Académique Documents

Professionnel Documents

Culture Documents

Tds g2 00

Transféré par

Achraf BoudayaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tds g2 00

Transféré par

Achraf BoudayaDroits d'auteur :

Formats disponibles

Forming Tech Data Sheet G2.

00

See TDS G3.00 & Design and Installation Manual for additional requirements

TERMS AND EXPLANATIONS

Lap or Butt Joint (E)

ENVELOPE

The insulation surrounding the pipeline or tank. This seamless envelope insulates and

protects the system.

FORMS

Accurate material coverage is provided by using a simple form system constructed of

sheet rock. Forming also eliminates material waste caused by uneven trenching.

SPACERS AND SUPPORTS Bulkhead Spreader (C)

Temporary spacers are used to hold forms in place during placement of GILSULATE

500XR. Temporary supports are used to support the pipe system at elevation during

placement of GILSULATE 500XR. Temporary spacers and supports must be removed Side Block (C)

as installation of GILSULATE 500XR progresses.The consolidated GILSULATE 500XR

will fully support the pipeline or tank. Form (A)

CONSOLIDATION

GILSULATE 500XR is designed with a specific gradation of particle sizes which allows

consolidation of the material by simple vibration and provides a load bearing system.

Shrinkage and reduction of insulation coverage caused by backfill loads is avoided as

Side Block & Bulkhead

occurs with loose bulk material installation. Consolidation is best accomplished by use

Forming Method

of a concrete vibrator with a 1-3/8 diameter vibrator head. Vibrators are available

from Wacker Corp. or Wyco Tool Co. and equipment rental firms. See note #5 below.

C ARBOLINE BITUMASTIC 50 Temporary Support - Lap or Butt Joint (E)

Remove as Insulation

A self-priming, waterproof coating made from pitch used to coat metal and concrete Material is Installed

structures that penetrate the GILSULATE 500XR envelope from the outside.

Application of Carboline bitumastic 50 is to occur just prior to placement of the

GILSULATE 500XR. The tacky Carboline Bitumastic 50 receives the GILSULATE Spreader

500XR and provides a seal along envelope penetrations. Koppers Super Service Black

meets these requirements.

MINERAL FIBER CUSHION Side Block (C)

An expansion absorbing cushion required at expansion loops and ELs. May be manu-

factured from inorganic glass fibers at 3 - 5lb. density with an upper temperature range

of 750F or spun ceramic fibers. Other preformed, snap-on pipe insulation composed

of fiberglass, bonded with phenolic resin and capable of withstanding the system design Form (A)

temperature are also suitable.

PACKING

High temperature rope, prefabricated Link Seals or other suitable materials are used

to seal the annulus at pipe entries through walls or floors.The packing is used to Side Block & Spreader

prevent migration of granules through the entry and yet will allow longitudinal pipe Forming Method

movement.

Temporary Support -

Remove as Insulation

Material is Installed

NOTES:

1. Pack wall entries as specified (See Design Manual).

2. Remove standing water prior to installation of insulation. Check soil permeability.

Section 4.0 A. Forms may be removed or left in place. Forms left in place should

3. Clear all foreign objects from insulation envelope to provide a seamless covering be of gypsum board and a minimum thickness of 1/2.

and eliminate short circuits. B. Use side block spacing as required to limit maximum bowing of

4. Clean pipes of all dirt, scale and other foreign materials. forms to 1/2.

5. Just prior to placement of GILSULATE 500XR coat anchors, guides, wall entries, etc. C. Side blocks are not attached to forms. Blocks are removed as

with Carboline bitumastic 50 to provide a seal. Carboline Bitumastic 50 is to be tacky. insulation is installed and compacted to mid-pipe height. After

6. Consolidate GILSULATE 500XR with rod-type concrete vibrator to 40 - 42 lb./cf. den- removal of block, fill void with insulation. Bulkheads are removed

sity. Walk on top of envelope. Density has been achieved if footprints are less than 1 as insulation is installed and compacted. After removal of bulk-

deep. heads, fill void with insulation.

7. Bulkhead uncompleted end and backfill top with 4 to 6 of soil backfill at the end of D. Backfill behind forms must be thoroughly compacted by mechan-

each day to protect insulation envelope until work resumes. ical or hand tamping. It should be installed at least to mid-pipe

8. If conditions cause excessive dusting, use NIOSH/MSHA approved face mask dust res- height before installation of insulation commences.

pirator. A material safety data sheet is available by calling (800) 833-3881. E. If lap joints are used, interior end must be spaced full Dim. A

from pipe.

