Académique Documents

Professionnel Documents

Culture Documents

Seat Material PDF

Transféré par

krisTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Seat Material PDF

Transféré par

krisDroits d'auteur :

Formats disponibles

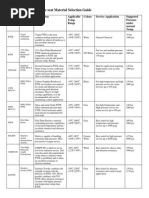

Ball Valves Seat Variations

METRIC

Standard Seats

PTFE 15% Glass Filled PTFE TFM UHMWPE NRG PCTFE

PEEK VIRGIN PEEK DELRIN VESPEL VX1 25% Glass Filled PTFE

SRS SRS

TFM NRG PVDF DEVLON V-API

Cavity Filler Seats One piece seat and seal to minimize body cavity voids

PTFE 15% Glass Filled PTFE TFM UHMWPE

Diverter Seats One piece seat & seal for diverter and double block & bleed valves

PTFE 15% Glass Filled PTFE TFM UHMWPE NRG

Materials: Pressure / Temperature Rating*:

T VIRGIN PTFE T PTFE J R Glass Filled PTFE H VX1 P NRG

Inert to most chemicals, low coefficient of friction,

recommended for water, foodstuff and corrosive U UHMWPE C PCTFE A TFM

chemicals. FDA grade. Colour: White

lb/in2 bar

J 25% GLASS FILLED PTFE

1595 110

Similar to 15% glass filled PTFE seats but better U R J AP H

103

resistance to wear and deformation under load. 100

Colour: Gray-White with red stripe 1400

90

R 15% GLASS FILLED PTFE

1200 -270C

Similar to 15% glass filled PTFE seats but better 80 -450F

Class 600

resistance to wear and deformation under load.

Colour: Gray-White with red stripe 70 C T

1000 70

Pressure

69

H GLASS & METAL OXIDE

60

FILLED PTFE - VX1 800

Withstands higher temperatures and pressures 50

than filled PTFE, good resistance under load, not

recommended for foodstuff. Colour: Blue 600 Class 300

40

P CARBON FILLED PTFE - NRG

400 30

Specially for steam and thermal oil, low

coefficient of friction, inert to most media. 20 THERMAL

Colour: Pale Black with white stripe 200 FLUID Class 150

U ULTRA HIGH MOLECULAR WEIGHT 10

POLYETHYLENE (UHMWPE) lb/in 2

0 0 bar

Good for nuclear, Tobacco, H2SO4 and chemical 93 230 260 320

resistance applications, low coefficiant of friction. C -40 0 50 100 150 200 250 300 350

Temperature limit of 93C.

Colour: Pale White with green stripe Temperature

C PCTFE F -40 0 50 100 150 200 250 300 350 400 450 500 550 600 650 662

Cryogenic applications such as oxygen, hydrogen,

nitrogen and more, suitable for temperatures up to

-270C. Colour: See-through White

Y DELRIN K L PEEK S VESPEL W PVDF V DEVLON

A TFM (Modified PTFE)

TFM is a chemically modified PTFE that offers

enhanced properties while retaining all the proven lb/in2 bar

advantages of conventional PTFE. FDA grade. 6527 450

Color: white with brown stripe.

Y ACETAL RESIN (DELRIN)

6000

400

413 K

Suitable for high pressures, good resistance to wear 5500

and deformation under load, temeprature limit 80C. 350 Y Class 2500

Must not be used in presence of oxygen. 5000

Colour: Creamy White with black stripe 4500 L

300

K CARBON FILLED PEEK 4000

Pressure

Suitable for elevated temeperatures, good resistance

under high pressure loads, low coefficient of friction, 3500 250

suitable for many corrosive applications.

Colour: Charcoal Black with yellow stripe 3000 200 W

L VIRGIN PEEK 2500

Similar to filled PEEK but higher coefficient 150

2000

of friction, suitable for nuclear, Tobacco, clean

applications. FDA grade. Colour: Beige 1500 100

S VESPEL 1000

Vespel is a polyimide material that has high 50

500

temperature capabilities under load and is mainly

used for heat transfer applications, hot gases and 0 0

oils. Vespel must not be used with STEAM or 80 260

media containing WATER or WATER VAPOR. C -28 0 50 100 150 200 250 300 350

Colour: brown.

