Académique Documents

Professionnel Documents

Culture Documents

Acetamide From Urea Fertiliser

Transféré par

kanji630 évaluation0% ont trouvé ce document utile (0 vote)

21 vues5 pagesok

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentok

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

21 vues5 pagesAcetamide From Urea Fertiliser

Transféré par

kanji63ok

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 5

PAKISTAN JOURNAL OF SCIENCE (Vol. 61, No.1, Marc, 2008)

SYNTHESIS OF ACETAMIDE FROM INDIGENOUS SOURCES

Z. Iqbal*, I. Khokhar**, F. Deba*, E. Haq*, and A. Waheed*

*PCSIR Labs. Complex, Ferozepur Road Lahore.

‘**Punjab University, Lahore, 54600-Pakistan.

ABSTRACT: Acetamide was synthesized by reacting acetic acid and four brands of

‘commercially available urea fertilizers, kisan, sona, babbar sher, engro and pure urea.

Reaction conditions were optimized. Maximum yield was obtained by the reaction of

‘equimolar acetic acid and urea samples for 4.5 hours and distilling at 190-225°C. In each set

cof experiments all reaction conditions were same except the reflux time. Yields obtained by

using pure urea Kisan, Sona, Babbar sher and Engro urea were 89.7% 61.6%, 63.3%, 66.8%

and 68.9% respectively. The optimum yields ofthe reactions were obtained. FT-IR and GLC

‘were used for the identification and confirmation ofthe acetamide.

Keywords: Acetamide, Amonia, Synthesis, Organic

INTRODUCTION

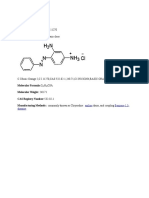

‘Acetamide is an amide of acetic acid having a

formulaC,H,NO, commercially known as lipamide

and schercomide (Michael and irene, 1986). tis a

neutral molecule, its acidic and basic properties

being so weak that they ae not manifested in water

solution (Kirk and Othemer, 2002). Owing to its

polarity and high dielectric constant, it acts as

Solvent for organic and inorganic compounds and

forms many stable solvates (Jander and Winkler,

1958; Kimiko and Kenichi, 1980). Its neutral and

amphoteric characteristics make it valuable as a

ant-acid in the lacquer, explosives and in cosmetic

industries (Isaac and Kerrdge, 1988). It has been

Widely used asa soldering fux ingredient, asa dye

solvent and in urea molding compounds (Eweka

and Kerridge, 1999). Its hygroscopic properties are

the reason forits use as a plasticizer in leather, cloth

and various other films and coatings and as a

hhumectant for paper (Dagang and Zhang, 2006).

ther uses involve activatorin bleaching liquors, as

‘4 Wetting agent and penetration accelerator in

dyeing, as a special food for promoting mold

growth andasaraw material in organic synthesis. It

is used in synthesis of many important drugs;

ampicillin, cephaclor, cephalexin, cephradine,

sulphacetamide, acetamidine hydrochloride and

rethyle amine (Maryadele eal 2006). Acetamide

‘was prepared by various ways Cheronis in 1957

prepared it from ester and ammonia, followed by

the heating of ammonium acetate at 100-200°C

(Cheronis, 1963). It was also prepared by the

heating of acetonitrile with hot hydrochloric acid

(Cheronis et a., 1965). Heating of ammonia and

acetic acid also produces acetamide and this study

was conducted by Cheronis and Ma (1964). It can

be prepared by the dehydration of ammonium

acetate (Ullmann, 2003). Acetamide and its

derivatives were prepared and their anticonvulsant

and antimicrobial activities were studied by

‘Ozkan et al. (1994). Acetamide has been used for

the synthesis of heterocyclic compounds. (Walid

and Pervaiz, 2002, Carolyn ef al, 2005). Its

halogenated derivatives were also

synthesized (Ranjit et al,, 2006, Kzuhara et a.,

2004 and Savinkina eta, 2007). Its also used in

the preparation of bioactive compounds (Vasoya et

al, 2005) .lishydrolysis behaviour was studied by

Berg etal, 2002 and Ikchoon etal, 2004). Its bond

lengths and strengths were studied by Matthias and

Martin (2001) and Rui et al. (2008). Acetamide

structure has been completely reviewed through

spectroscopic techniques by Thomas et al.(1997).

