Académique Documents

Professionnel Documents

Culture Documents

Design, Fabrication and Exprimental Analysis of Polymer Composites

Transféré par

VinodNKumarCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design, Fabrication and Exprimental Analysis of Polymer Composites

Transféré par

VinodNKumarDroits d'auteur :

Formats disponibles

DESIGN, FABRICATION AND EXPRIMENTAL ANALYSIS OF POLYMER

COMPOSITES

Polymer Matrix Composites are being increasingly employed as structural materials in civil,

military, aerospace, automotive and industrial applications where the weight reduction can

contribute toward saving in fuel and other materials. Acrylonitrile-Butadiene-Styrene (ABS) is a

widely used thermoplastic. ABS polymers have a high toughness, satisfactory rigidity, and good

resistance to heat, chemical, and environmental stress cracking. Moulded articles with high

dimensional stability and good surface quality can be produced by simple processing technique.

It is essential to carryout investigations to characterize ABS thermoplastic composites for its

wear behavior for tribological applications. Hence it is required to correlate the influence of

percent weight and grain size of reinforcements to the wear rate and friction coefficient.

In this investigation, different test specimens are fabricated with extrusion and injection

moulding processes. Experiments are conducted on pure ABS thermoplastic composites and

Glass fibre (E-Glass) filled ABS test specimens using pin-on-disc equipment under dry sliding

condition condition to determine wear and frictional coefficient and to analyze the wear

characteristics from the above experimental results. Experiments are planned using design of

experiments technique and wear tests are conducted as per Taguchis orthogonal array (L27)

technique.

Objective of the Present Study

The following objectives have been benefit for this project work:

To design the pure ABS composite and ABS filled with Glass fibre. The designing process

and materials selected has to be in accordance with ASTM standards.

To prepare composites of composition such as matrix resin and filler percentages i.e. 0%, 3%

and 5%, 10% and 15% and fabricate the composites by extrusion and injection molding

processes.

To perform the mechanical behavior of the ABS matrix and filled with glass fibre.

To evaluate the tribological properties by using pin-on-disc equipment under dry sliding

conditions on all the above composite specimens to determine the wear and friction.

Experiments are planned using Design of Experiments (DOE) technique and Wear tests are

conducted as per Taguchis orthogonal array on pure ABS, Glass fibre filled ABS under dry

sliding conditions.

Results can be analyzed using Minitab statistical software.

Besides the above all the objective is to develop new class of composites by incorporating Glass

fibre phases into ABS polymeric resin. Also this work is expected to introduce a new class of

polymer composite that might find tribological applications.

Methodology

In order to realize with the stated objectives, following methodology is adopted during the

present research work.

The required specimen for determining wear will be fabricated by Extrusion and Injection

molding processes are to be carried at GLS Polymers pvt Ltd, Peenya Indl area, Bangalore.

The mechanical behavior (Tensile, Hardness and Flexural) of the ABS matrix with different

filler percentages i.e., 0%, 3% and 5%, 10% and 15% composites will be carried at Brakes

India Pvt Ltd, Sundaram Polymer Division, Mysore.

The friction and wear tests will be carried at The Centre for Material Research, The National

Institute of Engineering, Mysore.

Screening wear tests are performed in ordered to establish the range of different tribological

parameters viz., load, sliding speed and sliding distance.

Experiments are planned using Design of Experiments (DOE) technique.

Wear tests are conducted as per Taguchis orthogonal array (L27) on pure ABS and Glass

fibre filled ABS under different test conditions.

Experimental results are to be analyzed by Minitab 14 statistical software, the tribological

behavior of pure ABS compared with Glass fibre filled ABS under dry sliding and lubricating

conditions.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- 01 - Codes ListDocument6 pages01 - Codes Listmanish kumarPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Packaging GuidelineDocument38 pagesPackaging GuidelineNazzneen AmeerPas encore d'évaluation

- Most Common Cause of Bearing FailureDocument7 pagesMost Common Cause of Bearing FailureTim KuPas encore d'évaluation

- Barriers To International TradeDocument3 pagesBarriers To International TradeVinodNKumarPas encore d'évaluation

- Janat Shah Chapter 2Document41 pagesJanat Shah Chapter 2RajanSharma100% (3)

- Improving APQP Process For Effective Program Execution: Dele AwofalaDocument31 pagesImproving APQP Process For Effective Program Execution: Dele AwofalaSelvaraj SPas encore d'évaluation

- Sa 980 P 11434 Cs Swing Check Valve Rev. t02Document3 pagesSa 980 P 11434 Cs Swing Check Valve Rev. t02altipatlar100% (1)

- Standard Operating ProcedureDocument23 pagesStandard Operating Procedurezhangj5Pas encore d'évaluation

- (BS 5628-3-2005) - Code of Practice For The Use of Masonry. Materials and Components, Design and WorkmanshipDocument136 pages(BS 5628-3-2005) - Code of Practice For The Use of Masonry. Materials and Components, Design and WorkmanshipStacy Wilson100% (1)

- Solusoft SE1 Liq - e TIDocument3 pagesSolusoft SE1 Liq - e TIekoyonatanPas encore d'évaluation

- Scrap MetalDocument23 pagesScrap Metalhermankl73Pas encore d'évaluation

- NCP 26 For PGPCM of NICMARDocument76 pagesNCP 26 For PGPCM of NICMARGunjan JaiswalPas encore d'évaluation

- Waste Segregator ReportDocument33 pagesWaste Segregator ReportVinodNKumar25% (4)

- Report Weed Removing MachDocument18 pagesReport Weed Removing MachVinodNKumarPas encore d'évaluation

