Académique Documents

Professionnel Documents

Culture Documents

Risk Ass. - Installation of Stainless Steel Label On The 10kva Inverter-3210-ELE-113

Transféré par

nsadnanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Risk Ass. - Installation of Stainless Steel Label On The 10kva Inverter-3210-ELE-113

Transféré par

nsadnanDroits d'auteur :

Formats disponibles

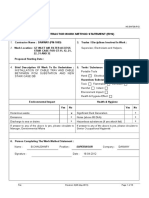

HS.SAF.09.

F12

CONTRACTOR WORK METHOD STATEMENT (EHS)

1. Contractor Name : DANWAY 3. Trades / Disciplines Involved In Work :

2. Work Location: Machinary house MCC Supervisor, Electricians and Helpers.

Room.

Proposed Starting Date :

4. Brief Description Of Work To Be Undertaken : 5. Tools / Substance

Installation of Stainless steel label on the 10Kva

Portable Tools

Inverter(3210-ELE-113)

Hand Electrical Pneumatic

Hazardous Substances

Toxic Flammable Corrosive

Harmful Irritant

Environment Impact

Health & Hygiene Effect

Environmental Impact Health & Hygiene

Yes No Yes No

x

Hazardous waste x Significant Dust Generation

x x

Emissions Noise (above 85 DbA)

x x

Discharge to sea or drains Hazardous substances (if yes attach list)

If answer to any of the above is yes, please circulate to If answer to any of the above is yes, please circulate to

Manager, Environmental Affairs Senior Occupational Hygienist

6. Person Completing The Work Method Statement :

Name : Position : SUPERVISOR Company : DANWAY

Signature : Date :

File: Revision: 0(26-May-2011) Page 1 of 6

HS.SAF.09.F12

7. Approvals

Contractors Site Rep. Name SULFEEK H Signature : Date :

EMAL Representative Name Signature : Date :

Area Owner Name Signature : Date :

Name Signature: Date:

EMAL EHS Department

The completed Work Method Statement must be submitted at least seven full working days prior to the

commencement of activities.

Where the Work Method Statement indicates the use of Hazardous Substances, a Material Hazard Data

Sheet must be attached.

After the Area Owners approval the Work Method Statement shall be forwarded to EHS department for

approval

The approved Work Method Statement must be attached to the permit(s) to work and all persons involved

in the job instructed in its requirements.

2. RISK ESTIMATOR CHART

The Risk Estimator chart should be used as an assistant for filling out the work

method statement.

Severity

Probability Low x1 Medium x 2 High x3

Low x1 Low Probability x Low Severity LP x MS LP x HS

1x1=1 1x2 = 2 1x3 =3

Medium x2 MP x LS MP X MS MP x HS

2x1 =2 2x2 =4

2x3 =6

High x3 HP x LS HP X HS HP x HS

3 x 1 =3 3x2 = 6 3x3=9

Significant Risk = High Risk (6-9) or Medium Risk (3-4) in terms of probability and severity

Tolerable Risk = Risk reduced to an acceptable level = Low Risk (1-2)

Residual Risk = Risk remaining after implementing recommended control actions (usually very minor).

File: Revision: 0(26-May-2011) Page 2 of 6

HS.SAF.09.F12

8. Safety Analysis

Severity x Probability =

Risk

Individual Activities To Identified Hazard(s) Persons Exposed To Precautions and Plan of actions To Be Taken

Complete Work. List In Residual Risk

Associated With Activity Hazard To Remove / Control Hazards

Sequence of Activity (Use Risk Estimator

Chart)

PREPARATION. Slips, trips and fall at Maintain housekeeping around in the

Emal rep., Engr.,

the same level. working area.

Supv. Elec, and 2x2=4

Hot environment All personnel involve in the activity must be

helpers

aware of heat stress, supervisor to ensure

drinking cold water is available.

File: Revision: 0(26-May-2011) Page 3 of 6

HS.SAF.09.F12

Start work after getting permit from Emal.

