Académique Documents

Professionnel Documents

Culture Documents

CQS-GTL-IN-GEN-SPC-001 - Rev 2.0 PDF

Transféré par

Atty AttyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CQS-GTL-IN-GEN-SPC-001 - Rev 2.0 PDF

Transféré par

Atty AttyDroits d'auteur :

Formats disponibles

DESIGN SERVICE FOR PROPOSED GENTEC

STORAGE TANK FARM

FIRE AND GAS SPECIFICATION

CQS-GTL-IN-FGS-SPC-001

3.0

07-12-15

Issued for Construction

U.J

SA

OA

2.0

30-11-15

Issued for Review

U.J

SA

OA

1.0

20-11-15

Issued for Interdiscipline Check

U.J

SA

OA

Rev

Date

Revision Status

Prepared By

Checked By

Approved By

Design Service for Proposed Gentec Storage Tank Farm

Fire and Gas Specification

CQS-GTL-IN-FGS-SPC-001

Rev 3.0

TABLE OF CONTENTS

1.0

2.0

3.0

4.0

5.0

6.0

INTRODUCTION ................................................................................................................ 5

1.1

PROJECT OVERVIEW .................................................................................. 5

1.2

DOCUMENT OBJECTIVES ........................................................................... 5

APPLICABLE CODES AND STANDARDS ....................................................................... 5

2.1

CODES AND STANDARDS .......................................................................... 5

2.2

ORDER OF PRECEDENCE .......................................................................... 6

2.3

REFERENCES .............................................................................................. 6

REQUIREMENTS FOR DETECTION EQUIPMENT PER LOCATION ............................... 7

3.1

GENERAL REQUIREMENTS ........................................................................ 7

3.2

STORAGE TANKS ........................................................................................ 7

3.3

LOADING GANTRY ....................................................................................... 7

3.4

SWITCHGEAR ROOM .................................................................................. 8

3.5

GENERATOR HOUSE .................................................................................. 8

3.6

PPH ............................................................................................................... 8

3.7

FWPH ............................................................................................................ 8

3.8

GATEHOUSE ................................................................................................ 8

DETECTION SYSTEMS..................................................................................................... 9

4.1

FIRE DETECTION ......................................................................................... 9

4.2

SMOKE DETECTION .................................................................................... 9

4.3

HEAT DETECTION........................................................................................ 9

AUDIO, VISUAL, MANUAL ALARM CALL POINTS ......................................................... 9

5.1

AUDIBLE ALARM .......................................................................................... 9

5.2

VISUAL ALARM ........................................................................................... 10

5.3

MANUAL ALARM CALL POINTS ................................................................ 10

FIRE PROTECTION SYSTEMS (FIRE WATER SYSTEMS) ............................................ 10

6.1

FIRE WATER SYSTEMS............................................................................. 10

6.2

FIRE WATER NETWORK ........................................................................... 10

6.3

FIRE WATER STORAGE TANK .................................................................. 11

6.4

FIRE WATER PUMP ................................................................................... 11

6.5

FIRE HOSES ............................................................................................... 11

6.6

SPRINKLER SYSTEM ................................................................................. 12

Page 2 of 14

Design Service for Proposed Gentec Storage Tank Farm

Fire and Gas Specification

6.7

7.0

8.0

CQS-GTL-IN-FGS-SPC-001

Rev 3.0

DELUGE SYSTEM ............................ERROR! BOOKMARK NOT DEFINED.

FIRE PROTECTION SYSTEMS (FOAM SYSTEMS) ....................................................... 12

7.1

FOAM SYSTEMS ........................................................................................ 12

7.2

FOAM CONCENTRATION .......................................................................... 12

7.3

FOAM PROPORTIONING SYSTEM ........................................................... 13

7.4

FIXED FOAM PROPORTIONING SYSTEM ................................................ 13

7.5

TESTING OF PROPORTIONING EQUIPMENT .......................................... 14

FIRE PROTECTION SYSTEMS (PORTABLE EXTINGUISHERS) .................................. 14

8.1

PORTABLE EXTINGUISHERS ................................................................... 14

Page 3 of 14

Design Service for Proposed Gentec Storage Tank Farm

Fire and Gas Specification

CQS-GTL-IN-FGS-SPC-001

Rev 3.0

ABBREVIATIONS

AGO

Automotive Gas Oil (Diesel)

