Académique Documents

Professionnel Documents

Culture Documents

E 8 CD

Transféré par

W Adi SaputroTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

E 8 CD

Transféré par

W Adi SaputroDroits d'auteur :

Formats disponibles

International Journal of Engineering Trends and Technology- Volume4Issue2- 2013

Neural Network based Closed loop Speed Control of

DC Motor using Arduino Uno.

Neerparaj Rai#1, Bijay Rai#2

Electrical and Electronics Engineering Department, Sikkim Manipal University

Sikkim, India

Abstract This paper presents the design and implementation of methods mentioned before: model reference direct inverse

Arduino Uno based DC motor speed control system using control and indirect adaptive control. The proposed method

Multilayer Neural Network controller and PID controller. A uses Levenberg-Marquardt back-propagation training

model reference structure is developed using PID control to algorithm and is desired to track a reference model. The

obtain the neural controller .The artificial neural network is

method can be considered as a direct controller design.

trained by Levenberg-Marquardt back propagation algorithm.

Feed forward neural network with two hidden neurons and one Although it does not require any knowledge of the system

output neuron is used. Speed of the dc motor is controlled by dynamics, it requires the sensitivity of the controlled system.

varying the duty cycle of the pwm signal which is fed to the gate This paper describes a method of implanting a fully connected

of the mosfet irf 640. Simulation and practical results are multi-layer neural network with multi-layer connections on a

presented to demonstrate the effectiveness and advantage of the very inexpensive Atmega 168 microcontroller

control system of DC motor with ANNs in comparison with the

conventional control scheme in Matlab/Simulink R2009b. PID I. DC MOTOR CONTROL WITH ANN

algorithm and ANN controller is implemented in Arduino Uno

A dc motor is widely used for control purposes because of

because of its easy compatibility and portability.

its stability and straight forward characteristics. For effective

analytical purposes, mathematical models are indispensable.

KeywordsDC motor, Arduino, Artificial neural networks,

The separately excited dc motor is the simplest of all dc

Atmega 168.

motors and it is the one most commonly found in industrial

Introduction applications.

DC motors are one of the most widely prime movers in A. Mathematical model of DC motor:

industry today. There are many ways for DC motor speed

control such as Proportional-Integral-Derivative (PID) control, The separately excited DC motor is described by the

state space control, digital PID control and others. However, following equations:

Artificial Neural Networks (ANN) have emerged as a tool for KFp(t) = Raia(t) La[dia(t)/dt] + Vt(t) (1)

difficult control problems of unknown non-linear systems. KFia (t) = J[dp(t)/dt] + Bp (t) + TL(t) (2)

Neural networks are used for modelling and control of where,

complex physical systems because of their ability to handle p(t) - rotor speed (rad/s)

complex input output mapping without detailed analytical Vt (t) - terminal voltage (V)

models of the systems. ia(t) - armature current (A)

TL(t) - load torque (Nm)

There are several control strategies for neural networks such J - rotor inertia (Nm)

as: 1) Feed forward control, 2) Direct inverse control KF - torque & back emf constant (Nm/A)

(extracting inverse dynamics), 3) Indirect adaptive control B - viscous friction coefficient (Nms)

method based on NN identification, 4) direct adaptive control Ra - armature resistance ()

with guarantied stability, 5) Feedback linearization, 6) La - armature inductance (H)

Predictive control [1]. In the direct inverse control method, a

MNN is trained by specialized back-propagation algorithm [2]. From these equations mathematical model of the DC motor

This method has attracted much attention in recent years can be created. The model is presented in Fig1. Where,

because it is intuitive, and simple to be implemented [3]. Ta -Time constant of motor armature circuit, Ta=La/Ra(s)

However, the plant to be controlled may not have a unique or and,

stable inverse, which is the drawback of direct inverse Tm Mechanical time constant of the motor Tm=J/B (s).

dynamics method.

