Académique Documents

Professionnel Documents

Culture Documents

Im 5ckyer Acson

Transféré par

Fauzi YakobCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Im 5ckyer Acson

Transféré par

Fauzi YakobDroits d'auteur :

Formats disponibles

INSTALLATION MANUAL

INVERTER CEILING CASSETTE

SPLIT TYPE AIR CONDITIONER

(E Series)

IM-5CKYER-1009(1)-ACSON

Part No.: R08019034194A

IM-5CKYER-1009(1)-COVER_AC(EN).i1 1 4/8/11 5:34:38 PM

IM-5CKYER-1009(1)-COVER_AC(EN).i2 2 4/8/11 5:34:40 PM

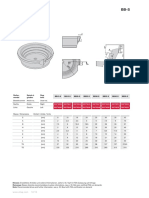

OUTLINE AND DIMENSIONS

English

Indoor Unit 5CKY20/25E/ER & 5CKY28/40/50ER

All dimensions are in mm

Original Instruction

C F

D E

H

K

A

G

I

J

Dimension A B C D E F G H I J K

Model

5CKY20/25E/ER 820 820 340 300 40 990 990 627 627 607 430

5CKY28ER

5CKY40/50ER 820 820 375 335 40 990 990 627 627 607 430

Outdoor Unit 5SLY20/25C/CR

L K L

All dimensions are in mm

N

M

T

N

C

A

O D G H

F

P

E

B

S

R

I J

Q

Dimension A B C D E F G H I J K L M N O P Q R S T

Model

5SLY20/25C/CR 855 730 328 513 182 44 93 149 101 113 603 126 164 15 47 3 23 73 75 362

1-1

1 EN 5CKYER-1009(1).indd 1 4/21/11 9:11:09 AM

Outdoor Unit 5SLY28CR

A

D

S

T K

E

S

T

R G R

B I H

O M N

Q

P

J

F

C

L

Dimension A U

B C D E F G H I J K L M N O P Q R S T U

Model

5SLY28CR 940 348 753 855 392 733 603 328 303 370 362 448 190 80 58 180 32 126 32 15 23

1-2

1 EN 5CKYER-1009(1).indd 2 4/21/11 9:11:13 AM

Outdoor Unit 5SLY40/50FR

English

All dimensions are in mm

AB AC AD

AE

AA

AF

AH

AG

AI

AJ

AK

C A

B

U

E

T

L

V

K

W

H I Q X

D

O

J

S

G P Z

AU R

AT

AM AL

AS

AN

AO AP AQ AR

Dimension A B C D E F G H I J K L M N

Model

900 1374 30 24 60 89 142 89 19 54 95 423 430 95

O P Q R S T U V W X Y Z

54 19 89 145 84 55 55 223 148 13 52 67

5SLY40/50FR AA AB AC AD AE AF AG AH AI AJ AK AL AM AN

350 140 620 140 30 320 30 59 43 40 94 117 102 70

AO AP AQ AR AS AT AU

45 376 191 70 58 16 16

1-3

1 EN 5CKYER-1009(1).indd 3 4/21/11 9:11:13 AM

INSTALLATION MANUAL

This manual provides the procedures of installation to ensure a safe and good standard of operation for the air conditioner unit.

Special adjustment may be necessary to suit local requirements.

Before using your air conditioner, please read this instruction manual carefully and keep it for future reference.

This appliance is intended to be used by expert or trained users in shops, in light industry and on farms, or for commercial use by lay persons.

SAFETY PRECAUTIONS

! WARNING ! CAUTION

Installation and maintenance should be performed by qualified Please take note of the following important points when

persons who are familiar with local code and regulation, and installing.

experienced with this type of appliance. Do not install the unit where leakage of flammable gas may

All field wiring must be installed in accordance with the national occur.

wiring regulation. If gas leaks and accumulates around the unit, it may cause

Ensure that the rated voltage of the unit corresponds to that of fire ignition.

the name plate before commencing wiring work according to Ensure that drainage piping is connected properly.

the wiring diagram. If the drainage piping is not connected properly, it may

The unit must be GROUNDED to prevent possible hazard due cause water leakage which will dampen the furniture.

to insulation failure. Do not overcharge the unit.

All electrical wiring must not touch the refrigerant piping, or This unit is factory pre-charged.

any moving parts of the fan motors. Overcharge will cause over-current or damage to the

Confirm that the unit has been switched OFF before installing compressor.

or servicing the unit. Ensure that the units panel is closed after service or

Disconnect from the main power supply before servicing the installation.

air conditioner unit. Unsecured panels will cause the unit to operate noisily.

DO NOT pull out the power cord when the power is ON. This Sharp edges and coil surfaces are potential locations which

may cause serious electrical shocks which may result in fire may cause injury hazards.

hazards. Avoid from being in contact with these places.

Keep the indoor and outdoor units, power cable and transmission Before turning off the power supply, set the remote

wiring, at least 1m from TVs and radios, to prevent distorted controllers ON/OFF switch to the OFF position to

pictures and static. {Depending on the type and source of the prevent the nuisance tripping of the unit. If this is not done,

electrical waves, static may be heard even when more than 1m the units fans will start turning automatically when power

away}. resumes, posing a hazard to service personnel or the user.

Do not operate any heating apparatus too close to the air

conditioner unit. This may cause the plastic panel to melt or

deform as a result of the excessive heat.

