Académique Documents

Professionnel Documents

Culture Documents

Stability Study With SAP Quality Management

Transféré par

torr123100%(1)100% ont trouvé ce document utile (1 vote)

497 vues54 pagesThe document discusses configuring SAP Quality Management for stability studies. Key points include:

1. Configuring inspection types, user status profiles, and notification types for stability studies.

2. Defining primary packaging, physical sample containers, storage conditions, and storage locations.

3. Creating a maintenance strategy, assigning inspection types and plans to materials, and assigning maintenance packages to inspection plans to generate planned stations.

4. The standard process of creating a quality notification to start a stability study.

Description originale:

SAP

Titre original

323234961 Stability Study With SAP Quality Management

Copyright

© © All Rights Reserved

Formats disponibles

TXT, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe document discusses configuring SAP Quality Management for stability studies. Key points include:

1. Configuring inspection types, user status profiles, and notification types for stability studies.

2. Defining primary packaging, physical sample containers, storage conditions, and storage locations.

3. Creating a maintenance strategy, assigning inspection types and plans to materials, and assigning maintenance packages to inspection plans to generate planned stations.

4. The standard process of creating a quality notification to start a stability study.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme TXT, PDF, TXT ou lisez en ligne sur Scribd

100%(1)100% ont trouvé ce document utile (1 vote)

497 vues54 pagesStability Study With SAP Quality Management

Transféré par

torr123The document discusses configuring SAP Quality Management for stability studies. Key points include:

1. Configuring inspection types, user status profiles, and notification types for stability studies.

2. Defining primary packaging, physical sample containers, storage conditions, and storage locations.

3. Creating a maintenance strategy, assigning inspection types and plans to materials, and assigning maintenance packages to inspection plans to generate planned stations.

4. The standard process of creating a quality notification to start a stability study.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme TXT, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 54

Stability Study with SAP Quality Management

Stability Study with SAP QM

1. Configuration

1.1. Inspection types

Although the inspection types for stability are preconfigured in SAP QM. Still,

you can configure the custom

inspection types for stability.

Follow the Path: IMG >> Quality Management >> Quality Inspection >> Inspection L

ot Creation >> Maintain

Inspection Types

16

Inspection for Storage Condition (Stabi)

1601 Initial Test (Stability Studies)

1602

Manual Insp. Lot for Storage Cond (Stab)

1.2. User Status Profile

The preconfigured user status profile has limitation to the fixed process for st

ability study. You can copy and

configure custom status profile as per the business requirement.

Run Transaction BS02 to access the status profiles.

Add/Remove/Modify the business transaction for a status by double clicking the s

tatus.

Generated by Jive on 2016-07-26Z

1

Stability Study with SAP Quality Management

Generated by Jive on 2016-07-26Z

2

Stability Study with SAP Quality Management

1.3. Notification type and the Action box

There are standard preconfigured notification type available. You can refer the

same and use it as a reference

to create a custom notification type. Also, you can add/remove/modify the action

box for the notification type.

Generated by Jive on 2016-07-26Z

3

Stability Study with SAP Quality Management

Generated by Jive on 2016-07-26Z

4

Stability Study with SAP Quality Management

Generated by Jive on 2016-07-26Z

5

Stability Study with SAP Quality Management

1.4. Primary Packaging

You need to define the primary packaging for Physical Samples

Definition: The packing material which is in direct contact with the product is

considered as primary packaging.

There may be container (bottle, ampule), closure (bottle cap) and desiccant (sil

ica gel)

Follow the menu path IMG >> Quality Management >> Stability Study >> Basic Data

>> Define Primary

Packaging

Generated by Jive on 2016-07-26Z

6

Stability Study with SAP Quality Management

1.5. Physical Sample Container

You need to define the physical sample container for physical sample

Definition: The containing material in which the samples are placed in stability

chamber.

1. E.g.

10 strips are packed in carton and placed in stability chamber then the carton i

s the physical sample container

10 strips (Aluminum and PVC blister) are placed in the stability chamber then th

e Aluminum and PVC blister is

the physical sample container

Follow the menu path IMG >> Quality Management >> Quality Inspection >> Sample M

anagement >> Define

Physical-Sample Container

Generated by Jive on 2016-07-26Z

7

Stability Study with SAP Quality Management

1.6. Storage Condition

You need to define the storage condition for Physical sample. It is the most imp

ortant configuration for stability

study

Definition: The temperature and humidity level in which the physical samples are

placed is called the storage

condition

1. E.g. Temperature 25C 2C and Relative Humidity 65% 5% is one of the storage cond

ition. It can

be a long term/real time storage condition for a zone or it can be an accelerate

d storage condition for

a zone. The storage condition has nothing to do with Long term / Intermediate /

Accelerated storage

condition. These word should not be the part of the description of a storage con

dition.

