Académique Documents

Professionnel Documents

Culture Documents

Comparative Strength Analysis of Concrete by Using Steel Slag As An Alternative To Normal Aggregates (Coarse) in Concrete

Transféré par

Gandhi HammoudTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Comparative Strength Analysis of Concrete by Using Steel Slag As An Alternative To Normal Aggregates (Coarse) in Concrete

Transféré par

Gandhi HammoudDroits d'auteur :

Formats disponibles

Comparative Strength Analysis of Concrete

by Using Steel Slag as an Alternative to

Normal Aggregates (Coarse) in Concrete

1 3

Ritesh Mall, 4R.D.Patel

Khalid Raza, 2Sharda Sharma

3

1 2

Research Scholar, Research Scholar, ResearchScholar, 4Associate Professor

Department of Civil Engineering (Structural Engg.) Department of Civil Engineering (Structural Engg.)

1, 2 3,4

M.M.M.University of Technology Gorakhpur M.M.M.University of Technology Gorakhpur

3

1

Khalidraza982@gmail.com riteshmall07@gmail.com

2sharda.ietstp@gmail.com

Conversion of iron to steel is poured into beds

and slowly cooled under ambient conditions. Steel

AbstractThe basic objective of this study slag can be used in the construction industry as

was to identify alternative source of good quality aggregates in concrete by replacing natural

aggregates which is depleting very fast due to aggregates [1].

the fast pace of construction activities in India.

Use of steel slag a waste industrial by-Product of The consumption of Slag in concrete not only helps

iron and steel production provides great in reducing greenhouse gases but also helps in

opportunity to utilize it as an alternative to making environmentally friendly material. During

normally available aggregates (coarse). In this the production of iron and steel, fluxes (limestone

study concrete of M40 grade for a W/C ratio of

and/or dolomite) are charged into blast furnace

0.40 respectively for the replacement of 0, 10, 20,

30, 40, and 50% of aggregates (coarse) by steel along with coke for fuel.[2]

slag Among those is steel sag which is produced

as a waste material in steel industry and has a Cement Concrete: Cement concrete is

negative impact on environment when disposed. defined as the mixture of cement, aggregates,

Whole study was done in single phase, i.e. sand with water which hardens into super

normal crushed coarse aggregate with granular strong building materials and will be used in

steel slag. The investigation revealed construction of buildings, foundations,

improvement in compressive strength, split

highway, sidewalks etc. Here, cement act as a

tensile, and flexural strength over control mixes

by 4 to 8%. The replacement of 50% slag binding material. Concrete is a composite

aggregate (coarse) increased concrete density by material which is composed of coarse granular

about 50 to 7% Compared to control mix. materials called aggregates or filler embedded

together in the form of a matrix with the help

Keywords-- Steel Slag aggregate, coarse of the cement or binding material that fills the

aggregate, alternative material for concrete, space between the aggregates particles and

Compressive strength, Flexural Strength.

glues them together.

Steel Slag : Steel slag is a by-product

I. INTRODUCTION obtained either from conversion of iron to steel

in a Basic Oxygen Furnace(BOF) or by the

Blast furnace slag is produced as a by-product melting of scrap to make steel in the Electric

during the manufacture of iron and steel. Arc Furnace (EAF). Steel slag is defined by

Significant quantities of steel slag are generated as the American Society for Testing and

the major by-product from the conversion of iron to Materials (ASTM) as a non-metallic product,

steel in the basic steel making processes (Cement consisting essentially of calcium silicates and

Australia Group). The steel slag generated from the ferrites combined with fused oxides of iron,

aluminum, manganese, calcium and

magnesium that are developed simultaneously

with steel in basic oxygen, electric arc, or open the characteristics of aggregates. The size and

hearth furnaces (Kalyoncu, 2001). Unlike the grading of aggregates are important parameters in

Basic Oxygen Furnace (BOF) process, the the design of a mix for a particular project because

Electric Arc Furnace (EAF) does not use hot they can influence the workability of fresh concrete

metal, but uses cold steel scraps. The main and its hardened strength.

constituents of iron and steel slags are silica,

alumina, calcium, and magnesia, which

together make about 95% of the total

II. OBJECTIVE

composition. Physical characteristics such as

porosity, density, particle gradation, are

affected by the cooling rate of the slag and its Use of Steel slag as a waste industrial materials

chemical composition. in cement concrete and determine its

compressive strength by cube test on 7days,

CURRENT USES OF STEEL SLAG

14days and 28days.

