Académique Documents

Professionnel Documents

Culture Documents

Handbook On Plug in Relays

Transféré par

Srinivas EnamandramTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Handbook On Plug in Relays

Transféré par

Srinivas EnamandramDroits d'auteur :

Formats disponibles

CAMTECH/S/2005/PR/1.

0 1

PLUG IN TYPE RELAY

1. Introduction

A relay is an electromagnetic device, which is used

for closing or opening of an electrical circuit. The

relay may be classified as Shelf type and Plug-In-

Type

Plug-in-type relays which are plugged in to pre-

wired terminal boards. It works on electromagnetic

principle. Each relay has a base electromagnet,

armature, contact spring, contacts, transparent cover,

and handle. A non-magnetic residual pin is fixed on

the inner face of armature, in all relay except

magnetic latch relays.

When current is applied through the coil, it sets up a

magnetic flux through the bar magnet, core, L shape

heelpiece and armature.

The flux causes armature to attract towards the pole

face. Armature picks up and fronts contact closes.

The residual pin maintains small air gap in attracted

position.

When current interrupts, magnetic flux collapses the

contact spring fixed above the armature helps in

restoring to its full released position thus front

contacts open.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 2

1.1. Classification of Signaling Relays

Relays may be classified into various ways

depending upon the following factors:

i) Mounting of relay

Shelf Type

Plug in type

ii) Feed source

DC Relay

AC Relay

Electronic Relay

DC relays are further classified as under

Neutral

Polar

Neutral Polar

iii) Contact material

Proved Type

Non proved Type

iv) Application

Track

Line

Special

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 3

v) Importance / vitality

Vital

Non Vital

Now a days Electronic relays are also used in

signalling circuit to achieve time delay.

1.2 Definition

i) Non fusible contacts

A pair of contacts in which one contact element

comprises of non fusible material which present

practically no risk of welding of contacts.

ii) Carbon contacts

Carbon in the expression Carbon to metal

contacts is used as a general term covering graphite

and compounds and mixtures of carbon and metals.

iii) Metal contacts

Metal in the expression Carbon to metal contacts

and Metal to Metal contacts is used as a general

term covering the use of silver, silver cadmium

oxide, tungsten, platinum or any other suitable

material to an approved specification.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 4

iv) Front contact

That contact which is made with the arm contact

when the relay is energised.

v) Back contact

That contact which is made when the relay is de

energised.

vi) Arm contact (Armature contact)

That contact which is the movable part of the pair of

contacts and makes with front contact when the relay

is energised and with back contact when the relay is

de-energised.

vii) Arm

The movable part of the pair of contacts.

viii) Dependent contact

The condition in which a movable arm contact

connects to a front contact when the relay is

energised. And the same arm contact connects to a

back contact when the relay is de-energised.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 5

ix) Independent contact

The condition in which the movable arm contact

connects to either a front or a back contact but not to

both.

x) Pickup value (Operate value)

The value of the current or ampere turns which is

just sufficient to close all the front contacts of relay

under specified conditions.

xi) Drop away (release) value

The value of the current or ampere turns at which all

the front contacts of relay get open under specified

conditions.

xii) Proved type Relay

Means a relay having Metal to Metal contacts. They

are used for controlling non vital circuits and hence

also called as non vital relays.

xiii) Non proved Relays

Means a relay having Metal to Carbon contacts, as

front contact. They are used for controlling vital

circuits and hence also called as vital relays.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 6

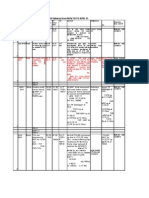

1.3 Comparison between Shelf and Plug in type

relays

Sr. Shelf type relays Plug - in -type

relays

1 Mounted on Shelf Plugged in to the

board.

2. Heavy and Large Light and compact.

3. More space required Less space required.

4. Less No. of contacts More no. of contacts.

5. Replacement takes Quicker and easy.

more time

6. Circuit must be Circuit need be

tested after tested for contact is

replacement, due to making after

chances of replacement.

dislocation of wiring.

7. Coding arrangement Coding is needed on

is not required. the relay to avoid

interchangeability

with relay of

different contact

configuration.

8. Anti tilting Not required

arrangement is

required

9. Pre- wiring is not Pre- wiring is

possible. possible.

Table-1

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 7

1.4 Metal to carbon & Metal to metal Relay

Metal to carbon Relay

All shelf type relays, Q series relays and all G

type relays except S1 type are metal to carbon relays.

Metal to metal Relay

These relays are also known as Proved type relays.

1.5 Track and Line Relay

Track Relay

Track relays are relays, which is directly connected

across the rails of the track to detect the occupation

of track.

Line Relay

Line relays are used for any other purposes other

than track circuit.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 8

Difference between track and line relays

Sr. Track Relay Line Relay

1 Directly connected Any relay other than

across the track track. Such as HR,

circuit. DR, NWKR etc.

2 Functions with less or Functions either with

more current. normal

supply voltage or with

no supply at all.

3 Always associated Not so.

with loss of energy.

Preferably

should work with low

power consumption.

4 More sensitive to Comparatively low in

variation in supply so percentage Release.

percentage release

should be high.

5 Reliability of Back contacts are

operation is very proved in the circuits.

important since the

facility to prove the

de-energisation of the

relay is not available.

6 Non fusible contact Not necessary.

for front contact is

Necessary. (carbon)

are used.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 9

Sr. Track Relay Line Relay

7. Coil resistance is low Coil resistance is high

permitting low to work on low

working voltage current which reduces

which reduces ballast line voltage drop.

leakage current.

Table-2

2. Plug In Type Relays

These are Miniature, Proved/ Non Proved, plug -in

type relays. Some of the commonly used Plugin

type relays in Signaling are listed below

Non proved Type

2.1 Style Q Relays ( Metal to Carbon)

2.2 Style G Relays( Metal to Carbon)

2.3 P Type Relays ( Metal to Carbon)

Proved Type

2.1 Siemen s Relays (Metal to Metal)

2.2 IHCS relay (Metal to Metal)

2.3 Hytronicis Relays ( Metal to Metal)

Note- Siemen s (k-50 Relays) are M to M type and all other

type relays mentioned above are M to C relays

except SI relays of type G relay. Out of these relays

P type relays are obsolete now.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 10

Common features of plugging type relay.

Standard plug boards are used for each type of relays

for mounting the same.

