Académique Documents

Professionnel Documents

Culture Documents

Performance of Tri-Axial Compression Test On Cohesive Soils Under Un-Consolidated Un-Drained Condition

Transféré par

MazharYasinDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Performance of Tri-Axial Compression Test On Cohesive Soils Under Un-Consolidated Un-Drained Condition

Transféré par

MazharYasinDroits d'auteur :

Formats disponibles

Geotechnical and Foundation Engineering December 21, 2016

EXPERIMENT # 11

PERFORMANCE OF TRI-AXIAL COMPRESSION TEST

ON COHESIVE SOILS UNDER UN-CONSOLIDATED UN-

DRAINED CONDITION

11.1 OBJECTIVE

This test method covers determination of the strength and stress-strain

relationships of a cylindrical specimen of either undisturbed or remolded

cohesive soil.

This test method provides data for determining undrained strength properties

(C & ) and stress-strain relations for soils.

The test is called "triaxial" because the three principal stresses are assumed to

be known and are controlled.

During shear, the major principal stress, 1 is equal to the

applied axial stress ( = P/A) plus the chamber (confining)

pressure, 3

11.2 APPARATUS

Axial Loading Device

Axial Load-Measuring Device

Triaxial Compression Chamber

Axial Load Piston

Pressure Control Device

Specimen Cap and Base

Deformation Indicator

Rubber Membrane

Sample Extruder

Specimen Size Measurement

Devices

Timer

Balances

Miscellaneous Apparatus

The University of Lahore 80

Geotechnical and Foundation Engineering December 21, 2016

11.3 SIGNIFICANCE AND USE

In this test method, the compressive strength of a soil is determined in terms of

the total stress, therefore, the resulting strength depends on the pressure

developed in the pore fluid during loading. In this test method, fluid flow is not

permitted from or into the soil specimen as the load is applied, therefore the

resulting pore pressure, and hence strength, differs from that developed in the

case where drainage can occur.

If the test specimens are 100 % saturated, consolidation cannot occur when the

confining pressure is applied nor during the shear portion of the test since

drainage is not permitted. Therefore, if several specimens of the same material

are tested, and if they are all at approximately the same water content and void

ratio when they are tested, they will have approximately the same undrained

shear strength. The Mohr failure envelope will usually be a horizontal straight

line over the entire range of confining stresses applied to the specimens if the

specimens are fully saturated.

If the test specimens are partially saturated or compacted specimens, where

the degree of saturation is less than 100 %, consolidation may occur when the

confining pressure is applied and during shear, even though drainage is not

permitted. Therefore, if several partially saturated specimens of the same

material are tested at different confining stresses, they will not have the same

undrained shear strength. Thus, the Mohr failure envelope for unconsolidated

undrained triaxial tests on partially saturated soils is usually curved.

The unconsolidated undrained triaxial strength is applicable to situations where

the loads are assumed to take place so rapidly that there is insufficient time for

the induced pore-water pressure to dissipate and for consolidation to occur

during the loading period (that is, drainage does not occur).

Compressive strengths determined using this procedure may not apply in cases

where the loading conditions in the field differ significantly from those used in

this test method.

11.4 RELATED THEORY

11.4.1 BACK PRESSURE

A pressure applied to the specimen pore-water to cause air in the pore space to

compress and to pass into solution in the pore-water thereby increasing the percent

saturation of the specimen.

11.4.2 EFFECTIVE CONSOLIDATION STRESS

The difference between the cell pressure and the pore-water pressure prior to

shearing the specimen

The University of Lahore 81

Geotechnical and Foundation Engineering December 21, 2016

11.4.3 FAILURE

The stress condition at failure for a test specimen. Failure is often taken to correspond

to the maximum principal stress difference (maximum deviator stress) attained or the

principal stress difference (deviator stress) at 15 % axial strain, whichever is obtained

first during the performance of a test. Depending on soil behaviour and field

application, other suitable failure criteria may be defined, such as maximum effective

stress obliquity, or the principal stress difference (deviator stress) at a selected axial

strain other than 15 %.

11.5 PROCEDURE

Place the membrane on the membrane expander or, if it is to be rolled onto the

specimen, place the membrane onto the cap or base. Place the specimen on

the base.

Place the rubber membrane around the specimen and seal it at the cap and

base with O-rings or other positive seals at each end. A thin coating of silicon

grease on the vertical surfaces of the cap or base will aid in sealing the

membrane.

With the specimen encased in the rubber membrane, which is sealed to the

specimen cap and base and positioned in the chamber, assemble the triaxial

chamber.

Bring the axial load piston into contact with the specimen cap several times to

permit proper seating and alignment of the piston with the cap.

When the piston is brought into contact the final time, record the reading on the

deformation indicator to three significant digits.

During this procedure, take care not to apply an axial stress to the specimen

exceeding approximately 0.5 % of the estimated compressive strength. If the

weight of the piston is sufficient to apply an axial stress exceeding

approximately 0.5 % of the estimated compressive strength, lock the piston in

place above the specimen cap after checking the seating and alignment and

keep locked until application of the chamber pressure.

