Académique Documents

Professionnel Documents

Culture Documents

SP0504R01

Transféré par

Avoor KhanDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SP0504R01

Transféré par

Avoor KhanDroits d'auteur :

Formats disponibles

JOB SAFETY ANALYSIS POWER TRANSFORMER TESTING

Title: Transformer Testing

Purpose and Scope: The purpose of this SWP is to outline the requirement for

performing these tests on out of service power transformers:

Performing High Voltage Testing in the field

Power Transformer DC Resistance Test

Oil Sampling

Ratio Test

Over-potential Test

Power Frequency Withstand Test

Load Loss Test

No Load Loss Test

Staffing Resources: Persons holding a minimum qualification of electrical fitter with adequate training in this practice and apprentices, trainees or other staff while under

direct supervision of qualified personnel.

Documentation/References:

Scope of works

Standard to which Transformer was designed. This SWP is based on:

AS2374.1 1997, Power transformers - General

AS2374.3.0 1982, Power transformers Insulation levels and dielectric tests General

requirements

Power Transformer Dielectric and Insulation Test Report form SP0504C01

Power Transformer Cold Winding Resistance Test Report form SP0504C02

Power Transformer No Load Ratio Test Report form SP0504C03

Power Transformer No Load Loss Test Report form SP0504C04

Power Transformer Load Loss Test Report form SP0504C05 and load loss calculation forms

SP0504C06

Check this is the latest Process Zone version before use.

Page 1 of 8

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Past test results if available

Instruction manual (Manufacturers or local) for relevant

Insulation Resistance test equipment.

DC Resistance test equipment

No Load Loss test equipment

Load Loss test equipment

Power Frequency Withstand test equipment

Over-potential Withstand test equipment

Ratio test equipment Scope of works

Reference SP0504R01 Ver 1

Reference Owner: Neil Dwyer, Manager Technical Services

JOB SAFETY ANALYSIS POWER TRANSFORMER TESTING

Key Tools and Equipment:

PPE Long sleeve shirt and long trousers, safety

footwear, safety helmet, gloves and protective

eyewear where signed.

Safety barriers and warning signs.

Shorting leads.

Time piece to record one to ten minute readings.

Insulation Resistance test equipment.

DC Resistance test equipment

Ratio test equipment.

Surface thermometer

Oil sample test equipment.

Oil spill kit

Test equipment will vary form site to site.

Load Loss test equipment.

Supply source capable of supplying at least

50% of winding Full Load Current (FLC),

DC Resistance equipment,

RMS Voltmeter, Measuring VTs, Ammeter,

Metering CTs, Wattmeter, (These meters may

be replaced by power analysers or other

appropriate meters.)

Shorting bars capable of full rated current of

the winding to be shorted

No Load Loss test equipment:

Voltage source capable of rated voltage of

transformer under test,

Average and RMS Voltmeters,

Measuring VTs, Ammeters, Metering CTs,

Wattmeter, (These meters may be replaced by

power analysers or other appropriate meters).

Power Frequency Withstand test equipment

including suitable single-phase test transformers of

sufficient voltage and VA, voltage and current

measuring equipment.

Ammeter with parallel spark gap

Measurement VT and voltage meter

Over-potential Withstand tests equipment including

a three phase high frequency generator, three

phase interposing test transformer, voltage and

current measuring equipment suitable for use at

the test frequency.

Voltage meters to measure test voltage (with

input impedance to match voltage divider).

Ammeters to measure the phase current.

Development Team: Phil Ives and Helena Tholsgard

Date Completed: 16 April 2003

Reviewed By: Robert Bates

Date Completed:27 September 2004

Related SWP No.:SP0504

SWP Owner Approval: Neil Dwyer

Key Stakeholders:

Check this is the latest Process Zone version before use.

Page 2 of 8

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Reference SP0504R01 Ver 1

Reference Owner: Neil Dwyer, Manager Technical Services

JOB SAFETY ANALYSIS POWER TRANSFORMER TESTING

Task

No.