Pre-wiring facilities are available for each type of

relay.

Facilities are available for terminating the wiring on

plug board connectors both by crimping or soldering.

All relays are provided with registration devices with

specified coding combination to prevent plugging in

wrong relay

Unless code pins are correctly engaged no electrical

connection between the relay and the plug board

connector is possible.

Non Proved Type Plug- In -Relay

For their front contacts, these relays make use of M

to C contact. Normally following two styles of relays

are in use under this group :

Style Q

Style G

2.1 Q- Series Relays

This series of plug in relay consists of more than 25

varieties. Out of which about 12 varieties are very

commonly used on Indian Railways.

These relays normally Operate on 12,24 or 50V DC

and can be provided with a max. of 16 independent

contacts.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 11

(Figure-1)

Plug board for Q series relay

This is divided into 4 vertical columns (A.B.C.D.)

and 10 horizontal rows numbered as 1 to 8 from top

to bottom.

The 9th and 10th rows are for coil terminals

(R1,R2,R3 & R4) .

Plug board is a one piece molding of the same

material as that of the relay base.

It is supplied with a wire clip, the purpose of which

is to retain the relay on the plug board tightly by

engaging with a groove provided in the handle of the

relay.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 12

Registration Device

Each relay is fitted with code pins commonly known

as Registration Device to prevent against plugging of

relay in a wrong base.

For this purpose 10 pin positions numbered as

A.B.C.D,E,F,G,H,J,& K are assigned on the relay

base for fixing the pin.

Plug board is provided with corresponding hole

position which allows the relay base pins to fit while

plugging.

Out of the ten only five pins are used on the relay

base & corresponding holes are drilled in the plug

board for the purpose of providing passes to the pins

fitted in the relay base.

Under this arrangement 252 different codes can be

formed.

Relays of the same type having different contact

arrangement will have different code numbers.

Plug board front & rear view is shown in the fig.

given below.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 13

Rear View Front View

(Plug Board for Q Series Relay)

(Figure-2)

Contact Arrangement

QN 1 Relay can be have max. 16 Nos. of

independent contacts.

Types of Q- Series Relays

Q Series relays are following type.

2.1.1 Track Relay

2.1.2 Line Relay

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 14

2.1.1 Track Relay

QT2 Style Relay

The construction of this relay is similar to that of a Q

Series line relay except that its contact load is

reduced drastically.

The relay is more sensitive and workable on a low

voltage.

Earlier version of this type is QT1 relay.

QT1 relay has a double core magnet with 2Fcontacts

while QT2 relay has only one core and 2F 1B

contacts.

The back contact is used for cross protection for TPR

circuit. This has a single coil unlike the shelf type

relay, which has two coils with open ends.

1. Core and coil

2. Heel Piece

3. Armature

4. Residual Pin

5. Front contact

6. Arm for front contact

7. Arm for Back contact

8. Back contact

9. Base

10. Pusher spring

11. Adjusting arm

12. Operating arm

13. Cover

14. Handle

(Figure-3)

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 15

QTA 2 relay (AC Immunised Relay)

This is similar to QT2 relay except a copper slug.

This copper slug is provided on the core to achieve

AC immunity.

Its AC immunity is not less than 75 Volt.

QTA2 relays are available in 9 Ohms coil resistance.

This relay requires more D.C. operating power and it

take more time to pick up and drop due to the copper

slug.

QBAT relay

This relay has a A.C. immunity level of 80 Volt A.C.

This is achieved by the provision of a biasing

permanent magnet on its core along with its copper

slug.

This is made to RDSO specification. No. 84 / 88.

The particulars of the Q- series track relay (plug-in-

types) are tabulated as under.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 16

Data Sheet For Q-Series Track Relays (Plug In

Type)

Spec. No.

Descripti

Coil Res.

Contacts

Position

Nominal

(ohms)

B. R.B

Relay

Relay

Spec.

Code

Volts

Style

S.No

Pin

No.

PU

on

Plug In

Type

Non 2F.

1 QT2 Imm. 938 A 26/6 1B 9 --- 1.4

DC

Track.

Relay

EHJK

2 ,, ,, ,, ,, ,, 4 0.5

X

Plug In

Type 939 A

Non

&

3 QTA2 Imm. 27/7 ,, 20 ---- 2.0

DC 966

Track. F2

Relay

FGH

4 ,, ,, ,, 9 1.4

KX

2F.

ABEJ

5 QBAT ,, ,, 84/88 2B 9 1.75

X

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 17

Current (MA)

Permissible

Relay Style

Min. P.U.

Max P.U.

Max P.U.

Min P.U.

Current

Volts

Volts

Volts

Max.

regd.

(MA)

Volt

Min.

S.No

QT2 300% 125%

1 1.158 117 0.834 103

PUV PUV

2 ,, 0.515 ,, 0.370 ,, ,, ,,

3 QTA2 2.020 92 0.460 81 ,, ,,

4 ,, 1.380 140 0.970 120 ,, ,,

QBAT 235 % 122%

5 1.733 175 1.134 140

PUV PUV

Relay P.U. D.A. A . C.

S. Min.

Style Time Time Imm. Usage

N % Rel.

(mS) (ms) (Volts)

QT2 in non RE

1 68 60 --

Areas.

,, in non RE

2 ,, ,, --

Areas.

QTA2 Upto 450

meters track

3 ,, 120 50

Circuit Lengths

in RE Areas.

4 ,, ,, 50 ,,

QBAT Upto 750

meters track

5 ,, 100 80

Circuit Lengths

in RE Areas.

Table-3

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 18

2.1.2 Line Relay

QN1 Style Relay

This is used for all control and detection circuit

except in external circuits of AC RE area.

Its specification No is B.R. No: 930A.

Though it is immune to 300 Volt AC 50Hz but only

in energencies can be used in RE area with

protection against AC Interface.

QS3 Style Relay

This is sensitive line relay.

It works on a low current. It works on 12V DC. QB3

relay is also of this type.

It is made to B.R. Specification 930A.

QB3 relay is biased neutral line relay.

Two relays of this type is used in parallel on

Tokenless block instrument to detect the line current

polarity in place of a polar relay.

Biasing stands good for 240 Volt DC.

QNN1 Style Relay

This comprises two neutral line relays whose

contacts and magnets are mounted side by side with

a common heel piece on a base.

BR specification 960.

These two relays operate independently to each

other.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 19

They have equal number of front and back contacts.

