Académique Documents

Professionnel Documents

Culture Documents

6%mo Technical Profile

Transféré par

adityadhTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

6%mo Technical Profile

Transféré par

adityadhDroits d'auteur :

Formats disponibles

FILLER MATERIALS FOR

6%Mo SUPERAUSTENITIC

STAINLESS STEELS

Metrode Products Limited

Hanworth Lane, Chertsey,

Surrey, KT16 9LL, UK

Tel: +44 (0)1932 566 721

Fax: +44 (0)1932 569 449

Email: info@metrode.com

http//www.metrode.com

Filler materials for 6%Mo

superaustenitic stainless steels

CONTENTS

Page

1 Introduction 1

2 Filler materials for 317LMN and 904L stainless steels 3

3 Filler materials for 6%Mo superaustenitic stainless steels 4

4 Filler materials for latest alloys 5

5 Dissimilar welds involving superaustenitic stainless steels 6

6 Welding process recommendations 6

7 Procedural guidelines 8

8 Mechanical properties 10

9 Corrosion performance 12

Appendix 1 Data sheets Go to Data Sheets Folder on this CD

Appendix 2 Weld Procedure Records Contact Metrode for a copy

Metrode Products Ltd

Filler materials for 6%Mo

superaustenitic stainless steels

1 Introduction

As the chemical industry developed in the 20th Century, so the need for increasingly corrosion

resistant alloys grew. The effect of molybdenum on improving pitting and crevice corrosion

resistance and the influence of nitrogen on stabilising austenite in stainless steels were combined to

form a series of alloys widely known as superaustenitics. The beneficial effect of Mo and N on

pitting corrosion resistance is demonstrated in Figure 1. The starting point was a development of

type 317L which in turn was an evolutionary development of type 316L in the form of a grade

known as type 317LMN. This stainless steel has about 4.5% molybdenum and 0.15% nitrogen. It

was followed by a development known as 904L in which there was increased chromium and nickel

and an introduction of copper for improved corrosion resistance in certain acid environments. The

typical composition of these two grades is shown in Table 1. Reference is also made to the pitting

resistance equivalent number (PREN ) and this is based on Cr + 3.3Mo + 16N.

The demands of the pulp and paper industry, particularly in Scandinavia, led to the introduction of

the so-called 6% molybdenum superaustenitics which in turn led onto the more recent

development of stainless steels with up to 7.5% molybdenum and 0.5% nitrogen as shown in

tables 2 and 3.

The latest generation fully austenitic stainless steels with elevated, 6-7%, molybdenum alloying and

a higher nitrogen level (and possibly increased Mn), show significantly improved resistance to

crevice and pitting corrosion attack, during prolonged exposure to media containing high levels of

chloride ions. They are also significantly stronger and have a 0.2% proof strength which is about

40% higher than that of the 6% Mo grades.

Metrode Products Ltd Page 1 of 12 Issue 3 August 2005

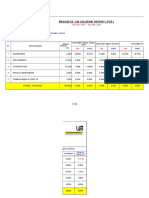

100

90

CPT, C (according to G48A)

80

70

60

50

40

30

20

10

0

0 10 20 30 40 50 60 70 80

Pitting Resistance Equivalent Number (PRE N)

PREN = Cr + 3.3Mo + 16N

Figure 1 Correlation between critical pitting temperature (CPT) and pitting resistance

equivalent number (PREN ) for base materials

Typical analyses of commercially available alloys, used extensively for pipework and vessel systems

in the offshore oil & gas, paper pulp bleaching and flue gas cleaning process industries, are given in

Tables 1, 2 & 3. Most of these alloys are also available as castings, which are used for a wide

range of pump and valve components for similar industrial applications.

Welding of the early superaustenitic alloy, 904L, was often carried out satisfactorily with matching

composition welding consumables. However as the alloying content is increased, so does the

segregation of molybdenum in the as-cast weld metal microstructure such that the weld metal

corrosion resistance falls well below that of the parent steel. This problem is resolved by solution

annealing or by the use of nickel base consumables which can accommodate high molybdenum

contents with less segregation than iron base consumables. With higher Mo, even if the nickel base

consumables do suffer from segregation, they still match the base material. Table 4 shows the

difference in Mo content that is produced in an as-welded microstructure as a result of segregation.