Task Step

Most Likely Breakdown Event (Loss Of

Control)

Hazard

Most Likely Outcome (Incident

Outcome)

Risk Score

Additional/

Existing

Alternate

Controls

Controls

Preliminary steps

Refer JSAs for Testing in the field

and workshop

Performing Insulation

Resistance Testing

Test Voltage from Test Equipment

Trapped Charges

Failure to keep persons clear of live

test equipment

Failure to discharge equipment under

test

Electric Shock

Low

Power Transformer Oil

Sampling

Transformer oil, PCB

Oil under pressure from head of

oil

Spillage

Skin irritation,

environmental harm

Low

Power Transformer DC

Resistance Test

High Electromagnetic Energy in

charged windings

Leads removed from winding before

discharge, high voltage spike from

collapsing magnetic field

Electric Shock

Low

Power Transformer Ratio

Test

Live LV from auxiliary supplies

Live LV from ratio test set

High Voltage from CT

secondaries

Inadvertent contact with LV in auxiliary

supplies or from test set

Open Circuited CT secondary

windings, unearthed VT windings

Electric Shock

Damage to equipment

CT secondary windings

Low

Power Transformer Power

High Voltage from CT

Open Circuited CT secondary

Electric Shock

Low

Check this is the latest Process Zone version before use.

Page 3 of 8

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Reference SP0504R01 Ver 1

Reference Owner: Neil Dwyer, Manager Technical Services

JOB SAFETY ANALYSIS POWER TRANSFORMER TESTING

Task

No.

Task Step

Frequency Withstand Test

Power Transformer Overpotential Test

Power Transformer Load

Loss Test

Most Likely Breakdown Event (Loss Of

Control)

Hazard

Most Likely Outcome (Incident

Outcome)

secondaries

Floating VT voltages

High Voltage from Test Set

LV from input supply to Test Set

windings, unearthed VT windings

Failure to isolate & earth transformer

under test after test

Inadvertent contact with LV supply

leads

Failure of leakage current ammeter

HV Test voltage exceeds set point or

control malfunction gives runaway

Insufficient clearance between test HV

leads and between test leads and

other apparatus

Damage to equipment

High Voltage from CT

secondaries

Floating VT voltages

High Voltage from Test Set

LV from input supply to Test Set

Open Circuited CT secondary

windings, unearthed VT windings

Failure to isolate & earth transformer

under test after test

Inadvertent contact with LV supply

leads

HV Test voltage exceeds set point or

control malfunction gives runaway

Insufficient clearance between test HV

leads and between test leads and

other apparatus

Electric Shock

Damage to equipment

High Voltage from CT

secondaries

Open Circuited CT secondary

windings, unearthed VT windings

Electric Shock

Damage to equipment

Check this is the latest Process Zone version before use.

Page 4 of 8

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Risk Score

Additional/

Existing

Alternate

Controls

Controls

CT secondary windings

HV Test Set

Transformer under test

Low

CT secondary windings

HV Test Set

Transformer under test

Low

Reference SP0504R01 Ver 1

Reference Owner: Neil Dwyer, Manager Technical Services

JOB SAFETY ANALYSIS POWER TRANSFORMER TESTING

Task

No.

Task Step

Hazard

Floating VT voltages

Applied Test Voltages

Hot test leads and connections

10

Power Transformer No Load

Loss Test

Complete and Clean up

High Voltage from CT

secondaries

Floating VT voltages

Applied Test Voltages

Undischarged or energised test

equipment

Energised HV apparatus without

fault protection

Check this is the latest Process Zone version before use.

Most Likely Breakdown Event (Loss Of

Control)

Most Likely Outcome (Incident

Outcome)

Exceeding the current rating of the

Test Equipment use of incorrect CT

tapings on measuring circuit

Use of under rated shorting bars

Failure to isolate & earth transformer

under test after test

Inadvertent contact with test supply

leads

Insufficient clearance between test HV

leads and between test leads and

other apparatus

Open Circuited CT secondary

windings, unearthed VT windings

Exceeding the rating of the Test

Equipment use of incorrect VT ratios

on measuring circuit

Failure to isolate & earth transformer

under test after test

Inadvertent contact with test supply

leads

Insufficient clearance between test HV

leads and between test leads and

other apparatus

Failure to isolate, discharge and earth

all test equipment

Failure to restore transformer under

test to condition as delivered (such as

shorted CTs)

