Académique Documents

Professionnel Documents

Culture Documents

Omae2013 10625 Pipeline Free Spans

Transféré par

genmikCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Omae2013 10625 Pipeline Free Spans

Transféré par

genmikDroits d'auteur :

Formats disponibles

Proceedings of the 32rd International Conference on Ocean, Offshore and Arctic Engineering

OMAE2013

9 14 June, 2013, Nantes, France

OMAE2013- 10625

FATIGUE ANALYSIS OF FREE SPANNING PIPELINES

SUBJECTED TO VORTEX INDUCED VIBRATIONS

F. Van den Abeele F. Bol M. Hill

Fugro GeoConsulting Belgium Fugro GeoConsulting Belgium Shell Exploration & Production

Brussels, Belgium Brussels, Belgium Houston, Texas, US

ABSTRACT VORTEX INDUCED VIBRATIONS FOR SUBSEA PIPES

Vortex induced vibration is a major cause of fatigue failure in The on bottom stability of offshore pipelines is governed

submarine oil and gas pipelines and steel catenary risers. Even by the Morisons equations [1-2], a semi-empirical set of

moderate currents can induce vortex shedding, alternately at the equations relating the pipeline diameter to the hydrodynamic

top and bottom of the pipeline, at a rate determined by the flow forces (lift, drag and inertia). In addition to these forces, a

velocity. Each time a vortex sheds, a force is generated in both turbulent von Karman vortex street can appear in the wake of a

the in-line and cross-flow direction, causing an oscillatory subsea pipeline for certain combinations of dimensions and

multi-mode vibration. This vortex induced vibration can give flow velocities. Each time a vortex sheds, a force is generated

rise to fatigue damage of submarine pipeline spans, especially both in the in-line and cross-flow direction, causing an

in the vicinity of the girth welds. oscillatory multi-mode vibration. When the vortex shedding

frequency is close to the natural frequency of the structure,

In this paper, an integrated numerical framework is presented to resonance or lock-in could occur, which may jeopardize the

predict and identify free spans that may be vulnerable to fatigue integrity of the structure. Figure 1 shows a von Karman vortex

damage caused by vortex induced vibrations (VIV). An elegant street in the wake of a subsea pipeline at the onset of

and efficient algorithm is introduced to simulate offshore turbulence.

pipeline installation on an uneven seabed. Once the laydown

simulation has been completed, the free spans can be

automatically detected. When the fatigue screening for both in-

line and cross-flow VIV indicates that a particular span may be

prone to vortex induced vibrations, a detailed fatigue analysis is

required.

Amplitude response models are constructed to predict the

maximum steady state VIV amplitudes for a given pipeline

configuration (mechanical properties) and sea state

(hydrodynamic parameters). The vibration amplitudes are

Figure 1: Von Karman street at the onset of turbulence

translated into corresponding stress ranges, which then provide

an input for the fatigue analysis. A case study from the offshore

Due to the alternating vortex wake, the oscillations in lift

industry is presented, and sensitivity analyses are performed to

study the influence of the seabed conditions, where special force occur at the vortex shedding frequency , and

emphasis is devoted on the selection of pipe soil interaction oscillations in drag force occur at twice this frequency.

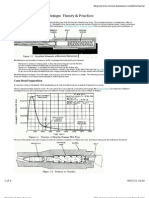

parameters. Figure 5 shows the evolution of the fluctuating lift and drag

forces exerted on an offshore pipeline span.

1 Copyright 2013 by ASME

Figure 2: Lift and drag forces on an offshore pipeline span

The oscillating signals reflect a fully developed turbulent

wake. Note that the average lift force is zero, while the average

drag force is a measure for the resistance against fluid flow. On

Figure 3, the Fast Fourier Transform (FFT) of the lift and drag

forces is shown, to reveal the frequency content of the signals. Figure 4: Path of a pipeline subjected to VIV

Clearly, the dominant frequency of the drag force is twice the

lift frequency. Then, a case study from the offshore pipeline industry

is presented to reveal the influence on the pipe soil

interaction parameters on the span prediction.

At the end of this paper, a remaining lifetime

assessment is presented for the identified critical

spans. Indeed, when the fatigue screening for both in-

line and cross-flow VIV indicates that a particular

span may be prone to vortex induced vibrations, DNV-

RP-F105 [8] recommends to perform a full fatigue

analysis based on an amplitude response model [8, 9].

SIMULATING PIPE LAYDOWN AND INSTALLATION

Offshore pipeline installation is performed from a lay

Figure 3: Frequency spectrum of lift and drag forces barge, typically in S-lay configuration. For smaller diameters,

pipeline reeling can be the most cost efficient solution, whereas

Like shown on Figure 4, these in-line and cross-flow J-lay is the only feasible approach in (ultra) deep water.

oscillations can give rise to an 8-shaped motion of the Depending on the installation method, the pipeline is subjected

pipeline span, which is detrimental to its fatigue life. A to different load patterns during installation, including

comprehensive overview on vortex induced vibrations is given hydrostatic pressure, lay tension and bending on the stinger and

in [3, 4], and a more recent review on VIV experiments and in the sagbend. A comprehensive overview on the mechanics of

simulations for offshore pipelines can be found in e.g. [5-7]. installation design can be found in [10].