AC Immunised DC neutral line relay

This is made to IRS Specification No. S60 78.

Some important provisions are as under

The relay design shall be inherently such that the

immunisation is achieved intrinsically without use of

any external means.

The relay shall not make any of its front contacts

when 1000 V (r. m. s) of 50 Hz AC is applied at any

instant to the terminals of relay coils.

The relay shall not break any of its back contacts

when 300 V (r. m. s) of 50 Hz AC is applied at any

instant to the terminals of relay coils.

AC Immunised Q- style line relays

AC Immunised Q- style line relays, commonly used

in signaling are as under.

QNA 1 Relay

The immunisation is achieved by provision of a

copper slug on the core at its armature end.

In all other respects, it is similar to QN 1.

Its Specification is BR specification no. 931A.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 20

QBA1 Relay

This is a DC biased AC immune neutral line relay.

A copper slug is provided on the core for

immunisation and a permanent magnet is provided

on the core for Biasing.

It does not operate if 20 times of the rated voltage is

applied in reverse direction.

Its specification is BR Specn No. 932 A.

QBCA 1 Relay

This is similar to QBA 1 relay but having two heavy-

duty front contacts.

Its Specification is BR specification no. 943A.

QSPA 1 relay

This made to BR specification no. 933A.

Only this relay is permitted to be used as the repeater

for immunised Q series track relays, due to its slow

to pickup character.

Provision of a copper slug between the core and the

heel piece behind and a magnetic shunt between the

core and the armature at the front contact make this

relay

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 21

Feature of QSPA1 relay is as under.

Slow to pick up by 540 /600 seconds.

Less slow to release by 140 / 200 seconds and

immune to AC.

QSRA 1 relay

This is made to B.R. Specification No. 934 A.

By provision of a copper slug it is made AC

immunised and by a magnetic shunt delayed release

feature is obtained.

The copper slug and magnetic shunt are provided in

the same rear side of the core.

Time Element Relay

Relays used for getting time lag are called as TIME

ELEMENT RELAY.

These relays are used in the signaling circuits to

release interlocking after certain period of time to

ensure safety.

Normally following types of Time Element Relays

are in use.

DC Thermal type

Siemens Motorised Clock Work time relay

Motor type

Electronic type

Out of the above 4 types of Time Element Relay DC

Thermal and Electronic type are most commonly

used.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 22

DC Thermal Type Element Relay (QJ1)

This type of relay employs heat operated contact

associated with an ordinary DC Neutral Relay.

It has a heating element (H) and a neutral line relay

(R) which together energise an external line relay

after a pre set time delay.

One of such type is QJI type relay.

The details of this relay is given below :

Rated Voltage 24 V DC or 50 V DC

Heat coil resistance40 to 42 Ohms

Max. heating power 15 Watt at rated

supply Voltage.

The Maximum numbers of operations should be

restricted to 100 / day otherwise characteristics of the

heating element may change.

An increase of 10 % in applied voltage may result in

a time decrease of up to 10% .

An decrease of 10% in applied voltage may result in

a time decrease of up to 20% .

A5 JSR A6 A7 R2 N24

)

TH

A4 JSR A3

H Contact JSR

R1 R3

B24 R4 C contact A8 A1 JSR A2

#

) JR

Circuit for time element relay

(Figure-4)

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 23

Fail safe Electronic Timer

Now a days fail safe Electronic Timer are being used

to achieve time delay either by charge, discharge

method or counting by clock pulse or integrated

circuits.

Siemens Motorised Clockwork Timer

This relay works on 11 OV A.C. +/- 10%.

It has a time range of 1 to 5 minutes.

The time can be adjusted.

Its reseating is automatic.

A synchronous motor drives and switches over

contacts after the lapse of preset time.

If the enersining circuit is prematurely interrupted,

the mechanism returns to its normal position before

actuating the contacts.

Two or three helper relays of K 50 type (AJTR1,

AJTR2 AND AJTR3 ) are used Along with this

relay for time control of circuits.

QL1 relay

This made to BR specification no. 935A.

This is a magnetically latched DC line relay. This

relay remains in full operated condition though the

feed to the relay is cut off.

This relay has two coils namely operate coil (R) and

release coil (N) and a permanent magnet.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 24

When feed to R coil is applied the relay get

energised.

As soon as it is energised the feeds to this coil cuts

off through the back contact of repeater relay.

The relay remain in pick up condition due to the

permanent magnet, provided near the core, because

the magnet flux in the core is just sufficient to hold

the armature against the pusher sparing pressure.

LPR R1 R2 N24

B24 (R) Coil

R3 R4

(N) Coil LR

(Figure-5)

To release the relay feed is applied to the N coil.

This sets up a flux in the core which is equal and

opposite to the permanent magnetic flux and

neutralises it.

The pusher spring and gravity normalise the

armature.

Feed to the N coil gets cut off after the release of

armature due to the inclusion of a front contact of the

relay in series with the release coil.

LR

N24

B24 LPR

(Figure-6)

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 25

QBCA1 relay

It is made to the specification to specn No. 943. It

has two heavy duty front contacts and four back

contacts of standard contact rating. The front

contacts can carry and switch upto 30A inductive

current at 110V.DC. Spark quenching is done by two

blow out (natural magnet) magnet provided on a

bracket by the side of the front contacts.

These relays can be used for 24 V DC as well as

110V DC point machine. These relays are immune to

120V, 50HZ abrupt application for AC Voltage. The

minimum front contact pressure is 56 grams instead

of 28 grams for the c to m contacts of other relays.

The operating characteristics of the relays, which

are commonly used under this series, are

tabulated as under.

SN Description style Contact Rated Reg.

Arrangements Voltage Ohms

1 Neutral QN1 12F/4B,8F/8B, 24 V. 400

6F/6B, 8F/4B DC

2 Neutral QN1 12F/4B,8F/4B, 50 V. 1600

8F/8B DC

3 AC QNA1 12F/4B,8F/8B, 24 V. 195

Immunized 8F/4B DC

DC Neutral

4 AC QNA1 12F/4B,8F/8B, 50 V. 1079

Immunized 8F/4B DC

DC Neutral

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 26

SN Description style Contact Rated Reg.