API

American Petroleum Institute

DPK

Dual Purpose Kerosene

FACP

Fire Alarm Control Panel

FM

Factory Manual

F&G

Fire & Gas

FGS

Fire and Gas System

FWP

Fire Water Pump

FWPH

Fire Water Pump House

HMI

Human Machine Interface

IR

Infrared

LSHH

Level Switch High High

LSLL

Level Switch Low Low

MACP

Manual Alarm Call Points

NFPA

National Fire Protection Act

PB

Push Button

PC

Personal Computer

PMS

Premium Motor Spirit (Petrol)

PLC

Programmable Logic Controller

PPH

Pump Product House

Page 4 of 14

Design Service for Proposed Gentec Storage Tank Farm

Fire and Gas Specification

1.0

1.1

CQS-GTL-IN-FGS-SPC-001

Rev 3.0

INTRODUCTION

Project Overview

It is the intention of Gentec Oil and Gas Limited to build three new storage tanks

comprising of white products (PMS, AGO and DPK). The work shall determine the modern

use for the terminal space and ensure a design is reached in line with industry standard

and meeting regulatory requirements.

In view of this, Crystaquantum Solutions Ltd. has been awarded the contract to carry out

this assessment and the requisite design to meet industry and regulatory requirement.

This facility is intended to majorly hold storage of white products:

Premium Motor Spirit (PMS)

Automotive Gas Oil (AGO)

Dual Purpose Kerosene (DPK)

The facility comprises of three (3) product tanks:

1 no.(ABJ-0103) PMS tank with fixed aluminium cone roof and internal floating skin

1 no. (ABJ-0203) AGO storage tank with fixed aluminium cone roof.

1 no. (ABJ-0302) DPK storage tank with fixed aluminium cone roof.

White product truck loading area is equipped with 2 Loading Islands with 3 Loading

Arms.

A pump station housing four (PBA-0104/05, PBA-0203 and PBA-0302) white

product loading pump.

One (ABJ-0403) slop tank and one (ABH-0103) Oil-Water Separator.

Fire fighting system includes a 1 no. (ABJ-0503) fire water tank, two (PBE-0507/08) fire

water pumps and one (PBE-0509) electric jockey pump, as well as water and foam

distribution systems to meet the firefighting requirement.

1.2

Document Objectives

This document sets out the basic Fire and Gas philosophy and principles guiding the

deployment of Fire and Gas protection system on the Gentec Tank Farm project.

The Fire protection system which includes Fire water Pumping system, Fire Hydrant

System, Fire Detection & Alarm System, Automatic Operated Water Spray System and

Hand Appliances suitable for the type of risk/fire for different buildings, equipments,

product storage tanks, loading gantry and other basic facilities recommended for bulk

storage.

Fire and Gas protection system shall be used to provide overall fire monitoring and

control in the Building and Operational Structures areas.

2.0

2.1

APPLICABLE CODES AND STANDARDS

Codes and Standards

Fire and Gas Systems for Gentec Tank Farm Project shall be designed and constructed

in accordance with the applicable issues of referenced specifications and latest edition

of the codes and standards.

These shall include but not be limited to the following:

Page 5 of 14

Design Service for Proposed Gentec Storage Tank Farm

Fire and Gas Specification

CQS-GTL-IN-FGS-SPC-001

Rev 3.0

INDUSTRY STANDARDS

2.2

Document

Document Title

NFPA 10

Standard for Portable Fire Extinguishers

NFPA 11

Standard for Low-, Medium, and High-Expansion

Foam,

NFPA 13

Standard for the Installation of Sprinkler Systems,

NFPA 15

Standard for water spray fixed systems for fire

protection

NFPA 16

Standard for the Installation of Foam-Water

Sprinkler and Foam-Water Spray Systems

NFPA 20

Standard for the installation of stationery pumps

for fire Protection

NFPA 25

Standard for the Inspection, Testing, and

Maintenance of Water-Based Fire Protection

Systems

NFPA 30

Flammable and Combustible Liquid Code

NFPA 45

Standard on Fire Protection for Laboratories Using

Chemicals

NFPA 72

National Fire Alarm Code

Order of Precedence

In case of conflict between the requirements of this specification and other document

referenced herein, the following order of precedence shall normally be used in

decreasing order of priority:

Local regulations governing health and safety

This specification

Referenced project specifications

National and international codes and standards

It shall be the Contractors responsibility to bring to COMPANYs attention any

discrepancy between the documents. The Contractor shall not proceed with any such

aspect of the work until he has received all necessary confirmation, in writing from the

COMPANY.

