Académique Documents

Professionnel Documents

Culture Documents

Unconvetional Machining Process

Transféré par

maheshCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Unconvetional Machining Process

Transféré par

maheshDroits d'auteur :

Formats disponibles

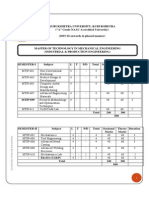

ME 317 - UNCONVENTIONAL MACHINING PROCESSES

Teaching Scheme: Examination Scheme:

Lectures: 3 hrs/week Tests -20 marks Mid-Sem. 30 marks

End Sem. Exam 50 marks

Objectives:

To learn about various unconventional machining processes, the various process

parameters and their influence on performance and their applications

Unit 1 [5 hrs]

Introduction

Unconventional machining Process Need classification Brief overview

Unit 2 [10 hrs]

Mechanical Energy Based Processes

Abrasive Jet Machining Water Jet Machining Abrasive Water Jet Machining - Ultrasonic

Machining. (AJM, WJM, AWJM and USM). Working Principles equipment used Process

parameters MRR-Variation in techniques used Applications.

Unit 3 [8 hrs]

Electrical Energy Based Processes

Electric Discharge Machining (EDM)- working Principle-equipments-Process

Parameters-Surface Finish and MRR- electrode / Tool Power and control Circuits-Tool

Wear Dielectric Flushing Wire cut EDM Applications.

Unit 4 [12 hrs]

Chemical Energy Based Processes

Chemical machining techniques of applying maskants-Process Parameters Surface finish and

MRR-Applications. Principles of ECM-equipments-Surface Roughness and MRR Electrical circuit-

Process Parameters-ECG - Applications.

Unit 5 [10 hrs]

Thermal Energy Based Processes

Laser Beam machining and drilling (LBM), plasma arc machining (PAM) and Electron

Beam Machining (EBM). Principles Equipment Types - Beam control techniques

Applications

Unit 6 [6 hrs]

Electro-Chemical Energy Based Processes

Electro-Chemical machining (ECM)-Etchants maskant- techniques of applying maskants-Process

Parameters Surface finish and MRR-Applications. Principles of ECM-equipments-Surface

Roughness and MRR Electrical circuit-Process Parameters- ECH - Applications.

Text Books:

1. Vijay.K. Jain Advanced Machining Processes Allied Publishers Pvt. Ltd., New Delhi, 2007

Reference Books:

1. Benedict. G.F. Nontraditional Manufacturing Processes Marcel Dekker Inc., New

York (1987).

2. Pandey P.C. and Shan H.S. Modern Machining Processes Tata McGraw-Hill, New

Delhi (2007).

3. Mc Geough, Advanced Methods of Machining Chapman and Hall, London (1998).

4. Paul De Garmo, J.T.Black, and Ronald.A.Kohser, Material and Processes in

Manufacturing Prentice Hall of India Pvt. Ltd., New Delhi ,8th Edition,2001.

Vous aimerez peut-être aussi

- Power Electronics Converters and their Control for Renewable Energy ApplicationsD'EverandPower Electronics Converters and their Control for Renewable Energy ApplicationsArezki FekikPas encore d'évaluation

- Electrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyD'EverandElectrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyÉvaluation : 4 sur 5 étoiles4/5 (1)

- Electrochemical MACHININGDocument14 pagesElectrochemical MACHININGpramod_k100% (2)

- Elect3 2Document2 pagesElect3 2pranav10dulkarPas encore d'évaluation

- Multiscale Modeling of Additively Manufactured Metals: Application to Laser Powder Bed Fusion ProcessD'EverandMultiscale Modeling of Additively Manufactured Metals: Application to Laser Powder Bed Fusion ProcessPas encore d'évaluation

- 02 Ucm SyllabusDocument1 page02 Ucm SyllabusSamuelHericPas encore d'évaluation

- Unconventional Machining ProcessesDocument2 pagesUnconventional Machining ProcessesP.N. MohankumarPas encore d'évaluation