CT secondary windings

Page 5 of 8

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Risk Score

Additional/

Existing

Alternate

Controls

Controls

Test Set

Transformer under test

Electric Shock

Damage to equipment

Low

CT secondary windings

Test Set

Transformer under test

Electric Shock

Damage to equipment

Low

VT secondary windings

Transformer that was

under test

Reference SP0504R01 Ver 1

Reference Owner: Neil Dwyer, Manager Technical Services

JOB SAFETY ANALYSIS POWER TRANSFORMER TESTING

Existing Control Measures

Task

No.

Elimination

Substitution

Engineering

Administration

Personal Protective

Equipment

Risk Ranking

C = Consequences E = Exposure P = Probability

C

Risk Score

Control measures are in place as described in the JSA Carry Out Field Testing SP0506R01 and its related

SWP SP0506 as well as the SWP Power Transformer Testing SP0504

Standard PPE,

fall restraint

harness

Low

Standard PPE,

Nitrile gloves and

full face shield

Low

Low

4

5

Standard PPE

Low

Standard PPE

Low

Standard PPE,

Low

Standard PPE,

leather gloves for

hot test leads

Low

Standard PPE

Low

10

Standard PPE

Low

Check this is the latest Process Zone version before use.

Page 6 of 8

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Reference SP0504R01 Ver 1

Reference Owner: Neil Dwyer, Manager Technical Services

JOB SAFETY ANALYSIS POWER TRANSFORMER TESTING

Additional/Alternative Control Measures

Task

No.

Elimination

Substitution

Check this is the latest Process Zone version before use.

Engineering

Administration

Page 7 of 8

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Personal Protective

Equipment

Risk Ranking

C = Consequences E = Exposure P = Probability

C

Risk Score

Reference SP0504R01 Ver 1

Reference Owner: Neil Dwyer, Manager Technical Services

JOB SAFETY ANALYSIS POWER TRANSFORMER TESTING

1: DETERMINE CONSEQUENCE: - The most likely outcome of a potential incident resulting from exposure to the

identified hazard.

4: RISK ASSESSMENT MATRIX

Probability x Exposure

Level

Descriptor

Disaster

Definition

1 to 2

Fatality; toxic release off-site with detrimental effect; financial loss (>$1,000,000).

Very Serious

Extensive injuries (e.g. permanent disability, amputation) requiring medical treatment, hospitalisation and

long term rehabilitation; off-site release with no detrimental effects loss of production capability; financial

loss ($500,000 to $1,000,000).

Serious

Disabling injuries requiring medical treatment and rehabilitation (e.g. broken limbs, hospitalisation); on-site

release contained with outside assistance; financial loss ($50,000 to $500,000).

Substantial

Medical treatment required (e.g. stitches, removal of foreign body); on-site release immediately contained;

financial loss ($5,000 to $50,000).

Minor

Descriptor

Continuous

6 to 10

11 to 23

24 to 36

Likelihood (How often?)

Almost

certain will

occur

Quite

possible

could occur

Possible

Unlikely but

possible

Extremely

unlikely

5. Disaster

Extreme

Extreme

Extreme

High

Moderate

4. Very Serious

Extreme

Extreme

High

Moderate

Low

3. Serious

Extreme

High

High

Moderate

Low

2. Substantial

High

Moderate

Moderate

Low

Low

1. Minor

High

Moderate

Low

Low

Low

Consequences

(How Bad?)

First aid treatment; negligible environmental damage; financial loss (<$5,000).

2: DETERMINE EXPOSURE: - How often a person interacts with a hazard.

Level

3 to 5

Definition

Many times a day.

Frequent

Occasional

Daily.

Weekly.

Infrequent

Between weekly and monthly.

Rare

Between monthly and yearly.

Very Rare

5: RISK TREATMENT STRATEGY

Less than once a year.

