Académique Documents

Professionnel Documents

Culture Documents

Design and Analysis of Detachable Type Backhoe and Loader

Transféré par

IJORATTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design and Analysis of Detachable Type Backhoe and Loader

Transféré par

IJORATDroits d'auteur :

Formats disponibles

International Journal of Research in Advanced Technology IJORAT

Vol 1, Issue 9, NOVEMBER 2016

DESIGN AND ANALYSIS OF

DETACHABLE TYPE BACKHOE AND

LOADER

1

R.JAISON M.E ., 2RAMESH KUMAR M.E .,

Assistant Professor, Department of Mechanical Engineering, Francis Xavier Engineering college, Tirunelveli.

Assistant Professor, Department of Mechanical Engineering, Francis Xavier Engineering college, Tirunelveli.

email-id: 1jaisonrmech@gmail.com,

Abstract:

In this project a detachable type backhoe components are designed and analysed using

ANSYS so that it can be mounted over an agricultural tractor and can be used for trenching, digging etc.

This design makes backhoe compact in size and shape so that it is fitted inside the tractor. This can be

used as a special attachment to the tractor like other attachments like driller, slicer, truck etc. This paper

deals with the design of backhoe components, loader components and special chassis for the tractor for a

limited load of 2000N backhoe and 6000N loader. This has hydraulic unit which is selected to run by the

tractor engine power of 50Hp whereas the original backhoe has 60Hp. It is made as a special detachable

attachment so that the load is limited when compared to original backhoe. The design process is carried

out from determining the component dimensions that are required to withstand the load by both

analytical calculations and software modelling. The components are 3D modelled using CREO

PARAMETRIC modelling software and then structural analysis is carried out over the components using

ANSYS.

Keywords: - Backhoe, Loader, BOOM, Stick, Bucket, etc.

I. INTRODUCTION

Backhoe loaders are very powerful and

versatile equipments they can perform many tasks,

like lifting and moving supplies or digging earth

etc. So far many researches have been carried out

in improvisation of backhoe by changing its size,

orientation, and materials used in it. These were

carried out on the basis of cost effectiveness and

for better utilization of the power. Since these

backhoes are mainly used for large scale and heavy

industrial work these are huge in size and they can

be used only for limited purposes. Based on this

feedback this research is been carried out for

designing a detachable type backhoe. So the tractor

can be used as a multipurpose equipment.

A. Components in Backhoe and Loader

The backhoe is the most important part the

backhoe loader. It has three segments are viz.

Boom, stick and bucket. This arrangement is very

similar to human arm. Human arm has three

segments - upper arm, forearm and hand. The

backhoe segments are connected by three joints,

comparable to your wrist, elbow and shoulder. The

backhoe moves in pretty much the same way as

your arm. In loader Boom and stick are the main

components.

All Rights Reserved 2016 IJORAT

FIG.1 Backhoe Loader Components

The stabilizers keep the tractor steady,

minimizing the jostling effect of digging with the

backhoe. They also secure the tractor so that it

wont slip into the ditch or hole. There are two

kinds of stabilizer legs they are inclined stabilizer

and vertical stabilizers.

Hydraulic systems simply used to transmit

forces from point to point through fluid. The fluid

that used in most systems is incompressible fluid

such as oil. Hydraulic systems in backhoe loader

includes: hydraulic power, hydraulic valves,

hydraulics in the backhoe, hydraulics in the loader

and hydraulic pump.

Levers are rigid bars that transmit force.

They pivot around a fulcrum. Levers can either

magnify the effort force to move the load force,

resulting in a force advantage, or decrease the

International Journal of Research in Advanced Technology IJORAT

Vol 1, Issue 9, NOVEMBER 2016

distance the effort force must travel to move the

load, resulting in a speed advantage. Class 1 levers

are used in the backhoe. This means that the

fulcrum is between the load and effort.

B. Moving the Backhoe

Hydraulics, levers and the gear pump are

combined to make a backhoe that can be bent and

turned in many ways. The three joints in the

backhoe can be bent like your shoulder, elbow and

wrist. Many hoses run from the pimp up the

backhoe to supply oil to the hydraulic rams

(pistons). The operator controls the hydraulics in

the backhoe with two joysticks.Two hydraulic

pistons connect the boom to the tractor. The pistons

allow the backhoe to rotate from side to side. When

one of them pushes, the other pulls, so that the

boom can be swung sideways.

There is also a piston connecting the

tractor and boom. Since the boom is a lever, when

the piston pushes or pulls it rotates on its fulcrum,

which would be its other connection to the tractor.

The other end of the boom, along with the rest of

the backhoe attached to it, is lifted and lowered like

this.

The stick and bucket are moved in the

same way, with a hydraulic piston rotating them

around the point where they are attached to the

previous part of the backhoe. The backhoe has two

stabilizer legs to keep the tractor steady when the

backhoe is digging. It also prevents the tractor from

falling into the hole that is being dug.