In the present studies we have prepared acetamide

from the locally available urea fertilizers and acetic

acid

MATERIALS AND METHODS

‘The commercial grade samples of urea fertilizers

(Kisan, Sona, Babbar sher and Engro) and acetic

acid were purchased from the local market, Pure

urea of 99.99% purity (E. Merk) was purchased

from local chemical supplier.

‘One hundred gram urea (1.66 moles) and 100 gram

acetic acid (1.66 moles) were charged into a three

necked round bottom flask. Condenser and

thermometer were adjusted and temperature was

raised gently. When the urea melted then the

temperature was raised rapidly by controlling the

thermostat of heating mantle. Heavy white fumes

PAKISTAN JOURNAL OF SCIENCE (Vl. 61, No.1, March, 2009)

‘of ammonium carbamate (NH,COONH, ) along

‘with ammonia and acetic acid started coming off.

‘The temperature 190°C was attained in 2.0 hours.

Material refluxes at this temperature (190°C) and it

was maintained for thirty minutes to ensure the

‘completion of reaction. The material was allowed

10.cool in the flask and then distillation was carried

‘out. Fraction collected from 195- 225 °C, was

cooled and crystals were re-crystallized by using

‘hot methanol and diethyl ether. It was then dried in

hot air oven at 60°C; yield was calculated and then

stored inn airtight container.

All experiments were performed by using the same

procedure except reflux time that varied from 2.0-

45 hours. In each case reaction was performed,

product was weighed and yield was calculated

Product was identified first by melting point, mixed

‘melting point and then by using copper sulphate,

phenol-hypochlorite test. Infrared spectroscopy of

all the samples was performed and results were

‘compared with the standard sample. It_ was

‘observed that all samples show almost same kind of

peak pattem. Three main areas were observed

‘which were 3500 to 3100em’, 1670-1640 cm’ and

1640-1550 cm’ respectively. pure acetamide also

show these peaks and these comparable to each

other. Then assay was performed by gas liquid

chromatography.

Analysis of the acetamide

Copper sulphate test: Fifty milligram of sample

‘was added to 2 ml of 20% NaOH solution ina test

tube. A filter paper was placed over the top of the

‘tube and crushed down around the tube. Two drops

‘of 10% copper sulphate solution were droppedover

the filter paper. Test tube was heated with a small

flame for one minute. A ring of blue color was

formed indicating the presence of acetamide.

Phenol- Hypochlorite test: One milliliter of 4%

aquous solution was mixed with | ml of aquous

sodium hypochlorite solution. Few crystals of the

sample were dropped in to the test tube and then

gently warmed. Blue color was developed

indicating the presence of acetamide.

Spectroscopic analysis: Thermo Nicolt FT-IR 200

(USA) was used for the analysis of acetamide. A

disc of acetamide with KBr (Potassium Bromide)

‘was prepared and absorptions by the various

functional groups were recorded. It was compared

‘with the IR spectrum of standard sample, Spectrum

of each sample was taken by the same procedure

and data was recorded for comparison.

16

Chromatographic analysis: Shimadzu C-R4A,

Chromatopac, GC fitted with flame ionizer

detector and’ data processor was used for the

analysis of acetamide. A PEG capillary column

(25m * 0.2mm id.) was operated with temperature

programming from 150t0300°C. The injection and

detector temperatures were maintained at 300 °C

and 290°C respectively. Helium atthe flow rate of

{60 ml/min and at split rato of 1:50 was used as

carrier gas. Identification and confirmation of

acetamide was based on the retention time as

Compared t0 the retention time of the standard

acetamide under the similar conditions.

RESULTS AND DISCUSSION

Four varieties of urea fertilizers and acetic acid

‘were used without purification forthe synthesis of

acetamide. It was observed that reaction time

imparts a dominant role in the yield of acetamide

and maximum yields pure urea 89.7%, kisan urea

61.6%, Sona urea 63.3%, babbar sher urea 66.8 %

and engro urea 68.9%, respectively, Formation of

‘ammonia from urea and carbon dioxide from acetic

acid take place quickly and they escape through

the condenser. This condition reduces the reactants

inthe flask considerably and so the product. On the

other hand when we heat reactants slowly and

reflux then product was obtained with good yield.