Risk Score

Required Actions

3: DETERMINE PROBABILITY

The likelihood of the breakdown event and nominated consequences occurring once the person is exposed to the

hazard.

Level

Descriptor

Definition

Almost Certain

Breakdown event will almost certainly occur from exposure to hazard.

Quite Possible

Not unusual for breakdown event occurring, even 50/50 chance.

Unusual but Possible

Remotely Possible

Conceivable but

Unlikely

Practically Impossible

Unusual for breakdown event to occur but possible.

Low

Moderate

Action required within agreed timeframe to minimise risk to As Low As Reasonably

Practicable (ALARP). Further action may be required and management responsibility

specified to take this action. The ALARP principle implies that controls have been

determined such that the level of risk-reducing action is in proportion to the benefit

obtained.

High

Action as soon as possible to minimise risk to acceptable level. Requires attention by

senior management and measures should be put in place to reduce the probability,

exposure and/or consequence of the outcome occurring to ALARP.

Remote possibility of breakdown event occurring but history of occurrence exists within industry.

No known history of breakdown event occurring after years of exposure but is conceivably possible.

Practically impossible for breakdown event to occur. Has never occurred before and is not likely to occur.

Check this is the latest Process Zone version before use.

Implement control measures and verify compliance by routine monitoring.

Extreme

Same treatment as for high risks however immediate action required to minimise risk to

acceptable level.

(Adapted from AS/NZS 4360:1999 Risk Management and NSCA Risk Score Calculator, 2001)

Page 8 of 8

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Reference SP0504R01 Ver 1

Reference Owner: Neil Dwyer, Manager Technical Services

Vous aimerez peut-être aussi

- Schneider Automatic Circuit Recloser SWP: 1. Purpose and ScopeDocument7 pagesSchneider Automatic Circuit Recloser SWP: 1. Purpose and ScopeJairo WilchesPas encore d'évaluation

- Current Transformer Testing SWP: 1. Purpose and ScopeDocument9 pagesCurrent Transformer Testing SWP: 1. Purpose and ScopeDEADMANPas encore d'évaluation

- Power Transformer Testing SWP: 1. Purpose and ScopeDocument14 pagesPower Transformer Testing SWP: 1. Purpose and ScopeRahim KhanPas encore d'évaluation

- Transformer PolarityDocument4 pagesTransformer Polarityboy2959Pas encore d'évaluation

- Bizu Teste Trafo Power Transformer Testing Brochure ENUDocument32 pagesBizu Teste Trafo Power Transformer Testing Brochure ENUdiogoufrn-1Pas encore d'évaluation

- Xr350-Tcsr by ReyrolleDocument3 pagesXr350-Tcsr by ReyrolleGunta RavitejaPas encore d'évaluation

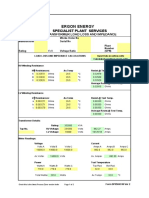

- Ergon Energy: Specialist Plant ServicesDocument4 pagesErgon Energy: Specialist Plant ServicesMohan Raj100% (1)

- Bus Assembly Testing SWP: 1. Purpose and ScopeDocument5 pagesBus Assembly Testing SWP: 1. Purpose and ScopeJarrett MathewsPas encore d'évaluation

- Power System Analysis: Merger TestDocument8 pagesPower System Analysis: Merger TestAnonymous mNQq7ojPas encore d'évaluation

- 4.various Tests Part 1Document69 pages4.various Tests Part 1Rohit JoshiPas encore d'évaluation

- Subject Code: Ee 1005 Subject Name: Power Quality: What Are The Causes Due To Short Circuit in TheDocument22 pagesSubject Code: Ee 1005 Subject Name: Power Quality: What Are The Causes Due To Short Circuit in TheChetan KotwalPas encore d'évaluation

- Current Transformers, Voltage Transformers and Instrument Transformers - IndiaDocument10 pagesCurrent Transformers, Voltage Transformers and Instrument Transformers - IndiaVijay PitchaiahPas encore d'évaluation

- Project Title: Operating Area: Main Contractor: T&C Contractor: Contract No.: SubstationDocument1 pageProject Title: Operating Area: Main Contractor: T&C Contractor: Contract No.: SubstationRam KumarPas encore d'évaluation