APPROVAL(Permit to Client coordination Emal rep., Engr.,

Supv. Elec, helpers Engineer / supervisor must ensure that the

work from EMAL) fails, job stopped, work

unapproved. work permit is valid for the date and time

All work force are inducted by EMAL

Operatives should be All personnel involve in the activities must

aware of emergency wear the required PPEs at all times (hard

procedure of EMAL hat, Clear safety glass, safety shoes, hand

gloves, dust mask, cover all))

Advance planning by contractor considering

the time consumption to recive the permit

from EMAL.

Emergency procedure must be displayed at

prominent location and cascade to

operatives on regular interval and recorded. 2x2=4

Ensure the operatives must be go through

EMAL and DANWAY safety induction.

Conduct tool box talk to explain procedures

and risks involved in the work to the crew.

All hand tools to be used must be in

INSTALLATION OF SS Using damaged hand Electricians & Helpers good condition. 2 x 1 =2

LABEL. tools. Inspect before use, periodically

maintained.

Competent workers to be deployed,

Incompetent workers. Electricians & Helpers 2 x 1 =2

supervisor to check the competency of the

workers.

Electricians ,

Slips, trips and fall at Maintain housekeeping around the 2 x 1 =2

supervisor & Helpers

the same level. working area.

File: Revision: 0(26-May-2011) Page 4 of 6

HS.SAF.09.F12

Using damaged Battery operated drill machine must be in

Electricians & Helpers 3x1=3

battery operated drill good condition with color coding inspection

machine. tag.

Unauthorized using of Electricians & Helpers Only competent and authorized worker for 3x1=3

battery operated drill the using of battery operated drill machine.

machine

Maintain housekeeping within the

Emal rep., Engr.,

working area 2 x 1 =2

Poor housekeeping Supv. Elec, Helpers.

Walkway and gangway to be kept

free of obstruction.

Wear P.P.E.'s at all times (hard hat, Clear

Emal rep., Engr.,

safety glass, safety shoes, hand gloves, 2x2=4

Not using P.P.E.'s Supv. Elec, Helpers.

dust mask, fire retardant long sleeve shirt /

pants).

Only competent and authorized person to

Unauthorized workers Other workers nearby do the inspection, ensure notified the client 1x3=3

INSPECTION

with all necessary documents.

This sheet must be properly completed detailing all of the steps required to complete the job along with the sequence of events and each of the hazards

arising. Failure to properly complete the form will result in non-approval.

(Additional sheets to be used as required)

File: Revision: 0(26-May-2011) Page 5 of 6

HS.SAF.09.F12

9. Chemical Analysis (This form to be used as required)

Product Name

MSDS supplied Yes / No

Dangerous Goods Class

Hazardous Material Yes / No

Nature of Hazard Irritation / Carcinogen / Corrosive / Toxic / Other

Form Solid /Liquid / Gas / Dust / Vapour / Mist

Exposure Route Inhalation / Skin / Eye / Ingestion

Number of People Exposed

Duration of Exposure

Frequency of Exposure

Controls to be implemented

Estimate of Exposure Negligible / Marginal / High

This sheet must be properly completed detailing all the necessary information. Failure to properly complete the form will result in non-approval.

File: Revision: 0(26-May-2011) Page 6 of 6

Vous aimerez peut-être aussi

- Contractor Work Method Statement (Ehs)Document11 pagesContractor Work Method Statement (Ehs)nsadnanPas encore d'évaluation

- RA For Fixing Warning LabelsDocument5 pagesRA For Fixing Warning LabelsnsadnanPas encore d'évaluation

- Risk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTDocument9 pagesRisk Ass - RECTIFICATION FOR DAMAGED CABLE TRAY SUPPORTnsadnanPas encore d'évaluation

- Modification of Cable Ladder in Bath Processing PlantDocument14 pagesModification of Cable Ladder in Bath Processing PlantnsadnanPas encore d'évaluation