The University of Lahore 82

Geotechnical and Foundation Engineering December 21, 2016

Place the chamber in position in the axial loading device. Be careful to align the

axial loading device, the axial load-measuring device, and the triaxial chamber

to prevent the application of a lateral force to the piston during testing.

Attach the pressure-maintaining and measurement device and fill the chamber

with the confining liquid. Adjust the pressure maintaining and measurement

device to the desired chamber pressure and apply the pressure to the chamber

fluid.

Wait approximately 10 min after the application of chamber pressure to allow

the specimen to stabilize under the chamber pressure prior to application of the

axial load.

Slightly above the specimen cap, and before the piston comes in contact with

the specimen cap, either: (1) measure and record the initial piston friction to

three significant digits and upward thrust of the piston produced by the chamber

pressure and later correct the measured axial load, or (2) adjust the axial load-

measuring device to compensate for the friction and thrust. If the axial load-

measuring device is located inside the chamber, it will not be necessary to

correct or compensate for the uplift force acting on the axial loading device or

for piston friction. In both cases record the initial reading on the deformation

indicator when the piston contacts the specimen cap.

Apply the axial load to produce axial strain at a rate of approximately 1 %/ min

for plastic materials and 0.3 % / min for brittle materials that achieve maximum

deviator stress at approximately 3 to 6 % strain. At these rates, the elapsed

time to reach maximum deviator stress will be approximately 15 to 20 min.

Continue the loading to 15 % axial strain, except loading may be stopped when

the deviator stress has peaked then dropped 20 % or the axial strain has

reached 5 % beyond the strain at which the peak in deviator stress occurred.

Record load and deformation values to three significant digits at about 0.1, 0.2,

0.3, 0.4, and 0.5 % strain; then at increments of about 0.5 % strain to 3 %; and,

thereafter at every 1 %.

Take sufficient readings to define the stress-strain curve; hence, more frequent

readings may be required in the early stages of the test and as failure is

approached.

The University of Lahore 83

Geotechnical and Foundation Engineering December 21, 2016

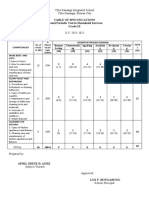

11.6 OBSERVATIONS & CALCULATIONS

11.6.1 FOR 40KPA CELL PRESSURE

11.6.1.1 INITIAL SPECIMEN PROPERTIES

Initial Specimen properties

Initial Water Content % 10.77 Initial Height m 0.072 mm 72

Initial Density of Sample (b) Kg/m3 1618.3 Initial Volume m3 7.328E-05 mm3 73284.912

Relative density % 95.3 Initial Area m2 0.0010178 mm2 1017.846

11.6.1.2 SATURATION STAGE

Time elapsed PWP =Back

Cell Pressure ( 3) B value Check

(min) pressure

1 20 0 -

10 30 10 -

20 40 15 0.5

30 50 21 0.6

40 60 30 0.9

50 70 39 0.9

60 80 48.5 0.95

70 90 58.3 0.98

80 100 68 0.97

11.6.1.3 CONSOLIDATION STAGE

Time Cell PWP

elapsed Pressure =Back Specimen Properties after consolidation

(min) (s3) pressure

Volume change

0 108 - cc 0

reading (DV)

Consolidated

Height after

20 108 - mm 0 volume Vc 73284.912

Consolidation (Hc)

(mm3)

Area after

50 108 - mm2 1017.846

Consolidation (Ac)

The University of Lahore 84

Geotechnical and Foundation Engineering December 21, 2016

11.6.1.4 SHEARING STAGE

ajar

Time Cell PWP Vertical Volume Volumtrc Deviator

vertical Vertical strain Corrected Principle

elapsed Pressure =Back Strain change stress

Load Deform. Area A' stress

(min) ( pressure () reading (vol.) ()

(1)