Do not install the units at or near doorway.

Do not operate any heating apparatus too close to the air

conditioner unit or use in room where mineral oil, oil vapour

or oil steam exist, this may cause plastic part to melt or

deform as a result of excessive heat or chemical reaction.

When the unit is used in kitchen, keep flour away from going

into suction of the unit.

This unit is not suitable for factory used where cutting oil

mist or iron powder exist or voltage fluctuates greatly.

Do not install the units at area like hot spring or oil refinery

plant where sulphide gas exists.

Ensure the color of wires of the outdoor unit and the

terminal markings are same to the indoors respectively.

IMPORTANT: DO NOT INSTALL OR USE THE AIR

CONDITIONER UNIT IN A LAUNDRY ROOM.

Dont use joined and twisted wires for incoming power

supply.

Avoid direct contact of any coil treatment cleaners on plastic

part. This may cause plastic part to deform as a result of

chemical reaction.

For any enquiries on spare parts please contact your

authorized dealer.

The equipment is not intended for use in a potentially

explosive atmosphere.

NOTICE

Disposal requirements

Your air conditioning product is marked with this symbol. This means that electrical and electronic products shall not be mixed with unsorted

household waste.

Do not try to dismantle the system yourself: the dismantling of the air conditioning system, treatment of the refrigerant, of oil and of other parts

must be done by a qualified installer in accordance with relevant local and national legislation.

Air conditioners must be treated at a specialized treatment facility for re-use, recycling and recovery. By ensuring this product is disposed of

correctly, you will help to prevent potential negative consequences for the environment and human health. Please contact the installer or local

authority for more information.

Batteries must be removed from the remote controller and disposed of separately in accordance with relevant local and national legislation.

1-4

1 EN 5CKYER-1009(1).indd 4 4/21/11 9:11:17 AM

IMPORTANT

English

Important information regarding the refrigerant used

This product contains fluorinated greenhouse gases covered by the Kyoto Protocol.

Do not vent gases into the atmosphere.

Refrigerant type: R410A

GWP (1) value: 1975

(1)

GWP = global warming potential

Please fill in with indelible ink,

n 1 the factory refrigerant charge of the product,

n 2 the additional refrigerant amount charged in the field and

n 1 + 2 the total refrigerant charge

on the refrigerant charge label supplied with the product.

The filled out label must be adhered in the proximity of the product charging port (e.g. onto the inside of the service cover).

1 factory refrigerant charge of the product:

see unit name plate (2)

2 additional refrigerant amount charged in the field

3 total refrigerant charge

4 contains fluorinated greenhouse gases covered by the Kyoto Protocol

5 outdoor unit

6 refrigerant cylinder and manifold for charging

(2)

In case of multiple indoor systems, only 1 label must be adhered*, mentioning the total factory refrigerant charge of all

indoor units connected in the refrigerant system.

Periodical inspections for refrigerant leaks may be required depending on European or local legislation. Please contact your

local dealer for more information.

* on the outdoor unit

1-5

1 EN 5CKYER-1009(1).indd 5 4/21/11 9:11:18 AM

INSTALLATION DIAGRAM

Indoor Unit Thermal Insulation

Drain Piping

Wrap the insulated pipe with the

finishing tape from bottom to top

Front Panel

Air Filter

(behind the grille)

Air Intake Grille

Air Discharge Louver

Air Intake

Air Intake

Air Discharge Outdoor Unit

1-6

1 EN 5CKYER-1009(1).indd 6 4/21/11 9:11:18 AM

INSTALLATION OF THE INDOOR UNIT

English

Preliminary Site Survey

Be sure to read this manual before installing the air-conditioner indoor unit.

Voltage supply fluctuation must not exceed 10% of rated voltage. Electricity supply lines must be independent of welding

transformers which can cause high supply fluctuation.

Ensure that the location is convenient for wiring, piping and drainage.

Do not exert pressure on the resin parts when opening the unit or when moving it after opening.

Do not move the unit from packaging while moving, until it reaches the installation site. Use safe material or protection

plates when unpacking it or lifting it to avoid damage or scratches to the unit.

Beam

0.3m or less

1m or more

3m or more

0.5m or more 0.5m or more 0.5m or more

Obstacle

Floor

Ensure a location where:

a) Drainage can be done easily.

b) Convenient for wiring and piping.

c) Which have enough space for installation and service work.

d) Where no risk of flammable gas leakage.

e) When free from any obstacles in path of cool air discharge and warm air return and must allow spreading of air throughout

the room (near the center of the room).

f) Must be provided clearance for indoor unit from the wall and obstacles as shown in figure below.

g) The installation place must be strong enough to support a load 4 times the indoor unit weight to avoid amplifying noise

and vibration.

h) The installation place (hanging ceiling surface) must be assuring levelness and the height in the ceiling is 350mm or

more.

i) The indoor unit must be away from heat and steam sources (avoid installing it near an entrance).

Unit Installation

990.0mm Measure and mark the position for the hanging rod. Drill

880.0~990.0mm (Ceiling Opening Site = 890mm) the hole for the angle nut on the ceiling and fix the hanging

770.0mm (Hanging Rod) rod.

The installation template is extended according to

temperature and humidity. Check on dimensions in use.

The dimensions of the installation template are the same as

880.0~990.0mm (Ceiling Opening Site)

those of the ceiling opening dimensions.