This technical profile describes matching consumables for the lower alloyed materials as well as

nickel base consumables for the latest most highly alloyed types.

Table 1 Early superaustenitic stainless steels

UNS EN Material C Cr Ni Mo Cu N PRE N

S31726 1.4439 317LMN <0.03 19 15 4.5 - 0.15 36

N08904 1.4539 904L (Uddeholme)

2RK65 (Sandvik)

Cronifer 1925LC (Krupp-VDM) <0.02 21 26 4.5 1.5 0.1 37

254SLX (Outokumpu)

B6 and B6M (Usinor Industeel)

Metrode Products Ltd Page 2 of 12 Issue 3 August 2005

Table 2 6% molybdenum superaustenitic stainless steels

UNS EN Material C Cr Ni Mo Cu N PRE N

S31254 1.4547 254SMO (Outokumpu) 0.01 20 18 6.1 0.8 0.20 43

N08367 - AL-6XN (Allegheny Ludlum) 0.015 20.5 24.0 6.3 0.2 0.22 44

N08926 1.4529 25-6MO (Special Metals) 0.01 20 25 6.5 0.9 0.20 45

N08925 - Cronifer 1925hMo (Krupp-VDM) 0.01 20.5 25 6.5 0.9 0.19 45

Table 3 Later superaustenitic stainless steels with high molybdenum and/or high

manganese and high nitrogen contents

UNS EN Material C Cr Ni Mo Mn Cu W N PRE N

S32654 1.4652 654SMO(Outokumpu) 0.01 24.5 22 7.5 3 0.4 - 0.5 57

S34565 1.4565 - 0.02 24 17 4.5 6 - - 0.5 47

Uranus B66

S31266 - 0.01 24 22 6.0 3 1.5 2 >0.4 >50

(Usinor Industeel)

Table 4 Mo segregation in weld metal

Weld metal Bulk Mo content, wt % Dendrite core, wt% Interdendritic region, wt%

S31254 6.2 4.2 8.1

ERNiCrMo-3 9.0 7.2 11.6

2 Filler materials for 317LMN and 904L stainless steels (table 5)

Filler metals are based on the concept of matching composition with the 904L types being suitable

for welding both 317LMN and 904L. These consumables give a fully austenitic, low carbon weld

metal with good resistance to corrosion in sulphuric, phosphoric and other inorganic and organic

acids. The weld metal PREN values are similar to those of the parent alloys, typically >35, but with

molybdenum levels of between 4.5 and 5% there is some risk of segregation. It is therefore

recommended that overmatching nickel base consumables are used when optimum performance is

required in severe chloride pitting media. (see section 3 below)

Table 5 Welding consumables for 317LMN and 904L

Process Consumable AWS C Mn Cr Ni Mo Cu N PREN

MMA Ultramet 904L E385-16 0.025 2 21 25 5 1.8 0.1 39

Ultramet B904L E385-15 0.025 2 21 25 4.8 1.8 0.1 38

TIG/MIG 20.25.4.Cu ER385 0.01 1.7 20 25 4.5 1.5 0.1 36

Metrode Products Ltd Page 3 of 12 Issue 3 August 2005

3 Filler materials for 6%Mo superaustenitic stainless steels

Filler material selection is based, primarily, on ensuring over-matching molybdenum content in the

weld deposit. There are also some specifications that impose other weld metal restrictions; for

example the NORSOK M601 specification (Revision 3, January 2004) requires Mo>8%, Cr>15%,

Cr+Mo>28%, C<0.03% and S<0.020% for weld metals to be used on 6%Mo alloys (eg. S31254).

To compensate for the tendency towards Mo segregation during weld solidification, even in nickel-

base alloys, an over-matching Mo content in the filler material is essential. Without this, areas of

the weld microstructure could develop significant loss of Mo-alloying (and PRE N) and be subject to

preferential pitting attack in service, Table 4.

High Mo nickel base alloy filler metals are suitable for a number of reasons:

9-15%Mo, over-matching consumables, are capable of compensating for any segregation

effects, and for maintaining a suitable overall minimum alloying level. In addition nickel base

weld metals exhibit a much lower tendency to segregation than iron-base alloys.

Consumables are readily availability as covered electrodes and as solid wires thus allowing the

use of most arc welding processes.

