oil

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Low reservoir permeability

May be an overall reservoir characteristic or limited to a

specific area.

Should be considered along with other causes of low

productivity.

Prob le m Well Analysis

Usually well productivity declines rapidly as fluids near

the wellbore are produced.

Production tests may aid in differentiating between low

permeability and formation damage.

Matrix acidizing of low permeability undamaged

reservoirs can only provide a small productivity increase.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Low reservoir permeability

Pro blem We ll Analysis

Effect of matrix acidizing an undamaged well.

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Low reservoir pressure

Should be documented by periodic subsurface measurements.

Dominant reservoir drives in a particular reservoir should be

considered and how these drive mechanisms are associated

with the real or apparent well problem being investigated.

Prob le m Well Analysis

Prior to considering workover of wells in a low or partially

pressure-depleted oil reservoir, an effective artificial lift should

be planned.

Pressure maintenance or an enhanced recovery programme is

usually the best long range approach to increase production

rate and oil or gas recovery from partially pressure-depleted

reservoirs.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Low Reservoir Pressure

Pro blem We ll Analysis

Typical pressure-production history for various

reservoir-drive mechanisms.

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Water production problems

May result from:

Natural water drive or Waterflood, aggravated by

fingering or conning.

Prob le m Well Analysis

Extraneous sources including casing leaks or

cementing failures.

Fracturing or acidizing into adjacent water zones

or to below the water-oil contact.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Water production problems

Water encroachment is normal in a water drive reservoir. Three

water-oil contacts may usually be defined in oil wells:

Lower water-oil contact

Producing water- oil contact

Pro blem We ll Analysis

Completion water-oil contact

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Water production problems

Fingering

Water conning

Water channelling

Irregular water encroachment in heterogeneous

reservoir can result in early water breakthrough.

Prob le m Well Analysis

Conning of Water

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Water Production- Chemical Control Techniques

Cements

Resins and hard set chemicals

Gel treatments

Swelling chemicals & particulates

Relative permeability modifiers

Pro blem We ll Analysis

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Prob le m Well Analysis

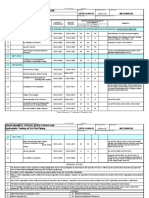

Water Production- Chemical Control Techniques

Quick reference guide-Treatment options for excess water

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Water Production- Chemical Control Techniques

Cement solutions

Casing & tubing leaks

Channels behind casing

If primary cement job fails

Pro blem We ll Analysis

Squeeze cementing

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Water Production- Chemical Control Techniques

Resins and other hard set chemicals

Low viscosity chemical mixtures that set up as

solid or hard inert plastic.

Resins are phenolic or epoxy base types.

Prob le m Well Analysis

Used in casing patches

Plug off cement channels and perforations

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Water Production- Chemical Control Techniques

Pro blem We ll Analysis

Gel treatments

Low viscosity chemical mixtures that stiffen at

varying degrees of temperatures.

Reduce or totally block a channel or highpermeability rock matrix zone through which

excess water is flowing into wellbore.

Carried out by mechanically isolating only the

zone, fractures or perforations that are the

source

Heavy metal cross linkers such as Chrome or

aluminium based

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Prob le m Well Analysis

Water Production- Chemical Control Techniques

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Placement Techniques

Pro blem We ll Analysis

Bullheading

Mechanical packer placement

Chemical packer placement

Dual injection

Iso-flow placement

Transient placement

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Placement Techniques

Prob le m Well Analysis

Bullheading

Injection of chemicals

through existing

Tubulars.

Used only when it is

determined that

aqueous injection

fluids will only enter

those water

producing zones that

are shut-in

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Placement Techniques

Pro blem We ll Analysis

Mechanical/Inflatable Packer

Selective zones are

isolated using packers.

In complex situations, it

maybe necessary to

isolate perforations that

are producing oil from

both above and below the

zone- Inflatable Dual

Packer System

Chemical Packers

In gravel packed or open

hole completions where

mechanical packers

cannot be used.

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Placement Techniques

Dual Injection Placement

Prob le m Well Analysis

Compatible fluids are injected down the

tubing and also annulus.