Before ceiling laminating work is completed, be sure to fit

622.0mm (Hanging Rod)

the installation template to the indoor unit.

990.0mm

NOTE

Be sure to discuss the ceiling drilling work with the installers

concerned.

Piping Direction

Unit Hanging

Confirm the pitch of the hanging rod is 770mm 622mm

sharp.

Hold the unit and hang it on the hanging rod with the nut

and washer.

Adjust the unit height to 30 mm between the indoor unit

bottom surface and the ceiling surface.

Indoor Unit

Confirm with a level gauge that the unit is installed

Ceiling horizontally and tighten the nut and bolt to prevent unit

Board falling and vibration.

30 mm

Open the ceiling board along the outer edge of the paper

installation template.

1-7

1 EN 5CKYER-1009(1).indd 7 4/21/11 9:11:18 AM

Drain Pump Work

Drain pipe must be in downward gradient for smooth

drainage.

Avoid installing the drain pipe in up and down slope to

prevent reversed water flow.

During the drain pipe connection, be careful not to exert

Indoor Unit extra force on the drain connector at indoor unit.

The outside diameter of the drain connection at the

flexible drain hose is 20 mm.

Pipe Clamp Be sure to execute heat insulation (polyethylene foam

with thickness more than 8.0 mm) on the drain piping to

avoid the condensed water dripping inside the room.

Drain Test

Connect the main drain pipe to the flexible drain.

Feed Water

Feed water from flexible drain hose to check the piping

Main Drain Pipe for leakage.

When the test is completed, connect the flexible drain

hose to the drain connector on the indoor unit.

Flexible Drain Hose

NOTE

This Indoor Unit uses a drain pump for condensed water drainage. Install the unit horizontally to prevent water leakage

or condensation around the air outlet.

Panel Installation

The front panel can only be fitted in one direction, follow the piping direction. (Follow piping arrow sticker on front panel)

Be sure to remove the installation template before installing the front panel.

Open

Screw

Open the air intake grille by pulling back the catchers and removing it together with filter from panel.

Install the front frame panel onto the indoor unit by 4 screws and tighten it completely to prevent cool air leakage.

Connect the LED wire and air swing wire to the indoor unit.

The air swing connector must put inside the control box after connected.

LED Wire

From

From Unit

Front Control

Panel Box

Air Swing Wire

1-8

1 EN 5CKYER-1009(1).indd 8 4/21/11 9:11:19 AM

Cover Lock Grille (The moving part protection for user direct touching)

Cover lock grill must be installed as the figure below.

English

Frame

Intake Grille

Cover Lock Grille

(2pcs)

Screw M4 x 6

(2pcs)

If the unit need to be service, steps below shall be followed:

1. Confirm that the unit had been switched off before servicing the unit.

2. Use screwdriver to unlock the screw on the cover lock grille.

3. Remove the cover lock grille and open the intake grille for the service purpose.

4. Install the intake grille and screw the cover lock grille after service and make sure the unit is proper install.

1-9

1 EN 5CKYER-1009(1).indd 9 4/21/11 9:11:19 AM

Wires Installation

Figure 1

Figure 1 and Figure 2 shows the location of cover wire in CKE unit.

Steps to install power supply wires and wires from outdoor unit.

1. Remove wire cover by removing 2 screws as shown in Figure 3.

2. Wires will go through the hole as shown in Figure 4 and 5 respectively without crossing the height of the hole.

3. After that, wire cover will be assembled back to close the wire.

Figure 2 Figure 3

Figure 4 Figure 5

! CAUTION

Do not install the unit at altitude over 2000m for both indoor and outdoor.

1-10

1 EN 5CKYER-1009(1).indd 10 4/21/11 9:11:19 AM

INSTALLATION OF THE OUTDOOR UNIT

English

The outdoor unit must be installed in such a way, so as to prevent short circuit of the hot discharged air or obstruction to

the smooth air flow. Please follow the installation clearance shown in the figures below. Select the coolest possible place

where intake air temperature is not greater than the outside air temperature.

Where a wall or other obstacles is in the path of outdoor units intake or exhaust airflow, follow the installation guidelines

below.

For any of the below installation patterns, the wall height on the exhaust side should be 1200mm or less.

5SLY20/25C/CR

Wall facing one side Wall facing two sides

More than 50 More than 100

More than 100 More than 150

More than 50 More than 50

Top View

Side View

Wall facing two sides

More than 150

More than 300

More than 50 Top View Unit: mm

5SLY28CR

Wall facing one side Wall facing two sides

More than 100 More than 350

More than 350

More

than 100

1200

or less

More than 50 More than 50

Side View Top View

Wall facing three sides

More than 100

More than 350

More than 50

Top View Unit: mm

1-11

1 EN 5CKYER-1009(1).indd 11 4/21/11 9:11:19 AM

5SLY40/50FR

Wall facing one side

More than 100 More than 500

Side View

Wall facing more than 1 side of obstacle

More

than More than 100

100

More

than 100

More than 100 More than 500

Top View Unit: mm

Allow more space for installation above with additional obstacle at top side and installation in series.