Metrodes product programme includes 3 types of filler metal composition and these are covered in

the following sections, and the accompanying data sheets, Appendix 1.

3.1 Alloy 625 consumables (table 6)

Alloy 625 type welding consumables have been successfully used for welding 6%Mo stainless steels

for at least 20 years. The 21%Cr-9%Mo nickel base weld deposit satisfies requirements for pitting

corrosion performance in 6%Mo joints (G48A >40C CPT) and provides excellent crevice and

stress-corrosion resistance. However, the high niobium level of 3.5% in alloy 625 was originally

intended to contribute to the alloys high temperature creep performance although it also has a

positive effect on corrosion resistance, particularly in severe pitting and crevice environments.

In some welding applications, the presence of Nb causes problems that may place restrictions on

the weld procedure. It may also adversely affect weld HAZ corrosion performance, albeit under

extreme service conditions:

Nitrogen can diffuse rapidly from the 6%Mo HAZ to the weld metal and result in the formation

of niobium nitrides at the weld deposit fusion boundary, leading to some loss of ductility and

corrosion resistance.

The above effect can be enhanced during the post weld solution anneal plus water quench

treatment routinely applied to welds in 6%Mo castings (and some thick walled wrought alloy

fabrications), and requires the use of lower or nil Nb weld metals to avoid failures in side-bend

and cross-weld tensile tests.

Microfissuring in alloy 625 weld deposits have been linked to the presence of niobium,

particularly with thicker section, higher restraint, fabrications welded using high deposition rate,

deeper penetration welding processes (eg SAW). Niobium, in conjunction with C and Si,

increases the tendency to produce a weld metal solidification temperature range.

Table 6 Alloy 625 welding consumables for 6% Mo superaustenitics

Process Consumable AWS BS EN C Mn Cr Ni Mo Nb Fe PREN

MMA Nimrod 625KS ENiCrMo-3 ENi6625 0.03 0.8 21.5 64 9 3.5 <1.5 51

TIG/MIG 62-50 ERNiCrMo-3 SNi6625 0.015 0.02 22 65 9 3.5 0.8 52

Metrode Products Ltd Page 4 of 12 Issue 3 August 2005

3.2 Alloy C22 and alloy 59 consumables (table 7)

To ensure optimum corrosion performance in 6%Mo alloys or for joints in 7%Mo or high nitrogen

alloys such as those shown in table 3, the use of alloy C22 consumables is preferred. Alloy C22

with ~15%Mo ensures that even allowing for micro-segregation the alloy content of the weld metal

will more than match that of these higher alloyed superaustenitic stainless steels, with a CPT

comfortably over 50C even in the as-welded condition.

Alloy 59 consumables are also suitable for welding 6-7%Mo base materials and meet the same

requirements as C22, but are generally not as readily available.

Table 7 Alloy C22 and alloy 59 welding consumables for 6% Mo superaustenitic and

for higher alloyed superaustenitic alloys

Process Consumable AWS BS EN C Mn Cr Ni Mo W Fe PREN

MMA Nimrod C22KS ENiCrMo-10 ENi6022 0.01 0.5 21 49 14 3 4 65

TIG HAS C22 ERNiCrMo-10 SNi6022 0.003 0.2 21 56 13.5 3 4 65

MMA Nimrod 59KS ENiCrMo-13 ENi6059 0.01 0.5 23 60 15.5 - 1 75

TIG/MIG HAS 59 ERNiCrMo-13 SNi6059 0.003 0.2 23 60 15.5 - 0.4 75

3.3 Metrode electrode 20.18.6.Cu.R (table 8)

Metrode 20.18.6.Cu.R electrode, based on a 6%Mo stainless steel composition matching S31254, is

recommended as an economic alternative to nickel base alloys in certain circumstances. It is only

suitable for welding castings and thick section wrought components where post-weld solution

annealing heat treatment is a mandatory requirement. The heat treatment is essential to ensure

homogenisation of the weld metal, and without which severe segregation of molybdenum would

remain in the as-deposited weld metal.