Reflux was started at 116°C (boiling point of acetic

acid). After that temperature was raised to 150°C

within thirty minutes. At that stage ammonium

heat the reaction mixture vigorously loss of

t@ ammonium carbamate also takes

place. That is why in the experiments where

reaction time was two hours the yield was low

because of the liberation of ammonia, carbon

dioxide, acetic acid and ammonium carbamate.

Temperature 190°C was attained by using air

condenser and then it was maintained for thirty

mints This temperature inate completion

‘of reaction and thinty minutes are req

remove water vapors trapped in the product.

In the next experiments the reflux time was

inereased keeping in mind that contact time and

slow heating of reactants will inerease the product.

Besides these fertilizers samples parallel

‘experiments were performed with pure urea under

the similar conditions and in all the cases it was

‘observed that the yield of acetamide was more than

any other sample. It was because that urea

fertilizers contain various concentrations of fillers,

binders and other ingredients in their formulation

PAKISTAN JOURNAL OF SCIENCE (Vol. 61, No.1, March, 2008)

which lead tothe formation ofby products. while in

the case of pure urea byproducts are not formedas it

contains no impurity. Reflux and distillation of the

product was carried out with air condenser. The

4istillation isthe critical condition for this product.

Acetamide was. recrystallized by using hot

‘methanol and diethylether. Product was identified

bby melting point (80.7 °C), mixed melting point

(81.4 °C), copper sulphate, phenol-hypochlorite

test (blue ring on filter paper), infrared

spectroscopy and assay was performed through

GLC (Snell and Ettre, 1969). The analysis of the

product was performed on GLC by using SE-30

column, injection temperature was 230°C,

detection temperature was 250°C and flow rate was

30ml / minute, Standard acetamide was taken from

E.Merk. Peak area and peak height ofthe samples

‘were sameas that of standard.

CONCLUSIONS: Acetamide was successfully

prepared from acetic acid and four brands of

commercially available urea fertilizers. Reflux

time and stirring parameters were studied. From

these experiments it is concluded that yield of

acetamide increases by stirring the reactants as

‘compared to without stirring in each case. Another

inference is that as we increase the reflux time the

‘yield of product also increases. When we increase

the reflux time liberation of ammonia is retarded

and reaction of ammonia with acetic acid increases.

Formation of ammonium carbamate and its

liberation to air stops and its conversion to

acetamide increases. The best yields are obtained at

reflux time 4.5 hours and beyond that yield did not

increase considerably. Out ofthese four brands and

pure urea the yield is Engro.rea> Babbar sher urea

> Sona urea > Kisan urea while the yield of pure

‘urea was greaterinall the cases. (Fig. 1-5).

Itis concluded from the study that urea fertilizers

can be utilized forthe production of acetamide.

REFERENCES

Berg M.N., DJ. Repeta and J. Laroche. Dissolved

organic nitrogen hydrolysis rates in Axenic

Aureococcus anophagefferens. Appl. Environ,

Microbiol. 68:401-404 (2002).

Carolyn E., L. E. Anderson, Overman and P.W.

Marry. Asymmetric rearrangement of allylic

trichloroacetamides. Org. Synth., 82:134 2005).

CCheronis N.D. and J.B. Entrikin. Identification of

‘organic compounds, Interscience puplishers, Inc,

‘New York, pp: 534 (1963),

7

(Cheronis N.D, J.B. Entrikin and EM. Hordnet.

Semi micro Qualitative organic analysis, 3rd

Edition, Interscience publisher, Inc, New York,

pp:ll7, 118,459 (1965).

Cheronis N.D and TS. Ma, Organic functional

group analysis by micro and semi micro methods,

Interscience publisher, Inc, New York, pp: 174

(1964).

Dagang L. and L. Zhang, Structure and properties

of soy protein plastics plasticized with acetamide.

Macromol. Mater Eng.,291: 820-828 (2006),

Eweka, E. 1. and D. H. Kerridge, Solution

chemistry of molten amide-nitrte eutectics. Chem

Papers. $3: 11-15(1999).

Ikchoon, L., C.K. Kim and B. Lee. Studies onthe

acid hydrolysis. J. Phy. Org. Chem.,3: 397-403

(2004).