REFRIGERANT PIPING

Allowable Piping Length

When the pipe length becomes too long, both the capacity and reliability drop. As a result, compressor reliability will be

affected. Always choose the shortest path and follow the recommendation as tabulated below:

Indoor 5CKY20E/ER 5CKY25E/ER 5CKY28ER

Outdoor 5SLY20C/CR 5SLY25C/CR 5SLY28CR

Max. allowable length, m 30 30 50

Max. allowable elevation, m 10 10 30

Liquid pipe size, mm/(in) 6.35 (1/4") 6.35 (1/4") 9.52 (3/8")

Gas pipe size, mm/(in) 12.70 (1/2") 15.88 (5/8") 15.88 (5/8")

Additional charge of refrigerant, g/m

20 20 50

(for piping length above 7.5m)

Indoor 5CKY40ER 5CKY50ER

Outdoor 5SLY40FR 5SLY50FR

Max. allowable length, m 75 75

Max. allowable elevation, m 30 30

Liquid pipe size, mm/(in) 9.52 (3/8") 9.52 (3/8")

Gas pipe size, mm/(in) 15.88 (5/8") 15.88 (5/8")

Additional charge of refrigerant, g/m

50 50

(for piping length above 30m)

1-12

1 EN 5CKYER-1009(1).indd 12 4/21/11 9:11:20 AM

Piping Works And Flaring Technique

Do not use contaminated or damaged copper tubing. If any pipings, evaporator or condenser had been exposed or had been

English

opened for 15 seconds or more, the system must be vacuumed. Generally, do not remove plastic, rubber plugs and brass

nuts from the valves, fittings, tubings and coils until it is ready to connect suction or liquid line into valves or fittings.

If any brazing work is required, ensure that the nitrogen gas is passed through coil and joints while the brazing work is

being done. This will eliminate soot formation on the inside walls of the copper tubings.

Cut the pipe stage by stage, advancing the blade of the pipe cutter slowly. Extra force and deep cut will cause more distortion

on the pipe and thus extra burr. See Figure A.

Remove burrs from cut edges of the pipes with remover Fig. A

as shown in Figure B. This will avoid unevenness on the Cutting Copper Tube

flare faces which will cause gas leak. Hold the pipe on

top position and burr remover at lower position to prevent 1/4t

metal chips from entering the pipe.

Insert the flare nuts, mounted on the connection parts of

both the indoor unit and outdoor unit, into the copper

pipes.

The exact length of pipe protruding from the top surface of

the swaging block is determined by the flaring tool. Refer Fig. B

Figure C.

Fix the pipe firmly on the swaging block. Match the centers

of both the flare die and the flaring punch, and then tighten Remove Burr

the flaring punch fully.

Piping Connection To The Units

Align the center of the piping and tighten the flare nut Fig. C

sufficiently with fingers. Refer Figure D.

Finally, tighten the flare nut with the torque wrench until Copper Tube D

the wrench clicks. Swaging Block

A

When tightening the flare nut with the torque wrench,

ensure that the tightening direction follows the arrow

indicated on the wrench.

The refrigerant pipe connection are insulated by closed

cell polyurethane.

Fig. D

Pipe Size (mm/in) Torque (Nm/ft-lb)

Flare Joint Flared Tube

6.35 (1/4) 18 (13.3)

9.52 (3/8) 42 (31.0)

12.70 (1/2) 55 (40.6)

15.88 (5/8) 65 (48.0)

Indoor Piping

19.05 (3/4) 78 (57.6) Flare Nut

Tube, D A (mm)

Inch mm Imperial Rigid

(Wing-nut Type) (Clutch Type)

1/4" 6.35 1.3 0.7

3/8" 9.52 1.6 1.0

1/2" 12.70 1.9 1.3

5/8" 15.88 2.2 1.7 Torque Wrench

3/4" 19.05 2.5 2.0 Spanar

1-13

1 EN 5CKYER-1009(1).indd 13 4/21/11 9:11:20 AM

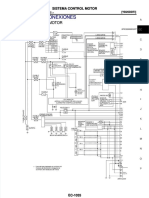

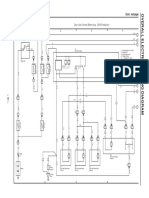

ELECTRICAL CONNECTION

IMPORTANT: * These values are for information only, they should be checked and selected to comply with the local and/or national

codes and regulations. They are also subjected to the type of installation and size of conductors used.

** The appropriate voltage range should be checked with the label data on the unit.

5CKY20/25E/ER - 5SLY20/25C/CR

Indoor Unit Outdoor Unit

Terminal Block Interconnection Terminal Block

Cable

1 1

2 2

SIG SIG

L

N Power Supply Cable

! There must be an all pole

disconnection in the supply

mains with a contact separation

of at least 3mm.

Model Indoor 5CKY20E/ER 5CKY25E/ER

Outdoor 5SLY20C/CR 5SLY25C/CR

Voltage range** Indoor 220V - 240V /1Ph /50Hz + !

Outdoor 220V - 240V /1Ph /50Hz + !

Power supply cable size* mm2 2.5 2.5

Number of conductors 3 3

Interconnection cable size* mm2 2.5 2.5

Number of conductors 4 4

Recommended time delay fuse* A 20 20

5CKY28ER - 5SLY28CR

Indoor Unit Outdoor Unit

Terminal Block Terminal Block

L Interconnection

L

Cable

N N

SIG

SIG

L

N

Power Supply Cable ! There must be an all pole

disconnection in the supply

mains with a contact separation

of at least 3mm.

Model Indoor 5CKY28ER

Outdoor 5SLY28CR

Voltage range** Indoor 220V - 240V/1Ph/50Hz + !

