Académique Documents

Professionnel Documents

Culture Documents

Flow Diagram For Inspection Practice On Concrete Construction

Transféré par

Rifqi FirmansyahDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Flow Diagram For Inspection Practice On Concrete Construction

Transféré par

Rifqi FirmansyahDroits d'auteur :

Formats disponibles

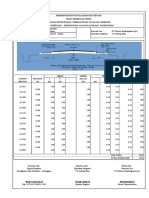

FLOW DIAGRAM FOR INSPECTION PRACTICE ON CONCRETE CONSTRUCTION

MATERIALS CONTROL CONSTRUCTION INSPECTION AND CONTROL

MIX DESIGN DRAWING AND SPECIFICATION

CONTROL

1. Performed by the laboratory 1. Receiving and logging of latest

2. Material component of revisions (*)

concrete approved by the 2. Distribution of plans to field (*)

Engineer (*)

3. Mix proportions approved by

the Engineer (*)

AGGREGATE CONTROL CEMENT CONTROL MIXING WATER CONTROL FORM DESIGN RESTEEL INSPECTION CONSTRUCTION &

1. Source verification 1. Source Verification and mill test Check monthly for chemical 1. Walls 1. Location CONTRACTION JOINT

2. Stockpilling: reports received (*) restractions (*) 2. Slabs 2. Size and length 1. Location

- Segregation 3. Beams 3. Spacing 2. Size and length

- Free draining 2. Check of unloading and transfer 4. Shoring 4. Minimum coverage

- Apperance changes to prevent loss and contamination 5. Columns 5. Stability

3. Laboratory testing: (*) 6. Bracing - Supports

- Sieve analysis - Ties

- Specific gravity & FORM INSPECTION 6. Dowels

absorption 1. Line and grade - Location

- Clay lump 2. Stability - Number

- Material passing - Ties - Projection

0.074 mm sieve - Bracing 7. Splices

- Sodium sulphate - Bearing 8. Mill test reports received

soundness 3. Oiled or wetted and accepted (*)

- Organic impurities 4. Openings:

- Los-Angeles abrassion - Size

- Location

5. Scaffolds safe

CONTROL OF MIX PROPORTIONS 6. Screeds set for drainage

1. Aggregate moisture checks

2. Use of proper mix and adjustment of

batch weights. Final inspection of entire placement by

3. Inspection of batching: Field Engineer

- Scale settings

- Observation of batching Determination of proper mix and rate of

- Condition of plant and trucks placement

4. Log of quantities batched (*)

Signing of approval placement by Field

MIXING AND TRANSPORTATION Engineer (*)

1. Minimum revolutions on mixer

2. Maximum time in mixer PRECONCRETING INSPECTION

1. Final cleanup

2. Vibrator equipment available

3. Provision for curing

4. Hot or cold weather provisions

ORDERING OF CONCRETE

CONCRETE TESTING (*) INSPECTION OF PLACEMENT

1. Slump test 1. Conveying to forms

2. Concrete temperature 2. Segregation of material

3. Air content 3. No excessive drying

4. Placing:

4. Molding, curing, and testing cylinders - Means of placing

- Continous operation

- Distance of concrete free fall

- Vibration

NOTES

- No dropping against resteel

1. Items marked (*) require quality control - Actual quantities placed

documentation.

2. For testing frequencies, refer to the test items and INSPECTION AFTER PLACEMENT

testing standards. 1. Finish

2. Curing

3. Form removal

EVALUATION OF TEST RESULT (*)

ADJUSTMENT OF VARIABLES Statistical analysis

1. Testing frequency

2. Materials

DISTRIBUTION OF TEST RESULT

3. Mix design

4. Construction techniques

Vous aimerez peut-être aussi

- Gelar Wika Asic 20 Ton (Ra) Friday, March 11, 2022: Ket StartDocument2 pagesGelar Wika Asic 20 Ton (Ra) Friday, March 11, 2022: Ket StartDanang BilyPas encore d'évaluation

- Pile Slab: Mapping Rigid Pavement (Main Road)Document86 pagesPile Slab: Mapping Rigid Pavement (Main Road)dickymrprasetyaPas encore d'évaluation

- Data Pasang Surut: Lokasi: Hari Tengah: 2015 Instrumen: Zona Waktu: GMT + 7 Nomor Seri: Satuan Data: MDocument2 pagesData Pasang Surut: Lokasi: Hari Tengah: 2015 Instrumen: Zona Waktu: GMT + 7 Nomor Seri: Satuan Data: MDianHardiantiPas encore d'évaluation

