Académique Documents

Professionnel Documents

Culture Documents

Cimcool Cimstar 585

Transféré par

tribolasTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cimcool Cimstar 585

Transféré par

tribolasDroits d'auteur :

Formats disponibles

FLUID TECHNOLOGY

Product

Application

Guide

CIMSTAR 585

Semi- Synthetic Metalworking

CIMSTAR 585 metalworking uid is a premium semi-synthetic

metalworking uid designed for moderate to heavy-duty machining of

ferrous and non ferrous materials.

CIMSTAR 585 can be used in central coolant systems or individual

machine sumps.

Metals: Carbon Steels, High Speed Steel, Cast Steels, Alloy Steels, Tool Steel,

Stainless Steel, Cast Iron, Aluminum, including ADC type Aluminium Alloys.

Duty Range: Moderate to Heavy-duty.

FEATURES AND BENEFITS

Developed by latest technology of metalworking uid.

Excellent corrosion control on cast iron, steel and typical grades of

aluminium including 2024, 7075, 390 and 6061

Good lubricity making tool life extended.

Contains new biocide package for long coolant life

Good antibacterial performance.

Mix remains stable as water hardness increases.

Easy to use and maintains.

TYPICAL PHYSICAL AND CHEMICAL PROPERTIES

Physical state:....................................................................................... Liquid

Appearance and odor: ......................................................... Clear / Chemical

Colors available: ...................................................................... Undyed / Pink

Solubility in water: ...................................................................100% Miscible

Specic gravity, (H2O = 1):.....................................................................1.030

pH, 5.0% mix, typical operating conditions:...............................................8.9

PACKAGING: 200L drums, 20L pails & 5L packs

CIMSTAR 585

Semi- Synthetic Metalworking

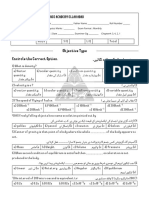

RECOMMENDED STARTING DILUTIONS

FOR INDUSTRIAL USE ONLY

Recommended Starting Dilution: 5% (1:20)

Typical Operating Range:

5% (1:20) to 10% (1:10)

Refractometer Factor:

1.6

The table below demonstrates potential Refractometer readings and the concentration % derived by using

the following formula: (Refractometer Reading x Refractometer Factor = Concentration %)

Refractometer Reading

Concentration %

1.8

2.5

3.1

3.7

4.4

5.0

5.6

6.2

10

REFRACTOMETER CALIBRATION AND INSTRUCTION FOR USE

Figure 01

1. Ensure that the refractometer (gure 1), water and metalworking

uid are at room temperature.

2. Place a few drops of water between the plastic cover and the prism.

3. Hold the refractometer horizontally and point it at a light source.

4. Look into the eyepiece and adjust the scale-calibrating screw until

the boundary line, which separates the light and dark areas

of the scale are aligned to zero 0 on the scale.

Figure 02

5. Lift the plastic cover and dry the prism with a clean, dry cloth.

6. Place one or two drops of the metalworking uid on the prism and

close the plastic cover.

7. Read the number on the scale at the point where the boundary line

separates the light and dark areas on the scale (Figure 2). For

the concentration, multiply this number by the refractometer factor.

CIMSTAR 585 to be mixed with water for use (add concentrate to

water). Add no other substances to the concentrate or mix unless

approved by CIMCOOL Technical Services.

For concentration analysis, use Total Alkalinity Titration Procedure, BCG

Titration Procedure, CIMCHEK Test Strip, or Refractometer.

EXAMPLE:

CIMSTAR 585 Refactometer Factor = 1.6

Take the Refractometer Scale Reading of 2.0

(i.e. Figure 2), multiplied by the Refractometer

Factor of 1.6 = 3.2% mix concentration.

Contact Details:

For additional information on CIMSTAR 585 refer to its MSDS or contact CIMCOOL Technical Services

e-mail: info@cimcool.com.cn Reprints/updates: www.cimcool.com.cn

This product is sold by CIMCOOL Fluid Technology, a division of Milacron LLC. Minor formulation changes or normal variations in the

manufacture of this product may cause slight variances in the data presented on this sheet.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Dummies Guide To AstroDocument18 pagesDummies Guide To AstroCristhian Fernando Paz CPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Color: A Coloring Book byDocument19 pagesColor: A Coloring Book byMarta Pérez Madrid50% (2)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Lectuer-11 EvaporatorDocument41 pagesLectuer-11 EvaporatorAurenio RibeiroPas encore d'évaluation