2.3

References

This philosophy should be read in conjunction with the following documents and

drawings:

Page 6 of 14

Design Service for Proposed Gentec Storage Tank Farm

Fire and Gas Specification

3.0

3.1

CQS-GTL-IN-FGS-SPC-001

Rev 3.0

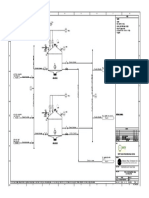

Process Operating Philosophy

Project Piping and Instrumentation Diagrams (P&IDs)

Project Utility and Instrumentation Diagrams (U&IDs)

REQUIREMENTS FOR DETECTION EQUIPMENT PER LOCATION

General Requirements

This section identifies the requirements for the various types of Fire and Gas detection

and protection equipments for each of the major locations and types of storage

equipment.

3.2

3.2.1

Storage Tanks

Fixed Roof Storage Tanks with Internal Floating Skin

The tanks will have basic protection from primary safety features such as re-circulation

vent which is suitable for this category of tanks. The tanks will have additional risk

reduction measures which are listed below:

Arrays of water sprinklers positioned around the tank shell and as well as on the

roof.

IR3 flame detectors positioned such that all angles, inlet and outlet valves from

the storage tanks are in its line of site.

Facilities to shut down product pumps and isolate all tanks.

Fixed fire water supply and ring main.

Foam system for base foam injection.

3.2.2

Fixed Roof Storage Tanks

Protection for these tanks is achieved with a pressure vacuum relief valve (breather

valve) as re-circulating vents will not be effective. The tanks will have additional risk

reduction measures which are listed below:

Arrays of water sprinklers positioned around the tank shell and as well as on the

roof.

IR3 flame detectors positioned such that all angles, inlet and outlet valves from

the storage tanks are in its line of site.

Facilities to shut down product pumps and isolate all tanks.

Fixed fire water supply and ring main.

Foam system for base foam injection.

3.3

Loading Gantry

The loading gantry shall have appropriate numbers of adequately sized foam sprinklers

installed at top and bottom of the loading gantry. Foam will be piped from the

proportioner to the gantry to fight fire at the gantry.

The loading gantry shall also be equipped with Infrared (IR) Flame detectors at each

island. The IR flame detectors are mounted such that the loading area will be in its line

of site. In the event of a fire/flame, the IR flame detector shall trigger the FACP.

Page 7 of 14

Design Service for Proposed Gentec Storage Tank Farm

Fire and Gas Specification

3.4

CQS-GTL-IN-FGS-SPC-001

Rev 3.0

Switchgear Room

Conventional smoke detection shall be installed. This detector will trigger the facility fire

alarm system when activated. It will be wired in a loop independent of the building alarm

detection devices (zoning on the c).

MACP shall be installed at the exits of the room in an event that the fire alarm condition

is triggered by the terminal personnel.

The wiring for the smoke detection and the MACP shall be such that when activated, it

would be easy for fire wardens to isolate the origin of the alarm.

Audio Visual alarms shall also be installed in the room to alert personnel.

Activation of any of the detectors shall initiate the audio/visual alarm.

3.5

Generator House

Flame detector shall be installed. This detector will trigger the facility fire alarm system

when activated. It will be wired in a loop independent of the building alarm detection

devices (zoning on the FACP).

MACP shall be installed at the exit of the room in an event that the fire alarm condition is

triggered by the terminal personnel.

The wiring for the flame detector and the MACP shall be such that when activated, it

would be easy for fire wardens to isolate the origin of the alarm.

Audio Visual alarms shall also be installed in the room to alert personnel.

Activation of any of the detectors shall initiate the audio/visual alarm.

3.6

PPH

In the PPH flame detectors shall be provided to detect flame/fire.

Audio Visual Alarms shall also be installed at this location and shall be initiated when

detected by the detectors.

3.7

FWPH

In the FWPH smoke detection shall be provided. And also MACP shall be installed at the

exit of the building. Both smoke detector and MACP shall be connected to FACP. Audio

Visual Alarm shall be installed at this location.

Activation shall initiate the audio/visual alarm

3.8

Gatehouse

In the gatehouse smoke detection shall be provided. And also MACP shall be installed at

the exit of the gatehouse. Both smoke detector and MACP shall be connected to FACP.

Audio Visual Alarm shall be installed at this location.

Activation shall initiate the audio/visual alarm.