KPa KPa N mm % cc mm2 KPa KPa

0 0 0 0 0 0 0 0 0 0 0

0.103 108 68 10 0 0.00 0.00 0.00 1017.85 9.82 49.82

0.377 108 68 13 0 0.00 0.00 0.00 1017.85 12.77 52.77

1.299 108 68 17 0 0.00 0.00 0.00 1017.85 16.70 56.70

1.428 108 68 20 0 0.00 0.00 0.00 1017.85 19.65 59.65

1.571 108 68 27 0 0.00 0.00 0.00 1017.85 26.53 66.53

1.728 108 68 30 0 0.00 0.00 0.00 1017.85 29.47 69.47

1.905 108 68 34 0 0.00 0.00 0.00 1017.85 33.40 73.40

2.091 108 68 37 0 0.00 0.00 0.00 1017.85 36.35 76.35

2.3 108 68 40 0 0.00 0.00 0.00 1017.85 39.30 79.30

2.53 108 68 44 0 0.00 0.00 0.00 1017.85 43.23 83.23

2.783 108 68 47 0 0.00 0.00 0.00 1017.85 46.18 86.18

3.061 108 68 51 0 0.00 0.00 0.00 1017.85 50.11 90.11

3.367 108 68 54 0 0.00 0.00 0.00 1017.85 53.05 93.05

3.706 108 68 57 0 0.00 0.00 0.00 1017.85 56.00 96.00

4.077 108 68 61 0 0.00 0.00 0.00 1017.85 59.93 99.93

4.483 108 68 64 0 0.00 0.00 0.00 1017.85 62.88 102.88

4.93 108 68 67 0.01 0.01 0.00 0.00 1017.99 65.82 105.82

5.426 108 68 71 0.04 0.06 0.00 0.00 1018.41 69.72 109.72

5.964 108 68 74 0.07 0.10 0.00 0.00 1018.84 72.63 112.63

6.565 108 68 77 0.11 0.15 0.00 0.00 1019.40 75.53 115.53

7.218 108 68 81 0.15 0.21 0.00 0.00 1019.97 79.41 119.41

7.94 108 68 81 0.21 0.29 0.00 0.00 1020.82 79.35 119.35

8.733 108 68 88 0.27 0.38 0.00 0.00 1021.68 86.13 126.13

9.609 108 68 91 0.33 0.46 0.00 0.00 1022.53 88.99 128.99

10.569 108 68 94 0.41 0.57 0.00 0.00 1023.68 91.83 131.83

11.626 108 68 98 0.5 0.69 0.00 0.00 1024.96 95.61 135.61

12.785 108 68 98 0.59 0.82 0.00 0.00 1026.26 95.49 135.49

14.065 108 68 101 0.69 0.96 0.00 0.00 1027.69 98.28 138.28

15.468 108 68 104 0.8 1.11 0.00 0.00 1029.28 101.04 141.04

17.017 108 68 108 0.93 1.29 0.00 0.00 1031.17 104.74 144.74

18.717 108 68 111 1.1 1.53 0.00 0.00 1033.64 107.39 147.39

20.589 108 68 111 1.31 1.82 0.00 0.00 1036.71 107.07 147.07

22.65 108 68 112 1.47 2.04 0.00 0.00 1039.06 107.79 147.79

The University of Lahore 85

Geotechnical and Foundation Engineering December 21, 2016

Axial Strain vs Deviator Stress

120

100

Devaitor Stress (KPa)

80

60

40 Kpa Cell Pressure

40

20

0

0 0.5 1 1.5 2 2.5

Axial Strain (%)

11.6.2 FOR 50KPA CELL PRESSURE

11.6.2.1 INITIAL SPECIMEN PROPERTIES

Initial Specimen properties

mm

Initial Water Content % 12 Initial Height m 0.076 76

mm3

Initial Density of Sample (b) Kg/m3 1618.3 Initial Volume m3 9E-05 86190.194

2

mm

Relative density % 95.3 Initial Area m2 0.0011 1134.0815

11.6.2.2 SATURATION STAGE

Time elapsed (min) Cell Pressure (s3) PWP =Back pressure B value Check

1 10 0 -

10 20 10 -

20 30 15 0.5

30 40 23 0.8

40 50 32 0.9

50 60 41.2 0.92

60 70 50.5 0.93

70 80 60.4 0.99

The University of Lahore 86

Geotechnical and Foundation Engineering December 21, 2016

11.6.2.3 CONSOLIDATION STAGE

Time Cell PWP

elapsed Pressure =Back Specimen Properties after consolidation

(min) (s3) pressure

Volume change

0 80 - cc 0

reading (DV)

Consolidated

Height after

20 80 -

Consolidation (Hc)

mm 0 volume Vc 86190.194

(mm3)

Area after

50 80 - mm2 1134.082

Consolidation (Ac)

11.6.2.4 SHEARING STAGE

PWP Vol. ajar

Time Cell Vertical Volume strain Deviato

=Back vertical Vertical Corrected Principl

elaps. Pressu Strain change r stress

(min) re (

pressur Load Def.

() reading (vol. Area A'

()

e stress

e ) (1)