- Traverse of DhyadiDocument44 pagesTraverse of DhyadiRam NepaliPas encore d'évaluation

- Traverse BMDocument33 pagesTraverse BMIwan Moslem FnPas encore d'évaluation

- Trial Mix 29 AprilDocument1 pageTrial Mix 29 AprilRifqi FirmansyahPas encore d'évaluation

- Summary Back Up Data: Ac - BCDocument22 pagesSummary Back Up Data: Ac - BCHarry ApriyantoPas encore d'évaluation

- JMF Aspal InggrisDocument33 pagesJMF Aspal InggrisAgoenk XdPas encore d'évaluation

- 4.2. (2b) Lapis Pondasi Agg Klsas S.Document18 pages4.2. (2b) Lapis Pondasi Agg Klsas S.Harry ApriyantoPas encore d'évaluation

- Tack Coat Rate Aplication: AASHTO M140 - 88Document12 pagesTack Coat Rate Aplication: AASHTO M140 - 881112198Pas encore d'évaluation

- JMF Aspal-1Document20 pagesJMF Aspal-1ayinglagah100% (1)

- #Tugas Perhitungan Box CulvertDocument24 pages#Tugas Perhitungan Box CulvertIdho PattyPas encore d'évaluation

- Data PGJDocument142 pagesData PGJHaidir WahidPas encore d'évaluation

- Time Schedule: Periode: Oktober 2010Document2 pagesTime Schedule: Periode: Oktober 2010Fadly RaihanPas encore d'évaluation

- Tabel Rancangan Lab Ac - BCDocument35 pagesTabel Rancangan Lab Ac - BCalpin95Pas encore d'évaluation

- Stabilitas Box Culvert 09 Jan 2018 ProtekDocument8 pagesStabilitas Box Culvert 09 Jan 2018 ProtekHanafiahHamzahPas encore d'évaluation

- DESIGN PAVEMENT Aashto1993 Uts P DADANDocument9 pagesDESIGN PAVEMENT Aashto1993 Uts P DADANdaraaamaaadiPas encore d'évaluation

- 2009 German Tax Organizer Siemens VersionDocument108 pages2009 German Tax Organizer Siemens VersionshaonaaPas encore d'évaluation

- Traverse CalculationDocument71 pagesTraverse Calculationmontrexis07Pas encore d'évaluation

- Alignment Calculation V 107Document94 pagesAlignment Calculation V 107junaidsurveyorPas encore d'évaluation

- Billing Rate InkindoDocument3 pagesBilling Rate InkindoJames HammondPas encore d'évaluation

- PERHITUNGANDocument22 pagesPERHITUNGANOckto Ferry Harahap EtsfPas encore d'évaluation

- Informasi Sifat Material Faba Dalam Pemanfaatan Sebagai Bahan Lapis Pondasi JalanDocument9 pagesInformasi Sifat Material Faba Dalam Pemanfaatan Sebagai Bahan Lapis Pondasi Jalanastwan81Pas encore d'évaluation

- Quality Assurance Process ChartDocument1 pageQuality Assurance Process ChartLenny NaidooPas encore d'évaluation

- Aci 230.1R - 1997 PDFDocument23 pagesAci 230.1R - 1997 PDFBhavanishankar ShettyPas encore d'évaluation

- Standard Specification For Cast-in-Place Nonreinforced Concrete Pipe (ACI 346-90) (Reapproved 1997)Document7 pagesStandard Specification For Cast-in-Place Nonreinforced Concrete Pipe (ACI 346-90) (Reapproved 1997)nathanPas encore d'évaluation

- As 3706.5-2000 Geotextiles - Methods of Test Determination of Puncture Resistance - Drop Cone MethodDocument2 pagesAs 3706.5-2000 Geotextiles - Methods of Test Determination of Puncture Resistance - Drop Cone MethodSAI Global - APACPas encore d'évaluation

- IACS US GaugingDocument3 pagesIACS US Gaugingbenderman1Pas encore d'évaluation

- 013 WFD-logging Tools and Appliction-Abbas Radhi PDFDocument21 pages013 WFD-logging Tools and Appliction-Abbas Radhi PDFroaa bablePas encore d'évaluation

- As 1289.1.2.1-1998Document9 pagesAs 1289.1.2.1-1998ThaiNguyenPas encore d'évaluation

- Quality Control Laboratory ManualDocument77 pagesQuality Control Laboratory Manualparvez100% (1)

- Caltrans Seismic Design Spec Steel Bridges 2nd Ed 2016Document110 pagesCaltrans Seismic Design Spec Steel Bridges 2nd Ed 2016diogogrebPas encore d'évaluation