II.SCOPE OF THE PROJECT

The main purpose of the project is to

design a detachable type backhoe. An extra

equipment and can be used for small scale purposes

by mounting it over agricultural tractor. The design

is carried out for a tractor of power 50 HP which

can carry a load of 2000N i.e. 205 Kg

approximately by the backhoe and 6000N by the

loader.

After the completion of parts modelling

the individual parts and components are subjected

to Structural analysis using Finite Element

packages like ANSYS.

Assembling the components are carried

out after carrying out the component analysis and

the components are structurally analysed till the

safe design is obtained.

IV.DESIGN OF BACKHOE COMPONENTS

A. Degrees of Freedom

As the backhoe functions similar to human

arm, but DOF in the backhoe mechanism is less

than human arm as the human arm has 8 DOF

while the backhoe has 4 DOF.

By KutzBachs Criteria

Degrees of Freedom = 3(n-1) 2J1 J2

Here

J2= 0, J1 = 16, n= 13

Therefore

Degrees of Freedom = 4

B. Materials Used

Materials are considered based

on Crane Handbook Design Data and

Engineering Information used in the manufacture

and applications of Cranes by H.G. Greiner [3] are

shown in Table.1.

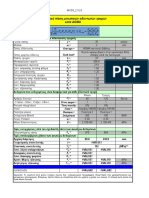

Table.1 Materials Used

Components

Material Used

1

2

3

4

S.No

Boom

Stick

Bucket

Swinger

Medium

Strength

Alloy Steel

Hydraulic

cylinder

Cylinder

piston

ASTM

A514

Mild Steel

SA 36 Grade

All Rights Reserved 2016 IJORAT

Yield strength

= 450 N/mm

Poisson Ratio

= .29

Density

= 7900 kg/m3

Ultimate Strength = 450 N/mm2

Yield strength

= 250 N/mm

Poisson Ratio

= .27

Density

= 5600 kg/m3

Ultimate Strength = 841 N/mm2

Pin

Hardened

carbon steel

ASTM EN8

III PROPOSED METHODOLOGY

The procedure for obtaining the objective

of the project is by performing the Analytical

calculations for the backhoe and loader components

initially with the required loading condition. The

bucket is designed using the modelling software

meeting the requirement by trial and error method.

The next step is to design the main

components of backhoe which are necessary to

move the bucket with the design of hydraulic units

like Cylinders and piston, etc.

Once the design calculations are carried

out the final dimensions are fixed and Modelling of

the backhoe and loader is carried out using

modelling

software

like

CREO,

CREO

PARAMETRIC 2.0, and Auto-CAD.

Material Properties

Ultimate Strength = 690 N/mm2

Yield strength

= 650 N/mm2

Poisson Ratio

= .29

Density

= 7850 kg/m3

C.Bucket Capacity

Bucket capacity is a measure of

the maximum volume of the material that can be

accommodated inside the bucket of the backhoe

excavator.It is calculated based on the equations

and referred from research paper SAE J296.

Bucket capacity (V) = Vs + Ve

Where

Vs = Dump Capacity

Ve = Excess Capacity

=

=

2

4

2

3

12

(1)

........ (2)

International Journal of Research in Advanced Technology IJORAT

Vol 1, Issue 9, NOVEMBER 2016

Parea= 67836 mm2 (measured from the Part

modelled using Creo- Elements)

Fig.2 Bucket Dimension

Maximum open Length of Bucket = 490 mm

Inner width of bucket ( Wf)

= 470 mm

Thickness of bucket (t)

= 6mm

Total width of bucket (Wr)

= 482mm

Therefore

Dump Capacity of Bucket: Vs = .0323 m3

Excess Capacity of Bucket:

Vs = .019188

m3

Total Bucket Capacity

V = .05 m3

D.Design of the Stick & Boom

Design is carried out for a load of 2000N.

Therefore the initial breakout force of the Bucket is

given by

Breakout force

Max. Lift Capacity =

(3)

(Factor Of Safety 1)

Factor of safety is taken According to

Roymech, UK standards [7]as 5,

(For materials

that are to be used in uncertain environments or

subject to uncertain stresses).

Breakout Force = Max.Lift Capacity * (FOS- 1)

.............

(4)

= 8000 N.

Bending Moment = Force X Distance

..(5)

Force is said to act at one end and the

effort is at the other end since it is of type CLASS 1

Levers. Therefore

Length = Bending Moment / Breaking Force (6)

Moment is Calculated Using Bending Moment

equation

M

=

. 7

I

Allowable Stress = Ultimate Strength/FOS ...... (8)

= 138 N/mm2

Moment of Inertia is given by the formula from

PSG DATA BOOK as.

bh3 b1 h13

I=

. (9)

12

Assumptions:

* The stick cross section is idealized into

Box Channel Cross Section of 100mm X 130 mm

with thickness of 12mm.

* The BOOM cross section is idealized

into C Channel Cross Section of 110mm X 155

mm with thickness of 12mm.