Table 8 All weld metal composition of Metrode 20.18.6.Cu.R

Process Consumable C Mn Cr Ni Mo Cu N PREN

MMA 20.18.6.Cu.R 0.025 0.7 20 18 6.5 0.7 0.2 45

4 Filler materials for latest alloys

The latest materials developed (7%Mo or higher nitrogen - Table 3) require the use of

consumables with higher Mo (~15%). This dictates that alloy C22 or alloy 59 consumables should

be used rather than 625 consumables in order to achieve weld metal corrosion properties that

match those of the base material.

Metrode Products Ltd Page 5 of 12 Issue 3 August 2005

5 Dissimilar welds involving superaustenitic stainless steels

6%Mo Zeron 100 6%Mo CMn

Superduplex s/s

TIG: HAS C22 MMA: Nimrod C22KS TIG: 62-50 * MMA: Nimrod 625KS

6%Mo CMn

* The alloy C22 or alloy 59 consumables would also

be suitable.

Alloy 625 cladding

TIG: HAS C22

MMA: Nimrod C22KS

Alloy 625 filler materials are recommended for joints involving dissimilar combinations of 6%Mo

stainless steel and CMn steel, where the principal requirement is a sound metallurgical bond.

Alloy C22 filler materials are recommended for joints involving dissimilar combinations of 6%Mo,

duplex, superduplex stainless steel and nickel-base alloys, together with specific corrosion

resistance requirements.

6 Welding process recommendations

6.1 TIG (GTAW)

This process is usually preferred for welding 6%Mo superaustenitic stainless steel pipework, thin

materials and small vessels and particular features are:

suitable for all positions

enables the precise control essential to achieve single-side root weld deposits both with

satisfactory underbead profile, and appropriate pitting resistant weld/HAZ microstructure.

1.6mm diameter filler wire is recommended for wall thicknesses up to 3mm, and 2.4mm

diameter for thicker sections

can be used for higher productivity joint filling, with butt joints in the ASME 5G and 6G positions

(BS EN 287 PF and H-L045) using 3.2mm diameter wire, to take advantage of longer run-out

and reduced stop/starts, at currents up to 200A, depending on material thickness.

Argon gas for both shielding and back-purging is recommended.

Metrode 62-50 & HAS C22 are generally available in 1.6, 2.4 and 3.2 diameter; and HAS 59 is

available in 2.4mm diameter.

Metrode Products Ltd Page 6 of 12 Issue 3 August 2005

6.2 MMA (SMAW)

For joint filling in material above ~15mm, the MMA process can be used (Nimrod 625KS, Nimrod

C22KS and Nimrod 59KS):

basic flux coating minimises weld metal oxygen content and so maximise as-welded fracture

toughness

Metrodes KS range of nickel base electrodes optimises operability, particularly in the

challenging 5-7 oclock overhead position of fixed pipe butt joints. Operation on DC+ is required

(AC is unsuitable)

2.5 and 3.2m diameter electrodes can be used in all positions including ASME 5G/6G positions

the 4 and 5mm are suitable for downhand welding (note only the Nimrod 625KS is available in

5mm diameter).

20.18.6.Cu.R electrode has a rutile flux coating and is designed for:

optimum down hand operability for the welding of castings in the flat position in a foundry

available in 3.2 and 4mm diameter

post-weld solution annealing, which must be applied when this electrode is used. The heat

treatment eliminates segregation and significantly improves weld/HAZ corrosion performance

and fracture toughness.

6.3 MIG (GMAW)

The MIG process is not widely used, but where this process can be viably applied for joint-filling,

maximum operability and weld deposit are more readily achieved via a combination of:

pulsed arc, controlled droplet metal transfer (PGMAW), using 1.0mm diameter wire (positionally)

or 1.2mm diameter wire (downhand)

shielding gas mixtures based on high purity Ar + 38%He (<2%CO 2) are necessary to ensure

smooth, spatter-free metal transfer.

Where pulsed MIG welding facilities are unavailable, satisfactory operability, albeit only in the

downhand position, can be achieved using:

1.2mm diameter wire and, typically, 230-240A, 29-30V spray transfer arc conditions

high purity Argon + 2.5%CO 2.

Metrode 62-50, HAS C22 and HAS 59 is generally available as spooled MIG wire.

6.4 Submerged Arc (SAW)

Submerged arc welding is not widely used for welding superaustenitic alloys because of the need

to tightly control heat input and interpass temperature. If SAW is to be used for maximum

productivity joint filling on 6%Mo vessels and thicker wall pipework fabrication it is therefore

subject to procedural constraints. These restraints are imposed to ensure optimum corrosion

properties are achieved but also to avoid the risk of solidification and liquation cracking to which

fully austenitic weld metal microstructures are inherently sensitive.

