Académique Documents

Professionnel Documents

Culture Documents

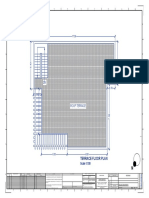

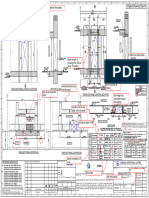

1000 7-7 31-5 Pag 5ZL 40 12 112 A-28510

Transféré par

Kauê CarvalhoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1000 7-7 31-5 Pag 5ZL 40 12 112 A-28510

Transféré par

Kauê CarvalhoDroits d'auteur :

Formats disponibles

1 2 3 4 5 6 7 8 9 10 11 12

Direction of Rotation Direction of Air-flow

A Leading Tip3.4 8 A

Trailing Tip16.7 8

B B

Trailing Base49 4

Leading Base24 4

1000 h14

C C

Mounting Side

D D

107.8

E A E

12

Bolt guide: Impeller weight guide:

5 Bolts @ M6x25 DIN 912 BCD 90 4.95 kg

7 Bolts @ M6x30 DIN 933 BCD 174

3.30

Part number: Part descriction: Quantity: Material:

15100200018 5ZL/PAG Fan Blade 7 PAG

F 21070708109 Z-Retaining plate/7/000075 2 EN AC-47100

24000708900 Boss/1129040/75 1 EN AC-47100

51000000002 Z-Pitch Setting Pin/PAGI 7 PAGI

*Not indicated tolerances and balancing grade are applied unless otherwise specified in the customer request field

40 Not indicated machine surface texture* Not indicated MWI geometrical product specification* Not indicated plastic mould tolerance* Not indicated machine taper angle tolerance*

ISO 2768-c 0,025

112 General limits and fits according to DS/EN 20286-2 Hub plates:

Not indicated aluminium mould tolerance* Not indicated machine tolerance*

Ra 1.6

MWI limits and fits within 0,2 mm Datum A: Centerhole diameter location DIN 1688 GTA 13/5 0,2 - 0,5

Boltholes: Position 0,2 to datum A

A Ra 1.6

Keyway surfaces: Hub plate back surface: Flatness 0,3

Not indicated balancing according to*

ISO 1940-1 G 6.3 @ 950Rpm

Not indicated edges*

No sharp edges

Ra 2.5 Drawing no.: Customer request field

Other surfaces: Bosses:

Ra 3.2 28510

Datum A: Mounting recess diameter location

Mounting Dimensions SECTION A-A

Bolthole surfaces:

Ra 6.3 Datum B: Mounting flange back surface location

Boltholes: Position 0,2 to datum A Multi-Wing International A/S

Not indicated machine bore and keyway tolerance*

SCALE 1 : 3 Boss and hub aluminium material: Centerhole diameter: Coaxial 0,2 to datum A Impeller code:

Exterior boss diameter: Coaxial 0,2 to datum A Staktoften 16

DK-2950 Vedbaek 1000/7-7/31.5/PAG/5ZL/40/12/112/A

EN AC-44100 Gravity die casting Mounting flange diameter: Coaxial 0,2 to datum A Denmark Pitch angle can be measured on the blade at - Pitch ref - Projection method:

All bore tolerance up to and including 48. H7 - DS/EN 20286-2 Millimeter keyway standard. Js9 according to BS 4235-1 (Table 1 & 3) EN AC-43000 Gravity die casting Mounting flange back surface: Circular Run-out 0,2 to datum A Tlf: +45 45890133 (if pitch ref is not present and for 2W/3W please contact local MW office)

All bore tolerance over 48. G7 - DS/EN 20286-2 Inch keyway standard. BS46 -1 (table 2) EN AC-47100 High pressure die casting Mounting flange front surface: Parallel 0,2 to datum B Fax: +45 45893133

Tolerance on taper diameter (Large end) +0,05/-0,05 Taper keyway standard for width according to. Js9 according to BS 4235-1 (Table 1 & 3) e-mail: info@multi-wing.com