In this paper, an integrated numerical framework is The simulation of the pipelaying process is one of the most

presented to predict and identify free spans that may be challenging tasks once the optimum route has been selected.

vulnerable to vortex induced vibrations (VIV): Implementing pipeline installation in a general purpose finite

element package can be a time consuming and tedious job, in

First, an elegant and efficient algorithm is introduced particular when importing vast amounts of seabed data. Most

to simulate offshore pipeline installation on an uneven often, advanced scripting techniques are required to define the

seabed. Once the laydown simulation has been seabed profile, select the optimum pipeline route and simulate

completed, the free spans can be automatically the laydown process. In addition, the available constitutive

detected. models for pipe-soil interaction may not comply with industry

standards.

2 Copyright 2013 by ASME

In this paper, the SAGE Profile software suite [11, 12] is used

to simulate pipelaying on an uneven seabed, and evaluating the

susceptibility of free spans to vortex induced vibrations. This

finite element analysis software has been tailored to assist the

pipeline engineer during offshore pipeline design. Using a

transient dynamic explicit solver, it can accurately mimic the

actual pipeline installation process.

The pipe is simulated by discretising the entire pipeline

into section of finite length. These sections are represented by

beam elements with 12 degrees of freedom (DOF), bounded at

either side by nodes. The distributed mass of the pipe is lumped

at these nodes. The finite element kernel uses an explicit

integration algorithm, which computes the dynamic motion of

the pipe and is therefore ideally suited to simulate the pipe

laying process.

During this pipeline installation process, new pipe Figure 5: Pipeline catenary shape during S-lay installation

elements are continuously created and the pipe is laid along the

target path defined on the seabed. The residual lay tension at For long pipelines and significant water depths, simulating

the seabed is used as an input and the unstressed length of the entire laydown process (from the barge down to the seabed)

the last element is updated such that the axial force corresponds tends to be time consuming and is computationally expensive.

to the applied lay tension: The sophisticated architecture of the solver used for this

analysis allows for a significant reduction in the resources

required to simulate pipeline laydown. By default, the lay barge

(03)

and most of the free hanging pipe is replaced by a single

feeding point in the water column moving close to the seabed,

with the original element length, like shown on Figure 6.

This feeding point acts as a submarine lay barge,

(04)

4 generating new pipe joints as it moves forward. The lay tension

is now applied at the feeding point, generating a residual on

the cross sectional area of a circular pipe with inner diameter bottom tension in the laid pipe section.

and outer diameter , and

1 2 (05)

the pressure induced axial force component, accounting for

both the internal pressure and the (hydrostatic) external

pressure . As a result, both empty and water filled installation

can be simulated. In (03), is the Poissons coefficient of the

pipeline steel, where and are the surface areas of the

interior and exterior of the pipe respectively. When the growing

element becomes longer than twice the initial length, the

element is split in two new elements. An additional node is

placed along the last element such that the newly formed Figure 6: Definition of feeding point and target path

element obtains the original unstressed length.

Assuming a catenary shape [10], the lay tension at the

This algorithm accurately reflects the continuous supply of feeding point can be expressed in terms of the submerged

welded pipe joints from a moving lay barge. The gravity, weight per unit length

applied during the pipelay simulation, will force the newly

created pipe elements into place. Figure 5 shows the typical

1 1 tan (07)

catenary shape during pipeline installation. tan

3 Copyright 2013 by ASME

where is the angle between the pipe and the target path, and In this paper, a case study from the offshore industry is

is the height of the feeding point above the seabed. Replacing presented to demonstrate the added value of numerical

the lay barge with a feeding point close to the seabed allows for simulations to predict fatigue damage in free spanning pipes.

a significant reduction in calculation time, without losing An X70 flowline with an outer diameter = 10- (273.05

accuracy. Given the inherent complexity of pipeline laying, an mm) and a wall thickness = 7/8 (22.225 mm) is installed in

accurate and robust steering mechanism of the feeding point is the Gulf of Mexico in water depths exceeding 2400 meters. The

of paramount importance. The steering mechanism is governed irregular seafloor topography, shown on Figure 8, indicates that

by a Proportional-Integrating-Differentiating (PID) controller, this pipeline may be prone to free spans and hence vulnerable

providing a smooth movement of the feeding point and to vortex induced vibrations.

ensuring that the pipeline is installed on the pre-defined target

path (shown in red on Figure 6).

In addition to the concept of a feeding point, an efficient

element killing procedure has been implemented to control the

computational effort during pipeline laydown. Indeed, it would

be too expensive to simulate the entire length of the pipe from

its starting point up to the feeding point. In order to reduce the

required calculation time, elements that are already lying on the

seabed and are no longer moving will be removed from the

simulation. If the magnitude of the velocity vector for a node is

lower than a pre-defined threshold, the associated element has

little or no contribution to the simulation results and can be

killed without losing accuracy. On Figure 6, the elements that

have been killed are shown as well.