GILSULATE 500XR is manufactured for use by experienced and knowledgeable con-

tractors or maintenance personnel. For complete design and installation details please

consult Gilsulate International at (800) 833-3881. Gilsulate P.O. Box 802650

Santa Clarita, CA 91380

International Phone: (800) 833-3881

Incorporated Web: www.gilsulate.com

Copyright 2005 Gilsulate International, Inc. Registered U.S. Patent Office U.S. Patent No. 4,231,884

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- CA Energy Code - 2019 PDFDocument194 pagesCA Energy Code - 2019 PDFJustaUser2Pas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

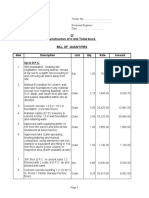

- Abstract of Estimate Estimate For Finshing Works in Marriage HallDocument2 pagesAbstract of Estimate Estimate For Finshing Works in Marriage HallsanthoshPas encore d'évaluation

- Zamil Steel Design ManualDocument282 pagesZamil Steel Design ManualYam Balaoing100% (3)

- ASHRAE 62.2 Ventilation and Acceptable Indoor Air QualitDocument37 pagesASHRAE 62.2 Ventilation and Acceptable Indoor Air QualitmansidevPas encore d'évaluation

- MYK Aquafin 2CDocument2 pagesMYK Aquafin 2Cnarmad_anil100% (1)

- Sci P399Document196 pagesSci P399vincent02hk_57881301100% (2)

- Ground Bearing Concrete Slabs - Chapter 2Document37 pagesGround Bearing Concrete Slabs - Chapter 2share4learn100% (1)

- Series LFII Residential, NFPA 13 Optimized Horizontal Sidewall Sprinklers 5.6 K-FactorDocument6 pagesSeries LFII Residential, NFPA 13 Optimized Horizontal Sidewall Sprinklers 5.6 K-FactorAchraf BoudayaPas encore d'évaluation

- Series LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Document8 pagesSeries LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Achraf BoudayaPas encore d'évaluation

- Series LFII Residential Concealed Pendent Sprinklers, Flat Plate 4.2 K-FactorDocument4 pagesSeries LFII Residential Concealed Pendent Sprinklers, Flat Plate 4.2 K-FactorAchraf BoudayaPas encore d'évaluation

- Series LFII Residential Flush Pendent Sprinklers 4.2 K-FactorDocument8 pagesSeries LFII Residential Flush Pendent Sprinklers 4.2 K-FactorAchraf BoudayaPas encore d'évaluation

- Series LFII Residential Horizontal Sidewall Sprinklers 4.2 K-FactorDocument8 pagesSeries LFII Residential Horizontal Sidewall Sprinklers 4.2 K-FactorAchraf BoudayaPas encore d'évaluation

- Style 10, 20, 30, 40, and 50 Recessed Escutcheons & Protective Paint Caps For Automatic Sprinkler Recessed InstallationDocument4 pagesStyle 10, 20, 30, 40, and 50 Recessed Escutcheons & Protective Paint Caps For Automatic Sprinkler Recessed InstallationAchraf BoudayaPas encore d'évaluation

- Model G1 & G4 Sprinkler Guards Model G1/S1 & G4/S3 Guards With Shields Series TY-B, TY-FRB, TY-L, and TY-FRL SprinklersDocument4 pagesModel G1 & G4 Sprinkler Guards Model G1/S1 & G4/S3 Guards With Shields Series TY-B, TY-FRB, TY-L, and TY-FRL SprinklersAchraf BoudayaPas encore d'évaluation

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 pageClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaPas encore d'évaluation

- Sprinkler Spray Patterns Refer To The General Description Section Before Applying The Spray Pattern DataDocument38 pagesSprinkler Spray Patterns Refer To The General Description Section Before Applying The Spray Pattern DataAchraf BoudayaPas encore d'évaluation

- Model G2 Sprinkler Guard, Model WS-2 Shield, and Model WSG-2 Sprinkler Guard With Shield Series ELO-231, ELO-231B, and ELO-231FRB SprinklersDocument4 pagesModel G2 Sprinkler Guard, Model WS-2 Shield, and Model WSG-2 Sprinkler Guard With Shield Series ELO-231, ELO-231B, and ELO-231FRB SprinklersAchraf BoudayaPas encore d'évaluation

- Installer Warning!!! Read The Following Cautions Before Handling or Installing Your SprinklersDocument4 pagesInstaller Warning!!! Read The Following Cautions Before Handling or Installing Your SprinklersAchraf BoudayaPas encore d'évaluation

- Jotashield Flex: Technical Data SheetDocument3 pagesJotashield Flex: Technical Data SheetAchraf BoudayaPas encore d'évaluation

- Flyer TycoDocument8 pagesFlyer TycoAchraf BoudayaPas encore d'évaluation

- Jotun Essence Easy Clean Matt: Technical Data SheetDocument3 pagesJotun Essence Easy Clean Matt: Technical Data SheetAchraf BoudayaPas encore d'évaluation

- Jotashield Extreme: Technical Data SheetDocument3 pagesJotashield Extreme: Technical Data SheetAchraf BoudayaPas encore d'évaluation

- Esab Pipeweld 6010R: Classifications: ApprovalsDocument1 pageEsab Pipeweld 6010R: Classifications: ApprovalsAchraf BoudayaPas encore d'évaluation

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 pageClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaPas encore d'évaluation

- Snubbers Type 31Document1 pageSnubbers Type 31Achraf BoudayaPas encore d'évaluation

- Rigid Struts Type 39Document1 pageRigid Struts Type 39Achraf BoudayaPas encore d'évaluation