Temperature

W PVDF F -18 0 50 100 150 200 250 300 350 400 450 500 550 600 650 662

Good chemical resistance and versatility of

application. Provides very good resistance to

aggressive acids and numerous solvents and

cleaning agents. PVDF is a trademark of Dyneon, DEVLON is a registered trademark of James walker,

Colour: white. DELRIN is a registered trademarks of DuPont, VESPEL is a registered trademark of DuPont,

TFM is a trademark of Dyneon, PEEK is a trademark of VICTREX

V DEVLON

Devlon V-API is a high molecular weight polyamide

that is specifically tailored for high temperature/

* The graph lines represent the maximum pressure / temperature rating of the seat material.

When selecting a seat material, the lower rating between the valve body and seat should be

pressure. Applications in the offshore oil & gas considered. For more information please contact Habonim.

sector.

Colour: yellow. Copyright 2012 HABONIM Ltd. All rights reserved

CATSEATST-624M

Kfar Hanassi, Upper Galilee 1, 1230500 Israel

Te l : + 9 7 2 - 4 - 6 9 1 4 9 1 1 F a x : + 9 7 2 - 4 - 6 9 1 4 9 0 2

E-Mail: habonim@habonim.com www.habonim.com

01/14

Vous aimerez peut-être aussi

- Seat Material Selection in Ball ValvesDocument2 pagesSeat Material Selection in Ball Valvescoolguy12345Pas encore d'évaluation

- ERIKS - O-Ring Datasheet - FKM 75-Compound 514322 BlackDocument1 pageERIKS - O-Ring Datasheet - FKM 75-Compound 514322 Blackseeralan_1986Pas encore d'évaluation

- 03 - Traffic and Equivalent Axle Loads (Updated)Document88 pages03 - Traffic and Equivalent Axle Loads (Updated)Besim QelajPas encore d'évaluation

- Canusa Pipeline Repair Products Installation GuideDocument2 pagesCanusa Pipeline Repair Products Installation GuideLewoski100% (1)

- 24-84-83-1648 - 0 Attachment-III PDFDocument5 pages24-84-83-1648 - 0 Attachment-III PDFSabu Abdul NoorPas encore d'évaluation

- Non-Intrusive Magnetic Pig SignallerDocument2 pagesNon-Intrusive Magnetic Pig SignallerAndresPas encore d'évaluation

- C - Evaluation Selection of Directional Drill Pipe Coatings - 2023 - P9Document51 pagesC - Evaluation Selection of Directional Drill Pipe Coatings - 2023 - P9Pammy JainPas encore d'évaluation

- Squares and Square RootsDocument8 pagesSquares and Square RootsJessica RamerPas encore d'évaluation

- Fabrication GAD of Equal Barred Tee - 10 Inch PDFDocument1 pageFabrication GAD of Equal Barred Tee - 10 Inch PDFThamaraikani Mani100% (1)

- Testing and Analysis of Pipeline Ball Valves Part 1 PDFDocument3 pagesTesting and Analysis of Pipeline Ball Valves Part 1 PDFNovianto Rachmad100% (1)

- Datasheet - Pig Signallers: Product Description and FunctionsDocument2 pagesDatasheet - Pig Signallers: Product Description and FunctionsMurli ramchandranPas encore d'évaluation

- Overview of Pipeline Coatings) PDFDocument7 pagesOverview of Pipeline Coatings) PDFTamer Hesham AhmedPas encore d'évaluation

- Double Block Bleed Twin Plug Ball Valve Single Body ANSI ASMEDocument4 pagesDouble Block Bleed Twin Plug Ball Valve Single Body ANSI ASMEBharuk MechPas encore d'évaluation

- Difference Between Izod and Charpy MethodsDocument2 pagesDifference Between Izod and Charpy Methodsvasudeva yasasPas encore d'évaluation

- BrederoShaw PDS FBE PDFDocument2 pagesBrederoShaw PDS FBE PDFJR RZPas encore d'évaluation

- tb2 Articulo 1 PDFDocument9 pagestb2 Articulo 1 PDFKaty Milagros Pacheco CalderonPas encore d'évaluation

- MISC Materials ListDocument10 pagesMISC Materials ListWaqas WaqasPas encore d'évaluation

- Pigging System PDFDocument4 pagesPigging System PDFeka resmanaPas encore d'évaluation

- Corrosion Coupon Rack: Installation & Operation ManualDocument7 pagesCorrosion Coupon Rack: Installation & Operation ManualVania Nicol Arapa YugarPas encore d'évaluation