Arrangements Voltage Ohms

5 Magnetically QL1 11F/4B, 8F/6B 24V DC PU 145

Latch TD 680

6 Magnetically QL1 11F/4B, 8F/6B 50V DC PU 670

Latch TD 754

7 AC Lamp QECX1 4F 0.25 39

Proving Amp.

AC

8 DC Track QT1 2F 0.5V 4

DC

9 AC QTA1 2F 1.4V 9

Immunized DC

10 Thermal QJ1 2F/1B 24V DC 360

Time

Element

11 Thermal QJ1 2F/1B 50V DC N#

(1640) T#

(174 -

182)

12 Neutral QN1 12F/4B 24 VDC 400

13 Neutral QN1 8F/8B 24 VDC 340

14 AC Immune QNA1 12F/4B 24 VDC 200

Neutral

15 AC Immune QNA2 4F/2B 24 VDC 1112

Neutral

16 AC Immune QBA1 2F/2B 1.75V 9

Biased DC

Track

(Table-4)

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 27

The particulars for Q- series neutral line relay is

shown table below.

Data sheet for Q series neutral line relay

Arrangement.

Description

Spec. No.

Spec. No.

Code No.

Code Pin

Positions

Contact

B.R.B

Relay

Relay

S. No

Style

1 2 3 4 5 6 7 8

D.C.

Neutral 01/16 12F. 4B ABC

1 QNI 930A 001

Line 01/18 8F. 4B DE

Relay

01/17 8F. 8B

ABC

2 ,, ,, ,, 01/19 6F. 6B 002

DF

01/20 4F. 4B

01/21 12F. 4B ABC

3 ,, ,, ,, 003

01/23 8F . 4B EF

01/22 8F. 8B

ABD

4 ,, ,, ,, 01/24 6F. 6B 004

EF

01/25 4F. 4B

,, CDE

5 QS3 ,, 4F. 4B

Sensitive KX

,,

ACD

6 QNNI (2-relay 960 19/1 6F . 2B 092

EK

unit)

,, 19/2 4F. 4B ACE

7 ,, 057

19/3 2F . 2B HJ

D.C.

Blassed

PTJ/ ABF

8 QB3 Line -- 6F . 2B --

QB3 GX

Relay

(N/I)

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 28

Arrangement.

Description

Spec. No.

Spec. No.

Code No.

Code Pin

Positions

Contact

B.R.B

Relay

Relay

S. No

Style

1 2 3 4 5 6 7 8

A.C.

Immune

DC/NL 05/11 12F.4B ABD

9 QNAI 931A 021

Relay 05/13 8F . 4B FH

05/12 8F. 8B

,, ABD

10 ,, ,, 05/14 6F. 6B 022

GH

05/15 4F. 4B

D.C.

Blassed

ACI 12F.4B

11 QBAI 932A

(N/L) 8F . 4B

Relay

---do

12 ,, ,, 8F . 4B

DC

biassed

2F

ACI BCE

13 QBCAI 943 (HD) 170

contactor JK

4B

Relay

Slow

Pick Up

ABD

14 QSPAI ACI N/L 933A 11/ 1 8F. 4B 041

EJ

Relay

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 29

Arrangement.

Description

Spec. No.

Spec. No.

Code No.

Code Pin

Positions

Contact

B.R.B

Relay

Relay

S. No

Style

1 2 3 4 5 6 7 8

Slow

Release ADE

15 QSRAI 934A 08/ 13 8F. 4B 061

ACI N/L FJ

Relay

DC

Magnetic ABC

16 QLI 935 09/ 05 8F. 6B 007

Latch EG

Relay

ABDE

17 ,, -Do- ,, 09/ 03 11F. 4B 009

G

DC thermal

Time

AFGH

18 QJI element 937 2F-1B

K

Relay

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 30

(volts) D.C.

Wkg. Volt.

Max. PUV

Min. DAV

Min. PUV

Immunity

Coil Res.

(Ohms)

(volts)

(volts)

(volts)

(volts)

Relay

S. No

Style

A.C.

1 2 9 10 11 12 13 14

QNI 340 to

1 24 19.2 -- 3. 6 300

470

,, ,,

2 ,, ,, ,, -- ,,

,, 1000/

3 1500

50 40.0 -- 7..5 --

,, --

4 ,, 50 ,, -- ,,

QS3 --

5 1000 12 9.35 7. 5 3. 75

6 QNNI 470 24 19.2 -- 3. 6 --

,, --

7 ,, 24 19.2 -- 3. 6

QB3 9.6 --

8 200 12 @ 8. 0 --

(45m

A)

QNAI 300

9 208 24 19.2 -- 3.6

,, ,,

10 208 24 ,, -- ,,

11 QBAI ,, 24 ,, -- ,, 300

,, ,,

12 ,, ,, ,, -- ,,

QBCAI 300

13 208 24 19.2 -- 3. 6

14 QSPAI ,, ,, ,, -- ,, 120

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 31

(volts) D.C.

Wkg. Volt.

Max. PUV

Min. DAV

Min. PUV

Immunity

Coil Res.

(Ohms)

(volts)

(volts)

(volts)

(volts)

Relay

S. No

Style

A.C.

1 2 9 10 11 12 13 14

15 QSRAI ,, ,, ,, -- ,, 120

QLI R-150

16 ,, ,, 9.6V -- --

N-680

17 ,, ,, ,, ,, ,, -- --

QJI

H-40

18 ,, ,, -- -- --

JSR-400

Current (Amps)

Contact Rating

Usage & other

Relay Style

D.A. Time

P.U. Time

(m. sec)

(m. sec)

Contiu

S. No

Ous

Switching

Remarks

1 2 15 16 17 18 19

QNI All ccts. Of Non-

RE &

Internal ccts. Of

1 150 20 3 2

RE. In

Emergency ccts.

Of RE area.

2 ,, ,, ,, ,, ,, ,,

,, Used as Track

3 ,, ,, ,, ,, Relays with

AFTC

4 ,, ,, ,, ,, ,, ,,

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 32

Current (Amps)

Contact Rating

Usage & other

Relay Style

D.A. Time

P.U. Time

(m. sec)

(m. sec)

Contiu

S. No

Ous

Switching

Remarks

1 2 15 16 17 18 19

In place of shelf

type relays

5 -- -- ,, ,,

QS3 : Ex: EVR &

SUPR of AXCs

QNNI All ccts. Of non-

RE &

6 -- -- ,, ,,

Internal ccts of

RE Area

7 ,, -- -- ,, ,,

QB3 CRRS of PTJ

8 380 20 ,, ,, make T/less

Blpck Instt.