IDENTIFICATION OF FREE SPANNING PIPELINES Figure 8: Seabed roughness along the pipeline route

Accurate prediction of free spans (location, length and The pipe is coated with a Fusion Bonded Epoxy (FBE)

height) is an important prerequisite in offshore pipeline design. coating and a Glass Syntactic Polyurethane (GSPU) coating

Indeed, free span lengths should be maintained within an with mechanical properties summarized in Table 1.

allowable range [07], which is determined during the design

phase. Pipelines installed on a very rough seabed can cause a Table 1: Mechanical properties of the coating layers

high number of free spans that can be difficult to rectify. A

judicious assessment of free spans can dramatically reduce the Water

Thickness Density

costs associated with seabed intervention (trenching, rock Coating Absorption

[] [kg/m]

dumping and span supports). [%]

FBE 0.018 1440 0

GSPU 3 833 5

The soil conditions along the route consist mainly of very

soft clay, typical for deepwater soils encountered in the Gulf of

Mexico. For the finite element simulations, presented here, a

submerged unit weight of = 7.5 kN/m is taken. The green

dots on Figure 9 represent field measurements of the undrained

shear strength as a function of depth. In this paper at hand,

we have used a bilinear approximation

0 0

(08)

Figure 7: Free spanning pipeline on an uneven seabed

like indicated by the blue lines on Figure 9. For the data set

Figure 7 demonstrates that finite element methods are presented in Figure 9, values for ground surface shear strength

capable of simulating pipeline installation on an uneven seabed, 0 = 0.39 kPa and strength increase rate = 12.27 kPa/m

and subsequently detecting free spans. and = 2.5 kPa/m were obtained.

4 Copyright 2013 by ASME

Figure 9: Undrained shear strength profile

This bilinear shear strength profile is converted into a non-

linear soil spring using the power-relationship

(08)

proposed by Aubeny [13] to relate the dimensionless bearing

resistance with the normalized pipeline embedment .

The catenary shape of the suspended pipeline during laying

(schematically shown on Figure 5) has been taken into account

to accurately capture the pipe embedment at the touchdown

point, and an enhanced soil model [12] is used to reflect the

elastoplastic soil behavior. The lateral and axial soil springs are

defined by a friction factor and a limiting soil resistance.

Simulation of the pipe laying process has been performed

with an element length of 1 meter, and assuming a residual

bottom tension = 100 kN. After the pipelay simulation has

been completed, the software automatically detects the spans

over the entire pipeline route, and plots the span location,

length and height in comprehensive and easy-to-read design

charts, like shown on Figure 11.

Figure 11: Overview of span location, height and length

On Figure 10, the observed spans (from an as-laid survey)

are compared to the spans predicted by the simulations. A span

is judged to be predicted (solid green dots) when the KP range

of the observed and simulated spans overlap for more than

50%. Although detailed analysis revealed that the length and

height for some simulated spans was slightly underestimated,

Figure 10: Comparison of observed and predicted spans the predictions correspond fairly well to the observed spans.

5 Copyright 2013 by ASME

The finite element tool has identified a number of low Nect, we perform a DNV-RP-F105 [8] span check to

rising spans (with a gap between the pipe surface and the evaluate whether such free spans are susceptible to fatigue

seabed lower than 0.2 meters) that have not been observed damage induced by VIV. For each detected span, we calculate

during the as-laid survey. This may be attributed to the the associated reduced velocity

resolution of the survey equipment, or to numerical artifacts

(especially for short, low rising spans). Most of the predicted

spans that have not been observed have a normalized span (9)

length 30, with the total pipe diameter

(including all coatings). For such spans, insignificant dynamic where is the mean current velocity (normal to the pipe),

response from environmental loads is expected [8]. Hence, they the significant wave-induced flow velocity, and an approxi-

are unlikely to experience vortex induced vibrations. mation for the lowest natural frequency given by

Sensitivity analyses were performed to investigate the

influence of element length, soil conditions and lay tension on 1 1 (10)

the ability to predict free spanning pipes. These analyses

indicate that

Reducing the element length enhances the accuracy of with the stiffening effect of the concrete coating, the

the simulated spans. The lower bound for the element effective span length [10], the effective mass, the

length is governed by the seabed resolution. effective axial force, the static deflection and the end

The suspended catenary has to be taken into account to boundary coefficient. The moment of inertia for the hollow

capture the actual pipeline embedment at the touch- circular pipe is given by

down point.

The predicted span length and height are sensitive to

(11)

the constitutive soil model. An elastic soil model tends 64

to over-estimate the span length. Hence, an elasto-

plastic soil model with bearing resistance based on a and the critical buckling load can be calculated as

bilinear depth profile for the undrained shear strength

is recommended.

1 (12)

The applied residual lay tension has a pronounced

influence on the span predictions. The simulated span

lengths increase with increasing lay tension. This is in where is an end boundary coefficient as well. In addition to

line with the observations reported in [14] on influence the reduced velocity (9), we calculates the stability parameter

of the effective axial force on free spanning pipes.

4 (13)

FATIGUE ANALYSIS FOR SPANS SUBJECTED TO VIV

Once the laydown simulation is performed, the solver for each span, where is the total modal damping ratio,

automatically detects the spans over the entire pipeline route, comprising structural damping, hydrodynamic damping and

like shown on Figure 11. The plots of seabed roughness, soil damping.

pipeline profile, span height and span length clearly indicate the

presence of a long free span starting at KP ~ 1940m. This free

span, with a length of 82 m and a maximum gap of 1.9 m, is

shown on Figure 12, where the color code reflects the span gap.

Figure 12: Long free spanning pipeline vulnerable to VIV Figure 13: Response model for in-line VIV motion

6 Copyright 2013 by ASME

Based on the values of the reduced velocity (9) and the The number of cycles to failure at a stress range is

corresponding stability parameter (13), the in-line vibration defined by an SN-curve of the form

amplitude can be estimated based on the response model shown

in Figure 13, and presented in the Appendix.