Outdoor 220V - 240V/1Ph/50Hz + !

Power supply cable size* mm2 2.5

Number of conductors 3

Interconnection cable size* mm2 1.5

Number of conductors 4

Recommended time delay fuse* A 25

1-14

1 EN 5CKYER-1009(1).indd 14 4/21/11 9:11:21 AM

5CKY40ER - 5SLY40FR (1 Phase)

5CKY50ER - 5SLY50FR (1 Phase)

English

Indoor Unit Outdoor Unit

Terminal Block Terminal Block

1 1

Interconnection

2 Cable

2

3

3

L

N

Power Supply Cable

! There must be an all pole

disconnection in the supply

mains with a contact separation

of at least 3mm.

Model Indoor 5CKY40ER 5CKY50ER

Outdoor 5SLY40FR 5SLY50FR

Voltage range** Indoor 220V - 240V/1Ph/50Hz + !

Outdoor 220V - 240V/1Ph/50Hz + !

2

Power supply cable size* mm 6 6

Number of conductors 3 3

Interconnection cable size* mm2 1.5 1.5

Number of conductors 4 4

Recommended time delay fuse* A 32 32

5CKY40ER - 5SLY40FR (3 Phase)

5CKY50ER - 5SLY50FR (3 Phase)

Indoor Unit Outdoor Unit

Terminal Block Terminal Block

Interconnection

1 Cable 1

2 2

3 3

L1

L2

L3

N

Power Supply Cable

! There must be an all pole

disconnection in the supply

mains with a contact separation

of at least 3mm.

Model Indoor 5CKY40ER 5CKY50ER

Outdoor 5SLY40FR 5SLY50FR

Voltage range** Indoor 220V - 240V/1Ph/50H + !

Outdoor 380V - 415V/3N~/50Hz + !

2

Power supply cable size* mm 4 4

Number of conductors 5 5

Interconnection cable size* mm2 1.5 1.5

Number of conductors 4 4

Recommended time delay fuse* A 20 20

1-15

1 EN 5CKYER-1009(1).indd 15 4/21/11 9:11:21 AM

All wires must be firmly connected.

Make sure all the wire do not touch the refrigerant pipings, compressor or any moving parts.

The connecting wire between the indoor unit and the outdoor unit must be clamped by using provided cord anchorage.

The power supply cord must be equivalent to H07RN-F which is the minimum requirement.

Make sure no external pressure is applied to the terminal connectors and wires.

Make sure all the covers are properly fixed to avoid any gap.

Use round crimp-style terminal for connecting wires to the power supply terminal block. Connect the wires by matching

to the indication on terminal block. (Refer to the wiring diagram attached on the unit).

Attach insulation sleeve

Electric wire

Round crimp-style terminal

Use the correct screwdriver for terminal screws tightening. Unsuitable screwdrivers can damage the screw head.

Over tightening can damage the terminal screw.

Do not connect wire of different gauge to same terminal.

Keep wiring in an orderly manner. Prevent the wiring from obstructing other parts and the terminal box cover.

Connect wires of the Do not connect wires of the Do not connect wires

same gauge to both side. same gauge to one side. of different gauges.

SPECIAL PRECAUTIONS WHEN DEALING WITH R410A UNIT

R410A is a new HFC refrigerant which does not damage the Use tools and materials exclusively for refrigerant R410A.

ozone layer. The working pressure of this new refrigerant is 1.6 Tools exclusively for R410A are manifold valve, charging

times higher than conventional refrigerant (R22), thus proper hose, pressure gauge, gas leak detector, flare tools, torque

installation / servicing is essential. wrench, vacuum pump and refrigerant cylinder.

Never use refrigerant other than R410A in an air conditioner As an R410A air conditioner incurs higher pressure

which designed to operate with R410A. than R22 units, it is essential to choose the copper pipes

POE or PVE oil is used as lubricant for R410A correctly. Never use copper pipes thinner than 0.8mm even

compressor, which is different from the mineral oil used though they are available in the market.

for R22 compressor. During installation or servicing, extra If the refrigerant gas leakage occurs during installation /

precaution must be taken not to expose the R410A system servicing, be sure to ventilate fully. If the refrigerant gas

too long to moist air. Residual POE or PVE oil in the piping comes into contact with fire, a poisonous gas may occur.

and components can absorb moisture from the air. When installing or removing an air conditioner, do not

To prevent mischarging, the diameter of the service port allow air or moisture to remain in the refrigerant cycle.

on the flare valve is different from that of R22.

1-16

1 EN 5CKYER-1009(1).indd 16 4/21/11 9:11:21 AM

VACUUMING AND CHARGING

English

Vacuuming is necessary to eliminate all moisture and air from the system. The series II Outdoor Unit is provided with flare

valve fittings.

Vacuuming The Piping And The Indoor Unit

Except for the outdoor unit which is pre-charged with Allen key Refrigerant Piping

Flare nut

refrigerant, the indoor unit and the refrigerant connection

pipes must be air-purged because the air containing moisture

that remains in the refrigerant cycle may cause malfunction

of the compressor.

Remove the caps from the valve and the service port. Service Port Outdoor Unit 3 ways valve

Connect the center of the charging gauge to the vacuum

pump.