KPa KPa N mm % cc mm2 KPa KPa

0 0 0 0 0 0 0 0 0

0.73 110.00 60.00 5.4 0.5 0.66 0 0 1141.59 4.73 54.73

1.08 110.00 60.00 5.7 0.72 0.95 0 0 1144.93 4.98 54.98

1.57 110.00 60.00 6.7 0.82 1.08 0 0 1146.45 5.84 55.84

1.73 110.00 60.00 8.1 0.93 1.22 0 0 1148.13 7.05 57.05

1.90 110.00 60.00 9.8 1.05 1.38 0 0 1149.97 8.52 58.52

2.09 110.00 60.00 11.8 1.17 1.54 0 0 1151.81 10.24 60.24

2.30 110.00 60.00 13.8 1.29 1.70 0 0 1153.66 11.96 61.96

2.53 110.00 60.00 15.8 1.33 1.75 0 0 1154.28 13.69 63.69

2.78 110.00 60.00 20.2 1.38 1.82 0 0 1155.05 17.49 67.49

3.07 110.00 60.00 24.3 1.49 1.96 0 0 1156.76 21.01 71.01

3.37 110.00 60.00 25.9 1.61 2.12 0 0 1158.63 22.35 72.35

3.70 110.00 60.00 30.7 1.69 2.22 0 0 1159.87 26.47 76.47

4.08 110.00 60.00 38.4 1.8 2.37 0 0 1161.59 33.06 83.06

4.49 110.00 60.00 45.1 1.9 2.50 0 0 1163.16 38.77 88.77

4.93 110.00 60.00 56.3 2 2.63 0 0 1164.73 48.34 98.34

5.42 110.00 60.00 63.3 2.1 2.76 0 0 1166.31 54.27 104.27

5.97 110.00 60.00 67 2.2 2.89 0 0 1167.89 57.37 107.37

6.56 110.00 60.00 66 2.3 3.03 0 0 1169.47 56.44 106.44

7.22 110.00 60.00 65 2.41 3.17 0 0 1171.22 55.50 105.50

7.94 110.00 60.00 61.7 2.43 3.20 0 0 1171.54 52.67 102.67

8.74 110.00 60.00 56.9 2.55 3.36 0 0 1173.45 48.49 98.49

9.61 110.00 60.00 58.3 2.59 3.41 0 0 1174.09 49.66 99.66

The University of Lahore 87

Geotechnical and Foundation Engineering December 21, 2016

Axial Strain vs Deviator Stress

70

60

50

Devaitor Stress (KPa)

40

30

20 50 Kpa Cell Pressure

10

0

0 0.5 1 1.5 2 2.5 3 3.5 4

Axial Strain (%)

11.6.3 FOR 60KPA CELL PRESSURE

11.6.3.1 INITIAL SPECIMEN PROPERTIES

Initial Specimen properties

Initial

Initial Water Content % 12 m 0.076 mm 76

Height

Initial Density of Sample Initial

Kg/m3 1569.5 m3 8.619E-05 mm3 86190.194

(b) Volume

Relative density % 95.3 Initial Area m2 0.0011341 mm2 1134.0815

11.6.3.2 SATURATION STAGE

Time elapsed (min) Cell Pressure (s3) PWP =Back pressure B value Check

1 20 0 -

10 30 10 -

The University of Lahore 88

Geotechnical and Foundation Engineering December 21, 2016

20 40 16 0.6

30 50 22 0.6

40 60 30.5 0.85

50 70 39.6 0.91

60 80 49 0.94

70 90 58.6 0.96

11.6.3.3 CONSOLIDATION STAGE

Time Cell PWP

elapsed Pressure =Back Specimen Properties after consolidation

(min) (s3) pressure

Volume change

0 80 - cc 0

reading (DV)

Height after

Consolidated

20 80 - Consolidation mm 0

volume Vc 86190.194

(Hc)

(mm3)

Area after

50 80 - Consolidation mm2 1134.0815

(Ac)

11.6.3.4 SHEARING STAGE

PWP Vol ajar

Time Cell vertic Exte Vertical Volume Deviato

=Back strain Corrected Principle

elapsed Pressur al nsio Strain change r stress

pressur Area A' stress

(min) e (

e

Load n () reading (vol.) ()

(1)