Isaac, LY. and D.H. Kerridge. Effect of acetamide

‘on solubility of metals, J. Chem. Soc. 21:2201-

7208 (1988).

Jander G. and G. Winkler. J.Inorg Nucl.Chem., 2:

24-33 (1958).

Kimiko U. and ©. Kenichi. Acetamide in polar

solvents: hindered internal rotation and

intermolecular interactions. Org Mag. Reson., 15:

13-17(1980),

Kirk and Othmer. Encycopedia of chemical

technology. 1:45-49, (2002).

KuzuharaS., H. Sato and E. Kasai. Effect of urea on

PCDD/Fs formation through De Novo synthesis.

Organohalogen Comp., 66 (2004).

Maryadele 4.0, N. Patricia, C. B. Koch, K. J

Roma. Merck index. Published by Merck Research

Laboratories, White House Station USA., 9-10

(20065.

Matthias B. and Martin K. Hydrogen bond

‘energetic: a simulation and statistical analysis of N-

Methyl acetamide, water and human lysozyme. J

Phys. Chem, 105: 11000-11015 (2001).

Michael and A. rene. The thesaurus of chemical

products, Genericto Trade, 1: (1986)

PAKISTAN JOURNAL OF SCIENCE (Vol. 61, No.1, March, 2009)

Ozkanli F., S. Dalkara, U. Calis and A. Willke.

Synthesis of some N-arylazole acetamide

derivative and their anticonvulsant and

antimicrobial activities. Arzeimitelforschung.,

44(8); 920-924 (1994),

Ranjit V., N, Munasinghe and JohnE.T. Corrie.

Optimised synthesis of 6-

iodoacetamidotetramethylrhodamide. Arkivoc.,

2:143-149 (2006).

Rui MS,, Aw. Robert and G. Labat. Hydrogen

‘bond pattems in the congruent comlex 4-nitphenol

‘acetamide. Acta Cryst., 64:306-308 (2008),

Savinkina, E. D., E. Al’bor, I. Bufavlev,

Zamilatskov. Synthesis and’ structures of

polyiodide acetmide complexs of transition metal

Russian J. of Inorg Chem., $2:1056-1062(2007).

Snell FD. and L. Ettre. Encyclopedia of industrial

chemical analysis, Inerscience publishers a

division of John Willy & Sons. New York.8: 597-

611 (1976).

18

‘Thomas D., T. Peter and C. Thomas. Synthesis of

propiolamide and NMR studies of formamide,

‘acetamide and propiolamide. Magnetic resonance

inchem.,35:571-76 (1997).

Ullmann’s Encyclopedia of industrial chemistry.

Sixteenth Edition, Germany, Vol. A-1, pp. 71-72,

‘vol. 24 pp.348 (2003),

‘Vasoya S.L.,PT. Chovatia D.H. Purohit and HS.

Josh. Green chemistry approach to the synthesis of

potentially bioactive aminobenzylated Mannich

bases through acitive hydrogen compounds. J.Serb,

Chem.Soc,, 70:1163-1167 2005)

‘Vogel A.:Test book of practical organic chemistry,

3rd Edition, Longman Greem & Co, New York, p:

401-403 (1956).

Walid M. Fathalla and Pavel Pazdera, Synthesis of

heterocyclic skeletons by reaction of N-(2-

Cyanophenyl)-benimidoy! chloride with

thioacetamides. Molecules., 17:96-103 (2002).

PAKISTAN JOURNAL OF SCIENCE (Vol. 61, No.1, March, 2008)

Fiore! Figwed

Paces il tao eae ed

ao oes

7 ore % a

wo Sl. 70 oa Ta

ms

eee es

: * i las

* ae Be

=

o 0

BYR Per Vito Relic tas le eons > ep eee.

ata Tie pate

Figuet Feu

Percentage yleld of acetamide from

Percentage yield of acetamide from Pure

Fess aa

Reflux Tine

mae =

. ‘0

= = 80

ia Jw

Bx 0

om -

10 a

o °

a eile peta: a hes 7 aes ea

Figure?