Metrode Products Ltd Page 7 of 12 Issue 3 August 2005

An effective approach to welding is based on:

small diameter (eg 1.6mm) wire in conjunction with low heat inputs and interpass temperature

control

fully basic flux (eg NiCr) to minimise residual weld metal Si, S, P and O2 levels

travel speeds that avoid tear-drop shaped weld pools and/or sharp chevron-patterned weld

bead ripples, associated with centreline segregation and possible cracking

weld deposit profiles with a depth/width ratio of 2:1 to minimise weld centreline cracking.

7 Procedural guidelines

Having selected the appropriate consumable and welding process, it is necessary to then use a

satisfactory welding procedure. One of the problems encountered when welding 6%Mo

superaustenitic alloys is the formation of an unmixed zone, Figure 2. This effect cannot be

completely overcome but it can be minimised by the use of the correct welding procedure. The

unmixed zone is a region along the fusion boundary where the weld metal and molten base

material have not completely mixed.

Base

material

Weld

metal

Figure 2 Micrograph showing the unmixed along the fusion boundary

Some regions of this unmixed zone can be lower in alloying than the adjacent base material or

weld metal because of segregation. If the unmixed zone is of sufficient width and extends to the

surface of the weld, then it can adversely affect the corrosion properties of the joint. To minimise

this risk, the width of the unmixed zone must be kept as narrow as possible by the application of

the correct welding procedure.

The weld procedure should aim to produce a pitting resistant weld root HAZ microstructure free

from Mo segregation and/or intermetallic precipitation. The weld procedure is optimised through

control of:

Joint configuration

Typical V-butt in 6 diameter Sch40 (7.11mm WT) pipe would have:

70-80V, 2.5-3mm root gap, 0.5-1.0mm root face.

establishing consistent fit-up to ensure 360 of reliable weld quality.

Metrode Products Ltd Page 8 of 12 Issue 3 August 2005

Root run

It is recommended that TIG root and 2nd cold pass layers are deposited in a series of equal run-

out length weld beads, to avoid the risk of random sections of overheated microstructure within the

360 circumference of the root bead.

avoiding excessive root melting (and dilution effects) to achieve a full penetration bead

maximising the amount of filler metal in the root weld deposit

pure argon should be used as both the shielding gas and the purge gas.

Heat input

This should be limited to 1.0kJ/mm maximum, which minimises fusion boundary and high

temperature HAZ alloy segregation, intermetallic precipitation, and also minimises the width of the

unmixed zone.

Interpass temperature

This should be controlled to 100C maximum, which directly influences cooling rate of deposited

beads at all stages of welding; this is important to ensure there is minimal risk of intermetallic

formation and to reduce the risk of hot cracking in the HAZ of cast alloys.

Weld run-out length

This should be limited to avoid the situation where weld zone background temperature rises to a

level above the maximum interpass temperature.

Buttering

In extreme cases where cast alloys are susceptible to cracking in the HAZ it may be necessary to

butter the joint faces before filling the joint. The buttering should be deposited with tightly

controlled heat input (<1.0kJ/mm) and interpass temperature (<100C).

Metrode Products Ltd Page 9 of 12 Issue 3 August 2005

8 Mechanical properties

8.1 Tensile strength

The minimum tensile requirements for some selected superaustenitic alloys are given in Table 9

along with the typical values achieved by a range of matching and nickel base weld metals.