- 220v DC SystemDocument16 pages220v DC SystemsanjeevchhabraPas encore d'évaluation

- Voltage Transformer TestingDocument19 pagesVoltage Transformer TestingAfrin HossainPas encore d'évaluation

- SP0507Document9 pagesSP0507karimiPas encore d'évaluation

- PSGDocument13 pagesPSGya vikaPas encore d'évaluation

- JCT College of Engineering and Technology: Pichanur, Coimbatore-641105, India ISO 9001:2008 Certified InstitutionDocument16 pagesJCT College of Engineering and Technology: Pichanur, Coimbatore-641105, India ISO 9001:2008 Certified InstitutionPrakash Chandran CPas encore d'évaluation

- Ts Based All StandardsDocument12 pagesTs Based All Standardsanjes1Pas encore d'évaluation

- Test On TransformerDocument13 pagesTest On TransformerGurvinder Singh Virdi100% (2)

- Tinh Dong Ngan Mach Va Ton That Co TaiDocument3 pagesTinh Dong Ngan Mach Va Ton That Co TaiNga VũPas encore d'évaluation

- SP0407Document12 pagesSP0407isukuruPas encore d'évaluation

- EE 466 Power System Protection: University of HailDocument22 pagesEE 466 Power System Protection: University of Hailselvithimmarajan@gmail.comPas encore d'évaluation

- Capacitor BankDocument16 pagesCapacitor BankKyaw Soe0% (1)

- EE - TransformerDocument5 pagesEE - TransformerNiño PerezPas encore d'évaluation

- Schematic/Wiring Diagram:: Sensitivity: LNT Construction Internal UseDocument6 pagesSchematic/Wiring Diagram:: Sensitivity: LNT Construction Internal UseramyapothurPas encore d'évaluation

- Power Quality TechniquesDocument9 pagesPower Quality TechniquesS Bharadwaj ReddyPas encore d'évaluation

- Transformer TestingDocument2 pagesTransformer Testingsajjad_pirzadaPas encore d'évaluation

- 04 Fault CalculationsDocument31 pages04 Fault CalculationsRatheesh KumarPas encore d'évaluation

- Tan Delta TestingDocument2 pagesTan Delta TestingNillutpal BoruahPas encore d'évaluation

- Site Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationDocument7 pagesSite Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationSyed Abbas100% (1)

- Fact Devices in Power System Net Work: Rakesh Dundigalla 14621A020 3Document20 pagesFact Devices in Power System Net Work: Rakesh Dundigalla 14621A020 3NSunnyJoyPas encore d'évaluation

- Transformer Protection and Transformer FaultDocument3 pagesTransformer Protection and Transformer FaultThirumalPas encore d'évaluation

- HV Pressure Tests - 3Document4 pagesHV Pressure Tests - 3ssPas encore d'évaluation

- Effect Residual Magnetism On The Magnetic Core of A TransformerDocument4 pagesEffect Residual Magnetism On The Magnetic Core of A Transformerhendro suprianto nugrohoPas encore d'évaluation

- Electromagnetic Fields Temperature: BurdenDocument2 pagesElectromagnetic Fields Temperature: BurdenBashaPas encore d'évaluation

- Site Testing Pre Commissioning PDFDocument2 pagesSite Testing Pre Commissioning PDFadi nugrohoPas encore d'évaluation

- Transformer Primary Injection Connection ScheduleDocument5 pagesTransformer Primary Injection Connection ScheduleNiall BegleyPas encore d'évaluation

- MV Transformer Testing (7200DB1001Document4 pagesMV Transformer Testing (7200DB1001sulthanabdulPas encore d'évaluation

- Power Transformer Turns Ratio Test - EEPDocument6 pagesPower Transformer Turns Ratio Test - EEPlouiswang1964Pas encore d'évaluation

- What Is The Difference Between Power and Distribution TransformerDocument8 pagesWhat Is The Difference Between Power and Distribution Transformermaniking1Pas encore d'évaluation