9 QNAI 220 70 ,, ,, External circuits

10 ,, ,, ,, ,, ,, Of R.E. Area

11 QBAI ,, ,, ---do----

12 ,, ,, ,,

QBCAI 30A Point Machine

30A-F

13 F Control in

3A-B

2A-B R.E. area.

QSPAI 540 For TPRs with

140/

14 / 3A 2A QTA26 OBAT

200

600 Track Relays.

QSRAI 260

0 For use in AC

15 -- ,, ,,

19.2 RE area

V

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 33

Current (Amps)

Contact Rating

Usage & other

Relay Style

D.A. Time

P.U. Time

(m. sec)

(m. sec)

Contiu

S. No

Ous

Switching

Remarks

1 2 15 16 17 18 19

16 QLI -- -- ,, ,, TCFR and

,, TOTR of PTJ

make T/less

17 -- -- ,, ,,

Block

QJI 30/

60/

18 90/ -- ,, ,,

120

Sec

(Table-5)

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 34

2.1.3 Q- style lamp proving relays

These relays are used in the signaling circuits for

proving the intactness of the filament of signal lamp.

Normally following types of lamp proving Relays in

use are shown in table below.

Data sheet for Q-series lamp proving relays.

IRS Contact

S. Relay Spec Relay Arrange- Pin

No Style . Type No. Ment Code No.

No.

QECX1 941 13/1

1 4F 071

(OFF/ ON) A (WSF)

QECX12 13/11

2 ,, 4F --

(OFF) (WSF)

QECX13 13/12

3 ,, 4F --

(ON) (WSF)

QECX14 13/13

4 ,, 4F 4B --

(WSF)

13/9

QUCX1 942

5 (WSF & 2F 2B --

A

Crompton)

QECX51 941 Crompton

6 4F 4B --

A make

QECX51

7 ,, ,, 4F 4B --

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 35

Voltage Drop

@250 mA

Max Full

Code Pin

Coil Res.

Current

Operate

Current

Position

(Ohms)

current

Rated

Relay

S. No

Style

QECX 9 + 0 .6 180

1 400 V.A.C mA

1 ABCDK 35

(off / mA

on)

QECX -- 120

2 12 ,, 4.7 ,, mA

(off)

QECX -- 225

3 13 CFKMX ,, ,, mA

(on )

QECX -- 220

650m

4 14 CFJKM ,, mA

A

QUC 3. 3 780

1400

5 X1 CFKLX 0 .76 V.A.C mA

mA

QECX 400 9 V.A.C 180

6 -- --

51 mA mA

QECX 75 mA

7 51 -- -- ,,

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 36

Max. Release

Min. Release

Interruption

Current

Current

Typical

Usage

Relay

S. No

Time

Style

QEC -- 110 100 ms

X1 mA @180

1 (off/ mA SL 35 Lamp

on) 200ms @

250 mA

QEC -- 60 100 ms

SL,17/SL,21

2 X12 mA @110

(DECR)

(off) mA

QEC -- 120 100 ms

SL,17/SL,21

3 X13 mA @120

(RECR)

(on ) mA

QEC -- 70 ,,

SL,17/SL,21

4 X14 mA

(DECR)

QUC 590 520 -- SL, 33 Direction

5 X1 mA mA Type

R/1 (4F . 4B)

QEC -- 110 --

SL,17/SL,21

6 X51 mA

(RECR)

QEC -- 35 --

SL,17/SL,21

7 X51 mA

(DECR)

(Table-6)

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 37

2.2. Style G plug in Relays

Plugging arrangement

Correct plugging arrangement is achieved by means

of providing holes in the base plate and the

corresponding code pins in the plug-board.

Rear and the front view of the plug-board is shown in

the figure given below.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 38

GN 1 Relay Plug Board

(Figure-7)

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 39

Registration Device

The registration feature prevents plugging of a relay

in wrong place.

It consists of two plates one with holes and other

with pins.

The female plate is attached with the base of relay

while the plate with pins is attached to the plug-

board.

There are 33 positions for holes in the registration

plate with corresponding pin position in the plug-

bard.

Any four out of 33 position are drilled in the

registration plate and corresponding four pins are

fitted to the relay plug-bard.

Insulators

These are made of molded backelite and fit into slots

in the plu-bard. Each plug board is provided with 11

numbers of insulators, which are held in position

tightly by nylon clip.

Special Features

There are two test terminals on the plug board.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 40

Current test terminal

Two-check current flowing through the relay coil a

current test terminal is provided on the plug-board

directly under the relay. A special tool can be

attached two the terminal to open the circuit to the

coil insert a milli-ammeter.

Voltage Test Terminal

To provide a simple means of checking Voltage

across the relay coil a voltage test terminal is

provided on the plug-board directly under the relay.

Voltage can be read by connecting a voltmeter across

the voltage test terminals.

Guide rods

Two guide rods each 8.5 long extending from the

face of plug-board helping & guiding the relay in

correct alignment with the plugs on the plug-bard.

Each rod has Knurled nut and a lock nut to screw the

relay on its plug-board.

Contact arrangement

A maximum of 6F/B dependent contacts can be

accommodated in G series relay. In which back

contacts are M to M and front contacts may be M to

M or M to C.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 41

Standard contacts arrangements are 6 F/B, 4F/B &

2F/B.

In this series the following varieties of relays are

available.

S Descripti Style Contact Rated Coil Rem

N on Arrange Volts Res. ark

ments Ohms

1 Neutral GN1 6F / B 12 DC 500

2 Pt. S1 4F / B 12 DC 500

Contactor

Relay

3 Over GOL 2F / B ----- PU 0. Cure

Load 064 nt

(OR) HO sensi

135 tive

4 AC GNA 6F / B 12 DC 500

Immune 1

Neutral

5 Track GT1 4F / B ----- 9

6 Track GTA 4F / B ----- 9

1

Table-7

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 42

3. Maintenance Checks

3.1 During maintenance visit relays should be checked

visually for the following.

Cleaning shall be done regularly so that dust is not

deposited on the relay.

There is no loose connection on the terminals, plug

in relays is fitted tightly & the sealing is intact.

Metal contacts are not blackened due to arching.

There is no pitting of carbon contacts.

No foreign materials are inside the relay.

There is no rusting or sulphation on the parts.