Page 8 of 14

Design Service for Proposed Gentec Storage Tank Farm

Fire and Gas Specification

4.0

4.1

CQS-GTL-IN-FGS-SPC-001

Rev 3.0

DETECTION SYSTEMS

Fire Detection

Infra-Red (IR) flame detectors are the preferred type for flame detection as they are not

susceptible to spurious trips, they can detect flames from smoky fires and they can

tolerate considerable dirt on the lens. They shall be solar blind and flicker frequency

sensitive for hydrocarbon fires. Detectors should generally be located in elevated

positions and aligned downwards to gain maximum benefit from the fixed angle of

sensitivity.

Detectors should be located in elevated positions looking downwards. Consideration

should be given to the possibility of smoke accumulation preventing the detector from

seeing a flame.

4.2

Smoke Detection

Smoke detectors shall be of the Optical type or Ionization type. Where smoke detection

is provided, at least one shall be installed at each location. The optimum locations for

conventional smoke detectors will be a function of the preferential air flow patterns and

the availability of flammable materials.

Activation of a single smoke detector shall initiate alarms (horns and strobe).

Note: False alarms from smoke detectors may be caused by fumes, dusts or

condensation. Some types of Ionization chamber type smoke detectors are highly

sensitive to high air speeds and may give false alarms.

Ionization type detectors shall be provided with a warning label highlighting they are a

radioactive source.

Smoke detection shall initiate the audio/visual alarm.

4.3

Heat Detection

Heat detectors shall be installed in specific locations. They will be set off by rate of

temperature rise or/and when they reach a preset temperature.

Heat detectors will be wired to the FACP and when heat is detected audio/visual alarm

shall be activated.

5.0

AUDIO, VISUAL, MANUAL ALARM CALL POINTS

5.1

Audible Alarm

Audible alarms shall be installed in all personnel areas inside or outside the building and

around the facility as a minimum.

The audible alarms will come with strobes which will function to alert personnel of the

source of the alarm.

Page 9 of 14

Design Service for Proposed Gentec Storage Tank Farm

Fire and Gas Specification

5.2

CQS-GTL-IN-FGS-SPC-001

Rev 3.0

Visual Alarm

The main visual alarm interface shall be the one the fire alarm control panel. This shall

either be a dedicated display on the operators work station or a graphic display on the

fire alarm control panel. The fire alarm control panel layout shall be based on the station

fire and gas detector layout drawings. It shall clearly highlight which detection circuit has

been activated and the area of the plant affected.

5.3

Manual Alarm Call Points

Manual Alarm Call points (MACP) shall be installed at all the facilitys main exits,

emergency exits, at the control room entrance, Generator shelter, maintenance shelter,

pump house, gate house and where staircase exist. They shall be distinguished by bold

signs and be easily seen from all directions. These manual call points when activated

shall trigger the alarm system via the fire alarm control panel.

It may be either of the hammer/break glass, push/break glass type or pull station type.

The material of construction shall be in accordance with the requirements for the

classified area where it is located in and be corrosion resistant and weather-proof.

Manual Alarm Call points (MACP) installed in hazardous areas shall be explosion proof

type with minimum protection of IP65.

6.0

FIRE PROTECTION SYSTEMS (FIRE WATER SYSTEMS)

6.1

Fire Water Systems

The fire water network consists of the following:

Water supply (a dedicated storage tank)

Pumps

Piping distribution network

Water application systems

The network outlets can be hydrants (for use, generally with hand-held or mobile

equipment), fixed systems such as base foam injection or fixed monitors.

6.2

Fire Water Network

The capacity of the water storage tank shall be in accordance with the worst case

design demand (worst case scenario). One hour water supply (as calculated) shall be

provided unless it can be clearly shown that incident durations will be less than this.

The number of fire water tanks installed shall be one.

The fire water network shall be designed to supply the calculated water demand at the

required discharge points and pressure and required flow rates.

The pumps shall discharge into a ring main with hydrants, fixed monitors and feeds to

fixed foam systems and sprinkler systems.

The fire water distribution piping shall be a ring main, with adequate loops and block

valves to ensure that a single line break can be isolated safely with minimum loss of

fire protection. Fire water distribution system shall be looped to provide two-way flow,

Page 10 of 14

Design Service for Proposed Gentec Storage Tank Farm

Fire and Gas Specification

CQS-GTL-IN-FGS-SPC-001

Rev 3.0

with sectional valves arranged to provide alternate water flow paths to any point in the

system. Single branch lines shall be avoided.

