Académique Documents

Professionnel Documents

Culture Documents

Bondable Resistors For Transducers

Transféré par

Marcus Vinicius FonsecaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bondable Resistors For Transducers

Transféré par

Marcus Vinicius FonsecaDroits d'auteur :

Formats disponibles

Bondable Resistors For Transducers

Micro-Measurements

Introduction and Designation System

Micro-Measurements manufactures a variety of fixed, RESISTANCE TOLERANCES

adjustable, and combination bondable resistors for use in A-Pattern resistors have fixed values (selected by the user)

many applications where precise resistance is required. and are supplied with tight tolerances. With adjustable types,

Appropriate patterns are available in both low and high it is impractical to supply precise values. Most resistors will

temperature-coefficient-of-resistance types. Widest use is in be within 20% of the specified nominal values, but

transducer bridge circuits to compensate for small occasionally resistances will fall outside that range. The

temperature-induced errors and to adjust bridge-balance various cutting steps will follow the same trend.

output.1 Figure 1 (on the facing page) shows a typical

application. RECOMMENDED ADHESIVES

M-Bond 610, M-Bond 43-B or M-Bond 450 adhesive should

Various foil types, sizes, and patterns are available, allowing be used for operation over the widest temperature range.

selection of the optimum resistor for specific applications. Other standard strain gage adhesives are acceptable within

Resistors are normally produced open-faced on the flexible their recommended temperature limits. The special backing

E or N2 polyimide backings. The recommended temperature treatment used permits good bond formation with all strain

range is 0 to +350F [20 to +175C] for the E type and gage adhesives except the solvent-evaporation-setting type.

0 to +300F [20 to +150C] for the N2. Standard Resistors should be mounted in areas of low strain

packaging for bondable resistors is 50 per package. (preferably less than 500) and on relatively flat surfaces.

If possible, grids should be aligned with the direction of

TEMPERATURE-COMPENSATED RESISTORS lowest strain.

Temperature-compensated A alloy and K alloy are available

in several resistor patterns. They are normally stocked in INSTALLATION AND WIRING

both 06 S-T-C for steel and 13 S-T-C for aluminum. Due to All resistor patterns should be bonded to the mounting

the difficulty of directly soldering to K alloy, all N2K resistors surface before adjustment or use. Prepare the specimen

are supplied with a copper soldering pad (DP) on each tab. surface and install the resistor using standard strain gage

materials and techniques. Install leadwires, and solder to the

TEMPERATURE-SENSITIVE RESISTORS attachment tabs with an appropriate solder.

Three different foil materials are available to fit a variety of

compensation requirements. After thorough flux removal, blot with clean sponges, and

allow the surface of the resistor to dry completely. Attach

Nickel Pure nickel has the highest resistance-versus- leadwires to an appropriate resistance-measuring

temperature sensitivity of the three available foil types and is instrument and adjust the resistor as described in

normally selected for span-versus-temperature compen- Adjustment Instructions until the desired resistance is

sation. It can be ordered as a fixed resistance value (A achieved.

Pattern) or adjustable (B Pattern). The temperature

coefficient of resistance (TCR) for nickel is +0.33%/F PROTECTIVE COATINGS

[+0.59%/C] over a temperature range of +50 to +150F For maximum long-term stability, coat the adjusted resistors

[+10 to +65C]. with a hard, heat-curing material such as Micro-

Measurements M-Bond 610, 43-B, or 450. Satisfactory

Balco Although having a slightly lower TCR than nickel, results may be obtained with appropriate air-drying coatings.

Balco has a higher resistivity, which makes higher resistance

values more easily obtained. It also has some price

advantage over nickel. The TCR for Balco is +0.24%/F

[+0.43%/C] over a temperature range of +50 to +150F

[+10 to +65C].

Note: Since resistance-versus-temperature for nickel and

Balco is not a linear function, values are given as chord

slopes over the specified temperature range.

Copper Pure copper has the lowest TCR of the three

materials and also very low resistivity. This makes it ideal for

minor adjustments when used in a corner compensation

approach (see Fig. 1). Copper also has a more linear TCR

than either Balco or nickel. When used for span-

versus-temperature correction, copper can produce a more

linear span compensation in some transducer designs.

Copper TCR is +0.22%/F [+0.40%/C].