Relays are not due for P.O.H.

Track Relay drops properly with 0.5 Ohms shunt.

Over energisation is not more than 300% of its P.U.

value for Plug in Type Relays.

3.2 Stipulations of S.E.M. on the requirements &

schedule of periodical inspection and overhauling

of relays.

All vital relays should be inspected visually once in

every two and three years for Track & Line Relay

respectively in respect of the following.

Movement of armature and contact carriage,

Wiping of contacts,

Arching of contacts if any,

Pitting or charring contacts,

Dust on contacts,

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 43

Electroplating,

Corrosion rusting of contacts,

Cracks or breakage in components,

Presence of fungus,

Charring of cover near contacts,

Corrosion of label.

Presence of seal.

All proved type relays should be checked and their

contacts cleaned at site, if required, at the time of

failure.

If failure persists, the relay should be removed and

sent for overhauling.

3.3 Overhauling

All types of track relays should normally be

overhauled every 10 years subject to a maximum of

12 years.

Date of overhauling should be counted from the date

of manufacture.

The Railways depending upon intensity of traffic and

other local conditions may reduce the periodicity of

overhauling of the relays.

All metal to carbon contact plug-in type relays other

then track relays should be overhauled only when

they are removed from service after a failure.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 44

4. Dos and Donts

4.1 Dos

Use standard plug board as per registration device

with specified code-pin of relay if required to replace

any plug board.

Wiring clip is properly locked in relay plug board.

Ensure that QNA1 relay is used in external circuit

and QN1 is in internal circuit.

Check the sealing of relay.

Replace the relay immediately if relay contacts are

black or pitted.

Retaining clips for holding the Q-type relay is intact

properly and latches at relay handle.

Store the relay in dry place and away from dust.

Always carry the relay through its handle.

Ensure that numbers of wires terminated in the relay

are as per wire count register.

After modification in any circuit the relay contact

must be registered in wire count register.

Replace the relay under proper disconnection memo.

Write relay identification as per signal-vice and

circuit-vice.

Check the release time of slow acting or timer relay.

Plug in type Relay March2005

CAMTECH/S/2005/PR/1.0 45

4.2 Donts

Do not drill any hole in plug board for plugging the

deferent type code pin relay.

Do not disturb the leasing of relay wiring.

Do not by pass the relay contact at the time of

failure.

Do not replace any relay during train movement.

Do not break the seal for cleaning of relay contact.

Do not used QN1 relay in place of QNA1 relay.

Plug in type Relay March2005

Vous aimerez peut-être aussi

- The Pevearsion of Russian LiteratureDocument8 pagesThe Pevearsion of Russian LiteratureStan MazoPas encore d'évaluation

- Civil Engineering Softwares and Their ImplementationsDocument13 pagesCivil Engineering Softwares and Their ImplementationsADITYAPas encore d'évaluation

- Pamphlet On Signalling in 25 KV AC Electrified AreaDocument28 pagesPamphlet On Signalling in 25 KV AC Electrified Areakbs prabhakar100% (1)

- LED SignalDocument32 pagesLED SignalJatin ParmarPas encore d'évaluation

- IRSE ARTICLE Signalling RelaysDocument23 pagesIRSE ARTICLE Signalling Relaysmaxxand100% (1)

- Relays tested for operating parametersDocument1 pageRelays tested for operating parametersThushianthan KandiahPas encore d'évaluation

- RRI System IIDocument4 pagesRRI System IISubrahmanyam RajagopalPas encore d'évaluation

- 1 S5J1 Route Relay InterlockingDocument63 pages1 S5J1 Route Relay InterlockingSantosh Dharphal100% (2)

- DC Track CircuitDocument19 pagesDC Track CircuitSatyamitra YerraguntlaPas encore d'évaluation

- Siemens 3 Phase Point MachineDocument6 pagesSiemens 3 Phase Point Machiner k mishraPas encore d'évaluation

- Electric Point Machine & Signal Machine PDFDocument70 pagesElectric Point Machine & Signal Machine PDFvaranasilko0% (2)

- NCR - Nomenclatures: Relay Nomenclature FunctionDocument4 pagesNCR - Nomenclatures: Relay Nomenclature Functionsayed100% (1)

- s21 Point MC & Signal MachineDocument72 pagess21 Point MC & Signal MachineNesarkiran Bagade100% (2)

- Draft Maintenance Handbook On RRI SiemensDocument73 pagesDraft Maintenance Handbook On RRI SiemensMadhav PrasadPas encore d'évaluation

- T7Document114 pagesT7Rameshscr09Pas encore d'évaluation

- ST-24 - UFSBI (Universal Fail Safe Block Interface) For D/LDocument32 pagesST-24 - UFSBI (Universal Fail Safe Block Interface) For D/Lvijay kumarPas encore d'évaluation

- Draft Maintenance Handbook On WESTRACE VLM6 Electronic Interlocking PDFDocument44 pagesDraft Maintenance Handbook On WESTRACE VLM6 Electronic Interlocking PDFVivek AnandPas encore d'évaluation

- Qecx 61 IntegraDocument1 pageQecx 61 IntegraThushianthan KandiahPas encore d'évaluation

- Pre-commissioning Checklist and Testing Procedure for Automatic Fire Detection SystemsDocument12 pagesPre-commissioning Checklist and Testing Procedure for Automatic Fire Detection SystemsPriya SinghPas encore d'évaluation

- Telecommunication Lab ManualDocument34 pagesTelecommunication Lab ManualYADAVAMITKUMAR007Pas encore d'évaluation

- BPAC DL LeafletDocument11 pagesBPAC DL LeafletAshok Maurya100% (1)

- S&T Question Bank for Group 'B' SelectionDocument31 pagesS&T Question Bank for Group 'B' SelectionManishPas encore d'évaluation

- Principles and Concepts of InterlockingDocument31 pagesPrinciples and Concepts of InterlockingMohd. ShafeequePas encore d'évaluation

- ST-10 Telephone InstrumentDocument13 pagesST-10 Telephone InstrumentRanjeet SinghPas encore d'évaluation

- Introduction to Micro- and Nanofabrication TechniquesDocument39 pagesIntroduction to Micro- and Nanofabrication TechniquesGauri DalviPas encore d'évaluation

- Locking Table Practice S5 Locking Table Practice Locking Table PracticeDocument34 pagesLocking Table Practice S5 Locking Table Practice Locking Table PracticePrasun Singhal100% (1)

