Académique Documents

Professionnel Documents

Culture Documents

Condur 41: A 2 Component Epoxy Resin Patching Mortar

Transféré par

chriscivil12Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Condur 41: A 2 Component Epoxy Resin Patching Mortar

Transféré par

chriscivil12Droits d'auteur :

Formats disponibles

Condur 41

A 2 COMPONENT EPOXY RESIN PATCHING MORTAR

DESCRIPTION MIXING

A solvent free 2 part epoxy resin thixotropic patching mortar Care should be taken to ensure that Condur 41 is mixed

consisting of a resin and hardener containing especially selected thoroughly. The hardener and the resin components should first

fillers. On mixing a multifunctional epoxy adhesive & repair mortar is be stirred separately to disperse any settlement. The entire contents

produced. of the hardener tin should then be poured into the resin tin and the

two components mixed thoroughly using a low-speed drill and

USES & ADVANTAGES paddle for at least 2 minutes until a uniform colour is obtained.

Condur 41 is an easy to apply epoxy mortar with medium size

fillers allowing for various uses, these include :- repair of precast APPLICATION

elements, finishing of I beam ends, repairing damaged concrete Apply the mixed Condur 41 with a notched trowel, putty knife,

edges, providing an abrasion resistant lining, vertical & overhead caulking gun, etc. depending upon the application. Bonded surfaces

repairs, also use as an adhesive. should be held rigidly together until the Condur 41 has set.

Advantages include:-

Easy to apply to precast elements & edges of concrete. COVERAGE RATES

2

Good build. Approx. 2 kgs/m /mm thickness.

Excellent adhesion.

Abrasion & impact resistance. CLEANING

Excellent strengths. Clean all tools immediately after use with thinner.

Suitable for both dry & damp surfaces.

Uneffected by high humidity. PACKAGING

Coloured components to ensure good mixing. 6 kg set (A+B).

Good chemical resistance.

STORAGE & SHELF LIFE

PROPERTIES Condur 41 has a shelf life of 12 months when stored in a dry

o

Colour: Part A - White / Part B - Black place below 35 C in unopened containers.

Density: Approx. 1.9-2.1 kg/litre

Mixing ratio: Part A : B = 2 : 1 by weight HEALTH & SAFETY

Part A : B = 2 : 1 by volume Prolonged and repeated skin contact with epoxy resins and curing

o

Pot Life: Temperature C 6 kg set agents may cause dermatitis in persons sensitive to these products.

Gloves, barrier creams, protective clothing and eye protection

40 30-40 min.

should be worn when handling these products. If poisoning occurs,

30 60 min.

contact a doctor or Poisons Information Centre. If swallowed, do

20 90 min.

NOT induce vomiting-give a glass of water. If in eyes, hold eyes

Note: To obtain maximum pot life, spread Condur 41

open, flood with water for at least 15 minutes. If skin contact

into a thin (less than 10 mm.) layer immediately

occurs, remove contaminated clothing and wash skin thoroughly.

after mixing.

Compressive strength: 1 Day 60-64 N/mm2

ASTM D695 7 Days 70-75 N/mm2

TECHNICAL SERVICE

The Cormix International Technical Service Department is available

28 Day 78-82 N/mm2

to assist you in the correct use of our products and its resources

Flexural Strength: 25-35 N/mm2 at 28 days

are at your disposal entirely without obligation.

Bond Strength: >13 N/mm2 at 28 days

ASTM C882

QUALITY ASSURANCE

Data quoted is typical for this product and does not constitute ISO 9001 : 2008 vertified by TUV Nord.

a specification.