1Strain Gage Based Transducers Their Design and Construction. Available from Micro-Measurements

Balco is a registered trademark of W.B. Driver Company.

www.micro-measurements.com For technical questions, contact: micro-measurements@vishaypg.com Document Number: 11564

36 Revision: 14-Jan-10

Bondable Resistors For Transducers

Micro-Measurements

Introduction and Designation System

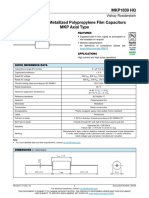

Self-Temperature-Compensation Pattern Configuration

Alloy Resistance*

Carrier Matrix (Backing) DP Copper Soldering Pad

Optional Feature

Example: XXX - XX - XXX - XXXXX/XX Option XXX

(E or N2)

to nearest 0.1 Option E2, polyimide film

Example: 00225 is 22.5 encapsulation for A02

and A06 pattern resistors

A: Constantan

B: Balco Standard feature on K-Alloy

F: Copper resistors

K: Modified Karma

T: High-Purity Nickel

(TR for High-Temperature-Coefficient Types)

*Note: It is impossible to guarantee initial or final resistance on adjustable resistor types. Most resistors will be within 20% of the nominal values

given.

FIG. 1 BRIDGE CIRCUIT WITH TYPICAL COMPENSATION RESISTORS.

Document Number: 11564 For technical questions, contact: micro-measurements@vishaypg.com www.micro-measurements.com

Revision: 14-Jan-10 37

Legal Disclaimer Notice

Vishay Precision Group

Disclaimer

All product specifications and data are subject to change without notice.

Vishay Precision Group, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf

(collectively, Vishay Precision Group), disclaim any and all liability for any errors, inaccuracies or incompleteness

contained herein or in any other disclosure relating to any product.

Vishay Precision Group disclaims any and all liability arising out of the use or application of any product described

herein or of any information provided herein to the maximum extent permitted by law. The product specifications do

not expand or otherwise modify Vishay Precision Groups terms and conditions of purchase, including but not limited

to the warranty expressed therein, which apply to these products.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this

document or by any conduct of Vishay Precision Group.

The products shown herein are not designed for use in medical, life-saving, or life-sustaining applications unless

otherwise expressly indicated. Customers using or selling Vishay Precision Group products not expressly indicated

for use in such applications do so entirely at their own risk and agree to fully indemnify Vishay Precision Group for

any damages arising or resulting from such use or sale. Please contact authorized Vishay Precision Group

personnel to obtain written terms and conditions regarding products designed for such applications.

Product names and markings noted herein may be trademarks of their respective owners.

Document Number: 63999 www.vishaypg.com

Revision: 22-Feb-10 1

Vous aimerez peut-être aussi

- 07 RLC 1 Voice (Revised)Document65 pages07 RLC 1 Voice (Revised)HarikrishnaChinthalaboyinaPas encore d'évaluation

- PYu-R INT-thick 7Document16 pagesPYu-R INT-thick 7Manu MathewPas encore d'évaluation

- Resistors Module 02Document17 pagesResistors Module 02ubaidPas encore d'évaluation

- Drift Calculation For Thin Film ResistorsDocument3 pagesDrift Calculation For Thin Film ResistorsDamian Huitzil CedilloPas encore d'évaluation

- BXEDocument79 pagesBXEAnkita WankhadePas encore d'évaluation

- The Ultimate Guide To Resistors (2017)Document34 pagesThe Ultimate Guide To Resistors (2017)Nivi ThomasPas encore d'évaluation

- Electrical Circuits IDocument22 pagesElectrical Circuits IBryar HusenPas encore d'évaluation

- Silicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388BDocument5 pagesSilicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388Bameer_jaburPas encore d'évaluation

- Loadbreak Products: Experience & ReliabilityDocument8 pagesLoadbreak Products: Experience & ReliabilityCbdtxd PcbtrPas encore d'évaluation

- How To Choose The Right PCB ResistorDocument15 pagesHow To Choose The Right PCB ResistorjackPas encore d'évaluation

- 1N8149US MicrosemiDocument6 pages1N8149US Microsemithuco.18Pas encore d'évaluation

- RESISTORSDocument16 pagesRESISTORShsejmal12345Pas encore d'évaluation

- Resistors and Resistive Materials: Jerry C. WhitakerDocument9 pagesResistors and Resistive Materials: Jerry C. WhitakerArifPas encore d'évaluation

- CONECTORDocument2 pagesCONECTORhdbryansPas encore d'évaluation

- Resistance ThermometrDocument9 pagesResistance Thermometrgopir28Pas encore d'évaluation

- Kpt/Kpse: ConnectorsDocument31 pagesKpt/Kpse: ConnectorsFerdy Fer DPas encore d'évaluation