Packers, bridge plugs, chemical plugs and

other mechanical isolation means can be

used.

Efficient placement

To protects critical perforations in

hydrocarbon zones-Non-sealing fluid

compatible with formation is used.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Placement Techniques

Pro blem We ll Analysis

Isoflow Placement

Alternative to dual injection

system.

Chemicals are directed into

selected intervals while

protecting hydrocarbon

producing or bearing zones

by simultaneous injection of

non-sealing formation

compatible fluid.

Gamma ray logging tools are

used to locate and track fluid

interface.

Suited for both wells with

negative surface pressures

and static fluids when shut

in.

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Water Production- Mechanical Techniques

Prob le m Well Analysis

Inner Liners

Patches

Packers

Sliding sleeves

Plugs

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Water Production- Mechanical Techniques

Pro blem We ll Analysis

Casing cladding

Thermally set composite

materials used to form

patches to fix damage

Tubulars.

Using inflatable systems to

carry composite materials

into the well.

Materials are usually

thermally setting resins and

carbon fibres built into a

sleeve wrapped around the

device.

Once device is opposite the

area to be treated, device is

inflated to push composite

sleeve into place moving

upwards.

After inflation, the sleeve is

heated to harden and

conform to casing.

Electric resistors provide

heating.

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Water Production- Mechanical Techniques

Prob le m Well Analysis

Packer straddle

Its a combination

of packers, sliding

sleeves and other

tools to isolate

excess water

production zones

or areas of

damaged pipe.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Water Production- Mechanical Techniques

Pro blem We ll Analysis

Bridge Plugs

Run and set to

plug off water

entering the

bottom of well or

perforations.

Essentially plugsoff remainder of

well or tubing

from the point of

setting all the

way to bottom of

the well.

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Gas problems in Oil wells

The primary sources of gas in oil wells are:

Gas dissolved in the oil

Primary or secondary gas caps which may expand, and

Gas flow from zones or reservoirs above or below the oil zone

Prob le m Well Analysis

Normal GOR behaviour corresponding to the drive mechanism for any

particular reservoir must be considered in problem well analysis.

Characteristic gas-oil performance for various reservoir-drive mechanisms

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Gas problems in oil wells

Gas flow from zones above or below the oil

zone may be due to:

Pro blem We ll Analysis

Casing leaks

Poor cement job

Natural or induced fractures communicating with

gas zone

Gas flow due to channel behind the casing

Reservoir with a gas cap

Problem due to gas conning

Problem due to gas cap expansion

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

High Viscosity Oil

High viscosity is sometimes defined as oil with less than

16 API gravity. Viscosities grater than 200 cp often cause

serious flowing and pumping problems.

Prob le m Well Analysis

Thermal stimulation may be applicable, however

economics should be carefully reviewed.

It the well tubing, casing, cement job, and packer

installation has not been designed to withstand high

temperature steam, thermal stimulation may cause

severe mechanical damage to the well.

Alternative to Thermal Stimulation of the Reservoir can

be considered.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Artificial Lift

Most wells will probably require some sort of artificial lift before

abandonment to increase drawdown and thus production.

Selection

Pro blem We ll Analysis

Revenue due to oil and gas production

Operating costs, and

Factors contributing to economics of

artificial lift systems

Initial capital costs

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Sucker Rod Pumping

Walking Beam

Equalizer

Bearing

Saddle Bearing

Horsehead

Samson

Post

Bridle

Pitman Arm

Ladder

Hanger

Brake

Lever

Wrist

Pin

Prime

Mover

Crank Arm

Counterweight

Polished Rod

Stuffing Box Seal

Prob le m Well Analysis

Brake

Cable

Flow Line

Rod String

Flow Tee

Production Tubing

Base

Production Casing

Downhole Pump

Drawings Courtesy of Lufkin Industries, Inc. Lufkin, Texas

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Sucker Rod Pumping

Pro blem We ll Analysis

Analysis:

Check the well test production rates. Is the rate limited by the

pump displacement.

If the well cannot be pumped off, or pumped down to a low intake

pressure with the existing equipment on the well, determine if a

larger unit is justified.

If the well is pumped off, use time cycle to alter displacement to

match formation inflow.