- Design and Implementation of Automatic Solar Grass CutterDocument5 pagesDesign and Implementation of Automatic Solar Grass CutterVinodNKumarPas encore d'évaluation

- The Recruitment, Selection and Training of People at Arcadia An Arcadia Case StudyDocument12 pagesThe Recruitment, Selection and Training of People at Arcadia An Arcadia Case StudyVinodNKumarPas encore d'évaluation

- 4 FabricationDocument14 pages4 FabricationVinodNKumarPas encore d'évaluation

- Dream Focus Solutions PH - 8951379407, 8951379452 MysuruDocument1 pageDream Focus Solutions PH - 8951379407, 8951379452 MysuruVinodNKumarPas encore d'évaluation

- Design and Fabrication of 3 Way Dumping TipperDocument2 pagesDesign and Fabrication of 3 Way Dumping TipperVinodNKumarPas encore d'évaluation

- General Linear Model: ABS +10%GF Versus Sliding Spee, Load, N, Sliding DistanceDocument12 pagesGeneral Linear Model: ABS +10%GF Versus Sliding Spee, Load, N, Sliding DistanceVinodNKumarPas encore d'évaluation

- InterviewDocument12 pagesInterviewVinodNKumarPas encore d'évaluation

- Hamsa LekhaDocument30 pagesHamsa LekhaVinodNKumarPas encore d'évaluation

- Flower Vase Table Cloth Projector Screen Water Bottle 8 Tube LightsDocument1 pageFlower Vase Table Cloth Projector Screen Water Bottle 8 Tube LightsVinodNKumarPas encore d'évaluation

- Login ID - MYS9225 PW - Lovelife10 or Lovelife10: YashtelDocument1 pageLogin ID - MYS9225 PW - Lovelife10 or Lovelife10: YashtelVinodNKumarPas encore d'évaluation

- Mechanical Property SpecimensDocument1 pageMechanical Property SpecimensVinodNKumarPas encore d'évaluation

- Kannada Films From 06 To 16Document5 pagesKannada Films From 06 To 16VinodNKumarPas encore d'évaluation

- Composite Materials DetailsDocument6 pagesComposite Materials DetailsVinodNKumarPas encore d'évaluation

- Mysore Opera House: - AddressDocument1 pageMysore Opera House: - AddressVinodNKumarPas encore d'évaluation

- Institution Setup CostDocument1 pageInstitution Setup CostVinodNKumarPas encore d'évaluation

- Flower Vase Table Cloth Projector Screen Water Bottle 8 TubelightsDocument1 pageFlower Vase Table Cloth Projector Screen Water Bottle 8 TubelightsVinodNKumarPas encore d'évaluation

- Assignment Solution RMSDocument2 pagesAssignment Solution RMSVinodNKumarPas encore d'évaluation

- DA14 - Design and Analysis of A Shock AbsorberDocument1 pageDA14 - Design and Analysis of A Shock AbsorberVinodNKumarPas encore d'évaluation

- Tourism in A NationDocument3 pagesTourism in A NationzsoiePas encore d'évaluation

- Traditional Underpinning Apr 09Document3 pagesTraditional Underpinning Apr 09imdgamePas encore d'évaluation

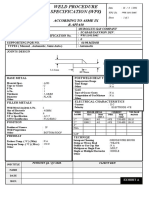

- Weld Procedure Specification (WPS) : According To Asme Ix &Document1 pageWeld Procedure Specification (WPS) : According To Asme Ix &Mina Roger SamyPas encore d'évaluation

- Definition of BiopharmaceuticsDocument3 pagesDefinition of BiopharmaceuticsvafaashkPas encore d'évaluation

- Cut Off Machines EnglishDocument8 pagesCut Off Machines EnglishMelissa SanchezPas encore d'évaluation

- Master Records & Material Master RecordsDocument8 pagesMaster Records & Material Master RecordsAshaPandaPas encore d'évaluation

- Submitted By: Haritha K Roll No: 4912 (Mcom 3 Semester) : Topic: DumpingDocument6 pagesSubmitted By: Haritha K Roll No: 4912 (Mcom 3 Semester) : Topic: DumpingJohn HonnaiPas encore d'évaluation

- Macro Test Details PDFDocument5 pagesMacro Test Details PDFNikesh Koli100% (1)

- Gear Solutions May 2011 Company Profile PDFDocument3 pagesGear Solutions May 2011 Company Profile PDFmarijaPas encore d'évaluation

- MGT4 1Document2 pagesMGT4 1InserahPas encore d'évaluation

- Igloo Plant Report FINAL VERSIONDocument29 pagesIgloo Plant Report FINAL VERSIONAhsan Azhar Shopan100% (2)

- Steel PlatesDocument36 pagesSteel PlatesAntónio Grade100% (1)

- 703 07s 05 SCMDocument12 pages703 07s 05 SCMDiana Leonita FajriPas encore d'évaluation

- Form Work, Jump Form TechniqueDocument55 pagesForm Work, Jump Form TechniquePrashant SunagarPas encore d'évaluation

- OSCM - Ch1 - Introduction To OSCMDocument67 pagesOSCM - Ch1 - Introduction To OSCMshakilhmPas encore d'évaluation

- 2BUHLER Lost CoreDocument20 pages2BUHLER Lost CoreAngel LagrañaPas encore d'évaluation

- Kaizen BudgetingDocument14 pagesKaizen BudgetingThasni MKPas encore d'évaluation

- Corrosion and Creep PhenomenonDocument3 pagesCorrosion and Creep PhenomenonZaidee AliasPas encore d'évaluation