- Non Trailable2EnglishDocument6 pagesNon Trailable2EnglishSuman ThakurPas encore d'évaluation

- RKT GuideDocument15 pagesRKT GuideRohit KumarPas encore d'évaluation

- Point Training SessionDocument33 pagesPoint Training SessionShashi Bhusan SinghPas encore d'évaluation

- Design Flow ChartDocument9 pagesDesign Flow ChartSubrahmanyam Rajagopal0% (1)

- Microsoft Word - SSDAC 2DP1S-IM Version 1.0, Rev.4Document127 pagesMicrosoft Word - SSDAC 2DP1S-IM Version 1.0, Rev.4innocent ali50% (2)

- Ssdac Dacf-710p ManualDocument163 pagesSsdac Dacf-710p ManualJeet DattaPas encore d'évaluation

- Blocked Rotor TestDocument11 pagesBlocked Rotor TestIjabi100% (1)

- EE466 C5 Distance Protection of Transmission Lines PDFDocument7 pagesEE466 C5 Distance Protection of Transmission Lines PDFSaisreePas encore d'évaluation

- Tack BondingDocument81 pagesTack BondingsubhajitPas encore d'évaluation

- SignallingDocument18 pagesSignallingankitsingh79834Pas encore d'évaluation

- Axel Counter Summer Training ReportDocument81 pagesAxel Counter Summer Training ReportMitil VarshneyPas encore d'évaluation

- MSIXML Design v1 7Document26 pagesMSIXML Design v1 7p1cadorPas encore d'évaluation

- Maintenence of Double Line Block Instrument Used in Indian RailwaysDocument7 pagesMaintenence of Double Line Block Instrument Used in Indian RailwaysVikas Srivastav100% (1)

- Handbook Symbols Signalling Terminology Indian RailwaysDocument35 pagesHandbook Symbols Signalling Terminology Indian RailwaysUday KumarPas encore d'évaluation

- 9 Ch6 Power SupplyDocument10 pages9 Ch6 Power Supply90germany100% (1)

- ESSENTIALS OF INTERLOCKING SIGNALSDocument13 pagesESSENTIALS OF INTERLOCKING SIGNALSmahmoudPas encore d'évaluation

- ABB relay specificationsDocument18 pagesABB relay specificationspkhumesh1Pas encore d'évaluation

- Indian Railway Standard for Universal Fail-Safe Block InterfaceDocument29 pagesIndian Railway Standard for Universal Fail-Safe Block Interfacema_purwoadiPas encore d'évaluation

- Track CircuitDocument20 pagesTrack CircuitTanay P100% (1)

- Figure 1 - Basic DC Track CircuitDocument17 pagesFigure 1 - Basic DC Track CircuitSourav MahatoPas encore d'évaluation

- Electrical Machines Three-Phase Induction Motors: Dr. Alivelu M ParimiDocument46 pagesElectrical Machines Three-Phase Induction Motors: Dr. Alivelu M ParimiRishavPas encore d'évaluation

- Relay PDFDocument38 pagesRelay PDFKishore YerramsettyPas encore d'évaluation

- Reactive Power ControlDocument6 pagesReactive Power ControlMANPAYAPas encore d'évaluation

- Report On Tripping of Delta I Relay On Running of Wag12 LocosDocument3 pagesReport On Tripping of Delta I Relay On Running of Wag12 LocosrdkrdsoPas encore d'évaluation

- Littelfuse Protection Relay Protection Relays White Paper PDFDocument6 pagesLittelfuse Protection Relay Protection Relays White Paper PDFRamphani NunnaPas encore d'évaluation

- Hand Book Ver. No. Ver. No. 0111SB03.1: S&T Training Centre, Podanur Iso 9001-2008 Certified UnitDocument57 pagesHand Book Ver. No. Ver. No. 0111SB03.1: S&T Training Centre, Podanur Iso 9001-2008 Certified Unitsampreethp100% (1)

- CRS Condonation VPL - JustificationDocument7 pagesCRS Condonation VPL - JustificationRamojiNaikPas encore d'évaluation

- Irs Point MachineDocument97 pagesIrs Point MachineAMIT KUSHWAHAPas encore d'évaluation

- MLK-II Hard WareDocument136 pagesMLK-II Hard WareashishcnairPas encore d'évaluation

- Computer Hardware & Software IdentificationDocument14 pagesComputer Hardware & Software IdentificationRanjeet SinghPas encore d'évaluation

- Relays FOR RAILWAY SIGNALINGDocument26 pagesRelays FOR RAILWAY SIGNALINGVikas Srivastav98% (51)

- Signalling Relay Spec PDFDocument2 pagesSignalling Relay Spec PDFIndranilPas encore d'évaluation

- 11 Chapter 2Document31 pages11 Chapter 2Srinivas EnamandramPas encore d'évaluation

- Assignment (Relay)Document7 pagesAssignment (Relay)Riya KumariPas encore d'évaluation

- Relay: From Wikipedia, The Free EncyclopediaDocument9 pagesRelay: From Wikipedia, The Free EncyclopediaApri ZaldyPas encore d'évaluation

- User GuideDocument14 pagesUser Guidenayla amarPas encore d'évaluation

- Mobile Phone Detector1Document7 pagesMobile Phone Detector1Srinivas EnamandramPas encore d'évaluation

- Datasheet 3G-1+2Document2 pagesDatasheet 3G-1+2Srinivas EnamandramPas encore d'évaluation

- Electric Traction in Indian Railways: Submitted by Vishwas Jain 11emhex062Document34 pagesElectric Traction in Indian Railways: Submitted by Vishwas Jain 11emhex062Srinivas EnamandramPas encore d'évaluation

- MR General Rules Public Carriage Passengers Rules 2013Document121 pagesMR General Rules Public Carriage Passengers Rules 2013Srinivas EnamandramPas encore d'évaluation

- 11 Chapter 2Document31 pages11 Chapter 2Srinivas EnamandramPas encore d'évaluation

- RAMS in The Railway 01Document7 pagesRAMS in The Railway 01Ugljesa Milovic67% (3)

- Surveying NotesDocument39 pagesSurveying NotesInhen Yero75% (4)

- Structural Analysis 2Document52 pagesStructural Analysis 2Srinivas EnamandramPas encore d'évaluation