Connect the charging gauge to the service port of the 3-way LOW PRESSURE GAUGE HIGH PRESSURE GAUGE

valve. -760mmHg GAUGE MANIFOLD

Start the vacuum pump. Evacuate for approximately 30

minutes. The evacuation time varies with different vacuum HANDLE LO HANDLE HI (ALWAYS CLOSED)

pump capacity. Confirm that the charging gauge needle has CHARGE HOSE

CHARGE HOSE

moved towards -760mmHg. VACUUM PUMP

ADAPTER FOR

Caution COUNTER FLOW

PREVENTION

If the gauge needle does not move to -760mmHg, be sure to LIQUID VALVE

CHECK VALVE

check for gas leaks (using the refrigerant detector) at flare

GAS VALVE

type connection of the indoor and outdoor unit and repair (3-WAY)

the leak before proceeding to the next step.

CONFIGURATION OF AIR

Close the valve of the changing gauge and stop the vacuum PURGE BY CHARGING

pump.

On the outdoor unit, open the suction valve (3 way) and

liquid valve (2 way) (in anti-clockwise direction) with 4mm LOW PRESSURE GAUGE HIGH PRESSURE GAUGE

key for hexagon sacked screw. -760mmHg GAUGE MANIFOLD

Charge Operation HANDLE LO HANDLE HI (ALWAYS CLOSED)

This operation must be done by using a gas cylinder and a CHARGE HOSE

precise weighing machine. The additional charge is topped-up CHARGE HOSE

into the outdoor unit using the suction valve via the service CHECK VALVE

port.

LIQUID VALVE

Remove the service port cap.

Connect the low pressure side of the charging gauge to the GAS VALVE

(3-WAY)

suction service port center of the cylinder tank and close

CONFIGURATION OF AIR

the high pressure side of the gauge. Purge the air from the PURGE BY CHARGING

service hose.

Start the air conditioner unit.

Open the gas cylinder and low pressure charging valve.

When the required refrigerant quantity is pumped into

the unit, close the low pressure side and the gas cylinder

valve.

Disconnect the service hose from service port. Put back the

service port cap.

1-17

1 EN 5CKYER-1009(1).indd 17 4/21/11 9:11:22 AM

ACCESSORY PARTS

Short Duct Specification

The indoor unit is provided with air discharge and air intake knock-out hole for duct connection. However the connection

of the short duct for air discharge is possible on only one side.

The use of short duct for air discharge will improve airflow distribution if there is an obstruction (such as a lighting fixture)

or in a long, narrow room or an L-shaped room. It also use for air conditioning of two rooms simultaneously.

Possible Direction For Air Discharge And Air Intake Possible Opening Dimension For Duct Connection

Air Discharge Air Discharge

PCD 140

10 50 50 50 50 50 10

20

100

90

70

20

115 20 115

Air Discharge Knock Out Hole Air Intake Knock

Air Intake

Air Discharge Air Discharge Out Hole

NOTE

Avoid using the short duct on which the air discharge grille can be completely closed, to prevent evaporator

freezing.

In order to prevent condensation forming, be sure that there is sufficient thermal insulation and no leakage of cool

air when installing the short duct.

Keep the introduction of fresh air intake within 20% of total air flow. Also provide chamber and use booster fan.

Sealing Material

It is possible to seal one of the four air discharge outlet. (sealing two or more air discharge outlet could cause a

malfunction)

Remove the front panel and insert the sealing material into the air discharge outlet on the indoor unit to seal the air

outlet.

The sealing material is the same length as the longer air discharge outlet. If it is desired to seal the shorter air discharge

outlet, cut the sealing material to shorten it.

Push the sealing material in about 10 mm beyond the bottom surface of the indoor unit so that it does not touch the air

louver. Be sure not to push the sealing material in any farther than about 10mm.

1-18

1 EN 5CKYER-1009(1).indd 18 4/21/11 9:11:22 AM

BELOW INFORMATION IS APPLICABLE FOR 5SLY40/50FR ONLY

English

1. Handling 5. Pump-down operation

Never by-pass the low pressure switch or low pressure sensor

during pump down operation.

Power supply must be cut off before pump-down operation.

After opening the front panel, cover the PCB and terminal

board with insulation sheet to avoid electric shock by

accidental touching of LIVE parts.

Do not leave the unit unattended if the front panel is open.

Close the front panel before leaving the outdoor unit.

Figure 1 Turn on the power supply and carry out pumping-down

As shown in Figure above, it is recommended to move the operation according to the steps written at front panel.

unit by grabbing the left and right grip. Place your hands on

the corner to avoid deforming of the casing. 6. Electrical wiring work

2. Refrigerant piping

Figure 2b

Figure 4

W Y

X

Figure 2a Figure 2c

A total of 4 direction options (refer figure 2a) for connecting

pipe (w, x, y, z) are available for your convenience.

Cutting out the 2 slits with a metal saw make it possible to

install as shown in Figures 2a.

In order to make the connecting pipe in a downward direction

(refer Figure 2b), make a knockout hole by drilling through

the center area around the knockout hole.

It is recommended to use a 6mm drill for this process

(refer Figure 2c).

After completing the knockout process, it is recommended

to apply repair paint to the edge and surrounding surfaces to

prevent rusting.

Cover the pipe through-holes with

insulation material to conceal all gaps

to prevent small animals or insects from Secure the ground wire to the stop valve attachment plate

entering the outdoor unit which may (refer Figure 4) so that it does not slide.

Ensure the front cover does not rise up after the wiring work

result short circuit in the control box.

is down. Close the front cover securely.