- Risk Ass. - Load Current Measurement and Cleaning of Oil CoolerDocument7 pagesRisk Ass. - Load Current Measurement and Cleaning of Oil CoolernsadnanPas encore d'évaluation

- Risk Ass. - INSTALLATION OF CBCT IN SUBSTATION 4730-ESS-001Document12 pagesRisk Ass. - INSTALLATION OF CBCT IN SUBSTATION 4730-ESS-001nsadnanPas encore d'évaluation

- D02 MS Ra Pov PDFDocument35 pagesD02 MS Ra Pov PDFnsadnanPas encore d'évaluation

- Risk Ass. - INSTALLATION OF 25 MM G.I. PIPE WITH EXISTING LINEDocument12 pagesRisk Ass. - INSTALLATION OF 25 MM G.I. PIPE WITH EXISTING LINEnsadnanPas encore d'évaluation

- Installation of Gi TrunkingDocument7 pagesInstallation of Gi TrunkingnsadnanPas encore d'évaluation

- Fuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)Document8 pagesFuel Gas Compressor Enclosures: Contractor Work Method Statement (Ehs)nsadnanPas encore d'évaluation

- Contractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingDocument8 pagesContractor Work Method Statement (Ehs) : Installation of Wooden ScaffoldingnsadnanPas encore d'évaluation

- Risk Ass. - AD 417 - Installation of SocketDocument6 pagesRisk Ass. - AD 417 - Installation of SocketnsadnanPas encore d'évaluation

- PM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBDocument16 pagesPM-1009 Installation of Cable Tray and Cable Betwwen PCM Substation and New Stair Case DBnsadnanPas encore d'évaluation

- Risk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMDocument16 pagesRisk Ass - CABLE PULLING LAYING Power Cables, Control Cables & FO CablesMnsadnanPas encore d'évaluation

- Risk Ass. - RELOCATION OF 11 KV CABLE FROM EXISTING ROUTE TO NEW LOCATIONDocument6 pagesRisk Ass. - RELOCATION OF 11 KV CABLE FROM EXISTING ROUTE TO NEW LOCATIONnsadnan100% (1)

- Contractor Work Method Statement-GIS Parts, Equipmentand ToolsDocument10 pagesContractor Work Method Statement-GIS Parts, Equipmentand ToolsnsadnanPas encore d'évaluation

- Cable Pulling, Glanding and TerminationsDocument6 pagesCable Pulling, Glanding and TerminationsnsadnanPas encore d'évaluation

- Risk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPDocument20 pagesRisk Ass - INSTALLATION OF PLC CABINET HMI CABINET IPCPnsadnanPas encore d'évaluation

- Iecex PTB 09.0039uDocument5 pagesIecex PTB 09.0039uFrancesco_CPas encore d'évaluation

- 1 - Hydraulic Bollard Manual by BS 05052020 PDFDocument16 pages1 - Hydraulic Bollard Manual by BS 05052020 PDFJESUS HUAMANIPas encore d'évaluation

- 4.5.3!01!02 Incedent Injury Report Rev 1 - QTEL CABLE - C1Document4 pages4.5.3!01!02 Incedent Injury Report Rev 1 - QTEL CABLE - C1loveson709Pas encore d'évaluation

- Ps - UtilitiesDocument174 pagesPs - UtilitiesBipin SasikumarPas encore d'évaluation

- Sample Project SpecsDocument30 pagesSample Project SpecsUvie M. PtwolanPas encore d'évaluation

- A en 05802 00Document32 pagesA en 05802 00jose florPas encore d'évaluation

- Sayed Mahmoud Jalili CV RDocument5 pagesSayed Mahmoud Jalili CV RSayed mahmoudPas encore d'évaluation

- Calculation Method For Soakaway Depths PD30Document3 pagesCalculation Method For Soakaway Depths PD30sosi2020Pas encore d'évaluation

- D en 06350 00Document49 pagesD en 06350 00Antonio LoretoCortesPas encore d'évaluation