EN AW-2011 Bar material Boss front surface: Parallel 0,2 to datum B www.multi-wing.com Date: Signature: Scale: Sheet Size

Tolerance on the internal recess. +0,3/-0,0 Taper keyway standard for depth according to. DIN 6888 Boss back surface: Parallel 0,2 to datum B

20/08/15 Jonathan Jorge 1:6 A3

The Designer software is 100 % automatic and provided as-is without any warranty of any kind. Results, provided by the Designer software are shown for informational purpose only. Under no circumstances shall Multi-Wing or its group companies, associates and subsidiary companies be liable for any mistakes in the Designer software or direct, indirect, special,

incidental, or consequential damages resulting from the use, misuse, or inability to use Designer software. This software has been designed to be used by professionals and is NOT suitable and cannot be used by consumers.

This document is the property of Multi-Wing International as and should at any time be kept confidential. It is intended solely for the use of the individual to whom it is addressed and should not be transmitted to any third party in any form.

Vous aimerez peut-être aussi

- Madeleine Ker - TakeoverDocument91 pagesMadeleine Ker - Takeover66677785100% (1)

- Space DynamicsDocument37 pagesSpace Dynamicspurushottam KashyapPas encore d'évaluation

- CAT Ground Engaging ToolsDocument35 pagesCAT Ground Engaging ToolsJimmy Nuñez VarasPas encore d'évaluation

- Sradham ChecklistDocument9 pagesSradham ChecklistpswaminathanPas encore d'évaluation

- NDE Procedure - Radiographic TestingDocument43 pagesNDE Procedure - Radiographic TestingJeganeswaranPas encore d'évaluation

- Project On Stones & TilesDocument41 pagesProject On Stones & TilesMegha GolaPas encore d'évaluation

- BMW Motronic CodesDocument6 pagesBMW Motronic CodesxLibelle100% (3)

- Ricoh 4055 PDFDocument1 280 pagesRicoh 4055 PDFPham Nguyen Hoang Minh100% (1)

- SO2 scrubber package unit layoutDocument1 pageSO2 scrubber package unit layoutAyahKenziePas encore d'évaluation

- Technical drawing dimensionsDocument1 pageTechnical drawing dimensionsUğur BölükbaşıPas encore d'évaluation

- Spectrum: Techno Consultants PVT LTDDocument2 pagesSpectrum: Techno Consultants PVT LTDshubhamoffice007Pas encore d'évaluation

- Issued For Construction: NotesDocument1 pageIssued For Construction: NotesjebripahlaviPas encore d'évaluation

- For Discussion: SpectrumDocument2 pagesFor Discussion: Spectrumshubhamoffice007Pas encore d'évaluation

- Typical General Arrangement Drawing of Box Culvert For NewDocument3 pagesTypical General Arrangement Drawing of Box Culvert For NewRajender Reddy ParnePas encore d'évaluation

- Trommel Frame 2000 Diax2800 LGDocument3 pagesTrommel Frame 2000 Diax2800 LGFelipe Ignacio100% (1)

- 806 Ed MJB 01 4102 R1Document1 page806 Ed MJB 01 4102 R1ManukantShrotriyaPas encore d'évaluation

- Spectrum: Techno Consultants PVT LTDDocument4 pagesSpectrum: Techno Consultants PVT LTDjkchennai2023Pas encore d'évaluation

- For Discussion: SpectrumDocument6 pagesFor Discussion: Spectrumshubhamoffice007Pas encore d'évaluation

- P&id For Bed& Fly Ah SystemDocument3 pagesP&id For Bed& Fly Ah Systemraaj bharathPas encore d'évaluation

- 02a-4 D-Can Xlrteh4300g033850Document1 page02a-4 D-Can Xlrteh4300g033850Daniel PricopPas encore d'évaluation

