Académique Documents

Professionnel Documents

Culture Documents

Unit 5 Mechanicalmeasurementsandmeasurementsystems 140821032356 Phpapp01

Transféré par

SwaksharJyoti Hazarika0 évaluation0% ont trouvé ce document utile (0 vote)

40 vues34 pagesMechanical measurements

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentMechanical measurements

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

40 vues34 pagesUnit 5 Mechanicalmeasurementsandmeasurementsystems 140821032356 Phpapp01

Transféré par

SwaksharJyoti HazarikaMechanical measurements

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 34

UNIT-5: Measurements and measurement systems:

Definition, significance of measurement, generalized

measurement system.

Definitions and concept of accuracy, precision,

calibration, threshold, sensitivity, hysterisis, repeatability,

linearity, loading effect, system response-times delay.

Errors in measurement, classification of errors.

Transducers, transfer efficiency, primary and secondary

transducers, electrical, mechanical, electronic transducers,

advantages of each type transducers.

Hareesha N Gowda, DSCE, Blore-78 2

MEASUREMENT SYSTEM:

Measurement means determination of anything that exists in some amount.

If those things that exist are related to mechanical engineering, then the

determination of such amounts are referred to as mechanical measurements.

An engineer is not only interested in the measurement of physical variables but

also concerned with their control.

These two functions are closely related because one must be able to measure a

variable such as temperature, or flow in order to control it.

The accuracy of control is essentially dependent on the accuracy of measurement.

Hence, a good knowledge of measurement techniques is necessary for the design

of control systems.

Definition of Measurement :

Measurement is defined as the process or the act of obtaining a quantitative

comparison between a predefined standard and an unknown magnitude.

Hareesha N Gowda, DSCE, Blore-78 3

Hareesha N Gowda, DSCE, Blore-78 4

SIGNIFICANCE OF MEASUREMENT SYSTEM

Measurement provides the fundamental basis for research and development.

Development is the final stage of the design procedure involving the

measurement of various quantities pertaining to operation and performance of

the device being developed.

Measurement is also a fundamental element of any control process, which

requires the measured discrepancy between the actual and the desired

performances.

Many operations require measurement for proper performance. For example :

In modern central power stations, temperatures, pressures, vibrational

amplitudes etc., are monitored by measurement to ensure proper performance.

Measurement is also a bias of commerce, because the cost of the products are

established on the basis of amounts of materials, power, expenditure of time

and labour, and other constraints.

Hareesha N Gowda, DSCE, Blore-78 5

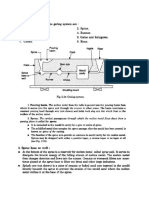

THE GENERALIZED MEASURING SYSTEM

Most measuring systems fall within the framework of a general

arrangement consisting of three phases or stages:

Stage 1. A detection-transduction, or sensor-transducer, stage

Stage 2. An intermediate stage, which we shall call the signal-

conditioning stage

Stage 3. A terminating, or readout-recording, stage

Each stage consists of a distinct component or group of

components that performs required and definite steps in the

measurement. These are called basic elements: their scope is

determined by their function rather than by their construction. Figure 1.2

outline the significance of each of these stages.

Hareesha N Gowda, DSCE, Blore-78 6

First, or Sensor-Transducer, Stage

The primary function of the first stage is to detect or to sense the measurand.

At the same time, ideally, this stage should be insensitive to every other possible

input.

For instance, if it is a pressure pickup, it should be insensitive to say,

acceleration;

if it is a strain gage, it should be insensitive to temperature;

if a linear accelerometer, it should be insensitive to angular acceleration; and so

on.

Unfortunately, it is rare indeed to find a detecting device that is completely

selective.

Unwanted sensitivity is a measuring error, called noise.

Hareesha N Gowda, DSCE, Blore-78 7

Second, or Signal-Conditioning, Stage

The purpose of the second stage of the general system is to

modify the transduced information so that it is acceptable

to the third, or terminating stage.

In addition, it may perform one or more basic operations,

such as selective filtering to remove noise, integration,

differentiation, as may be required.

Probably the most common function of the second stage is

to increase either amplitude or power of the signal, or both,

to the level required to drive the final terminating device.