The piping material may be steel for above or below ground; the pipe shall be protected

by physical barriers where necessary to reduce the possibility of impact by vehicles.

All valves in the system shall be clearly identified with their function and normal status.

System pipework shall be routed such that wherever possible it is not exposed or close

to a potential source of fire or excessive thermal radiation. In particular, the following

guidelines shall be applied:-

6.3

Firewater pipework shall not pass through tank bund areas.

Firewater pipework shall not pass through areas where product spills can

accumulate underneath them.

Fire water pipework shall be at least 15m from the bulk storage facilities.

Fire Water Storage Tank

The capacity of the water storage tank shall be in accordance with the worst case

design demand obtained from calculations. One hour water supply (as per calculation)

shall be provided unless it can be clearly shown that incident durations will be less than

this.

The primary source of water shall be stored in 1 x 603.41m3 fire water tanks. The tank

shall be supplied from a borehole in the tank farm.

The fire water tank internal lining shall be corrosion resistant.

Since the majority of the tank fill is likely to stand for considerable periods of time

consideration shall be given to batch dosing foam compatible corrosion inhibitor and

bactericide.

Where required due to the type of pumps being used, tanks shall be elevated to provide

positive suction when the operating pressure is low.

6.4

Fire Water Pump

Pumps and drivers shall comply with NFPA 20 (Installation of Centrifugal Fire Pumps).

Generally a minimum of one diesel driven and one electrical powered fire water pumps

shall be installed to ensure a reliable supply under all circumstances.

The pump can shall be activated either from a fire signal detected by the flame detector

or manually started.

A jockey pump shall be installed to maintain pressure in the system.

Fire water pumps shall be started weekly and performance tested annually. The annual

performance tests shall incorporate flow tests for the ring main itself. Flow and

pressure tests shall be performed on the fire water system to ensure that water demand

for the identified scenarios can be achieved.

6.5

Pumps shall be selected and installed in accordance with NFPA 20.

Fire Hoses

All hoses for fire fighting purposes shall comply with the requirements of the relevant

NFPA standards.

Page 11 of 14

Design Service for Proposed Gentec Storage Tank Farm

Fire and Gas Specification

6.6

CQS-GTL-IN-FGS-SPC-001

Rev 3.0

Sprinkler System

Sprinkler systems shall be designed in accordance with NFPA 13 or BS 5306 Part 2.

Sprinkler system hydraulic calculations shall be carried out using approved software or

by manual calculations.

All system sprinkler valves and nozzles shall be approved by the Underwriters

Laboratories (UL) or Factory Mutual (FM).

Sprinkler system inspection and testing shall be in accordance with NFPA 25 or BS

5306 Part 2.

7.0

FIRE PROTECTION SYSTEMS (FOAM SYSTEMS)

7.1

Foam Systems

Foam systems consist of 3 basic parts:

Foam concentrate - the liquid used to make foam.

Foam concentrates proportioning system - where the foam concentrate is

mixed, at a specific proportion, with water to make foam solution.

Foam maker (foam generator, foam application device) where air is mixed with

foam solution to make foam.

Foam makers can be further subdivided into aspirating types which use a venturi nozzle

system to suck air into the foam solution or non-aspirating devices which rely on

impinging jets of foam solution or turbulence as the foam solution leaves the nozzle to

generate bubbles of foam.

In any system it is important to ensure that the right combination of foam concentrate,

proportioning system and foam generating devices are selected for the particular

application.

Reference shall be made to the following standards for relevant aspects of foam system

design and foam concentrate specification:NFPA 11 - Standard for Low Expansion Systems

NFPA 16 - Deluge Foam - Water Sprinkler and Foam Water Spray Systems, 1995

ISO 7203 - 1 Fire Extinguishing Media, Foam Concentrates, 1995

UL 162, Seventh Edition - Foam Equipment and Liquid Concentrates, 1994

7.2

Foam Concentration

All foam concentrates used shall be 3% grade (i.e. to be used at 3% concentration in

proportioning systems).

The foam concentrate for hydrocarbon flammable liquids (e.g. crude or condensate)

shall be either fluoroprotein, film-forming fluoroprotein or multipurpose (alcohol

resistant) fluoroprotein or synthetic based type and shall conform to the requirements

of Underwriters Laboratories UL 162 7th Edition test requirements, or ISO 7203-1 Class

IIA or higher.