- Key Plan: Sub ConsultantDocument1 pageKey Plan: Sub ConsultantaqueelengPas encore d'évaluation

- YT-2400 Installation EDocument9 pagesYT-2400 Installation ERakesh Karan SinghPas encore d'évaluation

- Keep critical spares on hand to avoid costly downtimeDocument4 pagesKeep critical spares on hand to avoid costly downtimeMai TuấnPas encore d'évaluation

- National Submittal FinalDocument122 pagesNational Submittal FinalDinesh ChaudharyPas encore d'évaluation

- Sample SubmittalDocument9 pagesSample SubmittalTarique ImamPas encore d'évaluation

- High-Efficiency Cast Iron Submersible Sewage PumpDocument16 pagesHigh-Efficiency Cast Iron Submersible Sewage PumptuanPas encore d'évaluation

- Butterfly ValveDocument160 pagesButterfly Valvemohamed yousufPas encore d'évaluation

- Aftec Technical SubmittalDocument185 pagesAftec Technical SubmittalVictor NairPas encore d'évaluation

- DP SubmittalDocument9 pagesDP Submittalمحمود أبو الحسنPas encore d'évaluation

- Proposal For The BoosterDocument5 pagesProposal For The BoosterraziPas encore d'évaluation

- Bentofix® Geosynthetic Clay LinersDocument5 pagesBentofix® Geosynthetic Clay LinersHussein Amir MohsenPas encore d'évaluation

- Case Study Infiltration Road Soakaway Zayed University Abu DhabiDocument4 pagesCase Study Infiltration Road Soakaway Zayed University Abu DhabiHaitham IbrahimPas encore d'évaluation

- 00-GRC-EDA-100038-33 (Technical Submittal For Instruments) Rev02Document11 pages00-GRC-EDA-100038-33 (Technical Submittal For Instruments) Rev02Alaa RamadanPas encore d'évaluation

- Valve Box For Irrigation NDS 01Document58 pagesValve Box For Irrigation NDS 01ashwinPas encore d'évaluation

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Document3 pagesRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (1)

- Smart Fertigation SystemDocument6 pagesSmart Fertigation SystemJournalNX - a Multidisciplinary Peer Reviewed JournalPas encore d'évaluation

- QAISER CV PDFDocument3 pagesQAISER CV PDFQaiser MehmoodPas encore d'évaluation

- Post-weld Heat Treatment SafetyDocument7 pagesPost-weld Heat Treatment SafetySalam AlkataluniPas encore d'évaluation

- Butt Fusion Welding Procedure for HDPE PipesDocument9 pagesButt Fusion Welding Procedure for HDPE PipesVignesh BharathiPas encore d'évaluation

- Material Submittal - FCUDocument199 pagesMaterial Submittal - FCUriyazPas encore d'évaluation

- 344 PC 07 Arabtec SX MT 00061 - 03 Paint For Steel StructureDocument327 pages344 PC 07 Arabtec SX MT 00061 - 03 Paint For Steel Structurej f100% (1)

- US1851006 8566 Certified Test Curve 1Document5 pagesUS1851006 8566 Certified Test Curve 1Alvaro SernaPas encore d'évaluation

- Vendor Product Presentation Ratings FormDocument14 pagesVendor Product Presentation Ratings Formnsadnan100% (2)

- Project Management Co. approves abseiling system materialDocument54 pagesProject Management Co. approves abseiling system materialfrancisbautistaPas encore d'évaluation

- BOQ Calculation and AbstarctDocument166 pagesBOQ Calculation and AbstarctPratik DiyoraPas encore d'évaluation

- 1861B-MS-08-00002 Revision 2Document41 pages1861B-MS-08-00002 Revision 2Moh'd SameerPas encore d'évaluation

- BollardsDocument51 pagesBollardsMohammed Wasiuddin100% (1)