Steel slag is used as an ideal aggregate in hot To know the proportion of Steel slag with

mix asphalt (HMA) surface mixture super plasticizer (PC based) Design Mix.

application due to its high frictional resistance Also check the Flexural Strength by prism test

and skid resistance characteristics.The cubical on 7days, 14days and 28days.

nature of steel slag and its rough texture The original scope of this research was to

provides more resistance than round, smooth investigate the properties of concrete with steel

and elongated aggregates. slag aggregates.

It is also used for manufacture of Portland The main objective of this research is to study

cement. the effect of using the Steel slag that combined

It is also used in agriculture because it has with super plasticizer by different ratios on

minerals like iron, manganese, magnesium, improving the strength of the concrete.

zinc and molybdenum which are valuable plant

nutrients.

It is environment friendly. During the III. LITERATURE REVIEW

production of cement, the CO2 emissions are

reduced as slag has previously undergone the This chapter discusses concrete in general as

calcination process. well as the effects of incorporating steel slag

aggregates into the concrete mixture. Topics

Steel slag aggregates are used for soil

stabilization or soil improvement material and addressed include steel slag, how it is

for remediation of industrial waste water run- manufactured, its properties, comparison of

off. steel slag aggregates with natural aggregates,

and its feasibility for use as a replacement for

natural aggregates in concrete. Concrete is a

Aggregates: Aggregates provide dimensional

composite material which is composed of

stability and wear resistance for concrete. Not

coarse granular materials called aggregates or

only do they provide strength and durability to

filler embedded together in the form of a

concrete, but they also influence the

matrix with the help of the cement or binding

mechanical and physical properties of

material that fills the space between the

concrete. Aggregates act as a filler material

aggregates particles and glues them together.

and lower the cost of concrete. Aggregates

Aggregates are usually obtained from natural

should be hard, strong, free from undesirable

rocks, either crushed stones or natural gravels.

impurities and chemically stable.

They should not interfere with the cement or any

of the materials incorporated into concrete. They

should be free from impurities and organic matters A. Steel Rolling Mills

which may affect the hydration process of cement. There Are Four Working Factories

The workability, strength, durability and moisture

Jordan Steel

susceptibility of concrete are greatly influenced by

The Global steel industry area 150mmX150mm is made and tested in

General company for the manufacture of iron compression testing machine to determine the

specialist compressive strength of concrete.

Petra iron industry

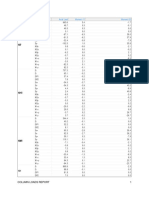

Table 2: Mix Proportion for Concrete

IV. EXPERIMENTAL INVESTIGATION

ON CONCRETE Replacement level of steel Mix proportion

slag for M40

concrete

A Materials: The materials involved in this

project are cement, fine aggregate, coarse

aggregate and admixtures such as Blast A 0% 1:1.65:2.92

furnace Slag and super plasticizer. The

properties of the materials are tested and B 10% 1:1.65:2.62

tabulated.

C 20% 1:1.65:2.33

Table 1: Physical Properties of Material D 30% 1:1.65:2.03

Property Value

E 40% 1:1.65:1.75

Specific gravity of CA 2.79

F 50% 1:1.65:1.45

Specific gravity of FA 2.65

Table No-2 represents the different ratio of

Specific gravity of steel slag 3.9 replacement level of Steel slag on M40 Mix

design.

Water absorption of steel slag 2.3%

Fineness modulus of steel slag 2.94 V. CONCLUSION:

Specific gravity of cement 3.15 The study concluded that compressive

strength of concrete improved by 5% to

Fineness modulus of CA 6.98 8% at all the replacement of crushed

coarse aggregate with slag.

The workability of concrete decreased

Water absorption of CA 0.6%

with 100% replacement of normal crushed

coarse aggregate with slag aggregate by

amount 8% in M40 gradeof concrete

compared to control mix of concrete.