- 02a-4 D-Can Xlrteh4300g033850Document1 page02a-4 D-Can Xlrteh4300g033850ПавелPas encore d'évaluation

- Spectrum: Techno Consultants PVT LTDDocument4 pagesSpectrum: Techno Consultants PVT LTDshubhamoffice007Pas encore d'évaluation

- Section A-A: Assembly, StairwayDocument2 pagesSection A-A: Assembly, StairwayWilliam VillamizarPas encore d'évaluation

- Ddf101-r0-Mks-typical Road Signs - Regulatory & Mandatory SignsDocument1 pageDdf101-r0-Mks-typical Road Signs - Regulatory & Mandatory Signsrohith eticalaPas encore d'évaluation

- Road signs layout planDocument1 pageRoad signs layout planrohith eticalaPas encore d'évaluation

- Trommel Frame 4500 Diax5200 LGDocument3 pagesTrommel Frame 4500 Diax5200 LGFelipe IgnacioPas encore d'évaluation

- El 01Document1 pageEl 01Faheem ShahzadPas encore d'évaluation

- DC detect and 3 seconds time delay activation circuit simulationDocument1 pageDC detect and 3 seconds time delay activation circuit simulationSaurabh VaidyaPas encore d'évaluation

- For Discussion: SpectrumDocument1 pageFor Discussion: Spectrumshubhamoffice007Pas encore d'évaluation

- 15Document1 page15Albino RibSarPas encore d'évaluation

- Audio 600Document3 pagesAudio 600rea sonerPas encore d'évaluation

- DWG - SLDDRW SR05 PDFDocument1 pageDWG - SLDDRW SR05 PDFluisA1923Pas encore d'évaluation

- 61-Lel-Axp-Pip-Is-0406 SHT 4 of 7Document1 page61-Lel-Axp-Pip-Is-0406 SHT 4 of 7Aravind BabuPas encore d'évaluation

- Sa09c2 Jve 27 XX DR Ce 00002Document9 pagesSa09c2 Jve 27 XX DR Ce 00002ghazi4uPas encore d'évaluation

- Terrace Floor Plan: Scale 1:100Document1 pageTerrace Floor Plan: Scale 1:100Manish MishraPas encore d'évaluation

- SO2 scrubber package unit layoutDocument1 pageSO2 scrubber package unit layoutAyahKenziePas encore d'évaluation

- KDocument27 pagesKcristianPas encore d'évaluation

- Hebri - Revised Culverts 27-05-23Document87 pagesHebri - Revised Culverts 27-05-23RAGHUMS GOWDAPas encore d'évaluation

- General arrangement of underground metro stationDocument1 pageGeneral arrangement of underground metro stationrohitPas encore d'évaluation

- Nagpur Metro-Cn-101&102-Nagpur Metro-Cn-102Document1 pageNagpur Metro-Cn-101&102-Nagpur Metro-Cn-102rohitPas encore d'évaluation

- Thread Insert RecommendationsDocument2 pagesThread Insert RecommendationsrolandPas encore d'évaluation

- Nocturna (Mas Grande)Document4 pagesNocturna (Mas Grande)matiaszloto4118Pas encore d'évaluation

- DW85 OF CUT & COVER. (1)Document1 pageDW85 OF CUT & COVER. (1)kallupahalawan3Pas encore d'évaluation

- Amb-Agcc02-Tun Ce 1002 - P0Document1 pageAmb-Agcc02-Tun Ce 1002 - P0Sugam JainPas encore d'évaluation

- Service Diagram ICONS 9845160072Document3 pagesService Diagram ICONS 9845160072kovács SándorPas encore d'évaluation

- Hy000 B4010 - 0 Pivot Thrust WasherDocument1 pageHy000 B4010 - 0 Pivot Thrust WasherAnyPas encore d'évaluation

- AUD600 Power Supply Rev 3.0.1 SimulationDocument1 pageAUD600 Power Supply Rev 3.0.1 SimulationGianmarco ScarabelloPas encore d'évaluation