(19)

For the (ultra)deep water pipeline, presented in this paper,

the contribution of wave induced velocities is neglected, i.e. we where , are fatigue exponents (i.e. the inverse slope of

assume 0 m/s. The current velocity is typically specified the bi-linear SN curve), , are characteristic fatigue

as a Weibull probability density function [15], which can be strength constants, and

estimated from the 1, 10 and 100 y return period. Since no

detailed metocean data was available, and given the magnitude

of the water depth (exceeding 2400 meter), we have used a 10 (20)

uniform current velocity distribution of 0.1 m/s in this

paper. Under these hydrodynamic conditions, the reduced is the stress at the intersection of the two SN-curves, with the

velocity for the long span, shown in Figure 12, exceeds the number of cycles for which the change in slope appears.

threshold for the onset of in-line VIV: Typically, log is either 6 or 7. The SN-curves may be

determined from dedicated laboratory test data, accepted

fracture mechanics theory, or the values recommended in [16].

1.18 0.909 , (14)

For fatigue calculations, the pipeline design engineer can

This allows calculating the maximum allowable span length either define his own SN curve, or select the SN-curves

, , , from DNV-RP-C203. The latter curves have a

that satisfies , as = 65.8 meter. The in-line

different shape for free corrosion (only one slope) or when

vibration amplitude can be determined from the response model

cathodic protection is present (two-slope curve). For instance,

(shown on Figure 13) as the value of that corresponds with the

the SN curves in seawater when cathodic protection is present

design value of the reduced velocity

are shown on Figure 14. The change in slope occurs at

10 . For the fatigue analysis, presented here, we have used the

(15)

SN-curve from [16], assuming cathodic protection is

present.

with the safety factor for the natural frequency, which

depends on the safety class and whether the span is (very) well

defined or not [8].

The dimensionless vibration amplitude can then be

translated into a stress range

2

(16)

with a safety factor, the reduction factor for the current

flow ratio

(17)

Figure 14: SN curves for cathodically protected pipelines

and the unit stress amplitude, i.e. the stress due to unit The marginal fatigue life capacity against in-line VIV in a

diameter in-line mode shape deflection. According to DNV-RP- single sea-state is calculated by integrating over the long-term

F105 [8], the unit stress amplitude may be approximated as distribution of the current velocity. As we assume a uniform

current velocity distribution, the fatigue life calculation

simplifies to

1

(18)

365 24 3600 (21)

with the mid-span boundary condition coefficient and the

stiffness of steel. For the critical free span shown in Figure 12, this leads to a

remaining fatigue life of 116 years, which is well above the

design life of the flowline.

7 Copyright 2013 by ASME

In addition to the in-line VIV assessment, we can also The onset velocity , is the value for the reduced velocity

constructs the response model for cross-flow VIV, based on the where in-line VIV starts to occur:

current flow ratio (17), and the Keulegan Carpenter number

1.0

0.4

(22) 0.6

, 0.4 1.6

(23)

with the significant wave-induced velocity, and the 2.2

corresponding frequency. Given the significant water depths, 1.6

exceeding 2400 meters, fatigue analysis for both cross-flow

VIV and cross-flow induced VIV can be omitted.

and the end velocity can be written as

CONCLUSIONS

4.5 0.8 1.0

, (24)

In this paper, an integrated numerical framework was presented 3.7 1.0

to predict and identify free spans that may be vulnerable to

fatigue damage caused by vortex induced vibrations (VIV). An The reduced velocities for the other two points indicated in

elegant and efficient algorithm was introduced to simulate Figure 13 are given by

offshore pipeline installation on an uneven seabed. Once the

,

laydown simulation has been completed, the free spans can be , 10 , (25)

automatically detected.

When the fatigue screening for both in-line and cross-flow VIV ,

, , 2

indicates that a particular span may be prone to vortex induced (26)

vibrations, a detailed fatigue analysis is required. SAGE Profile

offers a DNV-RP-F105 span check, which covers fatigue where , and , are the corresponding vibration amplitudes

screening (in-line VIV, cross flow VIV and direct wave action)

and more detailed fatigue analysis. , ,

max 0.18 1 ; (27)

1.2

When free spans are prone to VIV, amplitude response models

are constructed to predict the maximum steady state VIV and

amplitudes. The vibration amplitudes are translated into

corresponding stress ranges, which then provide an input for ,

the fatigue analysis. 0.13 1

1.8 (28)

A case study from the offshore industry was presented. For a These amplitude values depend on the reduction factors

deepwater pipeline in the Gulf of Mexico, the remaining fatigue 0 , 1 and 0 , 1 who account

capacity of a long slender span subjected to VIV was analyzed for the effect of the turbulence intensity and the angle of

using this span check. attack ( , in radiance) for the flow [8].

This powerful capability provides a quick and easy tool to Also note that DNV-RP-F105 introduces an additional

evaluate the severity of free spans for a given pipeline route, reduction function to account for reduced in-line VIV in wave

and hence can save a tremendous amount of time and money dominated conditions:

associated with seabed rectification.

0.0 for 0.5

0.5

APPENDIX: RESPONSE MODEL FOR IN-LINE VIV for 0.5 0.8

0.3 (29)

1.0 for 0.8

The in-line response of a pipeline span in current dominated

conditions (like the one shown on Figure 12) is associated with

either alternating or symmetric vortex shedding. Contributions Thus, if 0.5, in-line VIV may be ignored.

from the first instability region and the second instability region

are included in the response model proposed in [8]. This

response model, schematically shown on Figure 13, can be

constructed based on the design value of the stability parameter

, where is a safety factor.