- 44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2Document6 pages44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2عبدالغني القباطيPas encore d'évaluation

- Thermistor SelectionDocument6 pagesThermistor SelectionrajeshPas encore d'évaluation

- Is Now Part ofDocument8 pagesIs Now Part ofGabrielConsentidoPas encore d'évaluation

- AC03 Safety (AC03..CS) : Vishay DraloricDocument3 pagesAC03 Safety (AC03..CS) : Vishay Draloricyenassiri278Pas encore d'évaluation

- TLE 7 and 8 q2 w2Document5 pagesTLE 7 and 8 q2 w2jommel vargasPas encore d'évaluation

- CuClad Laminates Data SheetDocument4 pagesCuClad Laminates Data SheetDenis CarlosPas encore d'évaluation

- Single Conductor 25-35KV Shielded MV-105Document5 pagesSingle Conductor 25-35KV Shielded MV-105villanueva.texsiPas encore d'évaluation

- Avx FilmDocument20 pagesAvx FilmVilnis PetersonsPas encore d'évaluation

- MKP1839 HQ: Vishay RoedersteinDocument13 pagesMKP1839 HQ: Vishay RoedersteinSTE ABMCPas encore d'évaluation

- Guide To ResistorsDocument34 pagesGuide To ResistorsViet Anh NguyenPas encore d'évaluation

- Wall-Colmonoy Wallex-12 ENG January2021Document3 pagesWall-Colmonoy Wallex-12 ENG January2021pranav kariaPas encore d'évaluation

- EPCOS Switching Spark Gap, 230V Breakdown Voltage, 300A, 25Hz Max. Switching Frequency, 2000000Document4 pagesEPCOS Switching Spark Gap, 230V Breakdown Voltage, 300A, 25Hz Max. Switching Frequency, 2000000Mansoor AsifPas encore d'évaluation

- BT51 ManualDocument2 pagesBT51 Manualajaydce05Pas encore d'évaluation

- Resistors Module 02 PDFDocument17 pagesResistors Module 02 PDFShubham kumarPas encore d'évaluation

- SM8S10A Thru SM8S43A: High Temperature Stability and High Reliability ConditionsDocument5 pagesSM8S10A Thru SM8S43A: High Temperature Stability and High Reliability ConditionsSumitomo ExcavatorPas encore d'évaluation

- ResistorDocument5 pagesResistorMvk ChaitanyaPas encore d'évaluation

- To Study The Elastic Stress Strain Behavior in Bending Using Electrical Resistance Strain GaugesDocument8 pagesTo Study The Elastic Stress Strain Behavior in Bending Using Electrical Resistance Strain GaugesFaisal SardarPas encore d'évaluation

- Description Appearance: Silicon 5 Watt Zener DiodesDocument3 pagesDescription Appearance: Silicon 5 Watt Zener DiodesJosé RodríguezPas encore d'évaluation

- Short Form Catalogue 2007: Deki Electronics LTDDocument8 pagesShort Form Catalogue 2007: Deki Electronics LTDoscar100% (1)

- EE-199 L Basic Electrical and Electronics Engineering LabDocument17 pagesEE-199 L Basic Electrical and Electronics Engineering LabEtsham AmjadPas encore d'évaluation

- Aisladores ABB - GSADocument16 pagesAisladores ABB - GSALeonel BermudezPas encore d'évaluation

- EagleBurgmann Statotherm SSTC-TAL 9592 P enDocument1 pageEagleBurgmann Statotherm SSTC-TAL 9592 P enkeyur1109Pas encore d'évaluation

- mmbz5225-mmbz5267 VishayDocument5 pagesmmbz5225-mmbz5267 Vishayreza yousefiPas encore d'évaluation

- Earthing System Design Tool For Low Voltage InstallationsDocument36 pagesEarthing System Design Tool For Low Voltage InstallationsLim BoraPas encore d'évaluation

- Dhiviyansh PunamiyaDocument5 pagesDhiviyansh PunamiyaDhiviyansh Punamiya OT3 - 433Pas encore d'évaluation

- Polymer Aluminum Electrolytic CapacitorsDocument8 pagesPolymer Aluminum Electrolytic CapacitorsRanaJafaryPas encore d'évaluation

- Nexans XT Medium Voltage Single Core...Document15 pagesNexans XT Medium Voltage Single Core...Mathias CanalesPas encore d'évaluation