- Psps Unit 1 QBDocument9 pagesPsps Unit 1 QBNaveen RajPas encore d'évaluation

- Flexible AC Transmission SystemDocument2 pagesFlexible AC Transmission SystemNehaPriyadarshniPas encore d'évaluation

- Department of Eee Question Bank: Sub Code: Ee1004 Sub Name: Power System Transients Year: Iv SEM: ViiiDocument8 pagesDepartment of Eee Question Bank: Sub Code: Ee1004 Sub Name: Power System Transients Year: Iv SEM: Viiiqais652002Pas encore d'évaluation

- PS7203-Advanced Power System ProtectionDocument6 pagesPS7203-Advanced Power System ProtectionntrimurthuluPas encore d'évaluation

- Power Transformer Testing ProceduresDocument4 pagesPower Transformer Testing Proceduresyadav_sctPas encore d'évaluation

- 1 FailureDocument80 pages1 FailureSunil SinghPas encore d'évaluation

- Saturable ReactorDocument2 pagesSaturable ReactorGilberto ManhattanPas encore d'évaluation

- EE2036 2 MarksDocument19 pagesEE2036 2 MarksSaravanan RameshPas encore d'évaluation

- Understanding Transformer PolarityDocument3 pagesUnderstanding Transformer PolarityVENKATESAN R100% (1)

- New QBhve3yearDocument29 pagesNew QBhve3yearArun SelvarajPas encore d'évaluation

- Job Safety Analysis Power Transformer TestingDocument8 pagesJob Safety Analysis Power Transformer TestingAnilPagoluPas encore d'évaluation

- Testing Methods Required To Maintain Electrical EquipmentDocument104 pagesTesting Methods Required To Maintain Electrical EquipmenttibetanlamaPas encore d'évaluation

- Transformer Testing by Afees Ahamed Egger IndiaDocument27 pagesTransformer Testing by Afees Ahamed Egger IndialrpatraPas encore d'évaluation

- Routine Test-Acceptance Criteria IEC (Power Transformer)Document2 pagesRoutine Test-Acceptance Criteria IEC (Power Transformer)Yingyong_s75% (4)

- Advanced Transformer Diagnostics PDF ADTS 2023 Dupuis ENUDocument51 pagesAdvanced Transformer Diagnostics PDF ADTS 2023 Dupuis ENUfernandoquecaPas encore d'évaluation

- Transformers Test FacilityDocument25 pagesTransformers Test FacilityHIRAK CHATTERJEEPas encore d'évaluation

- Transformer TestingDocument24 pagesTransformer Testingmuaz_aminu142264% (14)

- TF TestingDocument25 pagesTF Testingask4vinod100% (1)

- Pod 4999168985-DHLDocument1 pagePod 4999168985-DHLAvoor KhanPas encore d'évaluation

- Pod 4999168985-DHLDocument1 pagePod 4999168985-DHLAvoor KhanPas encore d'évaluation

- 004 - 60a THN3362SS - 10103091SH109 Data SheetsDocument2 pages004 - 60a THN3362SS - 10103091SH109 Data SheetsAvoor KhanPas encore d'évaluation

- 003 Achilles Chemicals Allied Quick Start Guide 1Document1 page003 Achilles Chemicals Allied Quick Start Guide 1Avoor KhanPas encore d'évaluation

- Saco16d3 en A PDFDocument48 pagesSaco16d3 en A PDFPepeVichechePas encore d'évaluation

- Zone 1, 2, 21, 22 - Group IIB+H - Aluminium Junction Boxes - IP 66 / 67Document22 pagesZone 1, 2, 21, 22 - Group IIB+H - Aluminium Junction Boxes - IP 66 / 67Avoor Khan100% (1)

- Copper Penn-Crimps Telecommunication Lugs - Type Bblu-2Tc: 2 Hole Long Barrel Lugs For 8 Stranded Thru 2000 MCMDocument2 pagesCopper Penn-Crimps Telecommunication Lugs - Type Bblu-2Tc: 2 Hole Long Barrel Lugs For 8 Stranded Thru 2000 MCMAvoor KhanPas encore d'évaluation