If test rates suddenly decline on a well, check for mechanical

problems.

If decline in test rate is not a mechanical problem, then formation

damage, fill in annulus or perforation plugging may be the problem.

Gas interferences is a common problem on many pumping wells.

Where feasible vent the gas up the annulus and pump the oil and

water up the tubing.

Corrosion and scale are often major problems in pumping wells.

Paraffin deposition is another common problem.

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Gas Lift

Continuous Flow

Gas Lift Systems

Intermittent lift

Injected

gas

Prob le m Well Analysis

Injected

gas

Continuous gas lift

Intermittent gas lift

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Gas Lift

Annular gas injection

Tubing gas injection

Production

Production

Gas in

Tubing

Casing

Pro blem We ll Analysis

Gas in

Casing

Tubing

Gas entry

Liquid

Liquid

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Prob le m Well Analysis

Gas Lift Surveillance and Operating

Problems

Good well tests are essential to gas lift operation.

Periodic flowing pressure bottom-hole pressure surveys are

recommended.

Temperature surveys are often beneficial for both design

purposes and troubleshooting.

Sonic devices can be used to shoot fluid levels in the annulus of

gas lifted wells.

To produce at maximum rates, the injection gas depths should

be at maximum depths.

If there is a decrease in production test rate, the data should

be carefully reviewed.

In intermittent gas lift there are additional producing problems

to consider.

Check the flowing wellhead test pressures. High back pressure

is normally very detrimental to gas lift operations.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Electrical Submersible Pumping

Transformers

Motor

controller

Wellhead

Junction

box

Production

Primary cable

Pro blem We ll Analysis

Motor flat splice

Motor flat cable

Casing

Drain valve (optional)

Check valve (optional)

Tubing

Pump

Pump intake

Seal

Pothead

Motor

Perfs.

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

ESP Motor Problems

Major causes of motor

overheating

Overloading

Well pumped off

Gas locked

Stuck pump

Motor thrust bearing

components & complete

Lack of cooling

tubing or casing leak, scale,

motor laying against the

casing

Prob le m Well Analysis

Bearing

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Problems with ESP's

Cable failure (generally due to fluids penetrating the covering)

Protector leakage (fluids may contact motor)

Pro blem We ll Analysis

Too much free gas

Burnt motor can be caused by:

Contact with fluids due to protector leakage

Poor fluid circulation around motor for cooling

Corrosion of motor housing

Pump failure can be caused by

Solids

Pumping at rates/pressures outside of designed range

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Identifying problems with ESPs

May notice gradual increase in power usage and gradual

decrease in flow rate as indicators of pump problems

Power spikes and frequent automatic shut-downs may

indicate electrical leakages or other problems

Prob le m Well Analysis

Check for solids in fluid

Tubing, cable, and pump must be pulled to find exact

cause of a problem. Spool required to handle cable

Pump, seal, motor, and cable must be sent to

manufacturer for testing in order to locate the exact

problem

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Pro blem We ll Analysis

Electrical Submersible Pumping

Requires a rather precise design

Good operating practices

Careful equipment selection and repair

Reliable field electrical system

Stable operating conditions, and only

moderately high temperatures for successful

operation over well life

Selection of the electrical cable should provide

five years or longer trouble-free operating life.

ESP are adversely affected by free-gas, sand,

scale, and corrosion.

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

ESP Surveillance and Analysis

Well production test are the basic surveillance

method

Prob le m Well Analysis

A pump size should be chosen that will not

pump the well off. Minimum pump intake

pressures of 250 psig may be feasible, but 500

psig is a more realistic design.

Electrical problems are common and must

receive prompt attention. Good lighting

protectors are essential in many areas.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Hydraulic Pump and Jet System

Power fluid

Pump tubing

Casing

Nozzle

Production inlet

chamber

Throat

Pro blem We ll Analysis

Diffuser

Combined

fluid return

Well production

Jet pump

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Hydraulic Pump and Jet System

Prob le m Well Analysis

Power fluid return

Power fluid

Production

injection

Production and return

Power fluid

injection

Power fluid injection

Production and

return

Engine

Engine

Engine

Pump

Pump

(A)

Closed power

fluid system

Pump

(C)

Open power

fluid system

(free pump)

(B)

Open power

fluid system

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Hydraulic Pump and Jet Systems

The user has several options in the design and

installation of hydraulic reciprocating pumps:

Pro blem We ll Analysis

Individual well units, or a central system

Standard fixed pumps, or free pumps

Open, or closed power oil systems, and

Vented, or non-vented gas systems

Clean power fluid, normally oil, is essential to

good pump runs.