- Reference Specification: 175 C Operation Leaded MLCC For Automotive With AEC-Q200 RHS SeriesDocument17 pagesReference Specification: 175 C Operation Leaded MLCC For Automotive With AEC-Q200 RHS SeriesDanish Ur RahmanPas encore d'évaluation

- Frequency Response of Thin Film Chip Resistors: Resistive ProductsDocument4 pagesFrequency Response of Thin Film Chip Resistors: Resistive ProductsMauricio BulaPas encore d'évaluation

- Compact SubstationDocument6 pagesCompact SubstationHafiza Sulaiman100% (1)

- SM8 Transient SupressorDocument5 pagesSM8 Transient SupressorSergio ReyesPas encore d'évaluation

- Steel: Strain Measurements On SteelDocument4 pagesSteel: Strain Measurements On Steelhasan rashidPas encore d'évaluation

- Pyu-Pa e 51 RohsDocument11 pagesPyu-Pa e 51 Rohssales6Pas encore d'évaluation

- Applications and Buying Guide of 3.9K ResistorsDocument4 pagesApplications and Buying Guide of 3.9K ResistorsjackPas encore d'évaluation

- ohm Ω SI electrical resistance Georg Simon OhmDocument17 pagesohm Ω SI electrical resistance Georg Simon OhmPRincess ScarLetPas encore d'évaluation

- Basic Applied Electronics by BalamuruganDocument73 pagesBasic Applied Electronics by BalamuruganBalamurugan Thirunavukarasu100% (2)

- Diclad Series: Ptfe/Woven Fiberglass LaminatesDocument5 pagesDiclad Series: Ptfe/Woven Fiberglass LaminatesmaamriaPas encore d'évaluation

- (N) TMCGEH3S 3x120sqmm Orange TPU JacketDocument3 pages(N) TMCGEH3S 3x120sqmm Orange TPU JacketAbl Jara MamaniPas encore d'évaluation

- S SeriesDocument11 pagesS Series380665791408maksPas encore d'évaluation

- SM6S10 Thru SM6S36A: High Temperature Stability and High Reliability ConditionsDocument5 pagesSM6S10 Thru SM6S36A: High Temperature Stability and High Reliability ConditionsStuxnetPas encore d'évaluation

- Yageo Product Selection Guide 2016Document188 pagesYageo Product Selection Guide 2016John HallowsPas encore d'évaluation

- Vishay Beyschlag: FeaturesDocument11 pagesVishay Beyschlag: FeaturesBích Trâm Đào HoàngPas encore d'évaluation

- High Speed Detection of Broken Rails, Rail Cracks and Surface Faults PDFDocument37 pagesHigh Speed Detection of Broken Rails, Rail Cracks and Surface Faults PDFOmarPas encore d'évaluation

- Suzuki EN125 YES Catálogo de Peças PDFDocument58 pagesSuzuki EN125 YES Catálogo de Peças PDFSamuel Lopes0% (1)

- Manual Scilab-5.2.0 PT BRDocument3 342 pagesManual Scilab-5.2.0 PT BREduardo HirtPas encore d'évaluation

- Crack Detection System For Railway Tracks-4717Document8 pagesCrack Detection System For Railway Tracks-4717Marcus Vinicius FonsecaPas encore d'évaluation

- (Learn - German.nso) Warum Nicht - German Language Course (Series 01) Chapter 02 - Hey, Taxi! PDFDocument5 pages(Learn - German.nso) Warum Nicht - German Language Course (Series 01) Chapter 02 - Hey, Taxi! PDFMarcus Vinicius FonsecaPas encore d'évaluation

- Nso Warum Nicht - German Language Course (Series 01) A02 - IntroductionDocument6 pagesNso Warum Nicht - German Language Course (Series 01) A02 - IntroductionserbianspudPas encore d'évaluation

- (Learn - German.nso) Warum Nicht - German Language Course (Series 01) Chapter 03 - Hotel Europa PDFDocument3 pages(Learn - German.nso) Warum Nicht - German Language Course (Series 01) Chapter 03 - Hotel Europa PDFMirza RizvicPas encore d'évaluation

- (Learn - German.nso) Warum Nicht - German Language Course (Series 01) Chapter 01 - This Is A SongDocument2 pages(Learn - German.nso) Warum Nicht - German Language Course (Series 01) Chapter 01 - This Is A SongSrinivas RallabandiPas encore d'évaluation

- History of Photography Timeline Assignment 1Document14 pagesHistory of Photography Timeline Assignment 1api-357703158Pas encore d'évaluation

- Full Lab Report #8Document13 pagesFull Lab Report #8Joe Morrison100% (2)