=

pln

mes

7

ie

;

z

pies

2 0

* 2»

J

;

Vous aimerez peut-être aussi

- Technical Specifications For DIMETHYL ANTHRANILATEDocument1 pageTechnical Specifications For DIMETHYL ANTHRANILATEkanji63Pas encore d'évaluation

- Car KotakDocument15 pagesCar Kotakkanji63Pas encore d'évaluation

- 1 3 DiiminoisoindolineDocument6 pages1 3 Diiminoisoindolinekanji63Pas encore d'évaluation

- Listofdyes, Dye Intermediates, Agrochemicals and PharmaceuticalDocument11 pagesListofdyes, Dye Intermediates, Agrochemicals and Pharmaceuticalkanji63Pas encore d'évaluation

- RMC of Coal Tar 1.0 KG Rate Qty Cost Coal Tar Crude 6 1 6 After Water Remove 0.7 7Document1 pageRMC of Coal Tar 1.0 KG Rate Qty Cost Coal Tar Crude 6 1 6 After Water Remove 0.7 7kanji63Pas encore d'évaluation

- DR ArchadDocument4 pagesDR Archadkanji63Pas encore d'évaluation

- Intermediate of OmeprazoleDocument4 pagesIntermediate of Omeprazolekanji63Pas encore d'évaluation

- Research On The Preparation of 2,5-Diaminotoluene With 2-Aminoazotoluene Catalytic HydrogenationDocument1 pageResearch On The Preparation of 2,5-Diaminotoluene With 2-Aminoazotoluene Catalytic Hydrogenationkanji63Pas encore d'évaluation

- RMC of 3GKDocument1 pageRMC of 3GKkanji63Pas encore d'évaluation

- Green 7Document7 pagesGreen 7kanji63Pas encore d'évaluation

- Waste Water PatentDocument151 pagesWaste Water Patentkanji63Pas encore d'évaluation

- Workplace Housekeeping - Checklist For General Inspection Floors and Other AreasDocument2 pagesWorkplace Housekeeping - Checklist For General Inspection Floors and Other Areaskanji63Pas encore d'évaluation

- 4 Nitro N MethylphthalimideDocument1 page4 Nitro N Methylphthalimidekanji63Pas encore d'évaluation

- Acetyl Bronners Acid ChlorosulphonationDocument3 pagesAcetyl Bronners Acid Chlorosulphonationkanji63Pas encore d'évaluation

- Disperse Blue79Document2 pagesDisperse Blue79kanji63Pas encore d'évaluation

- Basic Blue 7Document1 pageBasic Blue 7kanji63Pas encore d'évaluation

- Basic Orange 2Document1 pageBasic Orange 2kanji63Pas encore d'évaluation

- Flowdiagram of Disperse Blue 79Document4 pagesFlowdiagram of Disperse Blue 79kanji63Pas encore d'évaluation

- EP0011048A1Document19 pagesEP0011048A1kanji63Pas encore d'évaluation

- Uses and Applications of AcetamideDocument2 pagesUses and Applications of Acetamidekanji6350% (2)

- Maintance Shift SchedualDocument2 pagesMaintance Shift Schedualkanji63Pas encore d'évaluation

- Tax Certificate HomeDocument1 pageTax Certificate Homekanji63Pas encore d'évaluation

- Disperse Blue79Document2 pagesDisperse Blue79kanji63Pas encore d'évaluation

- Green - 7Document28 pagesGreen - 7kanji63Pas encore d'évaluation

- Workplace Housekeeping - Checklist For General Inspection Floors and Other AreasDocument2 pagesWorkplace Housekeeping - Checklist For General Inspection Floors and Other Areaskanji63Pas encore d'évaluation

- Annexure-A Ambuja Intermediates LTD Raw Material SR No Name of R. M RemarkDocument2 pagesAnnexure-A Ambuja Intermediates LTD Raw Material SR No Name of R. M Remarkkanji63Pas encore d'évaluation

- FC & GM Loan PolicyDocument4 pagesFC & GM Loan Policykanji63Pas encore d'évaluation

- TFS Audit Program V2.0Document29 pagesTFS Audit Program V2.0kanji63Pas encore d'évaluation

- List of Licenses / Certificates: As Per List Attached Here WithDocument2 pagesList of Licenses / Certificates: As Per List Attached Here Withkanji63Pas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)