- Ucm SyllabusDocument5 pagesUcm SyllabusDhana MuruganPas encore d'évaluation

- UCM Course InformationDocument14 pagesUCM Course InformationThiyagu SundaramPas encore d'évaluation

- Syllabus PDF 1Document3 pagesSyllabus PDF 1gowrisankar32Pas encore d'évaluation

- # 1 - IntroductionDocument42 pages# 1 - IntroductionRohan RautPas encore d'évaluation

- Unconventional Machining Processes GuideDocument59 pagesUnconventional Machining Processes GuideAkilesh SPas encore d'évaluation

- Ucm SyllabusDocument2 pagesUcm Syllabusarun2386Pas encore d'évaluation

- Unconventional Machining Processes ExplainedDocument2 pagesUnconventional Machining Processes ExplainedpmagrawalPas encore d'évaluation

- Me 8073 UcmpDocument21 pagesMe 8073 UcmpAjay SriramPas encore d'évaluation

- NTM Module 1Document19 pagesNTM Module 1RishiJpPas encore d'évaluation

- Unconventional Machining and Testing MaterialsDocument4 pagesUnconventional Machining and Testing MaterialsajitsssPas encore d'évaluation

- Production ElectivesDocument20 pagesProduction ElectivesAdhi ThyanPas encore d'évaluation

- Ucm Two MarksDocument23 pagesUcm Two Marksarun kumarPas encore d'évaluation

- Amp Qb.Document6 pagesAmp Qb.svkarthik83Pas encore d'évaluation

- Ucmp NotesDocument46 pagesUcmp NotesAnonymous fowICTKPas encore d'évaluation

- Unconventional Machining Processes: A Course on Mechanical, Thermal, Electrical & Chemical Based TechniquesDocument74 pagesUnconventional Machining Processes: A Course on Mechanical, Thermal, Electrical & Chemical Based Techniquesashoku24007Pas encore d'évaluation

- 1.1 Introduction To Conventional and Non Conventional MachiningDocument42 pages1.1 Introduction To Conventional and Non Conventional MachiningDida KhalingPas encore d'évaluation

- Mechanical Engineering Course on Unconventional Machining ProcessesDocument2 pagesMechanical Engineering Course on Unconventional Machining ProcessesN Dhanunjaya Rao BorraPas encore d'évaluation

- Jawaharlal Nehru Technological University AnantapurDocument1 pageJawaharlal Nehru Technological University AnantapurManu RavuriPas encore d'évaluation

- Energy Systems LM - 7 Credits: Main Objectives and Contents of The CourseDocument4 pagesEnergy Systems LM - 7 Credits: Main Objectives and Contents of The CourseAbhishek TiwariPas encore d'évaluation

- Me6004 Unconventional Machining Processes Assignment 1,2,3,4,5Document5 pagesMe6004 Unconventional Machining Processes Assignment 1,2,3,4,5BIBIN CHIDAMBARANATHANPas encore d'évaluation

- 1optimization of Micro-WireDocument33 pages1optimization of Micro-WireAman BansalPas encore d'évaluation

- MMP NotesDocument81 pagesMMP NotestatiPas encore d'évaluation

- Modern Manufacturing Methods MOOC IIIDocument3 pagesModern Manufacturing Methods MOOC IIISree MurthyPas encore d'évaluation

- Modern Optimization Techniques For Advanced MachiningDocument9 pagesModern Optimization Techniques For Advanced MachiningPrapto PraptPas encore d'évaluation

- Experimental and Theoretical Investigations in ECDM Proc 2016 Procedia TechnDocument8 pagesExperimental and Theoretical Investigations in ECDM Proc 2016 Procedia TechnTanNguyễnPas encore d'évaluation

- Ucmp-Question Bank - NewDocument4 pagesUcmp-Question Bank - New9966197483Pas encore d'évaluation

- Our Official Android App - REJINPAUL NETWORK FromDocument1 pageOur Official Android App - REJINPAUL NETWORK FromNick “WWEXTRMEMENATOR” SpartaPas encore d'évaluation