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Hydraulic Pumping Surveillance

Well production tests are the primary means of

surveillance. The test data includes the oil, water and,

gas rates plus the injection power fluid rate and pressure

and the wellhead pressure.

Prob le m Well Analysis

A significant decline in production rate my result from

formation damage (skin) or be from inadequate pump

displacement, pump wear, pump gas interference

problems, or leaks.

Leaks are more likely in hydraulic systems since

pressures are higher and there is more exposure due to

the use of power oil lines and power fluid tubing.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Mechanical Failure in Wells

Different types of mechanical failures can cause

loss of production and/or increase costs in well

operation. More common problems are:

Primary cement channelling

Pro blem We ll Analysis

Casing, tubing, and packer leaks,

Artificial lift equipment, and

Well equipment, like wellheads, subsurface

valves, sliding sleeves, etc.

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Sand Control

Prob le m Well Analysis

Wells that sand-up or produce more than 0.1

percent sand are often good candidates for

sand control.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Sand Control

Pro blem We ll Analysis

Unconsolidated

Consolidated

Zero strength

Very very weak

Very weak

Consolidated

Dry sand

Damp sand

Weakly-cemented

Stronger cement

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Sand Control

In weak but consolidated formations:

Prob le m Well Analysis

Stage

Stage 11

Failure

Failure

Stage

Stage 22

Transportation

Transportation

Failure of reservoir

rock due to shear

stresses (failure of

bonds between grains)

Transportation

of

failed material due to

flow

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Pro blem We ll Analysis

Factors Affecting Sand Production

Overburden

Friction

Differential Stresses

Cementing Material

Degree of Consolidation

Fluid Viscosity

Production Velocity

Water Production

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Sand Problems-Casing / Liner Collapse

Failure may occur

due to:

Prob le m Well Analysis

Non uniform

lateral loading as

rock is produced.

High axial

compressive load

due to slumping of

the overlying

casing-bearing

formation.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Pro blem We ll Analysis

Sand Problems- Erosion

Sand production can cause erosion in both surface and downhole

equipment such as :

Downhole

Blast Joints

Chokes

Gas lift Equipment

Elbows / Tees

Standing Valves

Pumps

Valves

Metering Devices

Circulating sleeves

Flanges

Nipples

Wellhead

Tubular

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Prob le m Well Analysis

Sand Problems- Erosion

Bridges may form in casing

or tubing and obstruct well

flow.

They must be removed by

bailing or washing with

concentric strings.

If bridging is severe sand

control will be required.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Sand Control Methods

Pro blem We ll Analysis

Restrictive Production Rate

In Situ Consolidation

Resin Coated Gravel

Gravel Pack

Screens - Natural Sand Packing (OH)

Expandable Sand Screens

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Sand Control Methods

Restrictive Production Rate

Some weak formations have enough

strength to produce sand-free at low

rates.

Selective perforations placed in the

strongest formation (based on logs)

Rock properties may change during the

production (i.e., water production).

Prob le m Well Analysis

In Situ Consolidation

Resin material is pumped into the

formation.

Furan Resin glues formation graingrain into a consolidated structure

Compressive strength >1,000 psi with

60-75% retained permeability.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Sand Control Methods

Resin

Pro blem We ll Analysis

Resin Coated Gravel

Proppant ( Gravel ) is precoated with resin

material.

Particles are mixed with

viscous gel and pumped

into the formation.

Particles are contacted

grain-to-grain.

Temperature + H2O fuses

the particles together into

a consolidated permeable,

drillable network.

Gravel

Formation

(Unconsolidated)

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Sand Control Methods

Natural Sand Packing (Screens)

Installation of a screen system (no particles) in cased or open hole.