Hareesha N Gowda, DSCE, Blore-78 8

Third, or Readout-Recording, Stage

The third stage provides the information sought in a form

comprehensible to one of the human senses or to a

controller.

If the output is intended for immediate human recognition,

it is, with rare exception, presented in one of the following

forms:

As a relative displacement, such as movement of an indicating hand or

displacement of oscilloscope trace

In digital form, as presented by a counter such as an automobile odometer,

or by a liquid crystal display (LCD) or light-emitting diode (LED) display

as on a digital voltmeter

Hareesha N Gowda, DSCE, Blore-78 9

Hareesha N Gowda, DSCE, Blore-78 10

To illustrate a very simple measuring system, let us consider the familiar

tire gage used for checking automobile tire pressure. Such a device is

shown in Fig. (a).

It consists of a cylinder and piston, a spring resisting the piston

movement, and a stem with scale divisions.

As the air pressure bears against the piston, the resulting force

compresses the spring until the spring and air forces balance.

The calibrated stem, which remains in place after the spring returns the

piston, indicates the applied pressure.

The piston-cylinder combination constitutes a force-summing

apparatus, sensing and transducing pressure to force.

As a secondary transducer, the spring converts the force to a

displacement. Finally, the transduced input is transferred without signal

conditioning to the scale and index for readout.

Hareesha N Gowda, DSCE, Blore-78 11

Hareesha N Gowda, DSCE, Blore-78 12

Hareesha N Gowda, DSCE, Blore-78 13

Hareesha N Gowda, DSCE, Blore-78 14

Hareesha N Gowda, DSCE, Blore-78 15

Hareesha N Gowda, DSCE, Blore-78 16

Hareesha N Gowda, DSCE, Blore-78 17

Hareesha N Gowda, DSCE, Blore-78 18

Hareesha N Gowda, DSCE, Blore-78 19

Hareesha N Gowda, DSCE, Blore-78 20

Hareesha N Gowda, DSCE, Blore-78 21

Hareesha N Gowda, DSCE, Blore-78 22

Transducers

Transfer Efficiency:

The first contact that a measuring system has with the measurand is through

the input sample accepted by the detecting element of the first stage . This

act is usually accompanied by the immediate transduction of the input into

an analogous form.

The medium handled is information. The detector senses the information

input. Iin, and then transduces or converts it to a more convenient form. Iout,.

The relationship may be expressed as

Hareesha N Gowda, DSCE, Blore-78 23

THE PRIMARY AND THE SECONDARY TRANSDUCER

Consider the Bourdon lube pressure gage as shown in

Fig.

The primary detector-transducer element consists of a

circular tube of elliptical cross section.

When pressure is introduced the elliptical cross section

tends to become circular section. This causes the free

end A to move outward and the resulting motion is transmitted

by the link to sector gear and in-turn to pinion causing the

pointer to move over the scale.

In this example Bourdon tube serves as the primary detector-

transducer, changing pressure to linear displacement.

The link, sector gear and pinion acts as secondary transducer

and as an amplifier to give magnified output.

Hareesha N Gowda, DSCE, Blore-78 24

Passive Transducer

A component whose output energy is supplied entirely or almost entirely by its input

signal is called a passive transducer.

The output and input signals may involve energy of the same form (say both mechanical)

or there may be energy conversion from one form to another (say mechanical to

electrical).

In other words, a passive transducer requires an auxiliary source of energy.

Example : Bonded wire strain gage.

Active Transducer

An active transducer has an auxiliary source of power which supplies a major part of the

output power while the input signal supplies only an insignificant portion.

In other words, active transducers are self powered.

Further, in these transducers, there may or may not be a conversion of energy from one

form to another.

Example : electronic amplifiers, piezoelectric transducer.

Active transducers are those which require

electric current (a source of energy) for

working, while passive transducers are those

which does not need an external source.

Passive transducers directly produce electric

signals without an external energy source.