Using the above equations the

All Rights Reserved 2016 IJORAT

Length of Stick = 1700mm

Length of BOOM = 1970mm

E. Design of Banana Boom for Backhoe:

Banana boom as the name represent it is in

the shape of the banana the ratios of the basic

dimensions for the design of boom for backhoe are

given below

Length: Height (L:h) = 2:1

Ratio of inclination height and Length is

(a:L) = 1: 1.5

Angle of inclination of Boom is 30 to 50

In this design it is taken as 45

The length of the boom (L) is already

calculated using bending moment equation as

1970mm

The following figure gives the idea about the

representation of length and height

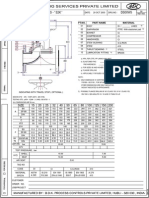

FIG .3 Length and Height of Banana Boom

Therefore

Height (h)

= 985 mm

Inclination height (a)

= 1313.13 mm

1310 mm

F. Hydraulic Pump

Pump Used:

Gear pump

Max.Pressure

= 250 bar

Operating Pressure

= 150 bar

Speed Range

= 700 rpm 1500 rpm

Operating Speed

= 750 rpm

Horse power

= 50 hp

The main reason for using gear pump is it

provides precise volumetric control of the fluid and

creates more output force for the given input

pressure.

G.Swing Design

The swing in backhoe is the component to

turn the backhoe to its right and left. It is similar to

a rocker arm provided with hydraulic force to turn

the backhoe. It is positioned at the bottom of the

BOOM to which the boom cylinder is attached.

6

International Journal of Research in Advanced Technology IJORAT

Vol 1, Issue 9, NOVEMBER 2016

It is created using modelling software with

the backhoe boom assembly the hydraulic cylinders

used to generate force are smaller in size when

compared to other hydraulic cylinders. Two

cylinders are used to swing it in either directions.

Fig.4 Swing Design

H.Hydraulic Cylinder and Piston

Component

For BOOM

For STICK

For BUCKET

For SWING

The stroke length of the piston is taken

based on the angle of rotation that has to be

achieved in the components Boom , Stick and the

Bucket. For maximum storing capacity the bucket

must have a rotation of 100 to 120 , the stick

must have 120 to 135 angle of rotation and the

boom is said to have a rotation of 55 to 70 . The

stroke length of the hydraulic unit is calculated

based on ratio with the angle of rotation of the

individual parts. The provided standard ratios are

Boom Cylinder: Boom Rotation

= 6:1

Stick Cylinder: Stick Rotation

= 5: 1

Bucket Cylinder: Bucket Rotation = 4:1

Initially the angle of rotation of

Boom, Stick and Bucket are taken as 60 120 , and

100 respectively.

Table 2 Standard Hydraulic Cylinder and Piston Dimension

Cylinder diameter Piston Diameter

Rod diameter

Cylinder

(mm)

Di(mm)

Dr(mm)

length

(mm)

120

100

65

550

120

100

55

800

100

80

45

600

100

80

60

400

TABLE.3 Hydraulic Cylinder and Piston Parameters

PARAMETERS

BOOM

STICK

BUCKET

SWING

CYLINDER BLIND END

7850

7850

5024

5024

AREA (mm2)

3316.62

2374.625

1589.635

2956.63

ROD AREA (mm2)

CYLINDER ROD END

4533.38

5475.375

3434.375

2067.37

AREA(mm2)

CYLINDER OUTPUT

117.75

117.75

75.36

75.36

FORCE (KN)

I. Position of Hydraulic Cylinder with Respect

to Boom, and Stick

The free body diagram of the boom and

stick contact is taken from SAE J1179 standard

Hydraulic Excavator and Backhoe: Digging

Forces [9] is used to determine the location of

the hydraulic cylinder and piston joints.

Stroke

Length

(mm)

350

600

400

300

STABILIZER

7850

3316.62

4533.38

117.75

Maximum angle between the boom

inclination and cylinder is taken as 15 degree.

Therefore

tan =

dE

= 375 mm

and

dA

= tan x dE

dA

= 315.5mm

dF = total stick length + max.open width of Bucket

dF

= 2220 mm

dB

= 520 mm

Total span

= BOOM length + dF - dE - dA

= 3499.5 mm

The backhoe is designed to cover a

distance of 3500 mm from the tractor which is

nearly 11.5 feet. The span of the backhoe is said to

be 11 feet.

FIG.5 Free Body Diagram

All Rights Reserved 2016 IJORAT

J.Bucket Curling Force and Digging Force

The bucket curling force is the

force that is generated in the bucket tip by the

7

International Journal of Research in Advanced Technology IJORAT

Vol 1, Issue 9, NOVEMBER 2016

movement of the stick to which the bucket is

attached. While the digging force is generated by

the bucket cylinder which controls the movement

of the bucket. With SAE J1179 standard

Hydraulic Excavator and Backhoe: Digging

Forces[9] as reference bucket curling and digging

forces are given by

=

P x x D 2A x dA x dE

4 x dF x dB

P x x D 2 x dA

....(10)

Bucket digging force

= 16.734 KN

H.Diameter of Pin

The pin length can be determined using

the respective component width as it is made to fit

inside the component.