- Project Name: 18RRETEPD12430 and Oil Movement Area Units at Rre Installation of Closed Process CondensateDocument4 pagesProject Name: 18RRETEPD12430 and Oil Movement Area Units at Rre Installation of Closed Process CondensateYogesh MittalPas encore d'évaluation

- EL1Document1 pageEL1Faheem ShahzadPas encore d'évaluation

- Compact overview of a boiler systemDocument2 pagesCompact overview of a boiler systemVonstrohePas encore d'évaluation

- 31.25m 4L Concrete Dime DRG - 1Document1 page31.25m 4L Concrete Dime DRG - 1arif_rubinPas encore d'évaluation

- 4L BOx Girder Concrete Dimension DRGDocument1 page4L BOx Girder Concrete Dimension DRGarif_rubinPas encore d'évaluation

- 1 - Carrier - Engine Tier IIIDocument25 pages1 - Carrier - Engine Tier IIIjosue.cq2310Pas encore d'évaluation

- Ddi-2704-R0-Pky-Rc - Details of 28M Span (6 Lane) - Wing (DS)Document1 pageDdi-2704-R0-Pky-Rc - Details of 28M Span (6 Lane) - Wing (DS)rohitPas encore d'évaluation

- Comments P020c30ug01prb Dras Civstrdwg 10032 03 ADocument1 pageComments P020c30ug01prb Dras Civstrdwg 10032 03 AghansaPas encore d'évaluation

- 61-LEL-WHP-PIP-IS-0232 SHT 2Document1 page61-LEL-WHP-PIP-IS-0232 SHT 2Aravind BabuPas encore d'évaluation

- Keyboard DRW 000 AA ECN 10406735Document1 pageKeyboard DRW 000 AA ECN 10406735лол кекPas encore d'évaluation

- S19 - 143 Water Sample Test Point (Cabinet Arrangement)Document1 pageS19 - 143 Water Sample Test Point (Cabinet Arrangement)Sol RogowskiPas encore d'évaluation

- Comau Powertrain technical drawing specificationsDocument1 pageComau Powertrain technical drawing specificationsRobson NerioPas encore d'évaluation

- Pages From SPDocument8 pagesPages From SPHaris PolutanPas encore d'évaluation

- Project Name: 18RRETEPD12430 and Oil Movement Area Units at Rre Installation of Closed Process CondensateDocument3 pagesProject Name: 18RRETEPD12430 and Oil Movement Area Units at Rre Installation of Closed Process CondensateYogesh MittalPas encore d'évaluation

- Annexure_A_SCMS ArchitectureDocument6 pagesAnnexure_A_SCMS Architectureirshadchukkan1Pas encore d'évaluation

- Schedule of Lap Length For ReinforcementDocument1 pageSchedule of Lap Length For Reinforcementchiranjeevimd2991 MDPas encore d'évaluation

- Diagrama Elétrico ZH350+ PLC 9823372100 v05Document36 pagesDiagrama Elétrico ZH350+ PLC 9823372100 v05Rodrigo Augusto TeixeiraPas encore d'évaluation

- Typical Door Elevation - 1 1: Detail - ADocument1 pageTypical Door Elevation - 1 1: Detail - AKumudu PereraPas encore d'évaluation

- 1 Ton Hurricane IGRDocument1 page1 Ton Hurricane IGRVitor OlivettiPas encore d'évaluation

- An Extended Harness Limit in Bulk NanoceramicsDocument8 pagesAn Extended Harness Limit in Bulk NanoceramicsKauê CarvalhoPas encore d'évaluation

- Resistencia Mecanica Tamanho de GraoDocument4 pagesResistencia Mecanica Tamanho de GraoKauê CarvalhoPas encore d'évaluation

- Deformacao Plastica2014Document6 pagesDeformacao Plastica2014Kauê CarvalhoPas encore d'évaluation