- Ball ValvesDocument4 pagesBall ValvesJorge Arana YiPas encore d'évaluation

- Railway Cased CrossingDocument1 pageRailway Cased Crossingbinay kumarPas encore d'évaluation

- PMSS Ball ValveDocument1 pagePMSS Ball ValveGourav SharmaPas encore d'évaluation

- Global Valve & Controls: Depend On Us, We Can Handle The PressureDocument4 pagesGlobal Valve & Controls: Depend On Us, We Can Handle The PressurealeeimeranPas encore d'évaluation

- A High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingDocument15 pagesA High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingpaimpillyPas encore d'évaluation

- Book Abstract ICDEMOS 2014Document70 pagesBook Abstract ICDEMOS 201423045566Pas encore d'évaluation

- Nozzles and DiffusersDocument3 pagesNozzles and DiffusersOwais SialPas encore d'évaluation

- CRA Pipes: Corrosion TestDocument2 pagesCRA Pipes: Corrosion TestNavafPas encore d'évaluation

- Thermoplastic Seals & Components For The Oil & Gas IndustryDocument20 pagesThermoplastic Seals & Components For The Oil & Gas Industrya100acom100% (1)

- The Meaning of Angel Number 1111 Is A Question That Many People Ask Every DayDocument2 pagesThe Meaning of Angel Number 1111 Is A Question That Many People Ask Every DayAsim Bashir100% (1)

- Pig SignallerDocument4 pagesPig SignallerHạo Nam-Born To WinPas encore d'évaluation

- Product Data Booklet Fibertec Ultimate HDD Coating SystemDocument8 pagesProduct Data Booklet Fibertec Ultimate HDD Coating Systemmkash028Pas encore d'évaluation

- Datasheet Pigging Control Systems 0212 Rev1Document5 pagesDatasheet Pigging Control Systems 0212 Rev1Murli ramchandranPas encore d'évaluation

- A860 WPHY52-WPHY70: DescriptionDocument2 pagesA860 WPHY52-WPHY70: DescriptionJuan SimbaPas encore d'évaluation

- Charpy Impact Test - WikipediaDocument18 pagesCharpy Impact Test - WikipediaAshik Speed YuvanPas encore d'évaluation

- Lecture Note 4 (Metallic & Non-Metallic Pipes) PDFDocument20 pagesLecture Note 4 (Metallic & Non-Metallic Pipes) PDFhkaqlqPas encore d'évaluation

- API 5L 45-th Edition: Item No SawlDocument6 pagesAPI 5L 45-th Edition: Item No SawlRob WillestonePas encore d'évaluation

- PPI Handbook of PE Pipe - Chapter 10Document37 pagesPPI Handbook of PE Pipe - Chapter 10Nicko Adrianto100% (1)

- DBB ValveDocument6 pagesDBB ValveshyamPas encore d'évaluation

- Crack Opening DisplacementDocument2 pagesCrack Opening Displacementsqaiba_gPas encore d'évaluation

- Technical Requirements For Pipes & FittingsDocument7 pagesTechnical Requirements For Pipes & FittingsKyaw Kyaw AungPas encore d'évaluation

- Law of AttractionDocument61 pagesLaw of Attractionrajiv ranjanPas encore d'évaluation

- Valve Materials DetailsDocument15 pagesValve Materials DetailsKasthuri Rangan KPas encore d'évaluation

- Surveying 2Document81 pagesSurveying 2زبیر شاہPas encore d'évaluation

- Tables of Flange PDFDocument5 pagesTables of Flange PDFAngel AngeleyePas encore d'évaluation

- Fracture Toughness and FatigueDocument10 pagesFracture Toughness and FatigueiamjemahPas encore d'évaluation

- Criteria For The Selection of Metallic Pipelines CoatingsDocument10 pagesCriteria For The Selection of Metallic Pipelines CoatingsVinicius CarvalhoPas encore d'évaluation

- Corrosion Coupon Installation Procedure PDFDocument31 pagesCorrosion Coupon Installation Procedure PDFtrichysayeePas encore d'évaluation

- Meliadine Brine Project DescriptionDocument22 pagesMeliadine Brine Project DescriptionNunatsiaqNewsPas encore d'évaluation

- Valve Seat Design PDFDocument2 pagesValve Seat Design PDFShahulPas encore d'évaluation

- Hydrostatic Test Procedure (Rev.1)Document8 pagesHydrostatic Test Procedure (Rev.1)lukman100% (1)