In this study, a control strategy is proposed for the real time

control of single-input single-output linear and nonlinear

systems. The proposed method resembles previous two

ISSN: 2231-5381 http://www.internationaljournalssrg.org Page 137

International Journal of Engineering Trends and Technology- Volume4Issue2- 2013

y(k+1)=f[y(k), y(k-1), .,y(k-na), u(k), u(k-1), .,u(k-nb)]

(3)

This process is called as one step ahead prediction and the

structure is called Time Delayed Neural network. Equation (3)

can be easily implemented [6]. In this paper, the ANN

controller is time delayed neural network. The proposed

method can be used as adaptive or non-adaptive controller. If

learning process continues, the controller will be an adaptive

controller. In non-adaptive case, learning process is executed

as offline or for a certain period of time. In designing and

Fig. 1 The mathematical model of separately excited dc motor. training an ANN to emulate a function, the only fixed

parameters are the number of inputs and outputs of the ANN,

B. PI control method: which are based on the input/output variables of the function.

The choice of the number of hidden neurons is based on

experience. It is also widely accepted that maximum of two

Firstly, for controlling the speed of DC motor PI control

hidden layers are sufficient to learn any arbitrary non-linearity.

strategy is applied. The block diagram for the PI control is

The back-propagation training technique adjusts the weights

developed in Matlab/Simulink and the transfer function for

and bias in all connecting links in the nodes so that the

the PI control is obtained using Ziegler-Nicholas method.

difference between the actual output and target output are

minimized for all given training patterns.[2]

The diagram of neural network used in the control of DC

motor is shown in figure 3. The time delayed neural network

is a multilayer neural network and has four inputs. The MNN

has one hidden layers, which consist of 2 neurons with tan

sigmoid activation function. The output layer of the NN has

only one neuron with pure linear activation function.

Fig. 2 Simulink model for PI controlled dc motor.

There are different methods to synthesize control systems of

DC motor, but for a comparison with method using ANNs, a

conventional PI control of DC motor is used. The plant

obtained in fig2 is used as the reference model to obtain the Fig. 3 ANN control schema for dc motor.

input and target samples.

The network is trained for 500 second applying a 0.2 Hz

C. The control system of DC motor using ANNs: square wave to the reference model. The load was 10gm-cm

A neural network comprises simple elements operating in during training. The architecture of the proposed ANN

parallel. In fact, it is a massively parallel distributed processor controller in MATLAB Simulink is shown in Fig. 4.

that stores experiential knowledge and makes it available for

use when needed. In using neural networks for system

identification, training data can be obtained by observing the

input-output behaviour of a plant. If previous values of the

input and output are present, the future value can be predicted

as:

ISSN: 2231-5381 http://www.internationaljournalssrg.org Page 138

International Journal of Engineering Trends and Technology- Volume4Issue2- 2013

The step pulse response of dc motor with trained neural

controller at 10gm-cm load is given in Fig. 5. The load is

increased to 30 gm-cm at 3sec, but the motor reverts back to

the set speed of 120 rad/sec within 0.2 sec. The response of

the motor to a sinusoidal input signal is also given in Fig. 6.

Fig. 4 Architecture of the proposed ANN controller in MATLAB Simulink.

D. Implementation in Arduino Uno

Fig.5 shows the block diagram of Design and

Implementation of Arduino Uno Based Speed Control of DC

Motor. The input for the set speed is given through GUI built

in MATLAB. The data processing unit contains Arduino

Microcontroller Atmega 168 unit. The DC motor driver circuit

is a mosfet which is configured as a switch and it is driven

from the microcontroller PWM 0 output. The DC motor Fig. 5 Step response of DC Motor with ANN.

module consists of speed sensing unit and DC motor. Speed

sensing unit consists of an opto coupler MOC7811 and an

optical encoder, which will give train of pulses with some

frequency depending upon the speed of the motor. The DC

motor used is less weight, low power consumption and high

speed etc. The lifetime of the motor may vary from a few

hundred hours to more than 10, 000 hours. The specifications

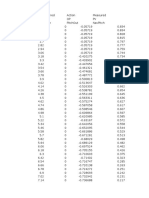

of DC motor used in the present study are shown in Table 1.

TABLE I

SPECIFICATIONS OF DC MOTOR

Description Value

Rated voltage 12 V DC

Fig. 6 Sinusoidal waveform response of DC Motor with ANN.

Rated current 170 mA

Maximum speed 1700 RPM Fig. 7 shows the regulation of speed at different levels for

Torque 80gm-cm both conventional PID control method and ANN control.