- Report On SoftenerDocument72 pagesReport On SoftenerNipu Sen100% (4)

- SAT - Physics - 11 Grade - 4T - 2020-2021Document7 pagesSAT - Physics - 11 Grade - 4T - 2020-2021Ануар ТуяковPas encore d'évaluation

- Mechanics of Deformable BodiesDocument14 pagesMechanics of Deformable BodiesarjunPas encore d'évaluation

- Performance Under Cyclic Load of Built-Up T-Stubs For Double T Moment ConnectionsDocument14 pagesPerformance Under Cyclic Load of Built-Up T-Stubs For Double T Moment ConnectionsMilmxmenPas encore d'évaluation

- Pu 00011931Document481 pagesPu 00011931Eduardo Salgado EnríquezPas encore d'évaluation

- InggrissinkholeDocument2 pagesInggrissinkholeRika Rika SilvianaPas encore d'évaluation

- Timoshenko Beam ElementDocument11 pagesTimoshenko Beam ElementMahmoud M.S. DwaikatPas encore d'évaluation

- MIDAS SteelCompositeCurvedBridgeTutorialDocument41 pagesMIDAS SteelCompositeCurvedBridgeTutorialOscar Mendoza100% (1)

- Institute of Aeronautical EngineeringDocument4 pagesInstitute of Aeronautical EngineeringACE PROFILESPas encore d'évaluation

- Enter Your Response (As An Integer) Using The Virtual Keyboard in The Box Provided BelowDocument102 pagesEnter Your Response (As An Integer) Using The Virtual Keyboard in The Box Provided BelowCharlie GoyalPas encore d'évaluation

- Elasticity - HeatDocument13 pagesElasticity - HeatHarsh GuptaPas encore d'évaluation

- Adding Forces Resultant and Equilibrium, Resolving Forces ComponentDocument18 pagesAdding Forces Resultant and Equilibrium, Resolving Forces ComponentHisyamAl-MuhammadiPas encore d'évaluation

- LZ96a Dist - Relay1Document40 pagesLZ96a Dist - Relay1RK K0% (1)

- Studies of Refractive Index of Different LiquidsDocument13 pagesStudies of Refractive Index of Different LiquidsSamrat HalderPas encore d'évaluation

- Vehicle Detection Using Hog and SVMDocument5 pagesVehicle Detection Using Hog and SVMBaargav BheemaPas encore d'évaluation

- CS 2742 (Logic in Computer Science) - Fall 2011: Antonina KolokolovaDocument3 pagesCS 2742 (Logic in Computer Science) - Fall 2011: Antonina KolokolovaZhichaoWangPas encore d'évaluation

- Save Money, Go Solar: Top 5 Reasons To Go Solar Special Incentives AvailableDocument3 pagesSave Money, Go Solar: Top 5 Reasons To Go Solar Special Incentives AvailableMaogageoffreyPas encore d'évaluation

- Batch-13 ReportDocument84 pagesBatch-13 ReportBindhu ShreePas encore d'évaluation

- Sony MDS-JB920QS Service ManualDocument72 pagesSony MDS-JB920QS Service ManualSinisa SlavinicPas encore d'évaluation

- Dimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutDocument11 pagesDimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutRizqi RamadhanPas encore d'évaluation

- Hot Rolled Bulb Flats PDFDocument4 pagesHot Rolled Bulb Flats PDFLaurentiu GavrilaPas encore d'évaluation

- Applications of Solar Energy PDFDocument42 pagesApplications of Solar Energy PDFpallav guptaPas encore d'évaluation

- Penerapan Metode Sonikasi Terhadap Adsorpsi FeIIIDocument6 pagesPenerapan Metode Sonikasi Terhadap Adsorpsi FeIIIappsPas encore d'évaluation

- Exercise 3 Rice Combine HarvesterDocument6 pagesExercise 3 Rice Combine Harvesterangelo lorenzo tamayoPas encore d'évaluation

- Simplified Model For Evaluating Soil Liquefaction Potential Using CPTUDocument8 pagesSimplified Model For Evaluating Soil Liquefaction Potential Using CPTUIbrahim SuryaPas encore d'évaluation

- Annexure-1 Wind Load ReportDocument4 pagesAnnexure-1 Wind Load ReportPrabartak DasPas encore d'évaluation

- BS4620 1970Document15 pagesBS4620 1970K H V V MADUSHANKA100% (1)

- Anti Sweat HeatersDocument2 pagesAnti Sweat HeatersbreavmacPas encore d'évaluation