Page 12 of 14

Design Service for Proposed Gentec Storage Tank Farm

Fire and Gas Specification

CQS-GTL-IN-FGS-SPC-001

Rev 3.0

Foam concentrates, whether in systems, drums or vehicles shall be stored such that

they are not exposed to direct sunlight. The manufacturers type certification shall be

available on site demonstrating full conformity with either UL 162 or ISO 7203-1, Class

IIA or higher.

This shall also include information on the following physical properties with measured

tolerances:

Specific gravity @ 20C

pH @ 20C

Sediment

Calculations shall be performed in order to establish the minimum quantity of foam

required for each application. In addition, and in accordance with NFPA, 100% of the

calculated quantity shall be available within 24 hours.

7.3

Foam Proportioning System

The foam proportioner is the device that is used to inject foam concentrate into the

water line to make foam solution. It is vital that the proportioner is such that it ensures

that the foam solution has the correct amount of foam concentrate in it (nominally 3%

- 3.6%) under all system operating conditions and flow requirements, including potential

blockage of one or more outlets.

Various types of proportioner are available as described in NFPA 11.

Foam concentrate tanks shall be high density polyethylene, GRP or stainless steel

316L construction, approved for use by the concentrate manufacturer.

Internal tank linings shall not be used in foam concentrate tanks.

7.4

Fixed Foam Proportioning System

Foam application systems can be either fixed or semi-fixed. In the case of fixed

systems, the proportioner and foam concentrate tank are permanently connected to

the fire water ring main so that no additional connection of foam concentrate supply is

required for system operation.

All proportioning stations shall be provided with a clear indication of the facilities to

which they relate and clear operating instructions including identification of valves.

Minimum and maximum operating pressures shall also be clearly identified.

Fixed proportioning systems shall be of the balanced pressure type (See NFPA 11).

All proportioning stations shall be provided with isolation valves and pressure gauges

at their inlet and outlet. In the case of pumped balanced pressure proportioning

systems, pressure gauges will also be provided in the foam concentrate line

downstream of the foam pump prior to the proportioner. Gauges shall be provided to

demonstrate that foam concentrate pressure and water pressure are balanced at the

point of concentrate injection.

The flow range of the proportioner and operating pressure range shall be clearly

marked on the proportioner.

Pumped balanced pressure proportioning systems shall be provided with the facility to

test the foam concentrate and circulate foam concentrate back to the concentrate tank

Page 13 of 14

Design Service for Proposed Gentec Storage Tank Farm

Fire and Gas Specification

CQS-GTL-IN-FGS-SPC-001

Rev 3.0

without discharging concentrate into the foam solution discharge line. Valves in the

system specifically provided to allow this function shall be provided with a lock so that

they can be locked during normal status.

Pumped balanced pressure proportioners shall have manual over ride capability to be

used in the event of failure of the automatic balancing system.

All foam concentrate tanks shall be provided with a sight glass with isolation valves. In

the case of diaphragm tanks the isolation valves will be provided with locks.

7.5

Testing of Proportioning Equipment

On an annual basis all proportioning systems and equipment shall be tested under

credible operational flow conditions to check that the percentage of foam concentrate

being proportioned is within the range 3-3.6%.

At 6 monthly intervals, foam concentrate tanks shall be inspected for signs of sediment.

All foam systems shall be discharge tested on an annual basis. The tests shall include

proportioning accuracy, foam expansion and drainage time. Results shall be compared

with system specification and manufacturers' data.

8.0

FIRE PROTECTION SYSTEMS (PORTABLE EXTINGUISHERS)

8.1

8.1.1

Portable Extinguishers

General

A suitable number of hand held extinguishers shall be provided at strategic locations.

Hand held extinguishers like DCP (Dry Chemical Powder), Sand Bucket, CO2 are used

to extinguish initial stages of fire. Each extinguisher shall be operated as per operation

instructions given on each extinguisher.

8.1.2

Standards For Portable Fire Extinguishers

All fire extinguishers shall be manufactured, tested and certified to conform to BS 5423

or equivalent (such as CEN-EN 3.1/2/3/4/5, NFPA 10, and Din 14406).

Additionally, the extinguisher body, filling nozzle and cap shall be made from material

having rigidity, durability and resistance to electrochemical corrosive effects of the

extinguishing media.