KPa KPa N mm % cc mm2 KPa KPa

0.099 119.00 59.00 10 0 0.00 0.00 0.00 1134.08 8.82 68.82

0.178 119.00 59.00 13 0 0.00 0.00 0.00 1134.08 11.46 71.46

0.26 119.00 59.00 17 0 0.00 0.00 0.00 1134.08 14.99 74.99

0.342 119.00 59.00 20 0 0.00 0.00 0.00 1134.08 17.64 77.64

0.415 119.00 59.00 24 0 0.00 0.00 0.00 1134.08 21.16 81.16

0.458 119.00 59.00 24 0 0.00 0.00 0.00 1134.08 21.16 81.16

0.502 119.00 59.00 27 0 0.00 0.00 0.00 1134.08 23.81 83.81

0.67 119.00 59.00 30 0 0.00 0.00 0.00 1134.08 26.45 86.45

0.733 119.00 59.00 34 0 0.00 0.00 0.00 1134.08 29.98 89.98

0.81 119.00 59.00 37 0 0.00 0.00 0.00 1134.08 32.63 92.63

0.977 119.00 59.00 40 0 0.00 0.00 0.00 1134.08 35.27 95.27

1.073 119.00 59.00 44 0 0.00 0.00 0.00 1134.08 38.80 98.80

1.183 119.00 59.00 47 0 0.00 0.00 0.00 1134.08 41.44 101.44

1.302 119.00 59.00 51 0 0.00 0.00 0.00 1134.08 44.97 104.97

1.574 119.00 59.00 54 0.01 0.01 0.00 0.00 1134.23 47.61 107.61

The University of Lahore 89

Geotechnical and Foundation Engineering December 21, 2016

1.732 119.00 59.00 57 0.02 0.03 0.00 0.00 1134.38 50.25 110.25

1.904 119.00 59.00 61 0.03 0.04 0.00 0.00 1134.53 53.77 113.77

2.095 119.00 59.00 64 0.05 0.07 0.00 0.00 1134.83 56.40 116.40

2.3 119.00 59.00 67 0.08 0.11 0.00 0.00 1135.28 59.02 119.02

2.533 119.00 59.00 74 0.1 0.14 0.00 0.00 1135.58 65.17 125.17

2.786 119.00 59.00 77 0.12 0.17 0.00 0.00 1135.87 67.79 127.79

3.062 119.00 59.00 81 0.13 0.18 0.00 0.00 1136.02 71.30 131.30

3.367 119.00 59.00 88 0.14 0.19 0.00 0.00 1136.17 77.45 137.45

3.706 119.00 59.00 91 0.15 0.21 0.00 0.00 1136.32 80.08 140.08

4.078 119.00 59.00 94 0.16 0.22 0.00 0.00 1136.47 82.71 142.71

4.483 119.00 59.00 101 0.16 0.23 0.00 0.00 1136.55 88.87 148.87

4.931 119.00 59.00 108 0.17 0.24 0.00 0.00 1136.62 95.02 155.02

5.422 119.00 59.00 111 0.21 0.29 0.00 0.00 1137.22 97.61 157.61

5.968 119.00 59.00 118 0.25 0.35 0.00 0.00 1137.82 103.7 163.71

6.561 119.00 59.00 125 0.3 0.42 0.00 0.00 1138.58 109.7 169.79

7.218 119.00 59.00 128 0.34 0.47 0.00 0.00 1139.18 112.3 172.36

7.942 119.00 59.00 135 0.41 0.57 0.00 0.00 1140.23 118.4 178.40

8.733 119.00 59.00 142 0.48 0.67 0.00 0.00 1141.29 124.4 184.42

9.605 119.00 59.00 145 0.54 0.75 0.00 0.00 1142.20 126.9 186.95

10.565 119.00 59.00 152 0.62 0.86 0.00 0.00 1143.41 132.9 192.94

11.625 119.00 59.00 155 0.71 0.99 0.00 0.00 1144.78 135.4 195.40

12.788 119.00 59.00 162 0.8 1.11 0.00 0.00 1146.15 141.3 201.34

14.066 119.00 59.00 165 0.9 1.25 0.00 0.00 1147.67 143.7 203.77

15.471 119.00 59.00 168 1.01 1.40 0.00 0.00 1149.36 146.1 206.17

17.017 119.00 59.00 172 1.14 1.58 0.00 0.00 1151.35 149.3 209.39

18.717 119.00 59.00 175 1.27 1.76 0.00 0.00 1153.35 151.7 211.73

20.591 119.00 59.00 185 1.41 1.96 0.00 0.00 1155.52 160.1 220.10

22.651 119.00 59.00 185 1.58 2.19 0.00 0.00 1158.16 159.7 219.74

24.913 119.00 59.00 185 1.76 2.44 0.00 0.00 1160.97 159.3 219.35

The University of Lahore 90

Geotechnical and Foundation Engineering December 21, 2016

Axial Strain vs Deviator Stress

180

160

140

Devaitor Stress (KPa)

120

100

80

60 Kpa Cell Pressure

60

40

20

0

0 0.5 1 1.5 2 2.5 3

Axial Strain (%)

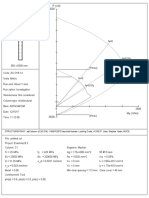

11.7 RESULTS

Plot the Mohrs circle between normal stress and shear stress and obtain

corresponding consolidated un-drained shear strength parameters (c and ) of given

soil specimen.

The University of Lahore 91

Geotechnical and Foundation Engineering December 21, 2016

C= 0.3 KPa

= 35

11.8 REFERENCE

ASTM D2850

Standard Test Method for Unconsolidated-Undrained Triaxial Compression Test on

Cohesive Soils

11.9 COMMENTS:

Triaxial test is a soils laboratory test to determine shear strength parameters. The

shear strength of soil is needed to design foundation, slopes, tunnels, dams, and other

geotechnical systems. It is a most widely used technique of determining the shear

strength of soils.

The sample, which is cylindrical, is tested inside a Perspex cylinder filled with water

under pressure. The sample under test is enclosed in a thin rubber membrane to seal

it from the surrounding water. The pressure in the cell is raised to the desired value,

and the sample is then brought to failure by applying an additional vertical stress.

One of the major advantages of the triaxial apparatus is the control provided over

drainage from the sample. When no drainage is required (i.e. in undrained tests), solid

end caps are used. When drainage is required, the end caps are provided with porous

plates and drainage channels. It is also possible to monitor pore-water pressures

during a test.