The pin diameter is determined using the

bending moment equation in equation no.7Where

y= distance from the centre axis to the outside

surface of pin i.e D/2. Factor of safety is taken

According to Roymech, UK standards [7]The

FOS =4 Materials obtained for reputable suppliers

to relevant standards operated in normal

environments and subjected to loads and stresses

that can be determined using checked calculations

Here breakout force includes the

component weight also which is taken from the

ANSYS result.

B

=

(11)

4 x dF

Where

P operating pressure, dA,dE,dF,dB are

taken from the free body diagram, D A is the

diameter of the cylinder used for stick movement

and DB is the diameter of the cylinder used for the

bucket movement.

Bucket curling force= 17.377 KN

Table.4Component Weight and Pin Dimensions

S.NO

Component

Weight

Total load

Breakout

Length of

(N)

force (N)

pin (mm)

1

Bucket

19.8

2194.04

8776.16

170

2

Stick

48.2

2472.36

9889.44

175

3

Boom

60.31

2591.04

10364.15

200

All Rights Reserved 2016 IJORAT

Diameter of

pin (mm)

40

45

50

International Journal of Research in Advanced Technology IJORAT

Vol 1, Issue 9, NOVEMBER 2016

V. DESIGN OF LOADER AND CHASIS

A.Loader Bucket:

Maximum open Length of Bucket = 490 mm

Inner width of bucket (Wf)

= 1410 mm

Thickness of bucket (t)

= 6mm

Total width of bucket (Wr)

= 1422mm

Therefore

Dump Capacity of Bucket is calculated using the

Equation 1

Vs = .0961 m3

Excess Capacity of Bucket is calculated using the

Equation 2

Vs = .0808 m3

Total Bucket Capacity

V = Vs + Ve

V = .1769 m3

The loader is designed for a load of 6000

N with the same open length as in Backhoe of

490mm.

FIG.6 Loader Bucket Dimensions

The same dimension of hydraulic

cylinders used for moving the backhoe stick is used

here also for the bucket movement and boom

movement.

BLoader Boom

In this design the stick and arm present in

the normal loader is made in to a single boom with

the ratio of 1:1 inclination height and Boom

height.Similar to backhoe -boom design the section

is idealized to cross section of C-Channel of

130mm x 130 mm with thickness of 12mm. There

will be two booms present to lift the bucket at the

same time so the breakout force is divided into two.

Breakout force for one arm = 12000 N

I = 70.6X 105 mm4

Moment is Calculated Using Bending

Moment equation in eq.7 and eq.5.

M

= 23.66 X 106 N-mm

Length = Moment / Breaking Force

L

= 2140 mm

Length of the loader boom = 2140 mm.

The length to height ratio is 2:1 therefore

the height of the boom is 1070mm from the base of

the post.

Inclination height = 1070 mm

All Rights Reserved 2016 IJORAT

FIG.7Loader Boom Dimensions

C.Chassis Construction

The backhoe and loader designed are for

small scale purposes with the agricultural tractor as

the operating source which doesnt have a chassis.

In normal tractor the engine and other components

are mounted over the front and rear axle. So a

simple chassis must be designed to lay a platform

to mount these special attachments.

The wheel base of agricultural tractors

differ with the manufactures here MAHINDRA

Tractor 250 is considered which have front wheel

clearance of 350mm. and wheel base of 2650mm in

length.

Therefore the chassis must be in length

greater than or equal to 1.5 times the wheel base.

With the trial and error method of

modelling the finalized length of the chassis is

3900mm. The chassis is fitted to the front and rear

axle of the tractor. For increasing the strength of

the chassis a simple ladder shaped chassis is

designed.

The cross section of the chassis is taken as

BOX channel of 120mmX120mm with thickness of

12mm.

FIG.8Chassis Structure and Dimension

VI. 3D MODELLING AND ANALYSIS

The 3d modelling is carried out in creo

parametric software of version 2.0. Which is also

used for drafting. While the analysis is carried out

using ANSYS-Workbench. Structural analysis is

carried on the components in backhoe and loader to

ensure that the components will withstand at the

specified load.

A.Backhoe Bucket

The backhoe bucket is analysed for the

designed load of 2000N at maximum loading

condition. The load is applied in terms of force in

Y-Direction acting downwards.

Maximum

developed stress = 6.5 N/mm2

9

International Journal of Research in Advanced Technology IJORAT

Vol 1, Issue 9, NOVEMBER 2016

D.Loader Bucket Analysis

The loader bucket is analysed for the

designed load of 6000N at maximum loading

condition. The load is applied in terms of force in

Y-Direction acting downwards.

Maximum

developed stress = 8.9 N/mm2.

FIG.9 Equivalent Stress Analysis in Backhoe Bucket

B.Backhoe Stick

The stick is analysed for a load of 2500 N

which includes the bucket weight which is

determined during the analysis of the bucket. The

end connected to the boom is fixed and the load is

applied at the other end. The maximum developed

stress is 35.7 N/mm2.