- 9 Three Line DiagramDocument1 page9 Three Line Diagramapi-302117883Pas encore d'évaluation

- 459-De-SPADING of Fire Water Line For Deluge Skid and Sprinkler System SAT TestDocument4 pages459-De-SPADING of Fire Water Line For Deluge Skid and Sprinkler System SAT TestNasrullah JanPas encore d'évaluation

- 2012-11-17 DPR No 14Document12 pages2012-11-17 DPR No 14Gema SuryaPas encore d'évaluation

- Risk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBDocument13 pagesRisk Ass. - PM - 1009 - INSTALLATION OF CABLE TRAY AND CABLE BETWWEN PCM SUBSTATION AND NEW STAIR CASE DBnsadnanPas encore d'évaluation

- Risk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOMDocument8 pagesRisk Ass - INSTALLATION OF PLC CABINET IN SECTION ELECTRICAL ROOMnsadnan100% (1)

- Risk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatDocument6 pagesRisk Ass. - TK 4446 - Installation of Cable Tray, Cable Ladder & Scaffolding - PL 1 & PL 2 - Emal FormatnsadnanPas encore d'évaluation

- ONVIF Profile T Specification v1-0Document77 pagesONVIF Profile T Specification v1-0nsadnanPas encore d'évaluation

- ONVIF Profile - S Specification v1-2Document42 pagesONVIF Profile - S Specification v1-2nsadnan0% (1)

- ONVIF Profile Feature Overview v2-2Document6 pagesONVIF Profile Feature Overview v2-2nsadnanPas encore d'évaluation

- Excel Intelligent PduDocument21 pagesExcel Intelligent PdunsadnanPas encore d'évaluation

- Excel Intelligent Pdu User InstructionsDocument2 pagesExcel Intelligent Pdu User InstructionsnsadnanPas encore d'évaluation

- BSIA Cyber Secure It January 2019Document16 pagesBSIA Cyber Secure It January 2019nsadnanPas encore d'évaluation

- HVAC ManualDocument107 pagesHVAC ManualWissam JarmakPas encore d'évaluation

- Checklist For Access Control System InstallationDocument6 pagesChecklist For Access Control System Installationnsadnan71% (7)

- DDC Systems2Document28 pagesDDC Systems2nsadnan100% (1)

- 1 45Document3 pages1 45nsadnan0% (1)

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDocument5 pagesPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanPas encore d'évaluation

- Testing and Commissioning Pre-Check List (ID 1506)Document1 pageTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Checklist For Pre Commissioning of CCTV SystemDocument1 pageChecklist For Pre Commissioning of CCTV Systemnsadnan67% (6)

- Exc Installation GuideDocument1 pageExc Installation GuidensadnanPas encore d'évaluation

- Exc Fibre Installation GuideDocument38 pagesExc Fibre Installation GuidensadnanPas encore d'évaluation

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Document3 pagesRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (1)

- Exc Fibre Installation GuideDocument16 pagesExc Fibre Installation GuideMohamad FaifPas encore d'évaluation

- Sensor Line Cable InstallationDocument6 pagesSensor Line Cable InstallationnsadnanPas encore d'évaluation

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanPas encore d'évaluation

- Checklist For Commissioning of CCTV SystemDocument2 pagesChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- ADDC Electricity Wiring Regulations - Mar.2014Document276 pagesADDC Electricity Wiring Regulations - Mar.2014hajimak89% (18)

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Document1 pageCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- 109 Installation CCTV Systems PDFDocument60 pages109 Installation CCTV Systems PDFRodelDavidPas encore d'évaluation

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Tk-4741-Removal Works For Site Office FacilitiesDocument14 pagesRisk Assessment - Tk-4741-Removal Works For Site Office FacilitiesnsadnanPas encore d'évaluation

- RISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolerDocument5 pagesRISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolernsadnanPas encore d'évaluation

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 pagesRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanPas encore d'évaluation

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - Installation of Ventilation FanDocument6 pagesRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 pagesRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)