- MV Cables Data Sheet - SampleDocument5 pagesMV Cables Data Sheet - SampleAvoor KhanPas encore d'évaluation

- QUO-02553-X9Y3: Customer Information ليمعلا تامولعمDocument2 pagesQUO-02553-X9Y3: Customer Information ليمعلا تامولعمAvoor KhanPas encore d'évaluation

- The Saudi Parallel Market NomuDocument7 pagesThe Saudi Parallel Market NomuAvoor KhanPas encore d'évaluation

- Temp Access FormDocument1 pageTemp Access FormAvoor KhanPas encore d'évaluation

- HEX Lugs Price ListDocument10 pagesHEX Lugs Price ListAvoor KhanPas encore d'évaluation

- Model 4 MCC Buckets - D Selector Guide - Schneider Price ListDocument3 pagesModel 4 MCC Buckets - D Selector Guide - Schneider Price ListAvoor KhanPas encore d'évaluation

- Lighting Sketch BuildingsDocument15 pagesLighting Sketch BuildingsAvoor KhanPas encore d'évaluation

- Staffing by Ward May 2015Document1 pageStaffing by Ward May 2015Avoor KhanPas encore d'évaluation

- Code of EthicsDocument7 pagesCode of EthicsAvoor KhanPas encore d'évaluation

- TPE (Web) - MinDocument16 pagesTPE (Web) - MinAvoor KhanPas encore d'évaluation

- List of ManpowerDocument1 pageList of ManpowerAvoor KhanPas encore d'évaluation

- Tender TXX-TN 261110Document29 pagesTender TXX-TN 261110Avoor KhanPas encore d'évaluation

- Flange Weld Testers (FWT)Document1 pageFlange Weld Testers (FWT)moonstar_dmePas encore d'évaluation

- B04 HighVoltageElectricalWorkDocument38 pagesB04 HighVoltageElectricalWorkAvoor KhanPas encore d'évaluation

- Annexure - Equipments ListDocument3 pagesAnnexure - Equipments ListAvoor KhanPas encore d'évaluation

- Phenix 650-2P Portable AC Dielectric Test Set Phenix 6502P 650 2P 650-2P - TEquipmentDocument3 pagesPhenix 650-2P Portable AC Dielectric Test Set Phenix 6502P 650 2P 650-2P - TEquipmentAvoor KhanPas encore d'évaluation

- 004 Annexure D Job Safety SAnalysis JSADocument3 pages004 Annexure D Job Safety SAnalysis JSAAvoor Khan75% (4)

- Prequalification QuestionnairDocument28 pagesPrequalification QuestionnairAvoor KhanPas encore d'évaluation

- Project Management PQQ Part ADocument7 pagesProject Management PQQ Part AAvoor KhanPas encore d'évaluation

- Services HTMLDocument1 pageServices HTMLAvoor KhanPas encore d'évaluation

- Pre-Qualification Submittal FOR Testing and Pre-Commissioning of Electrical SystemsDocument1 pagePre-Qualification Submittal FOR Testing and Pre-Commissioning of Electrical SystemsAvoor KhanPas encore d'évaluation

- 026 Subcontracting Plan ModelDocument10 pages026 Subcontracting Plan ModelAvoor KhanPas encore d'évaluation

- Turbo Generator at NalcoDocument13 pagesTurbo Generator at NalcoSanjay Kumar PandaPas encore d'évaluation

- Unified Power Quality Conditioner (UPQC) : The Principle, Control and ApplicationDocument6 pagesUnified Power Quality Conditioner (UPQC) : The Principle, Control and ApplicationgametamilPas encore d'évaluation

- A0342 A0342m-04Document5 pagesA0342 A0342m-04bs2002Pas encore d'évaluation

- Resistance Electricity Class X Science Ncert Ncert Questions Science Class 10 Chapter 1 Ncert Notes Electrical ResistivityDocument2 pagesResistance Electricity Class X Science Ncert Ncert Questions Science Class 10 Chapter 1 Ncert Notes Electrical ResistivityPranavMehtaPas encore d'évaluation