Fire extinguishers shall be selected, installed and maintained in accordance with BS

5306 Part 3.

Page 14 of 14

Vous aimerez peut-être aussi

- Concrete Mix DesignDocument2 pagesConcrete Mix DesignAtty AttyPas encore d'évaluation

- Ibikunomaa CV SurveyingDocument2 pagesIbikunomaa CV SurveyingAtty AttyPas encore d'évaluation

- Engineering document revisions historyDocument1 pageEngineering document revisions historyAtty AttyPas encore d'évaluation

- Engineering document revisions historyDocument1 pageEngineering document revisions historyAtty AttyPas encore d'évaluation

- Engineering document revisions historyDocument1 pageEngineering document revisions historyAtty AttyPas encore d'évaluation

- NPD TKD Olf 07 Mod 0002Document1 pageNPD TKD Olf 07 Mod 0002Atty AttyPas encore d'évaluation

- Engineering document revisions historyDocument1 pageEngineering document revisions historyAtty AttyPas encore d'évaluation

- Shell Manhole DetailsDocument1 pageShell Manhole DetailsAtty AttyPas encore d'évaluation

- Engineering document revisions historyDocument1 pageEngineering document revisions historyAtty AttyPas encore d'évaluation

- Engineering document revisions historyDocument1 pageEngineering document revisions historyAtty AttyPas encore d'évaluation

- Engineering document revisions historyDocument1 pageEngineering document revisions historyAtty AttyPas encore d'évaluation

- NPD TKD Olf 07 Mod 0002Document1 pageNPD TKD Olf 07 Mod 0002Atty AttyPas encore d'évaluation

- Engineering document revisions historyDocument1 pageEngineering document revisions historyAtty AttyPas encore d'évaluation

- NPD TKD Orf 07 Asb 0001Document1 pageNPD TKD Orf 07 Asb 0001Atty AttyPas encore d'évaluation

- Engineering document revisions historyDocument1 pageEngineering document revisions historyAtty AttyPas encore d'évaluation

- NPD TKD Evf 07 Mod 0002Document1 pageNPD TKD Evf 07 Mod 0002Atty AttyPas encore d'évaluation

- Engineering document revisions historyDocument1 pageEngineering document revisions historyAtty AttyPas encore d'évaluation

- Engineering document revisions historyDocument1 pageEngineering document revisions historyAtty AttyPas encore d'évaluation

- Engineering document revisions historyDocument1 pageEngineering document revisions historyAtty AttyPas encore d'évaluation

- Engineering Request From NAOC PDFDocument1 pageEngineering Request From NAOC PDFAtty AttyPas encore d'évaluation

- BRASS WALKWAY DIAGRAM Layout 2Document1 pageBRASS WALKWAY DIAGRAM Layout 2Atty AttyPas encore d'évaluation

- BRASS WALKWAY DIAGRAM Layout 5Document1 pageBRASS WALKWAY DIAGRAM Layout 5Atty AttyPas encore d'évaluation

- CNC-KTL-PR-GEN-PFD-001 - Rev 3.0 PDFDocument1 pageCNC-KTL-PR-GEN-PFD-001 - Rev 3.0 PDFAtty AttyPas encore d'évaluation

- BRASS WALKWAY DIAGRAM Layout 4Document1 pageBRASS WALKWAY DIAGRAM Layout 4Atty AttyPas encore d'évaluation

- BRASS WALKWAY DIAGRAM Layout 1Document1 pageBRASS WALKWAY DIAGRAM Layout 1Atty AttyPas encore d'évaluation

- Cqs Epr Ts Gen PHL 001 Rev 3.0Document25 pagesCqs Epr Ts Gen PHL 001 Rev 3.0Atty AttyPas encore d'évaluation

- BRASS WALKWAY DIAGRAM Layout 3Document1 pageBRASS WALKWAY DIAGRAM Layout 3Atty AttyPas encore d'évaluation

- KATADocument2 pagesKATAAtty AttyPas encore d'évaluation

- CNC-KTL-PR-GEN-PID-001 - Rev 3.0 PDFDocument1 pageCNC-KTL-PR-GEN-PID-001 - Rev 3.0 PDFAtty AttyPas encore d'évaluation

- Cqs Epr Ts Gen Dts 001 Rev 3.0Document10 pagesCqs Epr Ts Gen Dts 001 Rev 3.0Atty AttyPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Compressed HydrogenDocument12 pagesCompressed Hydrogenkmrosario100% (1)