- As 1774.5-2001 Refractories and Refractory Materials - Physical Test Methods The Determination of Density PorDocument2 pagesAs 1774.5-2001 Refractories and Refractory Materials - Physical Test Methods The Determination of Density PorSAI Global - APACPas encore d'évaluation

- Procedure For Sampling and Quality Evaluation Testing of Rock For Riprap Slope ProtectionDocument9 pagesProcedure For Sampling and Quality Evaluation Testing of Rock For Riprap Slope ProtectionpabulumzengPas encore d'évaluation

- Moy D 1975 PHD ThesisDocument326 pagesMoy D 1975 PHD Thesisbhathiya01Pas encore d'évaluation

- 03 - HIRARD Piling WorkDocument3 pages03 - HIRARD Piling WorkJames JoviPas encore d'évaluation

- Procedures Inspecting Pipeline Systems Exposed To Atmosphere Purpose Legislation United StatesDocument10 pagesProcedures Inspecting Pipeline Systems Exposed To Atmosphere Purpose Legislation United StatesEric PintuelesPas encore d'évaluation

- ACI 230.1R-1990 State-of-the-Art Report On Soil Cement - Reap PDFDocument23 pagesACI 230.1R-1990 State-of-the-Art Report On Soil Cement - Reap PDFedwinbadajos0% (1)

- Design Report of Shoring System Rev 5Document78 pagesDesign Report of Shoring System Rev 5Nauman MumtazPas encore d'évaluation

- SyllabusDocument13 pagesSyllabusZuhaib KaziPas encore d'évaluation

- CIVIL-VII-PAVEMENT MATERIALS AND CONSTRUCTION NOTES - Part1Document29 pagesCIVIL-VII-PAVEMENT MATERIALS AND CONSTRUCTION NOTES - Part1Mohammed Abdul QuddusPas encore d'évaluation

- Determining Situ Deformation Modulus Using A Flexible Volumetric DilatometerDocument26 pagesDetermining Situ Deformation Modulus Using A Flexible Volumetric DilatometerelenaPas encore d'évaluation

- Aci 207.3R-94Document16 pagesAci 207.3R-94farhadam100% (1)

- Seminar Handouts CADocument1 pageSeminar Handouts CAThoong Yew ChanPas encore d'évaluation

- General Requirements FOR Titanium Bolts: Aerospace SeriesDocument28 pagesGeneral Requirements FOR Titanium Bolts: Aerospace SeriesXTINGO MAINAPas encore d'évaluation

- 8 Ch06 TrenchingDocument15 pages8 Ch06 TrenchingGustavo1722Pas encore d'évaluation

- Ballast StandartDocument11 pagesBallast StandartG AzPas encore d'évaluation

- Specs-Div 07Document33 pagesSpecs-Div 07Osama KheadryPas encore d'évaluation

- Basics well logging - fields applications -update 27-5-2018 طباعهDocument134 pagesBasics well logging - fields applications -update 27-5-2018 طباعهالاسمر الجنوبي50% (2)

- The Skid Resistance Behaviour of Thin Surface Course Systems UK - TRLReport - HFST - PPR564 - Feb2012Document62 pagesThe Skid Resistance Behaviour of Thin Surface Course Systems UK - TRLReport - HFST - PPR564 - Feb2012Philip KyungPas encore d'évaluation

- Sand Production Prediction Review - Developing An Integrated Approach PDFDocument12 pagesSand Production Prediction Review - Developing An Integrated Approach PDFRahul SarafPas encore d'évaluation

- As 1289.6.6.1-1998 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation TestsDocument2 pagesAs 1289.6.6.1-1998 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation TestsSAI Global - APACPas encore d'évaluation

- As 3706.4-2001 Geotextiles - Methods of Test Determination of Burst Strength - California Bearing Ratio (CBR)Document2 pagesAs 3706.4-2001 Geotextiles - Methods of Test Determination of Burst Strength - California Bearing Ratio (CBR)SAI Global - APACPas encore d'évaluation

- Irs T12-2009Document49 pagesIrs T12-2009a K sarkarPas encore d'évaluation

- Astm D 7263 09 PDFDocument7 pagesAstm D 7263 09 PDFMuhammad AsifPas encore d'évaluation

- Construction Materials Lab ManualDocument61 pagesConstruction Materials Lab Manualaugupta2001Pas encore d'évaluation

- Local Media3332866373887582384Document122 pagesLocal Media3332866373887582384Grant Jomar SiadorPas encore d'évaluation

- Ap 2a-0 Report-2-1Document16 pagesAp 2a-0 Report-2-1sgecs.chennaiPas encore d'évaluation