Note

Note: To obtain performance characteristics stated in this data CONTACT DETAILS

sheet, the mixing ratio must be maintained. Cormix International Limited

Regional Office,

SURFACE PREPARATION 89 Romklao Rd., Sansab, Minburi, Bangkok 10510

All grease, oil, chemical contamination, dust, laitance and loose Tel. (66 2) 917 3955-8, 543 8890

concrete must be removed by scabbling or light bush hammering Fax. (66 2) 917 3959, 543 8891

to provide a sound substrate. Concrete must be at least 14 days http://www.cormix.com E-mail : info@cormix.com

old prior to treatment. Steel surfaces should be grit blasted to white

metal. Surfaces which show any traces of oil must be degreased

with a chemical degreaser prior to grit blasting.

PRIMING

Surfaces to receive Condur 41 should be well primed with Condur

Rev. 004 : Jun 2010

EA2 first.

NOTE : Every reasonable precaution is taken in the manufacture of all CORMIX-products to ensure that they comply with CORMIXs high standard of quality.

The recommendations and properties of the product are based upon what is believed to be the most reliable information available, and are not intended as

recommendations which infringe on other patents. Although all CORMIX-products are subject to rigid quality tests, no specific guarantee can be given, because

results depend, not only on quality, but also on other factors beyond our control. We welcome therefore consultation in the event of doubt concerning application,

or performance, and point out that oral recommendations, which vary from the instructions contained herein, are not binding without written confirmation by

CORMIX. All transactions shall be subject to our terms and conditions of sale-delivery-and-service. This data sheet supersedes the previous one and a reprint may

be issued without notice to supersede this edition, as and when deemed necessary. The information given in this leaflet is to the best of our knowledge true and

reliable. Field service where provided does not constitute supervisory responsibility.Our guarantee is therefore limited to the quality of materials delivered.

Vous aimerez peut-être aussi

- TDS-EN-Condur 41 - Rev 007-Jun 22Document2 pagesTDS-EN-Condur 41 - Rev 007-Jun 22LONG LASTPas encore d'évaluation

- 05 - TDS - Concresive 1441 MET WSDocument3 pages05 - TDS - Concresive 1441 MET WSAlexi ALfred H. TagoPas encore d'évaluation

- Durepox 2K Primer TDSDocument4 pagesDurepox 2K Primer TDSOswaldo Manuel Ramirez MarinPas encore d'évaluation

- Nitobond EP STD: Constructive SolutionsDocument2 pagesNitobond EP STD: Constructive SolutionsYtyus BlackPas encore d'évaluation

- Datasheet Epidermix 344Document2 pagesDatasheet Epidermix 344Vicky MunienPas encore d'évaluation

- 3 Component Epoxy MortarDocument1 page3 Component Epoxy MortarVietpapayaPas encore d'évaluation

- TDS-EN-Condur EA2 - Rev 018-Mar22Document2 pagesTDS-EN-Condur EA2 - Rev 018-Mar22LONG LASTPas encore d'évaluation

- DR - Fixit Cipoxy 16DDocument3 pagesDR - Fixit Cipoxy 16DKiran KumarPas encore d'évaluation

- Nitobond TMDocument2 pagesNitobond TMVincent JavatePas encore d'évaluation

- 112 DR Fixit Pidifin 2kDocument3 pages112 DR Fixit Pidifin 2kreshmitapallaPas encore d'évaluation

- Tehnički List - KIMICOVER FIXDocument2 pagesTehnički List - KIMICOVER FIXMARKO MATUHAPas encore d'évaluation

- DR Fixit Pidifin 2K Dec 19Document3 pagesDR Fixit Pidifin 2K Dec 19Nav Nirman Con SpecialitiesPas encore d'évaluation

- CTE250 Tar Modified Epoxy CoatingDocument2 pagesCTE250 Tar Modified Epoxy Coatingmuhamadrafie1975Pas encore d'évaluation

- DR Fixit Pidifin 2KDocument3 pagesDR Fixit Pidifin 2KAsif AhmadPas encore d'évaluation

- CONCRESIVE 2200 - v1Document2 pagesCONCRESIVE 2200 - v1VaishamPas encore d'évaluation

- 15 - TDS - Concresive ERLDocument3 pages15 - TDS - Concresive ERLAlexi ALfred H. TagoPas encore d'évaluation