FIG.12Equivalent Stress Analysis in Loader Bucket

E.Loader Boom

Loader has two booms so the force is load

is equally divided among the two booms. Therefore

total load of 6800N including the bucket weight is

applied equally on two boom end connected to the

Bucket. The end connected to the post is fixed. The

maximum stress 6.5 N/mm2 is developed at the

fixed end.

FIG .10Equivalent Stress Analysis in Backhoe Stick

C.Backhoe Boom

The stick is analysed for a load of 3200 N

which includes the bucket weight and stick weight

which is determined during the analysis of the

bucket. The end connected to the swing is fixed and

the load is applied at the end connected to the stick.

The maximum developed stress is 8.03 N/mm2

FIG .13Equivalent Stress Analysis in Loader Boom

F. Chassis

The chassis designed is analysed with the

loading condition at two points and fixed support at

two points. The fixed support is provided at the

point where the chassis is connected to the wheel

axle and the load is applied at the points where the

backhoe and loader are placed. The load of 3400 N

is applied at the backhoe portion and 7300 N is

applied at the loader portion. The loads are applied

including the self-weight of the loader and backhoe

components.

FIG .11Equivalent Stress Analysis in Backhoe Boom

All Rights Reserved 2016 IJORAT

10

International Journal of Research in Advanced Technology IJORAT

Vol 1, Issue 9, NOVEMBER 2016

component this reduces the time consumption in

making of a improvement to the existing design.

REFERENCES

1.

Anand Thorat, and Seshagiri Rao G.V.R

(2012)Static Analysis of Loader Backhoe

chassis 770 Model International journal on

Modern applications,ISSN: 2277-9655, pp 6778

2.

Bhaveshkumar P. Patel, Dr. J. M. Prajapati,

(2011) Soil-Tool Interaction as a Review for

Digging Operation of

Mini Hydraulic

Excavator SAE INTERATIONAL J216, Vol. 3

No. 2, pp 894-901

3.

Crane handbook: design data and engineering

information used in the manufacture and

application of cranes 1967, Illustrated edition:

compiled by H.G. Greiner.

4.

Juber Hussain Qureshi , Manish Sagar

(2012) The Finite Element Analysis of Boom

of Backhoe Loader International Journal of

Modern Engineering Research (IJMER) Vol.2,

Issue.3, ISSN: 2249-6645, pp-882-884

5.

Luigi Solazzi, (2010 Design of aluminium

boom and arm for an excavator, Journal of

Terramechanics Vol.1. ISSN 3742-9857 pp

201207

6.

PSG Design DATA BOOK.

7.

Roymech, UK standards for FACTOR Of

SAFETY.

8.

Sachin B. Bende, and Nilesh P. Awate

(2008) Equipment Analysis, India Backhoe

Loader, ISSN:2955-4577, P.21

9.

SAE INTERNATIONALS (1990), SAE J1197,

Hydraulic excavator and backhoe digging

forces 400 commonwealth drive, Warendelle ,

pp 20- 29

FIG.14Equivalent Stress Analysis in Chassis

H. PIN

The pin is the component which is

subjected to tensile load at two points. In fig.15

bucket pin is analysed with both the ends fixed and

the load of 2194N (design load + bucket Load) is

equally applied at two points nearer to its fixed end.

The maximum equivalent stress developed is

11.129 N/mm2.

FIG.15Equivalent Stress Analysis in Pin

VII.CONCLUSION

In this design a detachable backhoe and

loader components are designed to be fitted on a

agricultural tractor to lift a load of 2000N and

6000N respectively. This attachment can be

removed once its work is completed and the tractor

can be used for other purposes like ploughing,

carrying loads etc. This backhoe is preferred for

trenching and digging in the fields where the

trenching process will be carried out often and to

carry waste from fields through the loader.

The detachable type backhoe components

are designed using theoretical calculations and with

modelling module using CREO PARAMETRIC.

Here Finite Element Analysis using ANSYS

WORKBENCH can be used as a tool to redesign

the component without making the prototype and

the loading condition can be simulated and make

the necessary changes at the design level, if

required for the proper functioning of the

All Rights Reserved 2016 IJORAT

10. Shiv Soni S. L (2014) Simulation and Static

Analysis on Improved Design of Excavator

Boom ISSN 2250-2459, Volume 4, Issue 3,

pp 232 238

11. UK

Essays

hydraulic

www.ukessays.com

Standards

12. Vimalkumar A. Patel

(2012 ) Static

Structural Analysis of Backhoe Loader

Chassis International Journal of Advanced

Science, Engineering and Technology ISSN

2319-5924 Vol 1, pp 17-20

11

Vous aimerez peut-être aussi

- Stress Analysis of Tractor Trolley Chassis With Effect of Various Thickness and Design Optimization For Weight Reduction Ijariie1894Document7 pagesStress Analysis of Tractor Trolley Chassis With Effect of Various Thickness and Design Optimization For Weight Reduction Ijariie1894anil sajjanarPas encore d'évaluation