- A Generic Approach Predicting The Effect of Fouling Control Systems On Ship PerformanceDocument25 pagesA Generic Approach Predicting The Effect of Fouling Control Systems On Ship PerformanceRyan InghamPas encore d'évaluation

- Guidelines ON Non-Destructive Testing OF Bridges: B&S DirectorateDocument134 pagesGuidelines ON Non-Destructive Testing OF Bridges: B&S DirectoratepanjiPas encore d'évaluation

- Plate Load Test: Principles and Case Histories of Deep Vibro TechniquesDocument25 pagesPlate Load Test: Principles and Case Histories of Deep Vibro TechniquesRifqi FirmansyahPas encore d'évaluation

- Wilson Dense Asphalt ConcreteDocument22 pagesWilson Dense Asphalt ConcreteRifqi FirmansyahPas encore d'évaluation

- Daelim - Wijaya Karya - Waskita Karya Jo: List of Material/Product Acceptance CriteriaDocument1 pageDaelim - Wijaya Karya - Waskita Karya Jo: List of Material/Product Acceptance CriteriaRifqi FirmansyahPas encore d'évaluation

- Documentation: Activity: Determining Location of Test Pit Points Borrow Area 4Document1 pageDocumentation: Activity: Determining Location of Test Pit Points Borrow Area 4Rifqi FirmansyahPas encore d'évaluation

- Trial Mix 29 AprilDocument1 pageTrial Mix 29 AprilRifqi FirmansyahPas encore d'évaluation

- USBR DesignStandardsEmbankmentDamsNo13 Chapter2 EmbankmentDesign1992aDocument76 pagesUSBR DesignStandardsEmbankmentDamsNo13 Chapter2 EmbankmentDesign1992aRifqi FirmansyahPas encore d'évaluation

- Earth-Fill (Core) Material Trial Embankment Method ZONE-1Document1 pageEarth-Fill (Core) Material Trial Embankment Method ZONE-1Rifqi FirmansyahPas encore d'évaluation

- Anchor BarDocument24 pagesAnchor BarRifqi FirmansyahPas encore d'évaluation

- Agg Base Class A LANUDDocument85 pagesAgg Base Class A LANUDRifqi FirmansyahPas encore d'évaluation

- Sieve Analysis: ASTM C.33-78Document14 pagesSieve Analysis: ASTM C.33-78Rifqi FirmansyahPas encore d'évaluation

- Cement 18 380 AGG 34 680 Sand 48 1043 Water 247 Keterangan 1 Zak Cement 40 KG 1 Bucket 12 KG (Cement) Job Mix Onsite (m3)Document2 pagesCement 18 380 AGG 34 680 Sand 48 1043 Water 247 Keterangan 1 Zak Cement 40 KG 1 Bucket 12 KG (Cement) Job Mix Onsite (m3)Rifqi FirmansyahPas encore d'évaluation

- Sand ConeDocument18 pagesSand ConeRifqi FirmansyahPas encore d'évaluation

- Correction For Coarse Particles in The Soil Compaction Test Fop For Aashto T 224 ScopeDocument6 pagesCorrection For Coarse Particles in The Soil Compaction Test Fop For Aashto T 224 ScopeRifqi FirmansyahPas encore d'évaluation

- Weekly Report (29 May - 11 June 2016)Document4 pagesWeekly Report (29 May - 11 June 2016)Rifqi FirmansyahPas encore d'évaluation

- Weekly Work Done Report: QA/QC DeptDocument2 pagesWeekly Work Done Report: QA/QC DeptRifqi FirmansyahPas encore d'évaluation

- Stainless Steel Cupboard 2 Shelves 1830 X 915 X 457 Ea 1 1: Item Spec No. Description Unit Q'ty Unit PriceDocument1 pageStainless Steel Cupboard 2 Shelves 1830 X 915 X 457 Ea 1 1: Item Spec No. Description Unit Q'ty Unit PriceRifqi FirmansyahPas encore d'évaluation

- Weekly Work Done Report: QA/QC DeptDocument4 pagesWeekly Work Done Report: QA/QC DeptRifqi FirmansyahPas encore d'évaluation

- WS Spec PDFDocument350 pagesWS Spec PDFMatthew Butler100% (1)

- Shelco 4FOS 5FOS Housings1Document2 pagesShelco 4FOS 5FOS Housings1ramonmzaPas encore d'évaluation

- 23 EN MADEL DCN Fixed Cones Diffusers 3Document5 pages23 EN MADEL DCN Fixed Cones Diffusers 3olafPas encore d'évaluation