- Con-Inject 2kDocument2 pagesCon-Inject 2kAnkita Baban GavadePas encore d'évaluation

- TDS-EN-Conflex PS - Rev 016-Aug21Document2 pagesTDS-EN-Conflex PS - Rev 016-Aug21LONG LASTPas encore d'évaluation

- Sikadur - 32 PDFDocument2 pagesSikadur - 32 PDFEka Manti SaputraPas encore d'évaluation

- 1476280769ps3851 Ritver Acrylic 2k Topcoat - HB - 2012Document3 pages1476280769ps3851 Ritver Acrylic 2k Topcoat - HB - 2012Zia Ur RehmanPas encore d'évaluation

- Ds Medapoxy RepDocument2 pagesDs Medapoxy RepfaridPas encore d'évaluation

- Adhesive CumDocument2 pagesAdhesive CumMokka SamaiyalPas encore d'évaluation

- Sikadur® 731Document2 pagesSikadur® 731Nguyễn Hoang AnhPas encore d'évaluation

- NP ArocoatDocument4 pagesNP ArocoatJohn HaPas encore d'évaluation

- Cicofloor FS-50 Cicomortar FX: Solvent Free Epoxy Floor Coating Multipurpose Fine Epoxy MortarDocument2 pagesCicofloor FS-50 Cicomortar FX: Solvent Free Epoxy Floor Coating Multipurpose Fine Epoxy MortarSibgathullahPas encore d'évaluation

- Bostik Boscolastic Rev1Document2 pagesBostik Boscolastic Rev1decenabuilders2016Pas encore d'évaluation

- Nippon Bodelac 9000 Alkyd Resin Enamel: DescriptionDocument2 pagesNippon Bodelac 9000 Alkyd Resin Enamel: Descriptionkominthitsar7474Pas encore d'évaluation

- Wearing CompoundDocument2 pagesWearing CompoundJuan GuillermoPas encore d'évaluation

- Camel: Sand Textured Paint Ma478 - SeriesDocument2 pagesCamel: Sand Textured Paint Ma478 - Seriessfwclau24Pas encore d'évaluation

- EpoPrime EH1 RevisedDocument2 pagesEpoPrime EH1 RevisedBilalPas encore d'évaluation

- Nitobond EP03 - 0911 ENG - Concrete AdhesifDocument2 pagesNitobond EP03 - 0911 ENG - Concrete AdhesifFadi HPas encore d'évaluation

- Ds Medapoxy SHDocument2 pagesDs Medapoxy SHfaridPas encore d'évaluation

- Sherwin Williams Macropoxy M262 PDS Promain 05 09 2022Document2 pagesSherwin Williams Macropoxy M262 PDS Promain 05 09 2022paPas encore d'évaluation

- Ac-Pqc-Injecto: Low Viscous Epoxy Injection ResinDocument2 pagesAc-Pqc-Injecto: Low Viscous Epoxy Injection ResinDeven PatlePas encore d'évaluation

- Nitomortar BDocument2 pagesNitomortar BtalatzahoorPas encore d'évaluation

- Brushbond: Uses PropertiesDocument2 pagesBrushbond: Uses PropertiesNagabhushanamPas encore d'évaluation

- 3 TekniFloor LDPDocument2 pages3 TekniFloor LDPAndy100% (1)

- Indoprotect 490ZCDocument3 pagesIndoprotect 490ZCSwapnil KupalePas encore d'évaluation

- Consol 71 FC: 2-Part Thixotropic Multipurpose Epoxy AdhesiveDocument2 pagesConsol 71 FC: 2-Part Thixotropic Multipurpose Epoxy AdhesiveMuhammad FirdausPas encore d'évaluation

- INDUBOND-VK4034: Technical Data SheetDocument2 pagesINDUBOND-VK4034: Technical Data SheetAbubakar Ashraf AnjumPas encore d'évaluation

- Loctite PC 7218 TDSDocument2 pagesLoctite PC 7218 TDSDavid MendozaPas encore d'évaluation