Main horizontal completion option.

Screen system can be :

slotted liner

pre-pack screen

wire wrapped

Prob le m Well Analysis

Annular is eventually filled with formation sand.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Sand Control Methods

Slotted liners

Pro blem We ll Analysis

One of the older methods of sand control.

They are tubing sections with a series of slots cut through the tubing

wall in an axial orientation.

The slot width is designed to initiate inter-particle bridging across the

slot. It was originally considered that it should be twice the diameter of

the 10 percentile sand grains .

There are two types of slot available, keystone and straight

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Sand Control Methods

Wire Wrapped

Prob le m Well Analysis

There are three main types of wirewrap screen; rod-based screens, pipebased slip-on and pipe-based direct

build screens.

Normally made from triangular shaped

wrap wire

The gap between the edges of the

wrap wire is sufficient to allow quite

large sand grains to pass through.

Gap

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Sand Control Methods

Pro blem We ll Analysis

Pre-packed screens

Similar configuration to the wire

wrap but use a different filtering

media.

A layer of resin-coated gravel is

placed around the internal

screen assembly and is

supported by a shroud or

external screen.

The thickness of the filtering

medium layer, and hence the

outside diameter of the screen

depends on the specific well

requirements.

Limitations in mechanical

strength

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Sand Control Methods

Premium screens

typically an all-metal design, with a metal mesh filtration media and

a protective outer metal shroud.

The metal mesh can be either a metal weave or metal fibres or

powder particles embedded within a square metal mesh.

Prob le m Well Analysis

The apertures (called pore throats) generally very from 60 micron

to 300 micron.

The concept is that the mesh will prevent the larger sand particles

from travelling through and allow the formation fines to pass.

Premium screens are typically run in long horizontals, often behind

gravel packs and have similar sand control properties to pre-pack

screens.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Sand Control Methods

Gravel pack

Pro blem We ll Analysis

The annulus between the

wellbore and a sand control

screen (wire wrapped, or

premium) is filled with gravel

that is sized to prevent sand

from the formation passing

through the pack.

Gravel packing in open-hole

(EGP External Gravel Pack) is

useful for preventing annular

flow and controlling sand in

heterogeneous formations.

Gravel packing in cased-holes

(IGP Internal Gravel Pack) is

useful for protecting the sand

screens from erosion flow. After

the liner is run and perforated,

the sand face completion is

run. The perforations may then

be washed and the GP packer

set.

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Sand Control Methods

Frac pack

Improve the productivity of

a well by creating a short,

wide fracture close to the

wellbore.

A proppant is placed inside

the fracture that will both

hold open the fracture and

control sand production.

Prob le m Well Analysis

Frac packs are also termed

high permeability fractures

(HPF)

Fracture filled

with gravel

/proppant

wellbore packed

with screen in

wellbore

In Frac packing the fractures

tend to be shorter but much

wider.

Typical frac pack crack

widths can be 1 inch or

potentially larger.

The lengths vary depending

on the design and are

usually in the region of 20 to

50 feet.

Fracture filled

with resin coated

gravel /proppant

Wellbore free of

equipment

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Sand Control Methods

Pro blem We ll Analysis

ESS (Expandable

Sand Screens)

2005 Abalt Solutions Limited. All rights reserved

Solutions

Prob le m Well Analysis

Abalt

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Re-completion

Can be avoided by careful planning and anticipation of

problems on the initial well completion.

Pro blem We ll Analysis

The usual workover procedure for changing zones or reservoirs

in perforated casing completion is merely to squeeze cement

and re-perforate in the new zone in the reservoir.

In open hole, it may be necessary to deepen or plug back, or to

cement a liner and selectively perforate a specific zone in the

reservoir.

Changing the producing interval in both single and multiple

completions are relatively simple operations if the operation

can be carried out through-tubing.

2005 Abalt Solutions Limited. All rights reserved

Abalt

Solutions

Plug and Abandonment

Most zones or reservoirs must be eventually plugged and

abandoned.

Most governmental regulating bodies have specific

guidelines that must be followed.

Prob le m Well Analysis

Careful considerations should be given to all options

before plugging a well.