- Batch To Continuous ProcessingDocument7 pagesBatch To Continuous ProcessingChem.EnggPas encore d'évaluation

- Lecture Notes - HydroDocument55 pagesLecture Notes - HydroAlvin Deliro100% (5)

- Eqo-Kleen SMP Pds - v2Document1 pageEqo-Kleen SMP Pds - v2tribolasPas encore d'évaluation

- Final Exam in Science 10Document4 pagesFinal Exam in Science 10Daiseree SalvadorPas encore d'évaluation

- FP - EN - Polybio 630 CU - BB - 1114 - 0Document1 pageFP - EN - Polybio 630 CU - BB - 1114 - 0tribolasPas encore d'évaluation

- FP - EN - GreenFlux 200 - BB - 1014 - 1Document1 pageFP - EN - GreenFlux 200 - BB - 1014 - 1tribolas100% (1)

- FP en Mecagreen 400 LM 0813 2Document1 pageFP en Mecagreen 400 LM 0813 2tribolasPas encore d'évaluation

- Q-Cut 235C (7.3.13) PDFDocument1 pageQ-Cut 235C (7.3.13) PDFtribolasPas encore d'évaluation

- Polybio 425: Metal Working Fluid Water Soluble OilDocument1 pagePolybio 425: Metal Working Fluid Water Soluble Oiltribolas100% (1)

- Condaform 3442 E - LM - 1209 - 0Document1 pageCondaform 3442 E - LM - 1209 - 0tribolas100% (1)

- FP - EN - Polybio 650 ABF - BB - 0815 - 3Document1 pageFP - EN - Polybio 650 ABF - BB - 0815 - 3tribolasPas encore d'évaluation

- Castrol Molub Alloy 860Document3 pagesCastrol Molub Alloy 860tribolasPas encore d'évaluation

- FP - EN - Polybio 650 ABF - BB - 0815 - 3Document1 pageFP - EN - Polybio 650 ABF - BB - 0815 - 3tribolasPas encore d'évaluation

- Condaform 237 - BB - 0208 - 2Document1 pageCondaform 237 - BB - 0208 - 2tribolasPas encore d'évaluation

- FP - EN - GreenFlux 400 - LM - 0909 - 4Document1 pageFP - EN - GreenFlux 400 - LM - 0909 - 4tribolasPas encore d'évaluation

- Mixtron Flyer PDFDocument2 pagesMixtron Flyer PDFtribolasPas encore d'évaluation

- FP - EN - GreenFlux 200 - BB - 1014 - 1Document1 pageFP - EN - GreenFlux 200 - BB - 1014 - 1tribolas100% (1)

- TI-Divinol Ecogrease LC 2 EP - EN-28130Document2 pagesTI-Divinol Ecogrease LC 2 EP - EN-28130tribolasPas encore d'évaluation

- Mixtron-Flyer F PDFDocument2 pagesMixtron-Flyer F PDFtribolasPas encore d'évaluation

- Drosera MSDocument1 pageDrosera MStribolasPas encore d'évaluation

- PDS Energol CSDocument1 pagePDS Energol CStribolasPas encore d'évaluation

- Mobil SHC Polyrex™ Series: High Temperature Synthetic Polyurea GreasesDocument2 pagesMobil SHC Polyrex™ Series: High Temperature Synthetic Polyurea GreasestribolasPas encore d'évaluation

- Mobilfluid 426Document2 pagesMobilfluid 426tribolasPas encore d'évaluation

- Polyrex EMDocument2 pagesPolyrex EMtribolasPas encore d'évaluation

- Q-Cut 225C.pdsDocument1 pageQ-Cut 225C.pdstribolasPas encore d'évaluation

- PDS - Q-Cut 245CDocument1 pagePDS - Q-Cut 245CtribolasPas encore d'évaluation

- Mobilfluid 422Document2 pagesMobilfluid 422tribolasPas encore d'évaluation

- Mobiltherm 43: Premium Heat Transfer OilDocument1 pageMobiltherm 43: Premium Heat Transfer OiltribolasPas encore d'évaluation

- Mobilfluid 424: Multipurpose Tractor LubricantDocument2 pagesMobilfluid 424: Multipurpose Tractor LubricanttribolasPas encore d'évaluation

- Xtreme Hone 790s (3.9.16) .PdsDocument1 pageXtreme Hone 790s (3.9.16) .PdstribolasPas encore d'évaluation

- Mobil Vacuoline 500: Circulating OilsDocument2 pagesMobil Vacuoline 500: Circulating OilstribolasPas encore d'évaluation