Weight 150 g Maximum overshoot is more in case of PID control which is

The output unit consists of 162 liquid crystal display to 16.7% compared to 5.8% in case of ANN control. Motor takes

display the measured DC motor speed in RPM with the help a longer settling time of 1.3 sec for PID control whereas the

of microcontroller. The measured speed also plotted in GUI motor takes only 0.2 sec with ANN control. To implement the

with the help of serial communication through serial port neural controller in Arduino, 278 training samples were

COM3 and Arduino Uno. obtained out of which 10% each was used for validation and

testing and rest 80% for training. After the implementation of

ANN and PID in Arduino, the speed response of the motor is

II. SIMULATION RESULTS with both the controllers is shown in Fig. 8.

The dc motor model is simulated with the PID controller and

ANN controller which is obtained after offline training. The

dc motor with ANN controller is also simulated with different

waveforms of reference signal. The controller parameters are

tuned in MATLAB using Ziegler Nichols method (kp=0.1617,

ki=0.7177 and kd=0.0) and the results of the best tuned PID

controller are presented. To obtain the neural controller, first

the training was completed with mean squared error of 0.003

then off line performance of the controller was tested for

different waveforms of reference signal and different load

conditions.

ISSN: 2231-5381 http://www.internationaljournalssrg.org Page 139

International Journal of Engineering Trends and Technology- Volume4Issue2- 2013

Fig. 7 Regulation of DC Motor speed with ANN and PID. methods. ANN control can be used for control mechanism of

machines with complicated load patterns.

ACKNOWLEDGMENT

The authors thank Prof.D.Suryanarayana for technical

assistance and guidance.

. REFERENCES

[1] Choi Y. K., Lee S. K., Kay Y.C., Design and Implementation of an

Adaptive Neural Network Compensator for Control Systems, IEEE

Transactions on Industrial Electronics, vol 48, April 2001.

[2] S. Hykin, Neural Networks, Macmillan, NY, 1994.

[3] Psaltis D., Sideris A., Yamamura A.A., Multilayer Neural Network

Controller. IEEE Control System Magazine, pg 17-21, 1988.

[4] Adepoju G. A, Aborisade, D.O Eluwole O. T., Speed Forecast of DC

Motor Using Artificial Neural Network, International Journal of

Applied Science and Technology, Vol. 1 No. 6,November 2011.

[5] Phan Quoc Dzung, Le Minh Phuong, Control system DC motor with

Fig8. DC Motor speed response with ANN and PID. speed estimator by neural networks,IEEE PEDS 2005.

(Set speed=200rpm) [6] N. Madhusudhana Reddy, K. Nagabhushan Raju,C. Chandra Mouli

and D.Chandrasekhar Reddy, Design and Implementation of Arm

Cortex based Speed Control of DC Motor, International Journal of

Industrial Electronics and Control, 2012,Volume 4, pp. 53-60.

III. CONCLUSION [7] Mr. M.V.Sudarsan Dr. G.R.K. Murthy Mr. G.R.S. Naga Kumar,

Desinging Of Ann Based Speed Controller For Phase Controlled Dc

Motor , IJEST 2011, 7 July, Vol. 3

A closed loop speed control of DC Motor was developed [8] Carmadi Machbub, Ary Setijadi Prihatmanto, Yoseph Dwi Cahaya,

using Atmega 168 Arduino microcontroller. PID and ANN Design and Implementation of Adaptive Neural Networks Algorithm

control was successfully implemented in Arduino for DC Motor SpeedControl System using Simple Microcontroller,

microcontroller and was tested on a DC Motor speed control Indonesia, IEEE PEDS,2001

[9] Akhilendra Yadav, Gurleen Kaur, Akanksha Sharma, Microcontroller

system. The system outputs also agreed with the theoritical Based Open-Loop Speed Control System For Dc Motor, IJREAS

results indicating better accuracy of the system. Volume 2, Issue 6 (June 2012).

Using ANN, there is no need to calculate the motor

parameters of the motor when designing the control system.

ANN based control has reduced the settling time to 0.2 sec.