8 Copyright 2013 by ASME

REFERENCES

[1] Morison J.R., OBrien M.P., Johnson J.W. and Schaaf

S.A., The Forces Exerted by Surface Waves on Piles,

Journal of Petroleum Technology, vol. 189, pp. 149-154

(1950)

[2] Van den Abeele F. and Vande Voorde J., Stability of

Offshore Pipelines in Close Proximity to the Seabed,

Proceedings of the 6th Pipeline Technology Conference,

Hannover, Germany (2011)

[3] King R., A Review of Vortex Shedding Research and its

Application, Ocean Engineering, voL. 4, pp. 141-172

(1977)

[4] Sarpkaya T., Vortex Induced Vibrations: a Selective

Review, Journal of Applied Mechanics, vol. 46(2), pp.

241-258 (1979)

[5] Goswami I., Scanlan R.H. and Jones N.P., Vortex Induced

Vibration of Circular Cylinders: Experimental Data and

New Models, Journal of Engineering Mechanics, vol. 119

(11), pp. 2270-2302 (1993)

[6] Gabbai R.D. and Benaroya H., An Overview of Modelling

and Experiments of Vortex Induced Vibrations for Circular

Cylinders, Journal of Sound and Vibrations, vol. 282, pp.

575-919 (2005)

[7] Fortaleza R., Analysis of Phenomenological Models of

Vortex Induced Vibrations, Proceedings of the 30th ASME

Conference on Ocean, Offshore and Arctic Engineering,

OMAE2011-49403 (2011)

[8] Det Norske Veritas, Recommended Practice on Free

Spanning Pipelines, DNV-RP-F105 (2006)

[9] Fyrileiv O., Mork K., Chezhian M. and Nielsen F.G.,

Updated Free Span Procedure DNV-RP-F105: Ormen

Lange Experience, Journal of Pipeline Engineering, Q2,

pp. 81-94 (2006)

[10] Bai Y. and Bai Q., Pipelines and Risers, Chapter 34:

Installation Design, pp. 597-636 (2005)

[11] Witgens J.F., Falepin H. and Stephan L., New Generation

Pipeline Analysis Software, Offshore Pipeline Technology,

OPT 2006

[12] Van den Abeele F. and Denis R., Numerical Modelling and

Analysis for Offshore Pipeline Design, Installation and

Operation, Journal of Pipeline Engineering, Q4, pp. 273-

286 (2011)

[13] Aubeny C.P., Shi H. and Murf J.D., Collapse Loads for a

Cylinder Embedded in Trench in Cohesive Soil, Inter-

national Journal of Geomechanics, vol. 5(4), pp. 320-325

(2005)

[14] Hagen O., Mork K.J., Nielsen F.G. and Soreide T.,

Evaluation of Free Spanning Design in a Risk Based

Perspective, Proceedings of the 22nd Conference on

Offshore Mechanics and Arctic Engineering, OMAE-

37419 (2003)

[15] Fyrileiv O., Aronsen K. and Mork K., DNV FatFree

Verification Document, Report No. 2000-3283 (2010)

[16] Det Norske Veritas, Recommended Practice on Fatigue

Design of Offshore Steel Structures, DNV-RP-C203

(2010)

9 Copyright 2013 by ASME

Vous aimerez peut-être aussi

- Subsea Rigid Pipelines – Methods of InstallationD'EverandSubsea Rigid Pipelines – Methods of InstallationÉvaluation : 5 sur 5 étoiles5/5 (1)

- HW3 SolutionsDocument15 pagesHW3 Solutionsellie<3100% (1)

- Subsea Pipeline Design, Analysis, and InstallationD'EverandSubsea Pipeline Design, Analysis, and InstallationÉvaluation : 3 sur 5 étoiles3/5 (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Aj30 Reporttow, SeafasteningDocument64 pagesAj30 Reporttow, Seafasteningsabah8800100% (7)

- Equilibrium Statics ProblemsDocument10 pagesEquilibrium Statics ProblemsTheAznPas encore d'évaluation

- Proctor Standard Soil CompactionDocument11 pagesProctor Standard Soil CompactionAmin Saufi100% (3)

- Opt 2008 Advanced Deepwater Spool Analysis Paper 27-02-08Document28 pagesOpt 2008 Advanced Deepwater Spool Analysis Paper 27-02-08hiyeonPas encore d'évaluation

- Copedi - Design of Subsea Rigid Pipelines - The Free Span Problem PDFDocument32 pagesCopedi - Design of Subsea Rigid Pipelines - The Free Span Problem PDFDonald.KPas encore d'évaluation

- Mechanics of Offshore Pipelines, Volume 2: Buckle Propagation and ArrestD'EverandMechanics of Offshore Pipelines, Volume 2: Buckle Propagation and ArrestPas encore d'évaluation

- HSE Report On Mooring IntegrityDocument313 pagesHSE Report On Mooring IntegritysanumajPas encore d'évaluation

- Designation: E1867 13Document5 pagesDesignation: E1867 13Lupita RamirezPas encore d'évaluation

- Numerical Modelling of Vortex Induced VibrationsDocument6 pagesNumerical Modelling of Vortex Induced VibrationscteranscribdPas encore d'évaluation

- Hydrodynamic Forces On Subsea Pipelines - KarremanDocument6 pagesHydrodynamic Forces On Subsea Pipelines - KarremanAlberto darianPas encore d'évaluation

- Class 10 Free Span AnalysisDocument37 pagesClass 10 Free Span AnalysisLK AnhDungPas encore d'évaluation