Table 9 Typical all-weld metal tensile properties and minimum base material

requirements

Specification Specification UTS 0.2% proof Elongation

grade Condition *

UNS or AWS EN MPa stress, MPa %

904L N08904 1.4539 - 530 220 35

Cast 6%Mo A351 CK3MCuN - - 550 260 35

6%Mo S31254 1.4547 - 650 300 40

25.20.6 NO8926 1.4529 - 650 300 40

7%Mo S32654 1.4652 - 750 430 35

S3456S S3456S 1.4565 - 800 420 30

20.25.4.Cu TIG AWS ER385 W 20 25 5 Cu L AW 650 490 35

Ultramet 904L AWS E385-16 E 20 25 5 Cu N L R AW 620 420 38

Ultramet B904L AWS E385-15 E 20 25 5 Cu N L B AW 620 440 38

20.18.6.Cu.R - - SA 715 380 50

62-50 TIG AWS ERNiCrMo-3 SNi6625 AW 780 520 42

Nimrod 625KS AWS ENiCrMo-3 ENi6625 AW 800 500 40

HAS C22 TIG AWS ERNiCrMo-10 SNi6022 AW 770 525 44

Nimrod C22KS AWS ENiCrMo-10 ENi6022 AW 780 550 36

HAS 59 TIG AWS ERNiCrMo-13 SNi6059 AW 730 510 34

Nimrod 59KS AWS ENiCrMo-13 ENi6059 AW 750 520 32

* SA - Solution annealed

AW - As-welded

The only area where some caution may be required in relation to tensile properties is with some of

the latest generation high nitrogen wrought alloys (eg S34564). The potential strength of these

alloys in wrought form is close that of any of the nickel base alloys; as castings that have been

solution annealed the nickel base weld metals should be strong enough.

Metrode Products Ltd Page 10 of 12 Issue 3 August 2005

8.2 Charpy toughness

The fully austenitic nickel base microstructures, deposited using recommended welding

consumables are capable of good toughness down to sub-zero temperatures (-196C). However,

results can be subject to the embrittling influences of grain boundary Nb-nitride precipitation at the

alloy 625 weld/HAZ fusion boundary, where adequate weld procedure control has not been

exercised. The elimination of Nb from alloy C22 filler materials removes this risk and this is

reflected in the higher absorbed energy levels reported.

The high alloy fully austenitic stainless steel microstructure of 20.18.6.Cu.R MMA weld deposit,

whilst not capable of matching type C22 Ni-base alloy performance, nevertheless shows excellent

toughness suitable for the specific application of solution annealed welds in castings. Typical

impact properties are given in Table 10.

Table 10 Typical all-weld metal impact properties (as-welded except 20.28.6.Cu.R)

Grade specification Test temperature, C Toughness, J

20.25.4.Cu TIG ER385 +20 210

Ultramet 904L E385-16 -196 50

Ultramet B904L E385-15 -196 50

20.18.6.Cu.R - -50 120

62-50 TIG ERNiCrMo-3 -196 80

Nimrod 625KS ENiCrMo-3 -196 60

HAS C22 TIG ERNiCrMo-10 -196 130

Nimrod C22KS ENiCrMo-10 -196 45

HAS 59 TIG ERNiCrMo-13 +20 140

Nimrod 59KS ENiCrMo-13 -50 50

Metrode Products Ltd Page 11 of 12 Issue 3 August 2005

9 Corrosion performance

9.1 Pitting corrosion resistance

In many fabrications and particularly pipe work the weld root, exposed to the corrosive medium, is

the critical region. Both the weld metal and the fusion zone may be adversely affected by welding

and it is important to measure the pitting resistance of the weld root and compare it with the base

material performance. This is usually done using the ASTM-G48 method A test (6%FeCl3 solution).

The typical critical pitting temperature of some materials is given in Table 11, and actual all-weld

metal results are in Table 12.

The offshore oil and gas industry typically specify a critical pitting temperature (CPT) of 40 or 50C

using the G48A test.

The latest generation of superaustenitic alloys will not generally show pitting at the maximum G48A

test temperature (~85C) and other test methods would need to be used to evaluate those

materials properly.

Table 11 Typical CPT values based on ASTM G48A tests

Material Condition CPT, C *

6%Mo parent material Solution annealed 65 70

Alloy 625 weld metal As-welded 45 50

Alloy C22 & 59 weld metal As-welded > 70

20.18.6.Cu.R weld metal Solution annealed > 50

S32654 Solution annealed >85

* CPT = Critical pitting temperature: temperature at which, after 24 hours exposure, initiation of pitting

2

can be detected or weight loss exceeds 4g/m (or measured on a standard 50mm x 25mm x wall

thickness specimen exceeds approximately 20mg)

Table 12 All-weld metal G48A test results

Material Condition Test Temperature, C Weight loss,mg or g/m2

20.18.6.Cu.R Solution annealed 40 1mg (0.3g/m2)