- Un Conventional Machining Processes SyllabusDocument2 pagesUn Conventional Machining Processes SyllabusKalai ArasanPas encore d'évaluation

- Fluid Machinery & Fluid PowerDocument3 pagesFluid Machinery & Fluid Poweras2faasbujsacPas encore d'évaluation

- Ucm - Unitwise Notes (r2017)Document168 pagesUcm - Unitwise Notes (r2017)A. AKASH 4001-UCE-TKPas encore d'évaluation

- Review of Electrochemical and Electrodischarge Machining: Digitalcommons@University of Nebraska - LincolnDocument15 pagesReview of Electrochemical and Electrodischarge Machining: Digitalcommons@University of Nebraska - LincolnVignesh SunilPas encore d'évaluation

- Review of Electrochemical and Electrodischarge MachiningDocument14 pagesReview of Electrochemical and Electrodischarge Machiningdinesh veerPas encore d'évaluation

- UmpDocument7 pagesUmpRahul TechPas encore d'évaluation

- Electrochemical Machining ReviewDocument5 pagesElectrochemical Machining ReviewBasavaraj HosurPas encore d'évaluation

- BME Course Data SheetDocument5 pagesBME Course Data SheetBasilPas encore d'évaluation

- 19EES113A CompressedDocument730 pages19EES113A CompressedYash AgrawalPas encore d'évaluation

- KCG College unconventional machining processes question bankDocument20 pagesKCG College unconventional machining processes question bankBalaPas encore d'évaluation

- Ucmp First Mid Course FileDocument160 pagesUcmp First Mid Course FileAraveetiCSReddyPas encore d'évaluation

- 084 - ME8073, ME6004 Unconventional Machining Processes - NotesDocument39 pages084 - ME8073, ME6004 Unconventional Machining Processes - NotesA. AKASH 4001-UCE-TKPas encore d'évaluation

- Un Conventional Machining Process NotesDocument174 pagesUn Conventional Machining Process Notesban murthy0% (1)

- DR. APJ ABDUL KALAM TECHNICAL UNIVERSITY STUDY SCHEME FOR B.TECH MANUFACTURING TECHNOLOGYDocument28 pagesDR. APJ ABDUL KALAM TECHNICAL UNIVERSITY STUDY SCHEME FOR B.TECH MANUFACTURING TECHNOLOGYSuraj OjhaPas encore d'évaluation

- ECDMDocument8 pagesECDMSaurabhBhardwajPas encore d'évaluation

- BDU Electrical Machines Electronics FundamentalsDocument4 pagesBDU Electrical Machines Electronics FundamentalswondiePas encore d'évaluation

- AIMTDR2016 - Full - Length PaperDocument6 pagesAIMTDR2016 - Full - Length PaperMM GoudPas encore d'évaluation

- Amm Model Test Paper Q1. (A) State The Characteristics and Function of Dielectric Fluid Used in EDMDocument12 pagesAmm Model Test Paper Q1. (A) State The Characteristics and Function of Dielectric Fluid Used in EDMErin BarryPas encore d'évaluation

- Modern Manufacturing TechnologyDocument15 pagesModern Manufacturing TechnologyTHE NORTHCAP UNIVERSITYPas encore d'évaluation

- Non-Traditional Machining of Metal Matrix CompositesDocument21 pagesNon-Traditional Machining of Metal Matrix CompositesDillip MahakhudaPas encore d'évaluation

- Supporting Document For Report - Wire Edm - HCHCR - For MuzammilDocument63 pagesSupporting Document For Report - Wire Edm - HCHCR - For MuzammilMUJA ICSPas encore d'évaluation

- M.tech Mechanical Engg. (I &P)Document44 pagesM.tech Mechanical Engg. (I &P)Upender DhullPas encore d'évaluation