- Class 10 - Free Span AnalysisDocument37 pagesClass 10 - Free Span AnalysisM R Patraputra100% (1)

- Free Span Analysis PDFDocument57 pagesFree Span Analysis PDFJiggyMHT05 -Pas encore d'évaluation

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsD'EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsPas encore d'évaluation

- 6 - NRG - Free SpanDocument23 pages6 - NRG - Free SpanBalanPas encore d'évaluation

- Case Studies in Pipeline Free Span FatigueDocument10 pagesCase Studies in Pipeline Free Span FatiguejoaogularPas encore d'évaluation

- UMF GN04 Issue 1 Free Span AnalysisDocument5 pagesUMF GN04 Issue 1 Free Span AnalysiszulikramPas encore d'évaluation

- 2D Pipeline Bottom Roughness - Mochammad ImronDocument6 pages2D Pipeline Bottom Roughness - Mochammad ImronLK AnhDungPas encore d'évaluation

- Choi 2000 Free Spanning Analysis of Offshore PipelinesDocument14 pagesChoi 2000 Free Spanning Analysis of Offshore Pipelinesbello imamPas encore d'évaluation

- Iors 2013Document35 pagesIors 2013jeedanPas encore d'évaluation

- Thermal Buckling Comparative Analysis Using Different FE Tools 01Document4 pagesThermal Buckling Comparative Analysis Using Different FE Tools 01Waldek BanasiakPas encore d'évaluation

- VIV Span EngineeringDocument15 pagesVIV Span EngineeringDianoDePas encore d'évaluation

- Model Pipe Resting On The Seabed Floor - AutoPIPE - Pipe Stress and Vessel Design - Wiki - Pipe Stress and Vessel Design - Bentley CommunitiesDocument7 pagesModel Pipe Resting On The Seabed Floor - AutoPIPE - Pipe Stress and Vessel Design - Wiki - Pipe Stress and Vessel Design - Bentley CommunitiesLK AnhDungPas encore d'évaluation

- Z-Subsea Free Span & VIVDocument2 pagesZ-Subsea Free Span & VIVxiaoPas encore d'évaluation

- Scour Mechanism Detection and Mitigation For Subsea Pipeline IntegrityDocument14 pagesScour Mechanism Detection and Mitigation For Subsea Pipeline Integritymarcelohtz3136Pas encore d'évaluation

- The Safe Design of Hot On Bottom PipelinesDocument26 pagesThe Safe Design of Hot On Bottom PipelinesZadeh NormanPas encore d'évaluation

- Static Analysis Report Rev-A PDFDocument16 pagesStatic Analysis Report Rev-A PDFbee4manuPas encore d'évaluation

- Natural Frequency Determination of Offshore Free Spanning PipelineDocument18 pagesNatural Frequency Determination of Offshore Free Spanning PipelineashutoshPas encore d'évaluation

- JEE309 Assignment3 OnBottomStabilityDocument2 pagesJEE309 Assignment3 OnBottomStabilityAnwarul Shafiq AwalludinPas encore d'évaluation

- LOTOS SIWZ A1-3 Z12 112996-EnG-RPT-00003 R02 IFC Pipeline Installation AnalysisDocument33 pagesLOTOS SIWZ A1-3 Z12 112996-EnG-RPT-00003 R02 IFC Pipeline Installation AnalysisJP EDSPas encore d'évaluation

- Soil Axial Resistance of A PipelineDocument3 pagesSoil Axial Resistance of A PipelineFemi Richard FakoyaPas encore d'évaluation

- Free Spanning Analysis of Offshore PipelinesDocument14 pagesFree Spanning Analysis of Offshore PipelinesMaringan JuliverPas encore d'évaluation

- Otc 21575Document7 pagesOtc 21575Mintu ChoudhuryPas encore d'évaluation

- SAGE Profile V6.3.2 User Manual - Volume 2Document73 pagesSAGE Profile V6.3.2 User Manual - Volume 2GodwinPas encore d'évaluation

- Evaluating Natural Frequency of Multi-Spanning Offshore Pipelines.Document11 pagesEvaluating Natural Frequency of Multi-Spanning Offshore Pipelines.Hasan MohdPas encore d'évaluation

- Pipeline Stabilisation Using Pre-Trenching and Sand BackfillDocument8 pagesPipeline Stabilisation Using Pre-Trenching and Sand BackfillDonny HarmokoPas encore d'évaluation

- Lateral BucklingDocument36 pagesLateral Bucklingrsb72Pas encore d'évaluation

- Upheaval Buckling of Pipelines PDFDocument13 pagesUpheaval Buckling of Pipelines PDFISRAEL PORTILLOPas encore d'évaluation

- 286 Oral WED 1B 04Document6 pages286 Oral WED 1B 04Guomin JiPas encore d'évaluation

- Flexible Jumper Design PremiseDocument12 pagesFlexible Jumper Design PremiseAgus BudionoPas encore d'évaluation

- Lazy AssignmentDocument5 pagesLazy Assignmentthefoot39Pas encore d'évaluation

- 1981 OTC 4067 PalmerDocument8 pages1981 OTC 4067 PalmerVeena S VPas encore d'évaluation

- 14 - NRG - Pipe Installation - Davit LiftDocument16 pages14 - NRG - Pipe Installation - Davit LiftBalanPas encore d'évaluation

- Omae2009-79778 - Advanced Dynamic Stability AnalysisDocument13 pagesOmae2009-79778 - Advanced Dynamic Stability AnalysisschpiplikPas encore d'évaluation