Hareesha N Gowda, DSCE, Blore-78 25

Classification of first stage devices

Hareesha N Gowda, DSCE, Blore-78 26

Hareesha N Gowda, DSCE, Blore-78 27

Hareesha N Gowda, DSCE, Blore-78 28

Hareesha N Gowda, DSCE, Blore-78 29

Hareesha N Gowda, DSCE, Blore-78 30

Hareesha N Gowda, DSCE, Blore-78 31

Hareesha N Gowda, DSCE, Blore-78 32

Hareesha N Gowda, DSCE, Blore-78 33

Hareesha N Gowda, DSCE, Blore-78 34

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Toyota Celica Wiring Diagram 1993Document18 pagesToyota Celica Wiring Diagram 1993Gary Reynolds100% (2)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 4 K53 Code C1 Pre Trip 1Document2 pages4 K53 Code C1 Pre Trip 1abubakr fingerPas encore d'évaluation

- ProductionDocument4 pagesProductionSwaksharJyoti HazarikaPas encore d'évaluation

- Hydraulic Pump ContDocument15 pagesHydraulic Pump ContbmdbmdbmdPas encore d'évaluation

- Elements Pics 11x8 5Document1 pageElements Pics 11x8 5Mehmet SoysalPas encore d'évaluation

- Qip Ice 06 Valve Timing DiagramsDocument29 pagesQip Ice 06 Valve Timing Diagramsام احمدPas encore d'évaluation

- MechanicalDocument5 pagesMechanicalGaurav MakwanaPas encore d'évaluation

- Chapter 2Document19 pagesChapter 2Pradeep KumarPas encore d'évaluation

- Mechanical Measurements and Control: Introduction to MeasurementDocument20 pagesMechanical Measurements and Control: Introduction to MeasurementSwaksharJyoti HazarikaPas encore d'évaluation

- Lec 1Document36 pagesLec 1SwaksharJyoti HazarikaPas encore d'évaluation

- Principles of CarburetionDocument38 pagesPrinciples of CarburetionArpit SinghaiPas encore d'évaluation

- Module 5: Combustion Technology Lecture 40: Internal Combustion EngineDocument9 pagesModule 5: Combustion Technology Lecture 40: Internal Combustion EngineSwaksharJyoti HazarikaPas encore d'évaluation

- 4.0 SpringsDocument17 pages4.0 SpringsSwaksharJyoti HazarikaPas encore d'évaluation

- Experimentation and Analysis of Zeolite-Water Paired Adsorption Refrigeration by Solar RadiationDocument1 pageExperimentation and Analysis of Zeolite-Water Paired Adsorption Refrigeration by Solar RadiationSwaksharJyoti HazarikaPas encore d'évaluation

- Project Report On Solar Powered Vapour Absorption Refrigeration SystemDocument68 pagesProject Report On Solar Powered Vapour Absorption Refrigeration SystemSwaksharJyoti Hazarika100% (9)

- 5.0 BrakesDocument12 pages5.0 BrakesSwaksharJyoti HazarikaPas encore d'évaluation

- Helicopter DesignDocument1 pageHelicopter DesignSwaksharJyoti HazarikaPas encore d'évaluation

- Review of PST WorkDocument6 pagesReview of PST WorkSwaksharJyoti HazarikaPas encore d'évaluation

- Review On Solar Adsorption Refrigeration CycleDocument37 pagesReview On Solar Adsorption Refrigeration CycleSafaa Hameed Al NaseryPas encore d'évaluation

- Experimentation and Analysis of Zeolite-Water Paired Adsorption Refrigeration by Solar RadiationDocument1 pageExperimentation and Analysis of Zeolite-Water Paired Adsorption Refrigeration by Solar RadiationSwaksharJyoti HazarikaPas encore d'évaluation

- Daniel MugnierDocument15 pagesDaniel MugnierSwaksharJyoti HazarikaPas encore d'évaluation

- The Design and Development of A Solar Powered RefrigeratorDocument40 pagesThe Design and Development of A Solar Powered RefrigeratorSwaksharJyoti HazarikaPas encore d'évaluation

- WWW - Iitj.ac - in CSP Material 20dec RefrigerationDocument126 pagesWWW - Iitj.ac - in CSP Material 20dec RefrigerationWarren RiveraPas encore d'évaluation

- WWW - Iitj.ac - in CSP Material 20dec RefrigerationDocument126 pagesWWW - Iitj.ac - in CSP Material 20dec RefrigerationWarren RiveraPas encore d'évaluation

- Wind Loading CalculationDocument2 pagesWind Loading CalculationMallesh NenkatPas encore d'évaluation

- LPG Carbon Dioxide Fire Suppression System Installation Manual .Document50 pagesLPG Carbon Dioxide Fire Suppression System Installation Manual .hrhgk100% (1)