B Mix Design: Mix has been designed for M40 The workability improved by 20% by

grade concrete by Indian standard replacing fine aggregate with granular slag

recommended method of concrete mix design up to 50% replacement level.

as per design code IRC 44 and IS: 10262- It could be said that 100% replacement of

1982. crushed coarse aggregate with slag

enhanced concrete density by 6to 8% in all

The experimental investigation carried out in the concrete mixes and reduce concrete

soil to determine their properties and the test density by 2% in case of replacing fine

aggregate with granular slag.

procedure for finding out the compressive

Super plasticizer is used as a admixture in

strength of concrete and flexural strength of concrete and it could be save 20-30%

concrete as per IS 516-1959. Slump test is used water but setting time will be increases.

to determine the workability of fresh concrete.

Slump test as per IS: 1199 1959 is followed.

The apparatus used for doing slump test are

Slump cone and tamping rod. The cube

specimen of the size 150mm X VI. REFERENCES:

1. ASTM C 33. (2003). Standard Specification

for Concrete Aggregates. ASTM International.

2. ASTM C 39/C 39M. (2003). Standard Test

Method for Compressive Strength of

Cylindrical Concrete Specimens. ASTM

International.

3. ASTM C 231. 2004. Standard Test Method for

Air Content of Freshly Mixed Concrete by the

Pressure Method. ASTM International.

4. Hansen, W.C., 1966. Significance of tests and

properties of concrete and concrete making

materials. ASTMSTP 169-A.

5. Hansen, W.C., 1966. Significance of tests and

properties of concrete and concrete making

materials. ASTMSTP 169-A.

6. Cajun Shi," Steel Slag-Its Production,

Processing, Characteristics and Cementites

Properties"-Journal of Materials in Civil

Engineering ASCE 2004.

7. Zore T. D. M.E. (Civil Soil) Candidate Govt.

College of Engineering, Aurangabad, India. S.

S. Valunjkar Asst. Prof., Govt. College of

Engineering, Aurangabad, India. Utilization of

Fly Ash and Steel Slag in Road Construction

A Comparative Study.

8. Mix Design Method for Asphalt Concrete and

Other Hot- Mix Types, Manual Series No.2,

The Asphalt Institute, Lexington, KY., 1993.

9. ASTM. 2003. Annual book of standard test

methods. Vol. 4.03. American Society for

Testing and Materials (ASTM), West Con-

shohocken, Pa.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Exam Preparation Chartered Member Past Paper 20220907Document16 pagesExam Preparation Chartered Member Past Paper 20220907Gandhi HammoudPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Seismic Evaluation of Flat Slab BuildingDocument13 pagesSeismic Evaluation of Flat Slab BuildingDuc Linh Dang100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Libya Wind Speed MapDocument4 pagesLibya Wind Speed MapGandhi HammoudPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Add BeamsDocument2 pagesAdd BeamsGandhi HammoudPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Seismic Evaluation of Flat Slab BuildingDocument13 pagesSeismic Evaluation of Flat Slab BuildingDuc Linh Dang100% (1)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Potential Maternal and Infant Outcomes From CoronavirusDocument16 pagesPotential Maternal and Infant Outcomes From CoronavirusMaura LimaPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Table of Reinforcement Anchorage Length & Lap Length - Eurocode 2Document7 pagesTable of Reinforcement Anchorage Length & Lap Length - Eurocode 2Gandhi HammoudPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Concrete Column DesignDocument2 pagesConcrete Column DesignGandhi HammoudPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Seismic Design of Reinforced Concrete Special Moment FramesDocument31 pagesSeismic Design of Reinforced Concrete Special Moment FrameswilfredPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Column Loads ReportDocument14 pagesColumn Loads ReportGandhi HammoudPas encore d'évaluation

- Create A Floor and Floor OpeningDocument2 pagesCreate A Floor and Floor OpeningGandhi HammoudPas encore d'évaluation

- Robot Structural Analysis 2020 Help - Tutorials - Building DesignDocument1 pageRobot Structural Analysis 2020 Help - Tutorials - Building DesignGandhi HammoudPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Rate of Underascertainment of Novel Coronavirus (2019 nCoV) Infection Estimation Using Japanese Passengers Data On Evacuation Flights by Hiroshi Nishiura, Tetsuro Kobayashi, Yichi Yang, Katsuma HaDocument3 pagesThe Rate of Underascertainment of Novel Coronavirus (2019 nCoV) Infection Estimation Using Japanese Passengers Data On Evacuation Flights by Hiroshi Nishiura, Tetsuro Kobayashi, Yichi Yang, Katsuma HaGandhi HammoudPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Add Beams, and WallsDocument2 pagesAdd Beams, and WallsGandhi HammoudPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Return of The Coronavirus 2019-nCoV by Lisa E. Gralinski, Vineet D. Menachery PDFDocument8 pagesReturn of The Coronavirus 2019-nCoV by Lisa E. Gralinski, Vineet D. Menachery PDFGandhi HammoudPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Return of The Coronavirus 2019-nCoV by Lisa E. Gralinski, Vineet D. Menachery PDFDocument8 pagesReturn of The Coronavirus 2019-nCoV by Lisa E. Gralinski, Vineet D. Menachery PDFGandhi HammoudPas encore d'évaluation