- 4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineDocument1 page4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineLorenaPas encore d'évaluation

- Catenary Cation of Cables PDFDocument153 pagesCatenary Cation of Cables PDFPrashanth Talkad Rajagopal100% (1)

- Wall Thickness Calculation of Offshore PipelinesDocument1 pageWall Thickness Calculation of Offshore PipelinesAlvin SmithPas encore d'évaluation

- Aspect-96-155 Lateral Buckling PalmerDocument20 pagesAspect-96-155 Lateral Buckling PalmerJuan Roberto López Betanzos100% (2)

- 8 - NRG - Pipeline Protection - AnchorDocument38 pages8 - NRG - Pipeline Protection - AnchorBalanPas encore d'évaluation

- Pipeline BucklingDocument14 pagesPipeline Bucklingmicael_89100% (1)

- World Pipelines Dec 14 - Specialised Services in AustraliaDocument5 pagesWorld Pipelines Dec 14 - Specialised Services in AustraliaUyavie ObonnaPas encore d'évaluation

- Mathcad - DevelopmentDocument4 pagesMathcad - Developmenttheo lucasPas encore d'évaluation

- Fundamentals of S Lay and Engineering Analysis Using OFFPIPE GEP PDFDocument98 pagesFundamentals of S Lay and Engineering Analysis Using OFFPIPE GEP PDFolalekan100% (1)

- 17 - On-Bottom Stability PDFDocument25 pages17 - On-Bottom Stability PDFSaid Ahmed SalemPas encore d'évaluation

- Free Span Design According To The DNV-RP-F105 For Free Spanning PipelinesDocument24 pagesFree Span Design According To The DNV-RP-F105 For Free Spanning PipelinesconanbhPas encore d'évaluation

- Fitness-For-Service Analysis of Skelp-End Welds in Spiral PipesDocument9 pagesFitness-For-Service Analysis of Skelp-End Welds in Spiral PipesMarcelo Varejão CasarinPas encore d'évaluation

- Manual Calculation For Touchdown Distance, Suspended LengthDocument9 pagesManual Calculation For Touchdown Distance, Suspended LengthkarthickPas encore d'évaluation

- 2-Trench Effect On The Fatigue Life of A SCR - Y.T.KimDocument15 pages2-Trench Effect On The Fatigue Life of A SCR - Y.T.KimYoungtae KimPas encore d'évaluation

- SAGE Profile V6.3.2 User Manual - Volume 1Document119 pagesSAGE Profile V6.3.2 User Manual - Volume 1Godwin100% (1)

- BAI Free Spanning PipelineDocument42 pagesBAI Free Spanning PipelineElendu Emmanuel ChigoziePas encore d'évaluation

- Project Brief For OrcaflexDocument4 pagesProject Brief For OrcaflexyogacruisePas encore d'évaluation

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsD'EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsPas encore d'évaluation

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityD'EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityPas encore d'évaluation

- OTC-2606-MS - Close For Fatigue Expression For Offshore StructureDocument12 pagesOTC-2606-MS - Close For Fatigue Expression For Offshore StructuregenmikPas encore d'évaluation

- Algoritma Genetika Dalam MatlabDocument94 pagesAlgoritma Genetika Dalam MatlabTomo Siagian50% (2)

- FatigueDocument116 pagesFatigueSezgin BayrakPas encore d'évaluation

- Induced Vibrations Using Wake Oscillator Model Comparison On 2d Response With ExperimentsDocument7 pagesInduced Vibrations Using Wake Oscillator Model Comparison On 2d Response With ExperimentsgenmikPas encore d'évaluation

- Design Analysis of Deep Water RisersDocument15 pagesDesign Analysis of Deep Water RisersgenmikPas encore d'évaluation

- Analyzing Random Vibration FatigueDocument4 pagesAnalyzing Random Vibration FatigueJos BecerraPas encore d'évaluation

- Genetic Algorithms TutorialDocument40 pagesGenetic Algorithms TutorialMichaele ErmiasPas encore d'évaluation

- Analysis and Control of Marine Cable SystemsDocument283 pagesAnalysis and Control of Marine Cable SystemsgenmikPas encore d'évaluation

- Statistics of ExtremeDocument62 pagesStatistics of ExtremegenmikPas encore d'évaluation

- 2005 - Omae - Influence of Pressure in Pipeline Design - Effective Axial Force PDFDocument8 pages2005 - Omae - Influence of Pressure in Pipeline Design - Effective Axial Force PDFgenmikPas encore d'évaluation

- Calculus of VariationsDocument61 pagesCalculus of VariationsPedro Palacios AvilaPas encore d'évaluation

- Intro To Lagrangian & Hamitonian Mechanics SJA Malham PDFDocument87 pagesIntro To Lagrangian & Hamitonian Mechanics SJA Malham PDFfractalgeoPas encore d'évaluation

- Calculus of VariationsDocument61 pagesCalculus of VariationsPedro Palacios AvilaPas encore d'évaluation

- Advances in Steel Catenary Riser DesignDocument5 pagesAdvances in Steel Catenary Riser Designdfal13Pas encore d'évaluation

- Assessing SURF Technologies For Deepwater Oil and Gas ExplorationDocument10 pagesAssessing SURF Technologies For Deepwater Oil and Gas ExplorationgenmikPas encore d'évaluation

- Hamiltons PrincipleDocument21 pagesHamiltons PrinciplegenmikPas encore d'évaluation