Figure 3

3. Caution for handling service port

To be able to recover all remaining refrigerant at charge

2

hose, always use a flexible charge hose with a push-rod and

1

valve. After the work, tighten the valve cover in place with

tightening torque: 11.5~13.9N.m

Figure 5

4. Charging refrigerant

2

For cases where complete recharge of refrigerant is required, 1

vacuuming via service part is mandatory, do not use stop valve

port in this case because vacuuming through this stop valve When cables are routed from the unit, a protection sleeve for

the conduits can be inserted at the knock-out hole.

port can not be executed completely.

It there is no wire conduit, do protect the wires with

Outdoor units have 1 port on the piping. It is between the heat vinyl tubes to prevent cutting the wires by sharp edges of

exchanger and the 4-way valve. knock-out hole.

1 Power supply wiring and earth wire

2 Interconnection wire

1-19

1 EN 5CKYER-1009(1).indd 19 4/21/11 9:11:23 AM

Vous aimerez peut-être aussi

- 205 Sweet Potato PieDocument2 pages205 Sweet Potato PieMelissa MorrisonPas encore d'évaluation

- LTM 1500 - KransteuerungDocument187 pagesLTM 1500 - Kransteuerungsi ei xi picsPas encore d'évaluation

- Moonlight SerenadeDocument1 pageMoonlight SerenadeFrancesca MarchiPas encore d'évaluation

- Rosenberger 4.3 10connectorDocument16 pagesRosenberger 4.3 10connectorCristiPas encore d'évaluation

- TSL-VDR-DW-ST01-0021 Roots Blower ZC01-FA002Document3 pagesTSL-VDR-DW-ST01-0021 Roots Blower ZC01-FA002dhiny.andrianiPas encore d'évaluation

- ELITE Manuale Telaio Turbo MuinDocument38 pagesELITE Manuale Telaio Turbo MuinutkuPas encore d'évaluation

- LSIS - H100 - Catalog - EN 1.pdf1Document7 pagesLSIS - H100 - Catalog - EN 1.pdf1Ηρακλης ΤσαπραζηςPas encore d'évaluation

- ACTUADORES - Aktu-Ato-RlerDocument10 pagesACTUADORES - Aktu-Ato-RlerManchoPas encore d'évaluation

- Systec D 100 150 200Document1 pageSystec D 100 150 200Alexander Guzmán HerreraPas encore d'évaluation

- ULS12000Document1 pageULS12000Victor AcunaPas encore d'évaluation

- Prirubnice 1Document6 pagesPrirubnice 1Vladan StarčevićPas encore d'évaluation

- E-Plan 5af Uw V4-3: Identnummer 61800012Document129 pagesE-Plan 5af Uw V4-3: Identnummer 61800012Patrick ByronPas encore d'évaluation

- Gleisplan MannheimDocument1 pageGleisplan MannheimClemens Michael KraftPas encore d'évaluation

- Din 7.16Document12 pagesDin 7.16Duong Thuy NgacPas encore d'évaluation

- BA 2180762-200-Zusammenbau TFW 300 Mit 2 PB 200 Schnecken - IdwDocument1 pageBA 2180762-200-Zusammenbau TFW 300 Mit 2 PB 200 Schnecken - IdwMatias AcunaPas encore d'évaluation

- Ausgrid Pulling EyeDocument1 pageAusgrid Pulling Eyekevin_au18Pas encore d'évaluation

- Turbo Mesh Kit - Assembly Guide - v1.5Document2 pagesTurbo Mesh Kit - Assembly Guide - v1.5patohp1970Pas encore d'évaluation

- Turbo Mesh Kit - Assembly Guide - v1.3vDocument2 pagesTurbo Mesh Kit - Assembly Guide - v1.3vEl BahloulPas encore d'évaluation

- T1940 Fortius Trainer 06Document2 pagesT1940 Fortius Trainer 06Rodolfo PimentelPas encore d'évaluation

- Ug 4safe On SW v7 deDocument4 pagesUg 4safe On SW v7 deandre kressnerPas encore d'évaluation

- Lamento No Morro - Tom JobimDocument1 pageLamento No Morro - Tom JobimAlexandre Jose SilvaPas encore d'évaluation

- GH Dufourstr. 101 1.OG EmptyDocument1 pageGH Dufourstr. 101 1.OG Emptyhaithem jabeurPas encore d'évaluation

- AnleitungDocument64 pagesAnleitungAz SymPas encore d'évaluation

- 321934Document1 page321934Bosko BijelacPas encore d'évaluation

- Hy SP 82Document1 pageHy SP 82Anne S. SokolovskaPas encore d'évaluation

- Berlin Hauptbahnhof - Locationpdf DataDocument1 pageBerlin Hauptbahnhof - Locationpdf DataFederico EzequielPas encore d'évaluation

- Grundig - CDP s150 SMDocument12 pagesGrundig - CDP s150 SMNhạc cụ MITUMIPas encore d'évaluation

- 3 12 Ma Knauf Pocket-Kit 2018Document24 pages3 12 Ma Knauf Pocket-Kit 2018EsadcesDavidisPas encore d'évaluation

- TT 20158 000 00 000Document1 pageTT 20158 000 00 000Ehab MohamedPas encore d'évaluation