- Emerging Viruses Without Borders The Wuhan Coronavirus by Shan-Lu Liu, Linda SaifDocument2 pagesEmerging Viruses Without Borders The Wuhan Coronavirus by Shan-Lu Liu, Linda SaifGandhi HammoudPas encore d'évaluation

- Incubation Period and Other Epidemiological Characteristics of 2019 Novel Coronavirus Infections With Right Truncation by Natalie M. Linton, Tetsuro Kobayashi, Yichi Yang, KatsumaDocument9 pagesIncubation Period and Other Epidemiological Characteristics of 2019 Novel Coronavirus Infections With Right Truncation by Natalie M. Linton, Tetsuro Kobayashi, Yichi Yang, KatsumaGandhi HammoudPas encore d'évaluation

- Potential Maternal and Infant Outcomes From CoronavirusDocument16 pagesPotential Maternal and Infant Outcomes From CoronavirusMaura LimaPas encore d'évaluation

- Potential Maternal and Infant Outcomes From CoronavirusDocument16 pagesPotential Maternal and Infant Outcomes From CoronavirusMaura LimaPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Improving properties of clay deposits for building brick manufacturingDocument16 pagesImproving properties of clay deposits for building brick manufacturingGandhi HammoudPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Estimating the Unreported Number of Novel Coronavirus (2019-nCoV) Cases in China in the First Half of January 2020 A Data-Driven Modelling Analysis of the Early Outbreak by Shi Zhao, Salihu S. Musa, Q (z-lib.org).pdfDocument6 pagesEstimating the Unreported Number of Novel Coronavirus (2019-nCoV) Cases in China in the First Half of January 2020 A Data-Driven Modelling Analysis of the Early Outbreak by Shi Zhao, Salihu S. Musa, Q (z-lib.org).pdfGandhi HammoudPas encore d'évaluation

- Panasonic CGR18650CGDocument1 pagePanasonic CGR18650CGhendra ayahputriPas encore d'évaluation

- TDA2611Document3 pagesTDA2611Gandhi HammoudPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- SP Column DesignDocument5 pagesSP Column DesignwelwelPas encore d'évaluation

- Seismic Behavior of Beam Column Joints in Reinforced Concrete Moment Resisting FramesDocument16 pagesSeismic Behavior of Beam Column Joints in Reinforced Concrete Moment Resisting FramesGandhi HammoudPas encore d'évaluation

- دراسة انتفاخ التربة الطينية بحث 4 د خالد وليدDocument13 pagesدراسة انتفاخ التربة الطينية بحث 4 د خالد وليدGandhi HammoudPas encore d'évaluation

- QC On Road Projects ch1-ch6Document9 pagesQC On Road Projects ch1-ch6Gandhi HammoudPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Determining Chloride Content of ConcretDocument3 pagesDetermining Chloride Content of ConcretGandhi HammoudPas encore d'évaluation

- GDHS-7 SummaryOfChangesDocument3 pagesGDHS-7 SummaryOfChangesGandhi Hammoud100% (1)

- Module 7 (Maintenance Practices) Sub Module 7.11 (Bearings) PDFDocument15 pagesModule 7 (Maintenance Practices) Sub Module 7.11 (Bearings) PDFshareyhou0% (1)

- Conti Secur® BFA - Instructions For Rubber-Metal BondingDocument2 pagesConti Secur® BFA - Instructions For Rubber-Metal BondingCarlosPas encore d'évaluation

- Stabilo Ink Compliance StatementDocument2 pagesStabilo Ink Compliance StatementNurul HaziqahPas encore d'évaluation

- Adhesion Test On Metallic CoatingDocument2 pagesAdhesion Test On Metallic Coatingget5rajeshPas encore d'évaluation