In our case the there is some variation in the values which may be due personal error

or due the instrument error

Our soil has minor cohesion value that is 0.3KPa and angle of internal friction = 35

The University of Lahore 92

Vous aimerez peut-être aussi

- Zones of ScrewDocument111 pagesZones of Screwzubi0585100% (2)

- UU TestDocument7 pagesUU TestVenu Gopal Mudhiraj100% (1)

- Lab 2 TriaxialLab 2 Triaxial Shear Test Shear TestDocument8 pagesLab 2 TriaxialLab 2 Triaxial Shear Test Shear Test7e1a88210% (1)

- Astm D 4767Document11 pagesAstm D 4767Darren KamPas encore d'évaluation

- Shear Box TestDocument13 pagesShear Box TestNoor100% (1)

- UU Test ReportDocument4 pagesUU Test ReportSharunieRavikumar33% (3)

- Triaxial Compression TestDocument53 pagesTriaxial Compression TestAndyra Jaiz BadduPas encore d'évaluation

- Experiment No. 5 To determine the shear strength parameters (ϕ) and (c) of a given soil sample using the triaxial compression test 5.1 ReferenceDocument10 pagesExperiment No. 5 To determine the shear strength parameters (ϕ) and (c) of a given soil sample using the triaxial compression test 5.1 ReferenceumarPas encore d'évaluation

- Slope Stability and Soil/rock StrengthDocument11 pagesSlope Stability and Soil/rock StrengthEmran Banat95Pas encore d'évaluation

- Energy Elastic Strain EnergyDocument14 pagesEnergy Elastic Strain EnergyamirwmPas encore d'évaluation

- CVG3109 - Lab - Consolidated Drained Tests For Sand - 2014Document11 pagesCVG3109 - Lab - Consolidated Drained Tests For Sand - 2014Rhedo.AbdPas encore d'évaluation

- Triaxial TestDocument3 pagesTriaxial TestkanyisilePas encore d'évaluation

- Lab 8 - Ciu, Cid Triaxial TestDocument7 pagesLab 8 - Ciu, Cid Triaxial TestAmirah Shafeera0% (1)

- Triaxial TestDocument14 pagesTriaxial TestSi Rerumpai LautPas encore d'évaluation

- Hot Weather ConcretingDocument6 pagesHot Weather ConcretingMazharYasinPas encore d'évaluation

- Architecture Design BasisDocument20 pagesArchitecture Design Basisamini_mohiPas encore d'évaluation

- Lecture Notes on Reinforced Concrete DesignD'EverandLecture Notes on Reinforced Concrete DesignPas encore d'évaluation

- Inspección de Esfera de GLP - Mexico PDFDocument10 pagesInspección de Esfera de GLP - Mexico PDFJorge Rogger Yopla BasaldúaPas encore d'évaluation

- Triaxial Test: Consolidated UndrainedDocument9 pagesTriaxial Test: Consolidated UndrainedNguyễn Hòa100% (1)

- SDOF Damped Forced Vibration - NewmarkDocument5 pagesSDOF Damped Forced Vibration - NewmarkMazharYasinPas encore d'évaluation

- Pressure Transient Formation and Well Testing: Convolution, Deconvolution and Nonlinear EstimationD'EverandPressure Transient Formation and Well Testing: Convolution, Deconvolution and Nonlinear EstimationÉvaluation : 2 sur 5 étoiles2/5 (1)

- Performance of Tri-Axial Compression Test On Cohesive Soils Under Consolidated Drained (CD) ConditionDocument14 pagesPerformance of Tri-Axial Compression Test On Cohesive Soils Under Consolidated Drained (CD) ConditionMazharYasinPas encore d'évaluation

- Uu TestDocument15 pagesUu TestMin MiynPas encore d'évaluation

- Triaxial Test 2850Document2 pagesTriaxial Test 2850Mostafa MagdyPas encore d'évaluation

- Triaxial Test Report - Group 2Document20 pagesTriaxial Test Report - Group 2Khalidah RosmanPas encore d'évaluation

- Soil Testing TriaxialDocument50 pagesSoil Testing TriaxialBekele AmanPas encore d'évaluation

- Triaxial Compression TestDocument17 pagesTriaxial Compression Testsajjad.ghazai2001Pas encore d'évaluation

- OedometerDocument7 pagesOedometerDaniel ShinnickPas encore d'évaluation

- Triaxial Compression TestDocument3 pagesTriaxial Compression TestNtsika SokasiPas encore d'évaluation

- MohrDocument12 pagesMohrJoseph JboyPas encore d'évaluation

- Load Controlled Cyclic Triaxial Strength of Soil: Standard Test Method ForDocument10 pagesLoad Controlled Cyclic Triaxial Strength of Soil: Standard Test Method ForROHITPas encore d'évaluation

- Shear Strength of SoilsDocument13 pagesShear Strength of Soilspankaj100% (1)

- Unit-V Shear Strength of SoilDocument113 pagesUnit-V Shear Strength of Soilgopierode4Pas encore d'évaluation

- Direct ShearDocument4 pagesDirect ShearMUHAMMAD RIAZ AHMAD 2009-CIV-140Pas encore d'évaluation

- Assignment 2 Soil and GeoDocument2 pagesAssignment 2 Soil and GeoAung KaungPas encore d'évaluation

- Triaxial Test (UC)Document3 pagesTriaxial Test (UC)Aisha MalikPas encore d'évaluation