- Ijstev2i12011 PDFDocument3 pagesIjstev2i12011 PDFIJSTEPas encore d'évaluation

- Study of Discharge Mechanism in Electrochemical Discharge Machining ProcessDocument17 pagesStudy of Discharge Mechanism in Electrochemical Discharge Machining ProcessNik SainiPas encore d'évaluation

- Control of Power Electronic Converters and Systems: Volume 4D'EverandControl of Power Electronic Converters and Systems: Volume 4Pas encore d'évaluation

- Reliability Investigation of LED Devices for Public Light ApplicationsD'EverandReliability Investigation of LED Devices for Public Light ApplicationsPas encore d'évaluation

- Industrial AutomationDocument2 pagesIndustrial AutomationmaheshPas encore d'évaluation

- Transform TechniquesDocument2 pagesTransform TechniquesmaheshPas encore d'évaluation

- Unconvetional Machining ProcessDocument2 pagesUnconvetional Machining ProcessmaheshPas encore d'évaluation

- T.Y. B.tech Open Elective Subject ListDocument1 pageT.Y. B.tech Open Elective Subject ListmaheshPas encore d'évaluation

- Finite Elements in EngineeringDocument2 pagesFinite Elements in EngineeringmaheshPas encore d'évaluation

- Transform TechniquesDocument2 pagesTransform TechniquesmaheshPas encore d'évaluation

- Operations EfficiencyDocument3 pagesOperations EfficiencymaheshPas encore d'évaluation

- Introduction To ERPDocument3 pagesIntroduction To ERPmaheshPas encore d'évaluation

- Electronic Communication SystemsDocument2 pagesElectronic Communication SystemsmaheshPas encore d'évaluation

- Experimental Designs and Data Analysis (Statistics) PDFDocument1 pageExperimental Designs and Data Analysis (Statistics) PDFmaheshPas encore d'évaluation

- Composite MaterialsDocument2 pagesComposite MaterialsmaheshPas encore d'évaluation

- Power Plant EngineeringDocument2 pagesPower Plant EngineeringmaheshPas encore d'évaluation

- Industrial AutomationDocument2 pagesIndustrial AutomationmaheshPas encore d'évaluation

- Operations EfficiencyDocument3 pagesOperations EfficiencymaheshPas encore d'évaluation

- Control System EngineeringDocument2 pagesControl System EngineeringmaheshPas encore d'évaluation

- Introduction To ERPDocument3 pagesIntroduction To ERPmaheshPas encore d'évaluation

- Power Plant EngineeringDocument2 pagesPower Plant EngineeringmaheshPas encore d'évaluation

- T.Y. B.tech Open Elective Subject ListDocument1 pageT.Y. B.tech Open Elective Subject ListmaheshPas encore d'évaluation

- Information SystemsDocument2 pagesInformation SystemsmaheshPas encore d'évaluation

- Finite Elements in EngineeringDocument2 pagesFinite Elements in EngineeringmaheshPas encore d'évaluation

- RoboticsDocument3 pagesRoboticsGauravSuryawanshiPas encore d'évaluation

- Operations EfficiencyDocument3 pagesOperations EfficiencymaheshPas encore d'évaluation

- Unconvetional Machining ProcessDocument2 pagesUnconvetional Machining ProcessmaheshPas encore d'évaluation

- T.Y. B.tech Open Elective Subject ListDocument1 pageT.Y. B.tech Open Elective Subject ListmaheshPas encore d'évaluation

- Composite MaterialsDocument2 pagesComposite MaterialsmaheshPas encore d'évaluation

- Transform TechniquesDocument2 pagesTransform TechniquesmaheshPas encore d'évaluation

- Industrial AutomationDocument2 pagesIndustrial AutomationmaheshPas encore d'évaluation

- Control System EngineeringDocument2 pagesControl System EngineeringmaheshPas encore d'évaluation

- Information SystemsDocument2 pagesInformation SystemsmaheshPas encore d'évaluation

- Composite Materials: Unit 1Document2 pagesComposite Materials: Unit 1maheshPas encore d'évaluation