- Platic Deformation of Nanocrystalline MaterialsDocument4 pagesPlatic Deformation of Nanocrystalline MaterialsKauê CarvalhoPas encore d'évaluation

- 1000 7-7 31-5 Pag 5ZL 40 12 112 A-28510Document1 page1000 7-7 31-5 Pag 5ZL 40 12 112 A-28510Kauê Carvalho100% (1)

- Gas Turb CatDocument31 pagesGas Turb Catparamjit689792Pas encore d'évaluation

- PDFViewer - JSP 3Document46 pagesPDFViewer - JSP 3Kartik ChaudharyPas encore d'évaluation

- Proposal Anguria Pasta NewDocument24 pagesProposal Anguria Pasta NewNOOR IRDINA HAFIZAH BT TAUPISPas encore d'évaluation

- LKC CS Assignment2Document18 pagesLKC CS Assignment2Jackie LeongPas encore d'évaluation

- LSUBL6432ADocument4 pagesLSUBL6432ATotoxaHCPas encore d'évaluation

- Quaternary Protoberberine Alkaloids (Must Read)Document26 pagesQuaternary Protoberberine Alkaloids (Must Read)Akshay AgnihotriPas encore d'évaluation

- Chap 2 Debussy - LifejacketsDocument7 pagesChap 2 Debussy - LifejacketsMc LiviuPas encore d'évaluation

- Coleman Product PageDocument10 pagesColeman Product Pagecarlozz_96Pas encore d'évaluation

- Application of Fertility Capability Classification System in Rice Growing Soils of Damodar Command Area, West Bengal, IndiaDocument9 pagesApplication of Fertility Capability Classification System in Rice Growing Soils of Damodar Command Area, West Bengal, IndiaDr. Ranjan BeraPas encore d'évaluation

- Lesson 2 Socio Anthropological View of The SelfDocument12 pagesLesson 2 Socio Anthropological View of The SelfAilyn RamosPas encore d'évaluation

- Current Relays Under Current CSG140Document2 pagesCurrent Relays Under Current CSG140Abdul BasitPas encore d'évaluation

- Retaining Wall-Masonry Design and Calculation SpreadsheetDocument6 pagesRetaining Wall-Masonry Design and Calculation SpreadsheetfarrukhPas encore d'évaluation

- Drugs Pharmacy BooksList2011 UBPStDocument10 pagesDrugs Pharmacy BooksList2011 UBPStdepardieu1973Pas encore d'évaluation

- 7890 Parts-Guide APDocument4 pages7890 Parts-Guide APZia HaqPas encore d'évaluation

- 2 - Soil-Only Landfill CoversDocument13 pages2 - Soil-Only Landfill Covers齐左Pas encore d'évaluation

- Oral Nutrition Support NotesDocument28 pagesOral Nutrition Support Notesleemon.mary.alipao8695Pas encore d'évaluation

- Antennas Since Hertz and MarconiDocument7 pagesAntennas Since Hertz and MarconiTaiwo Ayodeji100% (1)

- Motor Wiring Diagram: D.C. Motor ConnectionsDocument1 pageMotor Wiring Diagram: D.C. Motor Connectionsczds6594Pas encore d'évaluation

- 40 26Document3 pages40 26Maxi452Pas encore d'évaluation

- 24.postpartum Period-Physiological Changes in The MotherDocument16 pages24.postpartum Period-Physiological Changes in The MotherHem KumariPas encore d'évaluation

- Maintenance Handbook On Compressors (Of Under Slung AC Coaches) PDFDocument39 pagesMaintenance Handbook On Compressors (Of Under Slung AC Coaches) PDFSandeepPas encore d'évaluation

- Internship ReportDocument18 pagesInternship ReportRathan Kumar SMPas encore d'évaluation

- 47-Article Text-338-1-10-20220107Document8 pages47-Article Text-338-1-10-20220107Ime HartatiPas encore d'évaluation