- Zinc Anode 304 NPC Coating Zinc Anode 304 NPC Coating: Berger Industrial Manual Berger Industrial ManualDocument1 pageZinc Anode 304 NPC Coating Zinc Anode 304 NPC Coating: Berger Industrial Manual Berger Industrial Manualআফজাল -উল ইসলাম নূর0% (1)

- Technical Data Sheet: DescriptionDocument4 pagesTechnical Data Sheet: Descriptionerode els erodePas encore d'évaluation

- Boscoflex: Flexible Cementitious Waterprofing MembraneDocument2 pagesBoscoflex: Flexible Cementitious Waterprofing MembraneCLENTH FLORentinoPas encore d'évaluation

- Neromastic 800: Scope Application DetailsDocument1 pageNeromastic 800: Scope Application DetailsTanvir Ahmed Khan100% (1)

- Concresive Fluido: Two-Pack Solvent-Free Fluid Epoxy Adhesive For Fixings, Construction Joints and AnchoragesDocument3 pagesConcresive Fluido: Two-Pack Solvent-Free Fluid Epoxy Adhesive For Fixings, Construction Joints and AnchoragesKarl FarrugiaPas encore d'évaluation

- TDS Pidifin 2K Eng Rev.09 23 07 19Document3 pagesTDS Pidifin 2K Eng Rev.09 23 07 19Sumit SinhaPas encore d'évaluation

- Corrocoat Graphite SDocument3 pagesCorrocoat Graphite SstelioskoPas encore d'évaluation

- Neromastic 4000Document2 pagesNeromastic 4000m pallonjiPas encore d'évaluation

- Sikadur - 52: Low Viscosity Injection ResinDocument3 pagesSikadur - 52: Low Viscosity Injection ResinJoePas encore d'évaluation

- 04 - TDS - Concresive 2200Document3 pages04 - TDS - Concresive 2200aahtagoPas encore d'évaluation

- TDS - Solvent Free Epoxy STDDocument2 pagesTDS - Solvent Free Epoxy STDRameshp PalanisamyPas encore d'évaluation

- Sikadur - 52: Low Viscosity Injection ResinDocument3 pagesSikadur - 52: Low Viscosity Injection ResinSunny RohillaPas encore d'évaluation

- Vinilex 120 Active Primer - Spec - enDocument3 pagesVinilex 120 Active Primer - Spec - enDonzt Dontz FaujiPas encore d'évaluation

- Nitobond Ec (Epoxy Adhesive)Document3 pagesNitobond Ec (Epoxy Adhesive)Kris SiregarPas encore d'évaluation

- TDS - Supra Epoxy HB Mio CoatingDocument2 pagesTDS - Supra Epoxy HB Mio CoatingSachin SinghalPas encore d'évaluation

- Extract Page 1Document1 pageExtract Page 1SebastianAnPas encore d'évaluation

- Characteristics: Uses ApplicationDocument2 pagesCharacteristics: Uses Applicationazam RazzaqPas encore d'évaluation

- Alodine 1132 Touch-N-PrepDocument3 pagesAlodine 1132 Touch-N-PrepEduardo NozalPas encore d'évaluation

- Water-Based Paint Formulations, Vol. 3D'EverandWater-Based Paint Formulations, Vol. 3Évaluation : 4.5 sur 5 étoiles4.5/5 (6)

- CPIDetailDocument7 pagesCPIDetailchriscivil12Pas encore d'évaluation

- Presentation PAMPAS 2Document6 pagesPresentation PAMPAS 2chriscivil12Pas encore d'évaluation

- XLQ OnlyDocument45 pagesXLQ Onlychriscivil12Pas encore d'évaluation

- RSStocksDocument28 pagesRSStockschriscivil12Pas encore d'évaluation

- Sisi ProductionDocument1 pageSisi Productionchriscivil12Pas encore d'évaluation