- EJOT ASYST Component System Flyer 10.17Document5 pagesEJOT ASYST Component System Flyer 10.17Eren GülayPas encore d'évaluation

- Past Board Exam Problems in StaticsDocument15 pagesPast Board Exam Problems in Staticsherbulariojeeanne19Pas encore d'évaluation

- Superlift MetricDocument2 pagesSuperlift MetricAshley DeanPas encore d'évaluation

- Specification Chart of Pipes - Stainless Steel - Seamless Pipe - Mild Steel - Hollow SteelDocument3 pagesSpecification Chart of Pipes - Stainless Steel - Seamless Pipe - Mild Steel - Hollow SteelSunitha KumariPas encore d'évaluation

- Andromeda V1.2 Assembly GuideDocument19 pagesAndromeda V1.2 Assembly Guidenajoko6753Pas encore d'évaluation

- Taller Física Eléctrica MULTIPLE CHOICE. Choose The One Alternative That Best Completes The Statement or Answers The QuestionDocument3 pagesTaller Física Eléctrica MULTIPLE CHOICE. Choose The One Alternative That Best Completes The Statement or Answers The QuestionSergio Cuellar0% (1)

- Ty 5131Document4 pagesTy 5131Mohamed El-AyouttiPas encore d'évaluation

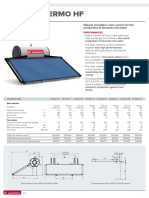

- Kairos Thermo HF Natural Circulation Solar System for Domestic Hot Water ProductionDocument4 pagesKairos Thermo HF Natural Circulation Solar System for Domestic Hot Water ProductionFILID MADPas encore d'évaluation

- CAT 320/323GC Electrical DiagramDocument33 pagesCAT 320/323GC Electrical DiagramSammyPas encore d'évaluation

- Lab 2 HardnessDocument8 pagesLab 2 HardnessMuhammad Zulhilmi0% (1)

- NQR 87-80-190 CREW - ARK0953 - v03Document4 pagesNQR 87-80-190 CREW - ARK0953 - v03LEON AGUILAR PEDRO RONALDPas encore d'évaluation

- SAND ProductionDocument18 pagesSAND Productionali100% (1)

- Group Assignment Q1Document2 pagesGroup Assignment Q1Muhdhadi SajariPas encore d'évaluation

- Dean Brochure High TempDocument10 pagesDean Brochure High TempAntonio VelardePas encore d'évaluation

- UiiuDocument20 pagesUiiupravi2010Pas encore d'évaluation

- Hydraulic Pressure TestDocument4 pagesHydraulic Pressure TestBola AdelPas encore d'évaluation

- A Low-Cost, Open Source Wind TurbineDocument23 pagesA Low-Cost, Open Source Wind TurbineStephen LynchPas encore d'évaluation

- VXN150 Vixion Radiator & Hose PDFDocument1 pageVXN150 Vixion Radiator & Hose PDFHarris Jum'aniandaPas encore d'évaluation

- Basic Cable&Cable CareDocument39 pagesBasic Cable&Cable CareDivyansh Singh ChauhanPas encore d'évaluation

- Mould Ejection OptDocument50 pagesMould Ejection OptMohamed HassanPas encore d'évaluation

- Biffi IS2000Document16 pagesBiffi IS2000Kolbert ArpadPas encore d'évaluation

- Three-Dimensional Force Systems: Today's ObjectivesDocument17 pagesThree-Dimensional Force Systems: Today's ObjectivesAtef NazPas encore d'évaluation

- TM 5-811-6 Generator and Electrical Facilities DesignDocument26 pagesTM 5-811-6 Generator and Electrical Facilities DesignrockclaudiuPas encore d'évaluation

- Durapac-Cylinder-Single Acting High Tonnage Locking CollarDocument4 pagesDurapac-Cylinder-Single Acting High Tonnage Locking CollarBùi Văn HợpPas encore d'évaluation

- Manual Motor Crrcpro26iDocument8 pagesManual Motor Crrcpro26ieduardo_albornoz_5Pas encore d'évaluation

- 2006 VA Powertrain SprinterDocument292 pages2006 VA Powertrain Sprinteractuator79100% (2)