Hence the overall study indicates an appreciable advantage of

artificial neural network control over the conventional control

ISSN: 2231-5381 http://www.internationaljournalssrg.org Page 140

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Sempatin JurnalDocument5 pagesSempatin JurnalkartikaPas encore d'évaluation

- DeepFake Detection For Human Face Images and Videos A SurveyDocument19 pagesDeepFake Detection For Human Face Images and Videos A Surveymcse-f20-004Pas encore d'évaluation

- Eti Unit1 2 3 Mcqs EtiDocument44 pagesEti Unit1 2 3 Mcqs EtiShlok PurohitPas encore d'évaluation

- Credit Card Fraud Detection - Machine Learning Methods: March 2019Document6 pagesCredit Card Fraud Detection - Machine Learning Methods: March 2019Pranshu SrivastavaPas encore d'évaluation

- Neural SearchDocument10 pagesNeural Searchchinni charanPas encore d'évaluation

- Business CommunicationDocument37 pagesBusiness CommunicationSmita AcharyaPas encore d'évaluation

- Burgoon, Nonverbal Signals PDFDocument245 pagesBurgoon, Nonverbal Signals PDFcacakakaPas encore d'évaluation

- Soft Computing Unit-2Document61 pagesSoft Computing Unit-2namak sung loPas encore d'évaluation

- 4.SentimentAnalysis FullPaperDocument38 pages4.SentimentAnalysis FullPaperrrifmilleniaPas encore d'évaluation

- Mahika Bansal A03Document2 pagesMahika Bansal A03Simarleen BhardwajPas encore d'évaluation

- Machine Learning Predicts DiabetesDocument18 pagesMachine Learning Predicts DiabetesMothish Kumar100% (1)

- Introduction To Industrial Automation Topic 1Document13 pagesIntroduction To Industrial Automation Topic 1Vedant .ChavanPas encore d'évaluation

- CS Practical File 2Document36 pagesCS Practical File 2Nikhil JohariPas encore d'évaluation

- (BK Control Manual) Feedback ControlDocument229 pages(BK Control Manual) Feedback Controlengrar100% (1)

- Convolution Neural Networks For Hand Gesture RecognationDocument5 pagesConvolution Neural Networks For Hand Gesture RecognationIAES IJAIPas encore d'évaluation

- Statista, The AI Advantage Powering Business CompetitivenessDocument25 pagesStatista, The AI Advantage Powering Business CompetitivenessPico PicoPas encore d'évaluation

- KSP KOS PID TuningDocument200 pagesKSP KOS PID TuningBlocky999Pas encore d'évaluation

- PID For Fixed-Wing UAV PDFDocument6 pagesPID For Fixed-Wing UAV PDFMUVNPas encore d'évaluation

- Automatic Image Captioning Bot With CNN and RNN: - Submitted By-Harkirat Singh CSE-3 01976802717Document10 pagesAutomatic Image Captioning Bot With CNN and RNN: - Submitted By-Harkirat Singh CSE-3 01976802717Harkirat SinghPas encore d'évaluation

- EE250 Fall2012 Lecture-NotesDocument230 pagesEE250 Fall2012 Lecture-NotesAnurag PandeyPas encore d'évaluation

- Discovering Knee Osteoarthritis Using CNN Enhanced With AlexnetDocument26 pagesDiscovering Knee Osteoarthritis Using CNN Enhanced With Alexnetrevathi pPas encore d'évaluation

- Athomewithai: Curated Resource ListDocument6 pagesAthomewithai: Curated Resource ListWisha FelishaPas encore d'évaluation

- Smoothing Frequency Domain FiltersDocument22 pagesSmoothing Frequency Domain FiltersRaymond PraveenPas encore d'évaluation

- Machine Learning KNN PresentationDocument28 pagesMachine Learning KNN PresentationAAW 1912Pas encore d'évaluation

- AI Set1Document6 pagesAI Set1subhenduchatterjee94Pas encore d'évaluation

- Simulation Studies of Inverted Pendulum Based On PID ControllersDocument10 pagesSimulation Studies of Inverted Pendulum Based On PID ControllersJuan Manuel MauroPas encore d'évaluation

- Barriers To Effective Human CommunicationDocument4 pagesBarriers To Effective Human CommunicationPatrick HariramaniPas encore d'évaluation

- Stock Market Prediction Using Machine Learning: Akarsh Bisht Akash ChaharDocument14 pagesStock Market Prediction Using Machine Learning: Akarsh Bisht Akash Chahar2K18CO037 AkashChaharPas encore d'évaluation

- Midterm Exam 1Document8 pagesMidterm Exam 1jagriti kumariPas encore d'évaluation

- Material List HanfeetDocument65 pagesMaterial List Hanfeetsameer233Pas encore d'évaluation