- Cid CiuDocument4 pagesCid CiuRazakMaidenPas encore d'évaluation

- Shear Strength of SoilsDocument10 pagesShear Strength of Soilstitukutty6032Pas encore d'évaluation

- Theory in Determining Shear Strength Parameters in A Soil by Triaxial Compression TestDocument6 pagesTheory in Determining Shear Strength Parameters in A Soil by Triaxial Compression Testmaxwell912Pas encore d'évaluation

- Triaxial Shear TestDocument5 pagesTriaxial Shear TestBellaPas encore d'évaluation

- Undrained Triaxial TestDocument7 pagesUndrained Triaxial TestadityatheaaaPas encore d'évaluation

- Tri Axial TestDocument10 pagesTri Axial TestAskart Nano Crime-artPas encore d'évaluation

- Test 09Document6 pagesTest 09Ateafac Anastasia NjuafacPas encore d'évaluation

- LAB 12 - CIU, CID TRIAXIAL (Level 0)Document8 pagesLAB 12 - CIU, CID TRIAXIAL (Level 0)Doris AsmaniPas encore d'évaluation

- BUADLARTDocument2 pagesBUADLARTShamRock CasasPas encore d'évaluation

- Week 8 (1) - CIU, CID TRIAXIAL (Level 0)Document8 pagesWeek 8 (1) - CIU, CID TRIAXIAL (Level 0)Zamiera ZamranPas encore d'évaluation

- ExperimentDocument22 pagesExperimentnora tannakPas encore d'évaluation

- BS5930-2015 192Document1 pageBS5930-2015 192Ford cellPas encore d'évaluation

- The Sample Is Sealed Inside A Rubber Membrane and Then Surround With WaterDocument6 pagesThe Sample Is Sealed Inside A Rubber Membrane and Then Surround With WaterhabiPas encore d'évaluation

- Standard Test Procedures Manual: 1. ScopeDocument5 pagesStandard Test Procedures Manual: 1. ScopeAeron RodriguezPas encore d'évaluation

- ASTM D 2664-95a Standard Test Method For Triaxial Compressive Strength of Undrained Rock Core Specimens Without Pore Pressure MeasurementsDocument4 pagesASTM D 2664-95a Standard Test Method For Triaxial Compressive Strength of Undrained Rock Core Specimens Without Pore Pressure MeasurementsPablo Antonio Valcárcel VargasPas encore d'évaluation

- ASTM D4767 (TriaxialCU) PDFDocument11 pagesASTM D4767 (TriaxialCU) PDFgtddyPas encore d'évaluation

- Well Control AssignmentDocument9 pagesWell Control AssignmentMathias NsimbePas encore d'évaluation

- 2 Resilient Modulus BuchananDocument0 page2 Resilient Modulus BuchananJuanDiegoRojasPas encore d'évaluation

- Cyclic StressDocument12 pagesCyclic StressBeljun FloresPas encore d'évaluation

- Step Rate TestDocument18 pagesStep Rate TestAditya KumarPas encore d'évaluation

- Report On Cyclic Triaxial Test: GE-502 Foundation Engg-IDocument12 pagesReport On Cyclic Triaxial Test: GE-502 Foundation Engg-IAjmal AfzalPas encore d'évaluation

- Undrained Shear Strength With A Triaxial Compression Test: Emmanuel Odera IgwebuikeDocument28 pagesUndrained Shear Strength With A Triaxial Compression Test: Emmanuel Odera IgwebuikeSalehuddin RamliPas encore d'évaluation

- Consolidation TestDocument3 pagesConsolidation TestAnuradha GunawardhanaPas encore d'évaluation

- Tri-Axial Design MethodDocument9 pagesTri-Axial Design Methodcat buenafePas encore d'évaluation

- Part 1 Introduction To Triaxial TestingDocument4 pagesPart 1 Introduction To Triaxial TestingFernando CachúPas encore d'évaluation

- Unconfined Compression Lab Rapor 2Document12 pagesUnconfined Compression Lab Rapor 2Abdulsamed GözePas encore d'évaluation

- Lab Direct Shear Test - NewDocument5 pagesLab Direct Shear Test - NewLaBuHiTamPas encore d'évaluation

- Lecture 1 & 2: Construction ProjectsDocument19 pagesLecture 1 & 2: Construction ProjectsMazharYasinPas encore d'évaluation

- Construction and Building MaterialsDocument9 pagesConstruction and Building MaterialsMazharYasinPas encore d'évaluation

- SBR LatexDocument2 pagesSBR LatexMazharYasinPas encore d'évaluation

- Drawing Lecture-1Document28 pagesDrawing Lecture-1MazharYasinPas encore d'évaluation

- Experiment No. 10: To Determine The Effect of Rate of Loading On The Compressive Strength of P.C.C Cube and CylinderDocument3 pagesExperiment No. 10: To Determine The Effect of Rate of Loading On The Compressive Strength of P.C.C Cube and CylinderMazharYasinPas encore d'évaluation