- Design and Analysis of 22 Ton Class Excavator Swing Braking SystemDocument6 pagesDesign and Analysis of 22 Ton Class Excavator Swing Braking SystemInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- FEA and Optimization of Telescopic Boom of Mobiles Hydraulic CraneDocument6 pagesFEA and Optimization of Telescopic Boom of Mobiles Hydraulic CraneAzmi Bin A MataliPas encore d'évaluation

- BS 6911-3 Testing Earth-Moving MachineryDocument12 pagesBS 6911-3 Testing Earth-Moving Machinerytariq0% (1)

- ME8651 Notes Design of Transmission SystemsDocument71 pagesME8651 Notes Design of Transmission SystemsAslam AhamedPas encore d'évaluation

- Rated Loads For Lattice - and Telescopic-Boom CranesDocument7 pagesRated Loads For Lattice - and Telescopic-Boom CranesAmirsham SamerPas encore d'évaluation

- The Application of Bevel GearsDocument6 pagesThe Application of Bevel GearsPrasanth ThiagarajanPas encore d'évaluation

- Crane Wheels: Worldwide Movement With Wheels FromDocument78 pagesCrane Wheels: Worldwide Movement With Wheels Fromrozi apriPas encore d'évaluation

- ExcavatorDocument1 pageExcavatorVenkata RamanaPas encore d'évaluation

- FEA Based Design Optimization of Hydraulic Shovel Bucket...Document17 pagesFEA Based Design Optimization of Hydraulic Shovel Bucket...mirza kasimPas encore d'évaluation

- TGN 11 Clip Spacing 09-12Document2 pagesTGN 11 Clip Spacing 09-12kayakeras3335Pas encore d'évaluation

- Design Guide - O-Ring, Quad-Ring, ERIKSDocument13 pagesDesign Guide - O-Ring, Quad-Ring, ERIKSDerekPas encore d'évaluation

- Design Principles - ExcavatorsDocument2 pagesDesign Principles - ExcavatorsalfavectorPas encore d'évaluation

- Calculation of A Helical Gear Pair: 1. Tooth Geometry and MaterialDocument14 pagesCalculation of A Helical Gear Pair: 1. Tooth Geometry and Materialsumeetsaini88Pas encore d'évaluation

- Irjet V5i4718 PDFDocument4 pagesIrjet V5i4718 PDFVinit YadavPas encore d'évaluation

- Gear Coupling 2014Document4 pagesGear Coupling 2014Dado Maja ArseninPas encore d'évaluation

- NORD Universal Worm Gear Units CatalogueDocument101 pagesNORD Universal Worm Gear Units CatalogueJ Jick PerSeiPas encore d'évaluation

- Sheave Design Manual NYCASTDocument8 pagesSheave Design Manual NYCASTChusnadiPas encore d'évaluation

- Involute Spline Strength CalculationsDocument1 pageInvolute Spline Strength CalculationsRjgandhi65Pas encore d'évaluation

- ETH-Leaflet US 1002Document20 pagesETH-Leaflet US 1002Abaz VelićPas encore d'évaluation

- BREVINI S-Series DrivesDocument126 pagesBREVINI S-Series DrivesEsra YansenPas encore d'évaluation

- Selection and Adaptation of Hydraulic Cylinders For Tipper HoistingDocument7 pagesSelection and Adaptation of Hydraulic Cylinders For Tipper HoistingManohar M Hegde100% (1)

- Calculating Excavator Structural StressDocument6 pagesCalculating Excavator Structural Stressrbachalli100% (1)

- Q420 Handbook of Metric GearsDocument526 pagesQ420 Handbook of Metric Gearslebob12100% (1)

- Industrial Brake Technology EnglishDocument76 pagesIndustrial Brake Technology EnglishEmerson BatistaPas encore d'évaluation

- Σχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMADocument1 pageΣχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMAkstayroskPas encore d'évaluation

- Pneumatic Scissor Lift ManualDocument14 pagesPneumatic Scissor Lift ManualGptc ChekkanuraniPas encore d'évaluation

- Hydraulic Cylinder MTD-WI-07Document21 pagesHydraulic Cylinder MTD-WI-07vinothPas encore d'évaluation

- Design Consideration For TraversersDocument17 pagesDesign Consideration For TraversersAmin PaniwalaPas encore d'évaluation

- Rubber Tyre Gantry ReportDocument2 pagesRubber Tyre Gantry Reportdjrashid100% (1)

- TadanoDocument9 pagesTadanoFATCHURPas encore d'évaluation

- Yuken Hydraulic CylinderDocument11 pagesYuken Hydraulic CylinderDk PanigrahiPas encore d'évaluation

- SwingClamp BottomFlangeDocument4 pagesSwingClamp BottomFlangePeter CusimanoPas encore d'évaluation