- DPT Kolam Retensi H 3.8m (No Water)Document6 pagesDPT Kolam Retensi H 3.8m (No Water)chriscivil12Pas encore d'évaluation

- Industry PerfDocument8 pagesIndustry Perfchriscivil12Pas encore d'évaluation

- Revit Tutorial Segment 3Document20 pagesRevit Tutorial Segment 3Budega100% (10)

- Cantilever Retaining WallDocument5 pagesCantilever Retaining Wallchriscivil12Pas encore d'évaluation

- Best Tank Calculation SheetDocument88 pagesBest Tank Calculation Sheetchriscivil12Pas encore d'évaluation

- Scafolding Set PDFDocument2 pagesScafolding Set PDFchriscivil12Pas encore d'évaluation

- Brosur HidrostalDocument2 pagesBrosur Hidrostalchriscivil12Pas encore d'évaluation

- Perhitungan Valuasi FADocument2 pagesPerhitungan Valuasi FAchriscivil12Pas encore d'évaluation

- Parameter Terpakai:: Tabel 4.11. Perhitungan Debit Andalan F.J Mock 1994Document2 pagesParameter Terpakai:: Tabel 4.11. Perhitungan Debit Andalan F.J Mock 1994chriscivil12Pas encore d'évaluation

- Cantilever Sheet Pile Wall, SI Units (DeepEX 2015) PDFDocument13 pagesCantilever Sheet Pile Wall, SI Units (DeepEX 2015) PDFchriscivil12Pas encore d'évaluation

- Award Report TemplateDocument3 pagesAward Report Templatechriscivil12Pas encore d'évaluation

- Sakaled Frameless Led 40wDocument1 pageSakaled Frameless Led 40wchriscivil12Pas encore d'évaluation

- IndexDocument8 pagesIndexSengottu VelusamyPas encore d'évaluation

- Retaining Wall With Counterfort - Rev00 - 05-Apr-2014Document9 pagesRetaining Wall With Counterfort - Rev00 - 05-Apr-2014chriscivil12Pas encore d'évaluation

- Manual of SurvivingDocument1 pageManual of SurvivingKristi GonzalesPas encore d'évaluation

- Media 111415 enDocument30 pagesMedia 111415 enchriscivil12Pas encore d'évaluation

- KCC FLOOR COATING (Catalogue) PDFDocument16 pagesKCC FLOOR COATING (Catalogue) PDFchriscivil12Pas encore d'évaluation

- AISC Properties ViewerDocument3 pagesAISC Properties Viewerchriscivil12Pas encore d'évaluation

- KCC FLOOR COATING (Catalogue) PDFDocument16 pagesKCC FLOOR COATING (Catalogue) PDFchriscivil12Pas encore d'évaluation

- Award Report TemplateDocument3 pagesAward Report TemplatekulukundunguPas encore d'évaluation

- Daftar Isian Alat IA LabDocument2 pagesDaftar Isian Alat IA Labchriscivil12Pas encore d'évaluation

- PremierInsight 170116Document3 pagesPremierInsight 170116chriscivil12Pas encore d'évaluation

- Watertreatmentplant 150602145903 Lva1 App6892Document172 pagesWatertreatmentplant 150602145903 Lva1 App6892chriscivil12100% (2)

- TM 5 809 12 PDFDocument54 pagesTM 5 809 12 PDFchriscivil12Pas encore d'évaluation

- KCC Floor Coating (Catalogue)Document16 pagesKCC Floor Coating (Catalogue)chriscivil120% (2)

- Market Structure and TrendDocument10 pagesMarket Structure and TrendbillPas encore d'évaluation

- Learning Spanish - 1dDocument23 pagesLearning Spanish - 1dChima C. Ugwuegbu100% (1)

- Project Report On HeritageDocument39 pagesProject Report On HeritageBALA YOGESH YANDAMURIPas encore d'évaluation

- Glory in The Cross - Holy Thursday - Schutte PDFDocument1 pageGlory in The Cross - Holy Thursday - Schutte PDFsharon0murphyPas encore d'évaluation