- Characterization of Minerals, Metals and MaterialsDocument723 pagesCharacterization of Minerals, Metals and Materialslfvorster99Pas encore d'évaluation

- Dowsil 335 Butyl Sealant: Primary Sealant For Insulating GlassDocument2 pagesDowsil 335 Butyl Sealant: Primary Sealant For Insulating GlassKhurshed Alam IndiaPas encore d'évaluation

- Tut 9 - PH 102 - 30052023Document1 pageTut 9 - PH 102 - 30052023PS SuryaPas encore d'évaluation

- Wivacryl As 50: Styrene Acrylic Paint BinderDocument7 pagesWivacryl As 50: Styrene Acrylic Paint Bindermahesh.nakPas encore d'évaluation

- Injection Molding of XIAMETER™ Liquid Silicone Rubber: Consumer SolutionsDocument20 pagesInjection Molding of XIAMETER™ Liquid Silicone Rubber: Consumer SolutionsMustafa ŞENPas encore d'évaluation

- Lec 6 Module 1Document18 pagesLec 6 Module 1vedant chavanPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- CombustionDocument35 pagesCombustionm_mukbel8752Pas encore d'évaluation

- A Study of The Effect of Magnetite Additions To Shell Molds On THDocument106 pagesA Study of The Effect of Magnetite Additions To Shell Molds On THneel gajPas encore d'évaluation

- X17CrNi16 2Document2 pagesX17CrNi16 2madodandembePas encore d'évaluation

- The Particle Nature of MatterDocument25 pagesThe Particle Nature of MatterMaria bonny aquinoPas encore d'évaluation

- Coal combustion calculationsDocument3 pagesCoal combustion calculationsShane PatulotPas encore d'évaluation

- Temperature Distribution in Concrete Bridges by E C Hambly PDFDocument6 pagesTemperature Distribution in Concrete Bridges by E C Hambly PDFAnonymous dxsNnL6S8hPas encore d'évaluation

- In-Situ Rock StressesDocument16 pagesIn-Situ Rock StressesAslam KhanPas encore d'évaluation

- MasterCast 141MDocument5 pagesMasterCast 141Mrobin rezkPas encore d'évaluation

- Polarography PDFDocument37 pagesPolarography PDFTejwant Singh KangPas encore d'évaluation

- k3) Luxatherm5600 7954Document2 pagesk3) Luxatherm5600 7954Syed FaridPas encore d'évaluation

- Mechanical Design-Material PropertiesDocument61 pagesMechanical Design-Material Propertiesgaza001Pas encore d'évaluation

- Contractor GuidelinesDocument3 pagesContractor GuidelinesRichardson VelascoPas encore d'évaluation

- GKSDocument8 pagesGKSDota NgPas encore d'évaluation

- Expanded Silicone Rubber Sponge - Grades SIL10, SIL16, SIL24 & SIL33Document3 pagesExpanded Silicone Rubber Sponge - Grades SIL10, SIL16, SIL24 & SIL33ari wiliamPas encore d'évaluation

- Lecture 1Document7 pagesLecture 1Dr. Aung Ko LattPas encore d'évaluation

- Assessment PN1096617Document14 pagesAssessment PN1096617Amr TarekPas encore d'évaluation

- J Est 2018 11 027Document14 pagesJ Est 2018 11 027Hiraya HaeldrichPas encore d'évaluation

- Aws D8.1M 2013Document40 pagesAws D8.1M 2013vishesh dharaiya100% (3)

- Dyeing Process of Cotton Fabric With Reactive DyesDocument6 pagesDyeing Process of Cotton Fabric With Reactive DyesMianAbrarAnjumPas encore d'évaluation

- Sheet Pile WallDocument11 pagesSheet Pile WallKhandaker Khairul AlamPas encore d'évaluation

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialD'EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialPas encore d'évaluation

- Shorting the Grid: The Hidden Fragility of Our Electric GridD'EverandShorting the Grid: The Hidden Fragility of Our Electric GridÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationD'EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationÉvaluation : 4 sur 5 étoiles4/5 (18)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationD'EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationPas encore d'évaluation

- Idaho Falls: The Untold Story of America's First Nuclear AccidentD'EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Introduction to Power System ProtectionD'EverandIntroduction to Power System ProtectionÉvaluation : 5 sur 5 étoiles5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsD'EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsPas encore d'évaluation