- 31 SeriesDocument4 pages31 SeriesJESUSCALVILLOPas encore d'évaluation

- Gearbox SuperDocument15 pagesGearbox Super10delpiPas encore d'évaluation

- Catalogo de Seleccion Sew PDFDocument812 pagesCatalogo de Seleccion Sew PDFHugo AcevedoPas encore d'évaluation

- G7 Gearmotor For HoistDocument16 pagesG7 Gearmotor For Hoistnaren1202Pas encore d'évaluation

- Gears and Gear TrainsDocument127 pagesGears and Gear TrainsVikki KotaPas encore d'évaluation

- ISO Gear StandardsDocument6 pagesISO Gear StandardsEslam YehiaPas encore d'évaluation

- Gosan - Barrel Coupling - AGBSDocument7 pagesGosan - Barrel Coupling - AGBSAndré RosolemPas encore d'évaluation

- BearingDocument13 pagesBearingshreyanshPas encore d'évaluation

- Planetary Gears PosterDocument1 pagePlanetary Gears PosterIhsan MahardhikaPas encore d'évaluation

- Cilindro Hidraulico MDRDocument22 pagesCilindro Hidraulico MDRMauricio MpintoPas encore d'évaluation

- Gravity Gradient Boom DesignDocument60 pagesGravity Gradient Boom Designapi-3758282Pas encore d'évaluation

- Front Suspension Cylinder Cap Capscrew ImprovementDocument4 pagesFront Suspension Cylinder Cap Capscrew ImprovementSandro GastanagaPas encore d'évaluation

- Rope Winches and GearboxesDocument20 pagesRope Winches and GearboxesGogyPas encore d'évaluation

- Design and Development of Telescopic Con PDFDocument3 pagesDesign and Development of Telescopic Con PDFregi friyadaPas encore d'évaluation

- Bearing PDFDocument64 pagesBearing PDFRajvardhan JaidevaPas encore d'évaluation

- Sibre Crane Wheel Systems PDFDocument13 pagesSibre Crane Wheel Systems PDFZehPas encore d'évaluation

- DIN 15018-1-1984, Cranes, Steel Structures PDFDocument38 pagesDIN 15018-1-1984, Cranes, Steel Structures PDFWojciech ChruścielPas encore d'évaluation

- Selection and Adaptation of Hydraulic Cylinders For Tipper Hoisting PDFDocument7 pagesSelection and Adaptation of Hydraulic Cylinders For Tipper Hoisting PDFMina RemonPas encore d'évaluation

- Design and Calculation of Planetary Transmission WDocument8 pagesDesign and Calculation of Planetary Transmission Wkarnail singh dhimanPas encore d'évaluation

- Tompkins Catalog UsaDocument332 pagesTompkins Catalog UsaLuis Puma100% (1)

- HYDRO Control Katalog PDFDocument174 pagesHYDRO Control Katalog PDFPedro Viru BernaolaPas encore d'évaluation

- IS 1891 Part 1Document23 pagesIS 1891 Part 1maheshkbandari100% (1)

- Is Iso 6547 1981Document9 pagesIs Iso 6547 1981Govind RaoPas encore d'évaluation

- Brakes Research HandbookDocument16 pagesBrakes Research HandbookChandaKundaPas encore d'évaluation

- JETIR1902975Document6 pagesJETIR1902975simpi.kunalPas encore d'évaluation

- Fatigue Analysis of Excavator Arm Reduced in Weight by Structural Optimization MethodsDocument6 pagesFatigue Analysis of Excavator Arm Reduced in Weight by Structural Optimization MethodsInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Design and Dynamic Analysis of Flywheel: December 2016Document7 pagesDesign and Dynamic Analysis of Flywheel: December 2016atiaPas encore d'évaluation

- Power Theft Identification Using GSM TechnologyDocument3 pagesPower Theft Identification Using GSM TechnologyIJORAT100% (1)

- Heat Transfer Improvement in Radiator by Effect of Different Walls EmissivityDocument4 pagesHeat Transfer Improvement in Radiator by Effect of Different Walls EmissivityIJORATPas encore d'évaluation

- Heat Transfer Augmentation in Double Pipe Heat Exchanger by Using Aloevera With EthylglycolDocument3 pagesHeat Transfer Augmentation in Double Pipe Heat Exchanger by Using Aloevera With EthylglycolIJORATPas encore d'évaluation

- An Edge Detection Technique With Image Segmentation Using Artificial Bee Colony OptimizationDocument5 pagesAn Edge Detection Technique With Image Segmentation Using Artificial Bee Colony OptimizationIJORATPas encore d'évaluation

- IoT of Civil InfrastructuresDocument4 pagesIoT of Civil InfrastructuresIJORATPas encore d'évaluation

- Overview On Finding End To End Communication For Discovery System in Manet Utilizing Anonymous Super HubDocument5 pagesOverview On Finding End To End Communication For Discovery System in Manet Utilizing Anonymous Super HubIJORATPas encore d'évaluation

- Stabilization of Problematic Soil Using Pond Ash and Mosaic DustDocument3 pagesStabilization of Problematic Soil Using Pond Ash and Mosaic DustIJORATPas encore d'évaluation