- Typical Tensile Properties: Classifications: Welding Current: Diffusible Hydrogen: Alloy Type: Coating TypeDocument1 pageTypical Tensile Properties: Classifications: Welding Current: Diffusible Hydrogen: Alloy Type: Coating TypeAchraf BoudayaPas encore d'évaluation

- Heavy Duty Spring Supports Type 28Document1 pageHeavy Duty Spring Supports Type 28Achraf BoudayaPas encore d'évaluation

- ANVIL PIPE HANGERS & SUPPORTS ContinuedDocument1 pageANVIL PIPE HANGERS & SUPPORTS ContinuedAchraf BoudayaPas encore d'évaluation

- Spring Supports Type 29Document1 pageSpring Supports Type 29Achraf BoudayaPas encore d'évaluation

- Weld-On Brackets Type 35Document1 pageWeld-On Brackets Type 35Achraf BoudayaPas encore d'évaluation

- Snubbers Type 30Document1 pageSnubbers Type 30Achraf BoudayaPas encore d'évaluation

- Anvil Pipe Hangers & SupportsDocument1 pageAnvil Pipe Hangers & SupportsAchraf BoudayaPas encore d'évaluation

- Heavy Duty Spring Hangers Type 22Document1 pageHeavy Duty Spring Hangers Type 22Achraf BoudayaPas encore d'évaluation

- Spring Hangers Type 21Document1 pageSpring Hangers Type 21Achraf BoudayaPas encore d'évaluation

- Spring Hangers Type 25Document1 pageSpring Hangers Type 25Achraf BoudayaPas encore d'évaluation

- ANVIL PIPE HANGERS & SUPPORTS (CTD)Document1 pageANVIL PIPE HANGERS & SUPPORTS (CTD)Achraf BoudayaPas encore d'évaluation

- RGB Article ASHRAE 62.1-Using The Ventilation Rate Procedure 0813 00Document3 pagesRGB Article ASHRAE 62.1-Using The Ventilation Rate Procedure 0813 00Grace Tessa Myra GunsalamPas encore d'évaluation

- Clint Over Prodotti ENG-GREEK 2018 WDocument2 pagesClint Over Prodotti ENG-GREEK 2018 WlibegradPas encore d'évaluation

- English ProjectDocument17 pagesEnglish Projectvirgile.hasslauerPas encore d'évaluation

- Schools (B+G+2), Secondary & Primary Schools at Al Wukair, QatarDocument2 pagesSchools (B+G+2), Secondary & Primary Schools at Al Wukair, QatarthomsonPas encore d'évaluation

- BLDG Est GuideDocument11 pagesBLDG Est GuideVALIENT CANCERANPas encore d'évaluation

- G52T001 Sem02 M09Document2 pagesG52T001 Sem02 M09GayanPas encore d'évaluation

- Question Bank For Basic Civil EngineeringDocument4 pagesQuestion Bank For Basic Civil EngineeringSenthil Kumar0% (1)

- StairsDocument41 pagesStairsDeepthideepu100% (2)

- 12 Lowry Close, Sandhurst - Steelwork DesignDocument8 pages12 Lowry Close, Sandhurst - Steelwork DesignInoshan Madushika JayawickramaPas encore d'évaluation

- Rauf Khan Column EstimationDocument4 pagesRauf Khan Column EstimationRauf KhanPas encore d'évaluation

- Bitzer Hyperpac 2010Document20 pagesBitzer Hyperpac 2010Harsha Vardhan B100% (1)

- Tipo PaqueteDocument40 pagesTipo PaqueteEric Manuel Mercedes AbreuPas encore d'évaluation

- Roof TestDocument7 pagesRoof TestJoel BeyerPas encore d'évaluation

- ETABS Concrete Frame Design: Eurocode 2-2004 Beam Section DesignDocument1 pageETABS Concrete Frame Design: Eurocode 2-2004 Beam Section DesignCSEC Uganda Ltd.Pas encore d'évaluation

- 2 1 1 A WoodframesystemsDocument3 pages2 1 1 A Woodframesystemsapi-308216293Pas encore d'évaluation

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Document6 pagesType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasinghePas encore d'évaluation

- Safe Footing ReportDocument154 pagesSafe Footing ReportLenielle AmatosaPas encore d'évaluation

- Outin Bbraun Correspondence 08 NovDocument1 100 pagesOutin Bbraun Correspondence 08 NovGia Minh Tieu TuPas encore d'évaluation

- Rooftiles Unicoppo Installation GuideDocument6 pagesRooftiles Unicoppo Installation GuideJessica SandersPas encore d'évaluation

- Feature Sra Amended PDFDocument4 pagesFeature Sra Amended PDFkkd108Pas encore d'évaluation

- Guttering Services BizHouse - UkDocument3 pagesGuttering Services BizHouse - UkAlex BekePas encore d'évaluation

- Armstrong - Fine Fissured & High NRCDocument2 pagesArmstrong - Fine Fissured & High NRCaditarian .pPas encore d'évaluation

- Masonry Buildings Failures & Codal RecommendationsDocument75 pagesMasonry Buildings Failures & Codal RecommendationsVaradrajPas encore d'évaluation