If a well is no longer economical to produce, has no use

as a service well, or has no use as a service well, or has

serious mechanical conditions, then immediate steps

should be taken to plug and abandon the zone.

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

INTRODUCTION TO HYDROCARBON EXPLOITATION

Development Phase

Workover Economics

Pro blem We ll Analysis

The team concept is a significant factor in

optimizing creative skill and imagination in:

Fact finding

Analysis

Experimentation

Job execution, and

Evaluation of results

Considering workover on programme basis

Profitability analysis

2005 Abalt Solutions Limited. All rights reserved

Abalt

abalt solutions limited - 2005

Solutions

September October 2005

Vous aimerez peut-être aussi

- Campos Subandino Sur PDFDocument29 pagesCampos Subandino Sur PDFAndrea CR100% (1)

- Sonatrach's - Problem Well Analysis PDFDocument42 pagesSonatrach's - Problem Well Analysis PDFArmando Pinto FloresPas encore d'évaluation

- Sonatrach's - Well Control PDFDocument25 pagesSonatrach's - Well Control PDFArmando Pinto FloresPas encore d'évaluation

- Applications of Petroleum Geochemistry To Exploration and Reservoir Management PDFDocument32 pagesApplications of Petroleum Geochemistry To Exploration and Reservoir Management PDFArmando Pinto FloresPas encore d'évaluation

- Sonatrach Directional DrillingDocument11 pagesSonatrach Directional DrillingUsama Bin SabirPas encore d'évaluation

- Diccionario Ingles-Espanol PDFDocument295 pagesDiccionario Ingles-Espanol PDFJose Daniel ChamorroPas encore d'évaluation

- Relationship Between Petroleum Composition and Depositional Environment of Source RocksDocument14 pagesRelationship Between Petroleum Composition and Depositional Environment of Source RocksArmando Pinto FloresPas encore d'évaluation

- Casing Design Manual - BG (2001)Document51 pagesCasing Design Manual - BG (2001)PetroleumEngineering100% (21)

- Sonatrach Directional DrillingDocument11 pagesSonatrach Directional DrillingUsama Bin SabirPas encore d'évaluation

- Sonatrach Directional DrillingDocument11 pagesSonatrach Directional DrillingUsama Bin SabirPas encore d'évaluation

- Coastal GeologyDocument297 pagesCoastal Geologytyukgomba100% (1)

- Sonatrach's StimulationDocument109 pagesSonatrach's StimulationSergio Flores0% (1)

- Artificial LiftsDocument78 pagesArtificial LiftsKola ShuaibPas encore d'évaluation

- Drilling Engineering - Dipl & PrasslDocument282 pagesDrilling Engineering - Dipl & Prassljultur4oPas encore d'évaluation

- Drilling Engineering - Dipl & PrasslDocument282 pagesDrilling Engineering - Dipl & Prassljultur4oPas encore d'évaluation

- Casing Design Manual - BG (2001)Document51 pagesCasing Design Manual - BG (2001)PetroleumEngineering100% (21)

- Campos Subandino Sur PDFDocument29 pagesCampos Subandino Sur PDFAndrea CR100% (1)

- Sonatrach's StimulationDocument109 pagesSonatrach's StimulationSergio Flores0% (1)

- Artificial LiftsDocument78 pagesArtificial LiftsKola ShuaibPas encore d'évaluation

- Relationship Between Petroleum Composition and Depositional Environment of Source RocksDocument14 pagesRelationship Between Petroleum Composition and Depositional Environment of Source RocksArmando Pinto FloresPas encore d'évaluation

- Sonatrach's - Well PerformanceDocument78 pagesSonatrach's - Well Performanceadrien_ducaillouPas encore d'évaluation

- Sonatrach's StimulationDocument109 pagesSonatrach's StimulationSergio Flores0% (1)

- Drill Pipe / Drill Collar TablesDocument3 pagesDrill Pipe / Drill Collar TablesArmando Pinto FloresPas encore d'évaluation

- 31 - Temperature in WellsDocument7 pages31 - Temperature in WellsAgus AlexandriPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- CBX SeriesDocument22 pagesCBX SeriesAtika AnjumPas encore d'évaluation