- Derailment in Track Switches: Martin AnderssonDocument50 pagesDerailment in Track Switches: Martin AnderssonSrinivas EnamandramPas encore d'évaluation

- Brief On Safety Oct 10Document28 pagesBrief On Safety Oct 10Srinivas EnamandramPas encore d'évaluation

- Ynk RVNL Obervatins CrsDocument1 pageYnk RVNL Obervatins CrsSrinivas EnamandramPas encore d'évaluation

- Amedment To General RulesDocument4 pagesAmedment To General RulesSrinivas EnamandramPas encore d'évaluation

- Draft Maintenance Handbook On IRS Type DLBIDocument43 pagesDraft Maintenance Handbook On IRS Type DLBISrinivas EnamandramPas encore d'évaluation

- Normalisation Formula v8 - 2013Document11 pagesNormalisation Formula v8 - 2013rmurali179Pas encore d'évaluation

- Normalisation Formula v8 - 2013Document11 pagesNormalisation Formula v8 - 2013rmurali179Pas encore d'évaluation

- APAR CircularDocument11 pagesAPAR CircularSrinivas EnamandramPas encore d'évaluation

- Track CircuitingDocument8 pagesTrack CircuitingSrinivas EnamandramPas encore d'évaluation

- SPN - 192 (1) EiDocument33 pagesSPN - 192 (1) EiDiptajyoti RoyPas encore d'évaluation

- TLB Final 6 MonthDocument205 pagesTLB Final 6 MonthSrinivas EnamandramPas encore d'évaluation

- From Verse Into A Prose, English Translations of Louis Labe (Gerard Sharpling)Document22 pagesFrom Verse Into A Prose, English Translations of Louis Labe (Gerard Sharpling)billypilgrim_sfePas encore d'évaluation

- CH - 3 Class XII Physics (E-Notes)Document9 pagesCH - 3 Class XII Physics (E-Notes)tejasPas encore d'évaluation

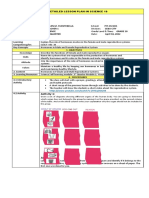

- FS 3 Technology in The Learning EnvironmentDocument24 pagesFS 3 Technology in The Learning EnvironmentJayson Gelera CabrigasPas encore d'évaluation

- PDFDocument478 pagesPDFPriyaranjan PradhanPas encore d'évaluation

- The Dilemma of Recognition Experienced Reality of Ethnicised Politics in Rwanda and BurundiDocument192 pagesThe Dilemma of Recognition Experienced Reality of Ethnicised Politics in Rwanda and BurundiShenandoa LeãoPas encore d'évaluation

- WRITTEN ASSIGNMENT Unit 2 - The Peer Assessment Strategy - 1Document2 pagesWRITTEN ASSIGNMENT Unit 2 - The Peer Assessment Strategy - 1asdsafsvvsgPas encore d'évaluation

- Jerome KaganDocument5 pagesJerome KaganMandeep morPas encore d'évaluation

- Social Studies For Brunei Darussalam Year 8 TextbookDocument152 pagesSocial Studies For Brunei Darussalam Year 8 TextbookChai Wei Chen100% (1)

- Cot 1 Detailed Lesson Plan in Science 10Document3 pagesCot 1 Detailed Lesson Plan in Science 10Arlen FuentebellaPas encore d'évaluation

- The Most Efficient and Effective Ways To Address New Literacies FDocument61 pagesThe Most Efficient and Effective Ways To Address New Literacies FAlpha MoontonPas encore d'évaluation

- Stock TakeDocument14 pagesStock Takesafare2222Pas encore d'évaluation

- Pilani MTech SS PDFDocument12 pagesPilani MTech SS PDFonline accountPas encore d'évaluation

- Active and Passive Cooling Technologies For Thermal Management of AvionicsDocument10 pagesActive and Passive Cooling Technologies For Thermal Management of AvionicsdavidPas encore d'évaluation

- Product Brand Management 427 v1Document484 pagesProduct Brand Management 427 v1Adii AdityaPas encore d'évaluation

- IED670 - A Major Leap in Grid ReliabilityDocument2 pagesIED670 - A Major Leap in Grid ReliabilityunorulezPas encore d'évaluation

- D820-93 (2009) Standard Test Methods For ChemicalDocument10 pagesD820-93 (2009) Standard Test Methods For Chemicalobis8053Pas encore d'évaluation

- 4880 AnsiDocument0 page4880 AnsiabualamalPas encore d'évaluation

- FNCP Family Nursing Care Plan 1 Poor Environmental Sanitation Health ThreatDocument2 pagesFNCP Family Nursing Care Plan 1 Poor Environmental Sanitation Health Threatbraceceeem03Pas encore d'évaluation

- Ayushi HR DCXDocument40 pagesAyushi HR DCX1048 Adarsh SinghPas encore d'évaluation

- Landmark Church School WBSDocument4 pagesLandmark Church School WBSbayoPas encore d'évaluation

- The Law of DemandDocument13 pagesThe Law of DemandAngelique MancillaPas encore d'évaluation

- English AssignmentDocument79 pagesEnglish AssignmentAnime TubePas encore d'évaluation

- Module #5 Formal Post-Lab ReportDocument10 pagesModule #5 Formal Post-Lab Reportaiden dunnPas encore d'évaluation

- Ms - 1294 - Part3 - 1993 - WALL AND FLOOR TILING PART 3 - CODE OF PRACTICE FOR THE DESIGN AND INSTALLATION OF CERAMIC FLOOR AND MOSAICSDocument7 pagesMs - 1294 - Part3 - 1993 - WALL AND FLOOR TILING PART 3 - CODE OF PRACTICE FOR THE DESIGN AND INSTALLATION OF CERAMIC FLOOR AND MOSAICSeirenatanPas encore d'évaluation

- BSM and NSM Best Practice 66Document67 pagesBSM and NSM Best Practice 66Freelancer83Pas encore d'évaluation

- R. Pasnau - Divisions of Epistemic LaborDocument42 pagesR. Pasnau - Divisions of Epistemic LaborMarisa La BarberaPas encore d'évaluation

- Bachelor Thesis MaritimeDocument43 pagesBachelor Thesis MaritimeMiriam PedersenPas encore d'évaluation

- Ruibal & Shoemaker 1984 - Osteoders in AnuransDocument17 pagesRuibal & Shoemaker 1984 - Osteoders in AnuransRuivo LucasPas encore d'évaluation