- Mechanical Construction GuideDocument81 pagesMechanical Construction GuideFarahidiPas encore d'évaluation

- Fire Risk Assessment For Workplaces Containing Flammable Substances Rr040Document66 pagesFire Risk Assessment For Workplaces Containing Flammable Substances Rr040Ali AbbasovPas encore d'évaluation

- Kashif Riaz E&I Supervisor-1-Merged - OrganizedDocument5 pagesKashif Riaz E&I Supervisor-1-Merged - Organizedkashif2080Pas encore d'évaluation

- Cause Sprinkler LeakageDocument7 pagesCause Sprinkler LeakageAmalia IstighfarahPas encore d'évaluation

- Fire Alarm System Design StandardsDocument23 pagesFire Alarm System Design StandardsAlbert Tuazon100% (2)

- Report M&e Function Ventilation SystemDocument8 pagesReport M&e Function Ventilation SystemAquw ArishaPas encore d'évaluation

- Solar Powered Isolated Uv Spray BoothDocument11 pagesSolar Powered Isolated Uv Spray BoothChintuPas encore d'évaluation

- Job Safety Analysis for HDPE Pipe InstallationDocument12 pagesJob Safety Analysis for HDPE Pipe InstallationtusharDJPas encore d'évaluation

- FF Plan Submission Guide-Rev3Document7 pagesFF Plan Submission Guide-Rev3FaseeshPas encore d'évaluation

- Pre-Hot Work Inspection and ChecklistDocument2 pagesPre-Hot Work Inspection and ChecklistDannyPas encore d'évaluation

- Firefighting Hydraulic CalculationDocument27 pagesFirefighting Hydraulic CalculationElaya Raja82% (17)

- Airport Terminal Design - Fire Safety Issues - Content Content From Fire Protection Engineering PDFDocument9 pagesAirport Terminal Design - Fire Safety Issues - Content Content From Fire Protection Engineering PDFBùi Trần Trung HậuPas encore d'évaluation

- 3D Model Review Check ListDocument27 pages3D Model Review Check ListIRANIAN 23Pas encore d'évaluation

- Apps Tyco EC-25 Storage Sprinkler 1-13Document16 pagesApps Tyco EC-25 Storage Sprinkler 1-13jhoger2012Pas encore d'évaluation

- RF Fire Department Connection in Let Flow AssessmentDocument68 pagesRF Fire Department Connection in Let Flow AssessmentAdam ThimmigPas encore d'évaluation

- Fire Sprinklers Hydraulic CalculationsDocument27 pagesFire Sprinklers Hydraulic CalculationsIlham Kelana100% (1)

- Vnt19-Area 13 Mil-R0Document6 pagesVnt19-Area 13 Mil-R0Hân TiênPas encore d'évaluation

- Understanding BIMMS & StandardsDocument32 pagesUnderstanding BIMMS & StandardsEllin Mae NocidoPas encore d'évaluation

- PIPENET - Leading Fluid Flow Analysis SoftwareDocument6 pagesPIPENET - Leading Fluid Flow Analysis Softwaresammar_10Pas encore d'évaluation

- Fire Protection System Design EstimateDocument12 pagesFire Protection System Design EstimateJerome AdduruPas encore d'évaluation

- Wet Pipe PDFDocument10 pagesWet Pipe PDFAntony JebarajPas encore d'évaluation

- ASP Flashcards - QuizletDocument36 pagesASP Flashcards - QuizletRehman MuzaffarPas encore d'évaluation

- Chapter 1Document128 pagesChapter 1JabirPerumperemelPas encore d'évaluation

- 010 - Reliable Sprinkler K22.4 - HL22Document5 pages010 - Reliable Sprinkler K22.4 - HL22Andy QuynhPas encore d'évaluation

- 13 A2021 AUT SSI CIReportDocument18 pages13 A2021 AUT SSI CIReportIan OsorioPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument33 pagesDisclosure To Promote The Right To InformationbisworupmPas encore d'évaluation

- NKDocument10 pagesNKGie BastPas encore d'évaluation

- Series ELO-231 - 11.2 K-Factor Upright and Pendent Sprinklers Standard Response, Standard Coverage General DescriptionDocument6 pagesSeries ELO-231 - 11.2 K-Factor Upright and Pendent Sprinklers Standard Response, Standard Coverage General DescriptionMónica BaquePas encore d'évaluation

- PR 3Document6 pagesPR 3Rexie ArcenaPas encore d'évaluation