62-50 TIG As-welded 40 0

2

42.5 0.8 g/m

Nimrod 625KS MMA As-welded 50 0

52.5 0.9 & 4.2 g/m2

HAS C22 TIG As-welded 40 0 & 1mg (0.3g/m2)

75 0

Nimrod C22KS MMA As-welded 40 1mg (0.3g/m2)

Metrode Products Ltd Page 12 of 12 Issue 3 August 2005

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Cat Flash File ReadxrefDocument179 pagesCat Flash File ReadxrefНиколай Белый89% (9)

- Volvo: Electrical Wiring DiagramDocument7 pagesVolvo: Electrical Wiring Diagramrusadi100% (5)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 943 0019Document40 pages943 0019Pablo Martir100% (1)

- MCQ DistributionDocument8 pagesMCQ Distributiongoyal.167009100% (2)

- Thyristor: Semi-Conductor DeviceDocument11 pagesThyristor: Semi-Conductor DeviceAmit RastogiPas encore d'évaluation

- W PRG S-Curve Feb 07th 2013 (For Mhe)Document184 pagesW PRG S-Curve Feb 07th 2013 (For Mhe)adityadh100% (1)

- Produced Water Re-InjectionDocument171 pagesProduced Water Re-InjectionrfarajzadehPas encore d'évaluation

- Manual 924HDocument811 pagesManual 924HJuliana Magalhães100% (1)

- PrefaceDocument45 pagesPrefaceaddy_callsoutPas encore d'évaluation

- Gardner Denver: Operating and Service ManualDocument41 pagesGardner Denver: Operating and Service ManualCESAR MORAPas encore d'évaluation

- Zdenek Fukar Waagner Biro Indonesia Bridges SEAsia 2010-08-03aDocument85 pagesZdenek Fukar Waagner Biro Indonesia Bridges SEAsia 2010-08-03aadityadh100% (1)

- PES 2017 Players and AbilitiesDocument2 pagesPES 2017 Players and AbilitiesadityadhPas encore d'évaluation

- BOQ Gudang PltuDocument3 pagesBOQ Gudang PltuadityadhPas encore d'évaluation

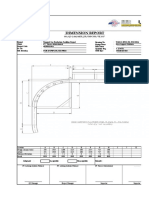

- Dimension Report: 001/QC-LAM/MDR - DR/TNSC-HS/VII.2017Document3 pagesDimension Report: 001/QC-LAM/MDR - DR/TNSC-HS/VII.2017adityadhPas encore d'évaluation

- 2.1. Excav PC200 - 200LC-8 - CEN00049-09Document5 pages2.1. Excav PC200 - 200LC-8 - CEN00049-09adityadhPas encore d'évaluation

- Draft: No. PP.: 001 Sheet: Date: 23 Agustus 2017 Rev.: Owner Project Title / CodeDocument1 pageDraft: No. PP.: 001 Sheet: Date: 23 Agustus 2017 Rev.: Owner Project Title / CodeadityadhPas encore d'évaluation

- Wide Flange Shape: Accordingjis 1993Document12 pagesWide Flange Shape: Accordingjis 1993adityadhPas encore d'évaluation

- List - TBC SoftDocument1 pageList - TBC SoftadityadhPas encore d'évaluation

- Yes/No Yes/No Yes/No Yes/No Yes/No Yes/No Yes Yes Yes Yes Yes YesDocument1 832 pagesYes/No Yes/No Yes/No Yes/No Yes/No Yes/No Yes Yes Yes Yes Yes YesadityadhPas encore d'évaluation

- Division 16 - SEC16000-I GeneralDocument4 pagesDivision 16 - SEC16000-I GeneraladityadhPas encore d'évaluation

- Division 16 - SEC16140-I Switches, ReceptaclesDocument2 pagesDivision 16 - SEC16140-I Switches, ReceptaclesadityadhPas encore d'évaluation

- Division 16 - SEC16065-I Lighting ProtectionDocument4 pagesDivision 16 - SEC16065-I Lighting ProtectionadityadhPas encore d'évaluation

- Brosur Cyclone VentilatorDocument4 pagesBrosur Cyclone VentilatoradityadhPas encore d'évaluation

- p92 & t23 - Esope France, 2004Document13 pagesp92 & t23 - Esope France, 2004adityadhPas encore d'évaluation