- Catalogo BVMDocument16 pagesCatalogo BVMLeonardo Rachen RodriguezPas encore d'évaluation

- New AVME EXPORT-20220530 - 090509Document4 936 pagesNew AVME EXPORT-20220530 - 090509Muthukumaran TPas encore d'évaluation

- Basic Practice Unit 2 Test Name SolutionsDocument4 pagesBasic Practice Unit 2 Test Name SolutionsMar Fuent100% (1)

- Polypropylene: Sub-Group Description ApplicationsDocument1 pagePolypropylene: Sub-Group Description ApplicationsJulio GarcíaPas encore d'évaluation

- DD 210714Document132 pagesDD 210714Ajay SinghPas encore d'évaluation

- Assignment 10 PDFDocument2 pagesAssignment 10 PDFarchies iescaPas encore d'évaluation

- MBCC ProfileDocument107 pagesMBCC ProfileNajeeb Ibn AbdullaPas encore d'évaluation

- Fire Damaged Concrete StructuresDocument11 pagesFire Damaged Concrete StructuresbarouniaminePas encore d'évaluation

- Acousti-Clear® BrochureDocument16 pagesAcousti-Clear® BrochureMelvin RubioPas encore d'évaluation

- Shibaura N843Document44 pagesShibaura N843wayne kiwicylinderheadsPas encore d'évaluation

- Fish Market - HyderabadDocument4 pagesFish Market - HyderabadsalemmanojPas encore d'évaluation

- Injection Molding Troubleshooting For Common Design DefectsDocument3 pagesInjection Molding Troubleshooting For Common Design DefectsAlmgihty ZeusPas encore d'évaluation

- Gebe005 Aug08 PDFDocument22 pagesGebe005 Aug08 PDFأسامة خالدPas encore d'évaluation

- Handbook On Vacuum Dewatering Concrete FlooringDocument18 pagesHandbook On Vacuum Dewatering Concrete FlooringPrasanta Parida100% (1)

- Ale Building Technology and MaterialsDocument2 pagesAle Building Technology and MaterialsiloilocityPas encore d'évaluation

- Mazzella WireRopeAtAGlance 0919Document5 pagesMazzella WireRopeAtAGlance 0919Tarek HareedyPas encore d'évaluation

- Trosten Ahu CatalogueDocument88 pagesTrosten Ahu Cataloguehanimamoo7Pas encore d'évaluation

- CECR Proposal FormDocument9 pagesCECR Proposal FormAshish ShahPas encore d'évaluation

- Chapter 6 Concrete Dam EngineeringDocument112 pagesChapter 6 Concrete Dam EngineeringmimahmoudPas encore d'évaluation

- Sample Residential Cost Plan Report July2016Document23 pagesSample Residential Cost Plan Report July2016Anbarasan SivarajPas encore d'évaluation

- Renewable Energy Technologies (Elective) Sample Question Paper (Msbte Study Resources)Document4 pagesRenewable Energy Technologies (Elective) Sample Question Paper (Msbte Study Resources)Lakshman Naik100% (1)

- Caterpillar Disassembly and Assembly Transmission 950g and 962g Wheel LoaderDocument20 pagesCaterpillar Disassembly and Assembly Transmission 950g and 962g Wheel Loaderpatrick100% (39)

- Site Inspection ReportDocument45 pagesSite Inspection ReportAhmad HasnanPas encore d'évaluation

- Saudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingDocument10 pagesSaudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingAhdal NoushadPas encore d'évaluation

- Bolted Composite JointDocument28 pagesBolted Composite JointHitesh Parghi50% (2)

- MS-CVL-009 Erection of Hollowcore Slabs 1Document12 pagesMS-CVL-009 Erection of Hollowcore Slabs 1Suju RajanPas encore d'évaluation

- Adobe Scan 27 Sept 2023Document1 pageAdobe Scan 27 Sept 2023guha_tuhinPas encore d'évaluation

- CSCS Application Form SBK SSPDocument2 pagesCSCS Application Form SBK SSPDina PuspitaPas encore d'évaluation

- Types of PumpsDocument68 pagesTypes of PumpsVicky JeganPas encore d'évaluation