- Circulare (12 - 85 MC - H) - Tip I-Butelie de Egalizare A Presiunilor dn250, 40 MC - h-1Document1 pageCirculare (12 - 85 MC - H) - Tip I-Butelie de Egalizare A Presiunilor dn250, 40 MC - h-1mihailacosminPas encore d'évaluation

- Das bin ja ich! Wie komplexe Persönlichkeitsstrukturen Filmfiguren lebendig machen.: Ein Wegweiser fürs Drehbuchschreiben und FilmeguckenD'EverandDas bin ja ich! Wie komplexe Persönlichkeitsstrukturen Filmfiguren lebendig machen.: Ein Wegweiser fürs Drehbuchschreiben und FilmeguckenPas encore d'évaluation

- Lageplan KGUDocument2 pagesLageplan KGUkonstib97Pas encore d'évaluation

- Tapcon 230 Expert 6655744 enDocument2 pagesTapcon 230 Expert 6655744 enLuis AravenaPas encore d'évaluation

- 001 01 LascheDocument1 page001 01 Lascheuser93457.2Pas encore d'évaluation

- Beater Plan - 0820-065e - Rev-02Document4 pagesBeater Plan - 0820-065e - Rev-02Đức NguyễnPas encore d'évaluation

- 32 Technische Daten Stufenwendel BB-SDocument2 pages32 Technische Daten Stufenwendel BB-SalfPas encore d'évaluation

- Ug Flatscan Rev PZ v5 deDocument12 pagesUg Flatscan Rev PZ v5 deandre kressnerPas encore d'évaluation

- Radetzky Marsch FDocument2 pagesRadetzky Marsch FJan MetaschPas encore d'évaluation

- F2500C Esquema EléctricoDocument42 pagesF2500C Esquema EléctricoemanuelPas encore d'évaluation

- PDF Nissan Yd25 Dddti 2010 Diag Elect 1 - CompressDocument48 pagesPDF Nissan Yd25 Dddti 2010 Diag Elect 1 - CompressitalojuanmanuelcaunaPas encore d'évaluation

- Passauer OpenSessionEsDocument83 pagesPassauer OpenSessionEswlipps99Pas encore d'évaluation

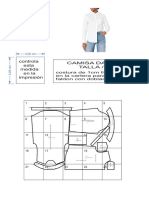

- Camisa Dama Talla / M Controla Esta Medida en La ImpresiónDocument26 pagesCamisa Dama Talla / M Controla Esta Medida en La Impresiónjjalfredom1234Pas encore d'évaluation

- Harian Oktober 2021Document448 pagesHarian Oktober 2021Marfuani PraditawatiPas encore d'évaluation

- Place Du Tertre-4tetDocument3 pagesPlace Du Tertre-4tetSaul100% (1)

- Cryogenic Nozzle DrawingDocument1 pageCryogenic Nozzle DrawingErlangga Yudha PratamaPas encore d'évaluation

- Wiring Diagram Central Door Lock Mobil Avanzaxenia Tahun 2006Document2 pagesWiring Diagram Central Door Lock Mobil Avanzaxenia Tahun 2006Mardiansyah Black100% (3)

- Hallenkran PDFDocument1 pageHallenkran PDFdavid fuerthauerPas encore d'évaluation

- TI 001 enDocument12 pagesTI 001 enDemian Leiva100% (1)

- HomelandDocument4 pagesHomelandThomas NüeschPas encore d'évaluation

- ZüriWC Normsolitär Mit PlakatDocument1 pageZüriWC Normsolitär Mit PlakatDenisa BalajPas encore d'évaluation

- WSCAD 2015 Przykładowy Schemat Elektryczny COMPACTDocument15 pagesWSCAD 2015 Przykładowy Schemat Elektryczny COMPACTŁukasz KutelaPas encore d'évaluation

- Hydrofixx 80 - 80 - 3 MC - H-Hydrofixx 80 - 80 Cu 2 Circuite de Incalzire-1Document1 pageHydrofixx 80 - 80 - 3 MC - H-Hydrofixx 80 - 80 Cu 2 Circuite de Incalzire-1Marian CismaruPas encore d'évaluation

- CampingtischDocument4 pagesCampingtischKeikoPas encore d'évaluation

- Ihes 4Document2 pagesIhes 4Nurul Hafiz NaspiPas encore d'évaluation

- Technical Drawing: A D D1 H K N P Q S WD A B H 400 80 102 680 345 420 160 240 645 335 170 290Document1 pageTechnical Drawing: A D D1 H K N P Q S WD A B H 400 80 102 680 345 420 160 240 645 335 170 290Vamsi Krishna KPas encore d'évaluation

- Klarinettenzauberei (Solopolka Für 2 Klarinetten in B Und Kleine Blasmusikbesetzung)Document3 pagesKlarinettenzauberei (Solopolka Für 2 Klarinetten in B Und Kleine Blasmusikbesetzung)Marlon T. Agapito Jr.Pas encore d'évaluation

- FWS 50Document1 pageFWS 50Artm YakovlevPas encore d'évaluation

- GEO SPECIAL 01/2020 - USA: Unterwegs an der WestküsteD'EverandGEO SPECIAL 01/2020 - USA: Unterwegs an der WestküstePas encore d'évaluation

- GEO SPECIAL 06/2020 - Australien: Sehnsucht nach Down UnderD'EverandGEO SPECIAL 06/2020 - Australien: Sehnsucht nach Down UnderPas encore d'évaluation