- Trading Rules To Successful ProfitsDocument89 pagesTrading Rules To Successful ProfitsOuattaraPas encore d'évaluation

- Unit 7 - Evolution and Classification: Regents BiologyDocument24 pagesUnit 7 - Evolution and Classification: Regents BiologyTalijah JamesPas encore d'évaluation

- Term Paper A and CDocument9 pagesTerm Paper A and CKishaloy NathPas encore d'évaluation

- LhiannanDocument6 pagesLhiannanGreybornPas encore d'évaluation

- Exam Ref 70 483 Programming in C by Wouter de Kort PDFDocument2 pagesExam Ref 70 483 Programming in C by Wouter de Kort PDFPhilPas encore d'évaluation

- Introduction To Human MovementDocument5 pagesIntroduction To Human MovementNiema Tejano FloroPas encore d'évaluation

- Ethics FinalsDocument22 pagesEthics FinalsEll VPas encore d'évaluation

- GSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserDocument13 pagesGSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserSanatana RoutPas encore d'évaluation

- Language EducationDocument33 pagesLanguage EducationLaarni Airalyn CabreraPas encore d'évaluation

- Jurnal Direct and Indirect Pulp CappingDocument9 pagesJurnal Direct and Indirect Pulp Cappingninis anisaPas encore d'évaluation

- Sip Poblacion 2019 2021 Revised Latest UpdatedDocument17 pagesSip Poblacion 2019 2021 Revised Latest UpdatedANNALLENE MARIELLE FARISCALPas encore d'évaluation

- 2002 CT Saturation and Polarity TestDocument11 pages2002 CT Saturation and Polarity Testhashmishahbaz672100% (1)

- English 6, Quarter 1, Week 7, Day 1Document32 pagesEnglish 6, Quarter 1, Week 7, Day 1Rodel AgcaoiliPas encore d'évaluation

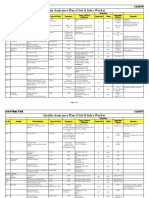

- Quality Assurance Plan-75FDocument3 pagesQuality Assurance Plan-75Fmohamad chaudhariPas encore d'évaluation

- Agreement - IDP - Transformation Institute - 2023Document16 pagesAgreement - IDP - Transformation Institute - 2023Elite ProgramPas encore d'évaluation

- Kpolovie and Obilor PDFDocument26 pagesKpolovie and Obilor PDFMandalikaPas encore d'évaluation

- ZyLAB EDiscovery 3.11 What's New ManualDocument32 pagesZyLAB EDiscovery 3.11 What's New ManualyawahabPas encore d'évaluation

- SST Vs BBTDocument7 pagesSST Vs BBTFlaxkikare100% (1)

- Quality Assurance Plan - CivilDocument11 pagesQuality Assurance Plan - CivilDeviPrasadNathPas encore d'évaluation

- Policy Implementation NotesDocument17 pagesPolicy Implementation NoteswubePas encore d'évaluation

- La La Mei Seaside Resto BAR: Final PlateDocument4 pagesLa La Mei Seaside Resto BAR: Final PlateMichael Ken FurioPas encore d'évaluation

- Mechanics of Materials 7th Edition Beer Johnson Chapter 6Document134 pagesMechanics of Materials 7th Edition Beer Johnson Chapter 6Riston Smith95% (96)

- Protected PCM USB Memory Sticks For Pa3X.Document1 pageProtected PCM USB Memory Sticks For Pa3X.mariuspantera100% (2)

- Finance 2021 23Document16 pagesFinance 2021 23GAURAV UPADHYAYPas encore d'évaluation

- Service M5X0G SMDocument98 pagesService M5X0G SMbiancocfPas encore d'évaluation

- How Should We Allocate Scarce Resources Over Our Business Portfolio?Document20 pagesHow Should We Allocate Scarce Resources Over Our Business Portfolio?Vivek AryaPas encore d'évaluation