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationadityadhPas encore d'évaluation

- Structural Analysis of Transfer Tower Conveyor T-315Document1 pageStructural Analysis of Transfer Tower Conveyor T-315adityadhPas encore d'évaluation

- Pre Design REPORT ContentsDocument1 pagePre Design REPORT ContentsadityadhPas encore d'évaluation

- PSG-X-AJ-As-0250 - Mech DWG of Detail Cooling Tower, OHC and Civil DWG of Blowdown Cooling Well Plan & SectionDocument9 pagesPSG-X-AJ-As-0250 - Mech DWG of Detail Cooling Tower, OHC and Civil DWG of Blowdown Cooling Well Plan & SectionadityadhPas encore d'évaluation

- Foto Laporan Wekley 10 Jan 2013Document2 pagesFoto Laporan Wekley 10 Jan 2013adityadhPas encore d'évaluation

- WULC - 14 - 1000-G. Selgi SAIPEM New Developments in High Pressure Equipment Design FeaturesDocument9 pagesWULC - 14 - 1000-G. Selgi SAIPEM New Developments in High Pressure Equipment Design FeaturesadityadhPas encore d'évaluation

- Washing Machine: Service ManualDocument41 pagesWashing Machine: Service Manualimagex5Pas encore d'évaluation

- Electrical Disturbances in LV Networks Due To Energization of MV NetworksDocument5 pagesElectrical Disturbances in LV Networks Due To Energization of MV NetworksAlejandro Solis GomezPas encore d'évaluation

- Hse Ems Enviornmental PolicyDocument7 pagesHse Ems Enviornmental Policyshaquan josephsPas encore d'évaluation

- MV Electrical TechnicianDocument1 pageMV Electrical TechnicianSundar ThangapandianPas encore d'évaluation

- Answer Key - CWT 1Document2 pagesAnswer Key - CWT 1Areeb AbbaxiPas encore d'évaluation

- Mat Sci Slides 2Document29 pagesMat Sci Slides 2abcdPas encore d'évaluation

- Central Lincolnshire Local Plan Core StrategyDocument370 pagesCentral Lincolnshire Local Plan Core Strategydaniel7120Pas encore d'évaluation

- Chapter 13 - Chemical EquilibriumDocument52 pagesChapter 13 - Chemical EquilibriummukhlishPas encore d'évaluation

- Position On Strategic GraphiteDocument26 pagesPosition On Strategic GraphitemcnpopaPas encore d'évaluation

- 42NQV050 060 SVMDocument102 pages42NQV050 060 SVMRob KoopmanPas encore d'évaluation

- On CryogenicsDocument15 pagesOn Cryogenicsaswinchand50Pas encore d'évaluation

- Daewoo Miniexcavadora SOLAR 030 / SOLAR 035Document6 pagesDaewoo Miniexcavadora SOLAR 030 / SOLAR 035MaquinzaPas encore d'évaluation

- DC Solar Pumps New-3 PDFDocument3 pagesDC Solar Pumps New-3 PDFRavi SharmaPas encore d'évaluation

- Advanced Motion Controls FC1010Document7 pagesAdvanced Motion Controls FC1010Servo2GoPas encore d'évaluation

- Development of A Network and Gas Lift Allocation Model For Production Optimization in The Ras Budran FieldDocument14 pagesDevelopment of A Network and Gas Lift Allocation Model For Production Optimization in The Ras Budran FieldTaiwo Adenike BashorunPas encore d'évaluation

- SM 18Document16 pagesSM 18Uriel HerreraPas encore d'évaluation

- 1. المضخهDocument20 pages1. المضخهالمهندسوليدالطويلPas encore d'évaluation

- GROHE Pricelist-2020 en GB PDFDocument1 020 pagesGROHE Pricelist-2020 en GB PDFNikhil AggarwalPas encore d'évaluation

- US Proposal Tax Credit Green H2Document36 pagesUS Proposal Tax Credit Green H2hlucasportaPas encore d'évaluation

- Lesson 12a - Et332bDocument23 pagesLesson 12a - Et332bLawiii KkkPas encore d'évaluation

- VLT2800 Quick Guide PDFDocument2 pagesVLT2800 Quick Guide PDFlieldPas encore d'évaluation