- Uol HRD EdifDocument1 pageUol HRD EdifMazharYasinPas encore d'évaluation

- CementDocument12 pagesCementMazharYasinPas encore d'évaluation

- Brick BondsDocument4 pagesBrick BondsMazharYasinPas encore d'évaluation

- Table: Assembled Joint Masses Joint Masssource U1 U2 U3 R1 R2 R3 CenterxDocument80 pagesTable: Assembled Joint Masses Joint Masssource U1 U2 U3 R1 R2 R3 CenterxMazharYasinPas encore d'évaluation

- SP ColumnDocument2 pagesSP ColumnMazharYasinPas encore d'évaluation

- Structurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceDocument1 pageStructurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceMazharYasinPas encore d'évaluation

- Structurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceDocument1 pageStructurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceMazharYasinPas encore d'évaluation

- GRE+GAT WORD LIST (Edited)Document442 pagesGRE+GAT WORD LIST (Edited)MazharYasinPas encore d'évaluation

- Heat Exchangers: Heat Transfer Lectures Chemical Engineering Department University of Technology, IraqDocument20 pagesHeat Exchangers: Heat Transfer Lectures Chemical Engineering Department University of Technology, IraqChemical EngineeringPas encore d'évaluation

- Example 11 - Cast-In-Place Concrete Cantilever Retaining WallDocument15 pagesExample 11 - Cast-In-Place Concrete Cantilever Retaining WallKawan EngPas encore d'évaluation

- E1-Material Log 6Document5 pagesE1-Material Log 6stefenjohnPas encore d'évaluation

- EGGAR - Final ReportDocument8 pagesEGGAR - Final ReportAndrew LeePas encore d'évaluation

- Faculty of Engineering and Science MAEN 1000: Engineering Materials Lab Report Cover SheetDocument18 pagesFaculty of Engineering and Science MAEN 1000: Engineering Materials Lab Report Cover SheetPanadol PanadolPas encore d'évaluation

- MKAE1153 SEAA4163 v5 Concrete DurabilityDocument49 pagesMKAE1153 SEAA4163 v5 Concrete DurabilityAbdullah RamziPas encore d'évaluation

- Gen Chem 2nd MEDocument3 pagesGen Chem 2nd MEJay Cariel GastonesPas encore d'évaluation

- Shell Omala S4 GXV 150Document2 pagesShell Omala S4 GXV 150Nokiabhre WijayaPas encore d'évaluation

- 2nd Q Summative G9 With TOSDocument5 pages2nd Q Summative G9 With TOSAPRIL KOHPas encore d'évaluation

- Gexol: World Class Type P Land & Offshore Oil & Gas CablesDocument32 pagesGexol: World Class Type P Land & Offshore Oil & Gas CablesMarcela SuarezPas encore d'évaluation

- 0608Document9 pages0608Marwan MokhadderPas encore d'évaluation

- NEET 2023 Question Paper G1Document43 pagesNEET 2023 Question Paper G1nemoPas encore d'évaluation

- D&F Block - Practice Sheet - Yakeen 3.0 2024Document4 pagesD&F Block - Practice Sheet - Yakeen 3.0 2024durkekarePas encore d'évaluation

- Materials Engineers Review Notes Set FourDocument3 pagesMaterials Engineers Review Notes Set Foursantiago andresPas encore d'évaluation

- Interseal 670HS: Surface Tolerant EpoxyDocument2 pagesInterseal 670HS: Surface Tolerant EpoxyAndri AjaPas encore d'évaluation

- EarthandLifeSci12 Q1 Mod3 Rock Metamorphism and Different Types of Stress Version2Document40 pagesEarthandLifeSci12 Q1 Mod3 Rock Metamorphism and Different Types of Stress Version2Arthur LaurelPas encore d'évaluation

- HydroPlus Information Website PDFDocument1 pageHydroPlus Information Website PDFTere CastellanosPas encore d'évaluation

- Topic 3-Particulate PollutantsDocument72 pagesTopic 3-Particulate PollutantsalyaPas encore d'évaluation

- Nails For Use With Wood and Wood-Base Materials: Standard Terminology ofDocument14 pagesNails For Use With Wood and Wood-Base Materials: Standard Terminology ofCarlos SandinoPas encore d'évaluation

- Hot Rolled Products of Structural SteelsDocument28 pagesHot Rolled Products of Structural SteelsAli MarsousiPas encore d'évaluation

- Advances in FerroelectricsDocument542 pagesAdvances in FerroelectricsPhelippe Mendonça de PaivaPas encore d'évaluation

- Relave Chile 2022Document65 pagesRelave Chile 2022sonia gutierezPas encore d'évaluation

- Chapter3 AnswersDocument3 pagesChapter3 AnswersKrishaad ManirajahPas encore d'évaluation

- Subcooling Flow BoilingDocument8 pagesSubcooling Flow BoilingBokiPas encore d'évaluation

- Microsensors and MicroactuatorsDocument46 pagesMicrosensors and MicroactuatorsShalan KosékarPas encore d'évaluation

- Reviewer in Inorganic ChemistryDocument5 pagesReviewer in Inorganic ChemistryPrincess Aleia SalvadorPas encore d'évaluation