- Fracture Analysis of Compact Tension SpecimenDocument7 pagesFracture Analysis of Compact Tension SpecimenIJORAT100% (1)

- Image Enhancement Through Contrast Improvement in Ultrasound Image Using MatlabDocument3 pagesImage Enhancement Through Contrast Improvement in Ultrasound Image Using MatlabIJORATPas encore d'évaluation

- TestDocument3 pagesTestNSS GBPECPas encore d'évaluation

- 2002 Sienna EcuimmobDocument14 pages2002 Sienna EcuimmobMiguel ruizPas encore d'évaluation

- Improving Dehumidification in HVAC SystemsDocument48 pagesImproving Dehumidification in HVAC Systems2360459Pas encore d'évaluation

- XCMG Hydraulic Excavator: Surat Bhubaneshwar MumbaiDocument8 pagesXCMG Hydraulic Excavator: Surat Bhubaneshwar MumbaiAvijitSinharoyPas encore d'évaluation

- FZ FiDocument59 pagesFZ FiRIDERZ CHOICEPas encore d'évaluation

- Active Suspension SeminarDocument12 pagesActive Suspension Seminarmujeeb0% (1)

- Me423 PDFDocument2 pagesMe423 PDFmaherkamelPas encore d'évaluation

- WL 862H - T2 Spec A4Document5 pagesWL 862H - T2 Spec A4Martha Veraida SilaenPas encore d'évaluation

- 9FA Installation GuideDocument71 pages9FA Installation GuideLandon Mitchell89% (9)

- Circuit Breaker Grade 9 PresentationDocument13 pagesCircuit Breaker Grade 9 PresentationJeffrey SawatiPas encore d'évaluation

- Danfoss CompressorDocument6 pagesDanfoss CompressorRD Dhanna50% (2)

- Roller Chain Connect Disconnect July 2006 PDFDocument7 pagesRoller Chain Connect Disconnect July 2006 PDFl_aguilar_mPas encore d'évaluation

- Diaphragm Valve Series - ' S2K ' DS00W5: Fluroplastic LinedDocument1 pageDiaphragm Valve Series - ' S2K ' DS00W5: Fluroplastic LinedThiruThirunavukkarasuPas encore d'évaluation

- EEE 315 ELECTRICAL MACHINES III Supplementary EXAM - 2017Document5 pagesEEE 315 ELECTRICAL MACHINES III Supplementary EXAM - 2017Abkul KunniPas encore d'évaluation

- MODEL: SC1650 Industrial Range Powered by Cummins: Diesel Generating Set 440/254V - 60 HZ - 3phaseDocument4 pagesMODEL: SC1650 Industrial Range Powered by Cummins: Diesel Generating Set 440/254V - 60 HZ - 3phaseRonald BoocPas encore d'évaluation

- This Study Resource Was: P T, C HDocument7 pagesThis Study Resource Was: P T, C Hjj Valle100% (1)

- Technical Specification - Prima P2B Pump: GeneralDocument2 pagesTechnical Specification - Prima P2B Pump: GeneralLuisMi SerranoPas encore d'évaluation

- Pneumatics Festo DidacticDocument218 pagesPneumatics Festo Didacticvab88100% (6)

- 489 Fanuc M 10ia Robot AdatlapDocument4 pages489 Fanuc M 10ia Robot AdatlapassPas encore d'évaluation

- Vehicle History WDC2511232A162800Document5 pagesVehicle History WDC2511232A162800vikas sharmaPas encore d'évaluation

- PHC VALEO Clutch Catalogue 2018-2019Document424 pagesPHC VALEO Clutch Catalogue 2018-2019Gsp Tony71% (24)

- Omm 1106eDocument84 pagesOmm 1106eDedy setiawanPas encore d'évaluation

- Design of Modern CNC Machines and Mechatronic ElementsDocument37 pagesDesign of Modern CNC Machines and Mechatronic Elementsnagappa talawarPas encore d'évaluation

- LTM 1070-4.1 PN PDFDocument16 pagesLTM 1070-4.1 PN PDFnamduong368Pas encore d'évaluation

- Atb 935Document5 pagesAtb 935Raul Rodriguez JuarezPas encore d'évaluation

- Ea New PMS CranesDocument183 pagesEa New PMS CranesGaurav MaithilPas encore d'évaluation

- Ferrari TestarrossaDocument210 pagesFerrari Testarrossaj.godignonPas encore d'évaluation

- Shimano SLX HG81 Cassette Service ManualDocument1 pageShimano SLX HG81 Cassette Service ManualJose Luis GutierrezPas encore d'évaluation

- Mercedes W 124 - Instrument Cluster - Engines 104 HFM-SFI 602 606 EcuDocument5 pagesMercedes W 124 - Instrument Cluster - Engines 104 HFM-SFI 602 606 Ecuadisby7Pas encore d'évaluation

- FG85Document701 pagesFG85papajoel8290% (10)