- O RingsDocument6 pagesO RingsCuepattPas encore d'évaluation

- Pipeline ROUDocument17 pagesPipeline ROUchezy100% (2)

- Ball Valves Seat Variations: Standard SeatsDocument2 pagesBall Valves Seat Variations: Standard SeatsSantiago GarciaPas encore d'évaluation

- Valve Seat Material Guide PDFDocument1 pageValve Seat Material Guide PDFmolinachPas encore d'évaluation

- Valves Eat Seal Materials and Service TypesDocument3 pagesValves Eat Seal Materials and Service Typess.mladinPas encore d'évaluation

- 5L E45 Purch Guidelines R0 201306Document1 page5L E45 Purch Guidelines R0 201306Ansuman KalidasPas encore d'évaluation

- Valve Seat Material GuideDocument1 pageValve Seat Material GuidewawanPas encore d'évaluation

- Valve Seat Material GuideDocument1 pageValve Seat Material GuideAndresPas encore d'évaluation

- Valve Seat Material Selection GuideDocument1 pageValve Seat Material Selection Guidemurtuza5Pas encore d'évaluation

- FEATURED IN THIS CATALOGUE ValveDocument1 pageFEATURED IN THIS CATALOGUE ValvekrisPas encore d'évaluation

- Standards Design and Manufacture Backseat DesignDocument1 pageStandards Design and Manufacture Backseat DesignkrisPas encore d'évaluation

- High Integrity Stem SealingDocument1 pageHigh Integrity Stem SealingkrisPas encore d'évaluation

- Standards Design and Manufacture Backseat DesignDocument1 pageStandards Design and Manufacture Backseat DesignkrisPas encore d'évaluation

- Blowout Proof StemDocument1 pageBlowout Proof StemkrisPas encore d'évaluation

- Installation and Use For A Perfect SealingDocument1 pageInstallation and Use For A Perfect SealingkrisPas encore d'évaluation

- Blowout Proof StemDocument1 pageBlowout Proof StemkrisPas encore d'évaluation

- Blowout Proof StemDocument1 pageBlowout Proof StemkrisPas encore d'évaluation

- Be301 02 PDFDocument56 pagesBe301 02 PDFNikita SharmaPas encore d'évaluation

- Check Globe Valve SeriesDocument3 pagesCheck Globe Valve SerieskrisPas encore d'évaluation

- Blowout Proof StemDocument1 pageBlowout Proof StemkrisPas encore d'évaluation

- Be301 02 PDFDocument56 pagesBe301 02 PDFNikita SharmaPas encore d'évaluation

- L&T Process Ball Valves PDFDocument16 pagesL&T Process Ball Valves PDFUnna MalaiPas encore d'évaluation

- ValveDocument28 pagesValveHotnCrispy CrispyPas encore d'évaluation

- SECTION 8.0 (Mandatory Spares)Document19 pagesSECTION 8.0 (Mandatory Spares)krisPas encore d'évaluation

- PVC Valve OperationsDocument4 pagesPVC Valve OperationskrisPas encore d'évaluation

- V03015Document20 pagesV03015krisPas encore d'évaluation

- RFQ For Detail Engineering - BDocument12 pagesRFQ For Detail Engineering - Bkris100% (1)

- Bondstrand PDFDocument8 pagesBondstrand PDFkrisPas encore d'évaluation

- Catalogo Valvulas Forged Velan PDFDocument36 pagesCatalogo Valvulas Forged Velan PDFCarlosEduardoMorenoManceraPas encore d'évaluation

- Attachment 02-Of Section 2.0Document10 pagesAttachment 02-Of Section 2.0krisPas encore d'évaluation

- IS 1239 (Part 1) - noPWDocument14 pagesIS 1239 (Part 1) - noPWkrisPas encore d'évaluation

- Section 11.0Document20 pagesSection 11.0krisPas encore d'évaluation

- Ecosport BrochureDocument8 pagesEcosport BrochurekrisPas encore d'évaluation

- Seat Material PDFDocument2 pagesSeat Material PDFkrisPas encore d'évaluation

- Seat Material PDFDocument2 pagesSeat Material PDFkrisPas encore d'évaluation

- API Thermoplastic Valve SeatsDocument6 pagesAPI Thermoplastic Valve SeatskrisPas encore d'évaluation

- Forged Flanges CatalogDocument48 pagesForged Flanges CatalogaltexstevePas encore d'évaluation

- Wear SSDocument1 pageWear SSkrisPas encore d'évaluation