- Chapterwise Board QuestionsDocument11 pagesChapterwise Board QuestionsMirza SabeelPas encore d'évaluation

- 6-Momentum Theory in Forward FlightDocument20 pages6-Momentum Theory in Forward FlightAravindAchuthanNairPas encore d'évaluation

- Vectors Ws PDFDocument2 pagesVectors Ws PDFJose Barrera GaleraPas encore d'évaluation

- Conservation of MomentumDocument7 pagesConservation of MomentumJaime Andres TejeiroPas encore d'évaluation

- Derivation of Lagrange Equations From D'AlembertDocument29 pagesDerivation of Lagrange Equations From D'AlembertAbhiPas encore d'évaluation

- HJS-480-0-220 480W Switching Power Supply InstructionsDocument11 pagesHJS-480-0-220 480W Switching Power Supply Instructionsdonsterthemonster0% (2)

- Unit 5 - A CASE STUDY - Using Pic MicrocontrollerDocument33 pagesUnit 5 - A CASE STUDY - Using Pic MicrocontrollerPoonthalirPas encore d'évaluation

- 03 - Power Arrester, 100KA-SPD3P100K-O-MH Technical SpecificationDocument9 pages03 - Power Arrester, 100KA-SPD3P100K-O-MH Technical SpecificationhammoumiPas encore d'évaluation

- Unit 8 Radar CrossectionDocument16 pagesUnit 8 Radar CrossectionVinamra KumarPas encore d'évaluation

- Transformer Design by KanakDocument24 pagesTransformer Design by KanakAmirul Alam Kanak100% (1)

- Compliance Inspection Test SheetDocument3 pagesCompliance Inspection Test SheetFlorin PanazanPas encore d'évaluation

- Fluid Dynamics I M Usman HamidDocument159 pagesFluid Dynamics I M Usman HamidNaik MuhamadPas encore d'évaluation

- Chapter 5Document11 pagesChapter 5dar •Pas encore d'évaluation

- Structural DynmicsDocument352 pagesStructural DynmicsAtul Kumar Engineer100% (1)

- Resonance CircuitsDocument68 pagesResonance CircuitsJohn Miko JavierPas encore d'évaluation

- Sound - Wikipedia, The Free EncyclopediaDocument6 pagesSound - Wikipedia, The Free EncyclopediaRoshanaManjunathPas encore d'évaluation

- PHYS 241 Lecture 1Document9 pagesPHYS 241 Lecture 1avixPas encore d'évaluation

- Critical SpeedDocument2 pagesCritical SpeedNaelPas encore d'évaluation

- Iit/Aiims Screening Test: 22A Section-I - : Straight Objective Type (4, - 1) Physics + Chemistry + MathematicsDocument8 pagesIit/Aiims Screening Test: 22A Section-I - : Straight Objective Type (4, - 1) Physics + Chemistry + Mathematicsb productivePas encore d'évaluation

- C3abmb000027 (26P) : B1adcf000001Document1 pageC3abmb000027 (26P) : B1adcf000001Danilo Concepción SánchezPas encore d'évaluation

- Memory-Motors Ostovic 2002Document8 pagesMemory-Motors Ostovic 2002Jo0251Pas encore d'évaluation

- DC Power SystemDocument24 pagesDC Power SystemboltgingerkoppyPas encore d'évaluation

- Maths Guru: B-242, DDA FLATS BINDAPUR ND-59.MOB:9818322670, EmailDocument2 pagesMaths Guru: B-242, DDA FLATS BINDAPUR ND-59.MOB:9818322670, Emailsanjay kumarPas encore d'évaluation

- Regulador Automatico de Voltaje SS053 - CRAMDocument1 pageRegulador Automatico de Voltaje SS053 - CRAMWALTERPas encore d'évaluation

- Unraveling The Commutation Mystery PDFDocument91 pagesUnraveling The Commutation Mystery PDFMohamed ElsayedPas encore d'évaluation

- Transformers - Voltage and Current - Rosy - CT 0106 - R01Document1 pageTransformers - Voltage and Current - Rosy - CT 0106 - R01Jainish GhadiyaPas encore d'évaluation