- Mobilfluid 125: Extra High Performance Power Transmission FluidDocument2 pagesMobilfluid 125: Extra High Performance Power Transmission FluidtribolasPas encore d'évaluation

- Mobilfluid 125: Extra High Performance Power Transmission FluidDocument2 pagesMobilfluid 125: Extra High Performance Power Transmission FluidtribolasPas encore d'évaluation

- CHE 176 Complete SlideDocument606 pagesCHE 176 Complete Slideolawandeilo123Pas encore d'évaluation

- Propagating Scalar Modes in (2+1) - CDT Quantum GravityDocument60 pagesPropagating Scalar Modes in (2+1) - CDT Quantum GravityAdam BrucePas encore d'évaluation

- Saponification Example: TriglyceridesDocument2 pagesSaponification Example: TriglyceridesAnonymous JOOQkGbwoRPas encore d'évaluation

- Opal GemstoneDocument1 pageOpal GemstoneJohn Angelo Fernandez OquianaPas encore d'évaluation

- SemUVF2013 Olivier 70thDocument35 pagesSemUVF2013 Olivier 70thWado Del CimaPas encore d'évaluation

- Effect of Chloride Ions On The Corrosion of Galvanized Steel Embedded in Concrete Prepared With Cements of Different CompositionDocument13 pagesEffect of Chloride Ions On The Corrosion of Galvanized Steel Embedded in Concrete Prepared With Cements of Different CompositionAbubakar Yakubu YakubuPas encore d'évaluation

- Wear of Hydrodynamic Journal BearingsDocument6 pagesWear of Hydrodynamic Journal Bearingskishorghatage89Pas encore d'évaluation

- Phy 9th CH 1 To 4Document4 pagesPhy 9th CH 1 To 4Hameedashiq7 AshiqhameedPas encore d'évaluation

- Department of Education: Learner'S Activity Sheet in Physical Science (Grade 12) Quarter 3, Week 5Document11 pagesDepartment of Education: Learner'S Activity Sheet in Physical Science (Grade 12) Quarter 3, Week 5Abegail Lampera CatindoyPas encore d'évaluation

- Bubble Evolution and Transport in PEM Water Electrolysis MechanismDocument36 pagesBubble Evolution and Transport in PEM Water Electrolysis MechanismMizanur RahmanPas encore d'évaluation

- Powder Coating Trouble Shooting TVSMDocument34 pagesPowder Coating Trouble Shooting TVSMPinnacle qualityPas encore d'évaluation

- January 2006 QP M1 EdexcelDocument13 pagesJanuary 2006 QP M1 EdexcelOmar HashemPas encore d'évaluation

- Imds Recommendation 019 Circuit BoardsDocument13 pagesImds Recommendation 019 Circuit BoardsNeemias de Macedo FerreiraPas encore d'évaluation

- Flux Decline in Skim Milk UltrafiltrationDocument19 pagesFlux Decline in Skim Milk Ultrafiltrationpremnath.sPas encore d'évaluation

- 6323 12101 1 SMDocument7 pages6323 12101 1 SMElna PurwantiPas encore d'évaluation

- Me 112 Module Unit 1 Schoology RevisedDocument16 pagesMe 112 Module Unit 1 Schoology Revisedkenmalgapo320Pas encore d'évaluation

- Surveying Prelim ReviewerDocument4 pagesSurveying Prelim ReviewerBanana QPas encore d'évaluation

- Study Guide Bonding Ionic CovalentDocument4 pagesStudy Guide Bonding Ionic Covalentapi-267858901Pas encore d'évaluation

- Fluid Mech Lecture Part 2 Principles of HydrostaticsDocument7 pagesFluid Mech Lecture Part 2 Principles of HydrostaticsRosalina JaboneroPas encore d'évaluation

- Chem Lab Oxidation ReductionDocument3 pagesChem Lab Oxidation ReductionMayara Halper100% (2)

- COOL CHEMISTRY® Brochure - REV Feb 2021Document2 pagesCOOL CHEMISTRY® Brochure - REV Feb 2021Selva KumarPas encore d'évaluation

- Math SlideDocument13 pagesMath SlideRose YacobPas encore d'évaluation

- CTPT Catalogue 2022Document6 pagesCTPT Catalogue 2022Energy TecPas encore d'évaluation

- What Is A Fuel CELL?Document49 pagesWhat Is A Fuel CELL?raveendrareddyeeePas encore d'évaluation