- Sikafloor - 957 SSDDocument3 pagesSikafloor - 957 SSDRodo Samuel SitorusPas encore d'évaluation

- ThermochemistryDocument3 pagesThermochemistryapi-304350501Pas encore d'évaluation

- Uta Fall23 Designbuild Pointzero CdsDocument14 pagesUta Fall23 Designbuild Pointzero CdsDerek MaynardPas encore d'évaluation

- Fit-Up Piping B192-5-S2Document22 pagesFit-Up Piping B192-5-S2Prathamesh OmtechPas encore d'évaluation

- Investigation On Mechanical Properties of Aluminum (6065) With Copper by PM TechniqueDocument4 pagesInvestigation On Mechanical Properties of Aluminum (6065) With Copper by PM TechniqueVinoth KumarPas encore d'évaluation

- 528-Volume 2 Part II - MEP SpecificationsDocument270 pages528-Volume 2 Part II - MEP SpecificationsSharique BaigPas encore d'évaluation

- AS4CDocument2 pagesAS4CDavid Saavedra100% (1)

- Tds-Orion Led Bay LightDocument1 pageTds-Orion Led Bay LightAjayPas encore d'évaluation

- Bokakob No VMDocument1 pageBokakob No VM2depicPas encore d'évaluation

- Table of Contents: Section 2.01 Section 2.02 Section 2.03Document162 pagesTable of Contents: Section 2.01 Section 2.02 Section 2.03aaaayyyynnnnPas encore d'évaluation

- FL - Hydraulic Elevators - ThyssenkruppDocument19 pagesFL - Hydraulic Elevators - ThyssenkruppCham Amirruddin100% (1)

- Eurocodes - Complete List and IndexDocument2 pagesEurocodes - Complete List and IndexEurocodesign Civil Structural EngineersPas encore d'évaluation

- TENDER BOI VOL-2 - Nerul - 25-10-2012Document13 pagesTENDER BOI VOL-2 - Nerul - 25-10-2012Kareem SaberPas encore d'évaluation

- 01 Samss 035 API LinepipeDocument28 pages01 Samss 035 API Linepipemdsazidalam100% (2)

- Estimating GuideDocument42 pagesEstimating Guidegerome aribanPas encore d'évaluation

- Morstar Overhead Cutouts: (Cầu Chì Tự Rơi Morstar)Document10 pagesMorstar Overhead Cutouts: (Cầu Chì Tự Rơi Morstar)Thùy PhanPas encore d'évaluation

- Temar PHFX A 1kvDocument6 pagesTemar PHFX A 1kvAzmyAbdelmaneamPas encore d'évaluation

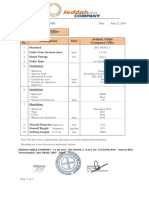

- Jeddah Cable Cu Xlpe-PvcDocument2 pagesJeddah Cable Cu Xlpe-PvcSoltani AliPas encore d'évaluation

- Table For For C-Q C-Q & & C-B C-B Compressors Compressors Series SeriesDocument1 pageTable For For C-Q C-Q & & C-B C-B Compressors Compressors Series SeriesDilmer AgudeloPas encore d'évaluation

- ASTM D2661 - Acrylonitrile-Butadiene-Styrene (ABS) Schedule 40 Plastic Drain, Waste, and Vent Pipe and FittingsDocument5 pagesASTM D2661 - Acrylonitrile-Butadiene-Styrene (ABS) Schedule 40 Plastic Drain, Waste, and Vent Pipe and FittingsSurat - SonaliSolarPas encore d'évaluation

- Structural Calculation of Slab DesignDocument32 pagesStructural Calculation of Slab DesignDavid CruzaleguiPas encore d'évaluation

- Daily Consumption Calculation Based On SEWA Standards: Meters Nos. of ServicesDocument1 pageDaily Consumption Calculation Based On SEWA Standards: Meters Nos. of ServicesRagul0042Pas encore d'évaluation

- SOM One Linear PDFDocument88 pagesSOM One Linear PDFDinuSkyPas encore d'évaluation

- Jeet Final Project Report Phase-1Document31 pagesJeet Final Project Report Phase-1Abhi ChavanPas encore d'évaluation

- Introduction To Schuco USA SystemsDocument47 pagesIntroduction To Schuco USA Systemssavage68100% (3)

- Emergency Estimate $72,590.61Document19 pagesEmergency Estimate $72,590.61Corporate OfficePas encore d'évaluation

- Alia ATF2000 Thermal Mass FlowmeterDocument4 pagesAlia ATF2000 Thermal Mass FlowmeterRexCrazyMindPas encore d'évaluation