- Multiple ScalesDocument8 pagesMultiple ScalesgenmikPas encore d'évaluation

- OrcafAPI ManualDocument39 pagesOrcafAPI ManualgenmikPas encore d'évaluation

- Extrem Value TheoremDocument25 pagesExtrem Value TheoremgenmikPas encore d'évaluation

- Wave SpectraDocument15 pagesWave SpectraPNPas encore d'évaluation

- Modal AnalysisDocument10 pagesModal AnalysisgenmikPas encore d'évaluation

- Belfroid 2007 FlowDocument9 pagesBelfroid 2007 FlowgenmikPas encore d'évaluation

- Optimum Design of Marine RisersDocument6 pagesOptimum Design of Marine RisersgenmikPas encore d'évaluation

- Omae2006 92334 PDFDocument9 pagesOmae2006 92334 PDFgenmikPas encore d'évaluation

- Reliability And: Quality ControlDocument18 pagesReliability And: Quality ControlgenmikPas encore d'évaluation

- TCET FE Applied Physics - I (2018-2019)Document308 pagesTCET FE Applied Physics - I (2018-2019)Kevin100% (1)

- Fusha Magnetike Dhe Forca MagnetikeDocument40 pagesFusha Magnetike Dhe Forca Magnetikefatjonmusli2016Pas encore d'évaluation

- Wichita Clutch Spring Set BrakesDocument12 pagesWichita Clutch Spring Set Brakesayman akrab100% (1)

- Lab 03Document4 pagesLab 03Ahmed zia tahirPas encore d'évaluation

- Paper-2: Cumulative Test-1 (Ct-1)Document44 pagesPaper-2: Cumulative Test-1 (Ct-1)vikram2002Pas encore d'évaluation

- Multiple Choice First Assessment Chapter 1 3Document3 pagesMultiple Choice First Assessment Chapter 1 3Frhea mae AlcaydePas encore d'évaluation

- About Methyl OrangeDocument3 pagesAbout Methyl OrangeMerrene Bright Divino JudanPas encore d'évaluation

- MIT Radiaton Lab Series V10 Waveguide HandbookDocument442 pagesMIT Radiaton Lab Series V10 Waveguide HandbookkgrhoadsPas encore d'évaluation

- 2SV888 DatasheetDocument4 pages2SV888 DatasheetsegalignoPas encore d'évaluation

- Chap2 2 Aufbau+PrincipleDocument29 pagesChap2 2 Aufbau+PrincipleMuizz ZainuddinPas encore d'évaluation

- Blowback Bolt WeightsDocument4 pagesBlowback Bolt Weightsorions_hammer100% (2)

- D5229 D5229MDocument18 pagesD5229 D5229MEngr Khalil AkramPas encore d'évaluation

- Kinetics of Catalytic Reactions: (Ch.5 Adsorption and Desorption Process)Document16 pagesKinetics of Catalytic Reactions: (Ch.5 Adsorption and Desorption Process)comeon2amPas encore d'évaluation

- Units, Dimensions and Measurements MCQ (Free PDF) - Objective Question Answer For Units, Dimensions and Measurements Quiz - Download Now!Document27 pagesUnits, Dimensions and Measurements MCQ (Free PDF) - Objective Question Answer For Units, Dimensions and Measurements Quiz - Download Now!Vinayak SavarkarPas encore d'évaluation

- CE 575-Lecture-4 (Partially Prestressed Concrete Beams)Document33 pagesCE 575-Lecture-4 (Partially Prestressed Concrete Beams)Yasser Alghrafy50% (2)

- CBSE Class 12 Physics Unit - 1 Syllabus: Electrostatics: Chapter - 1: Electric Charges and FieldsDocument2 pagesCBSE Class 12 Physics Unit - 1 Syllabus: Electrostatics: Chapter - 1: Electric Charges and FieldsRitesh SoniPas encore d'évaluation

- Design and Fabrication of Pedal Operated Water PumpDocument14 pagesDesign and Fabrication of Pedal Operated Water PumpNagesh Sunny67% (3)

- AFS 2211 - FUNDAMENTALS OF FOOD CHEMISTRY - Water PDFDocument40 pagesAFS 2211 - FUNDAMENTALS OF FOOD CHEMISTRY - Water PDFderrickPas encore d'évaluation

- Proof of Earth's ShapeDocument15 pagesProof of Earth's ShapeVinayaka RamPas encore d'évaluation

- Differentiation Formulas Integration FormulasDocument7 pagesDifferentiation Formulas Integration FormulasnirobPas encore d'évaluation

- Semyon Neskorodev+The Elbows Technique in Wing Chun PDFDocument63 pagesSemyon Neskorodev+The Elbows Technique in Wing Chun PDFAlexJKDCQCPas encore d'évaluation

- Coupled PendulumDocument5 pagesCoupled PendulumSubhasis PandaPas encore d'évaluation

- Irf 9520 NDocument9 pagesIrf 9520 NislaPas encore d'évaluation

- Grain Refinement and Nucleation Processes in Aluminium AlloysDocument204 pagesGrain Refinement and Nucleation Processes in Aluminium AlloysbountymaniPas encore d'évaluation

- Assignment in Power SystemDocument5 pagesAssignment in Power SystemRhiza NavallascaPas encore d'évaluation

- Feb 3 Questions Nuclear WasteDocument4 pagesFeb 3 Questions Nuclear WastedcudfhiudfiuPas encore d'évaluation