Follow the menu path IMG >> Quality Management >> Stability Study >> Basic Data

>> Define storage

Conditions

Generated by Jive on 2016-07-26Z

8

Stability Study with SAP Quality Management

1.7. Physical Sample Storage Location

You need to define the physical sample storage location for physical sample.

Definition: The stability chamber in which the samples are placed is called Phys

ical sample storage location.

E.g. it has nothing to do with the material storage location. It is the identifi

cation of a stability chamber.

It is helpful to have tractability of the sample

Follow the menu path IMG >> Quality Management >> Quality Inspection >> Sample M

anagement >> Define

Physical-Sample Locations

It is a plant specific configuration. You need to first define a plant for which

you are maintaining the stability

chamber. If you have a common chamber for multiple plant. You need to create the

same stability chamber for

each of plants.

Generated by Jive on 2016-07-26Z

9

Stability Study with SAP Quality Management

2. Master Data

2.1. Maintenance Strategy

You need to create a maintenance strategy for stability study. It is the most im

portant master data for the

stability study

Run Transaction IP11 or follow the menu path SAP Menu >> Logistics >> Quality Ma

nagement >> Stability

Study >> Stability Planning >> Strategy >> Edit (IP11)

The important part is the scheduling indicator. You need to select 1-Time-Key da

te to get the schedule on

key date. E.g. if you start the study on 12.07.2016 and you have 1month, 2 month

s, 3 months, 6 months, 9

months and 12 months stations, you will get 12.08.2016(1month), 12.09.2016(2mont

hs), 12.10.2016(3months),

12.01.2017(6months), 12.04.2017(9months) and 12.07.2017(12months). For remaining

two options (time and

2-time-factory calendar) you will not get the stations on the key date.

Generated by Jive on 2016-07-26Z

10

Stability Study with SAP Quality Management

Generated by Jive on 2016-07-26Z

11

Stability Study with SAP Quality Management

2.2. Material Master and Inspection type

You must assign and activate inspection type for a material which you intended f

or stability study.

You must assign inspection type 16 (Inspection lot for Storage condition), 1601

(Initial inspection lot) and 1602

(Manual or additional inspection lot) or custom inspection types substitute for

each one.

Generated by Jive on 2016-07-26Z

12

Stability Study with SAP Quality Management

2.3. Inspection plan

You need to have inspection plan for inspection processing for stability study

I hope everyone on this forum for Quality Management must be aware of the inspec

tion plan. So, I will not

describe the same in details. But, the following points must be considered.

No Dynamic Modification Rule work for stability Study as the task list usage is

3-universal

The inspection plan should have sample drawing procedure in order to support the

physical samples

The most important part is to assign the maintenance strategy and maintenance pa

ckage to the

inspection plan which decide the planned stations for the particular storage con

dition.

Generated by Jive on 2016-07-26Z

13

Stability Study with SAP Quality Management

2.4. Assign Maintenance Packages to the Inspection

plan

You must assign a maintenance strategy and required maintenance package to an in

spection plan in order to

create maintenance plan with the required planned stations.

1. E.g. you need to assign maintenance packages 3 Months, 6 Months, 9 Months and

12 Months for an

Accelerated stability study.

Also, you need to create different inspection plan for each strategy. E.g. if yo

u are planning for Long

term(3,6,9,12,18,24,36 months), intermediate(3,6,9,12,18,24 months) and Accelera

ted (3,6,9,12 months)

strategy. You need to create three different inspection plan for each one of the

m.

Run the transaction CWBQM or follow the menu path SAP Menu >> Logistics >> Quali

ty Management >>

Stability Study >> Stability Planning >> Inspection Planning >> Workbench (CWBQM

)

You get the first screen as follows to select either Header area or Operations a

rea for the inspection plan

workbench

Select always Q_TSK_000000000010 - Insp. plan, mater.-routing alloc., lock and c

lick on Continue

You get the below screen.

Enter the selection criteria and execute. E.g. Material, Plant, Task list type (

always Q-Inspection plan), Group

and Group Counter and execute (load task lists)

Generated by Jive on 2016-07-26Z

14

Stability Study with SAP Quality Management

You get the below screen. Here you have all the inspection plan against the sele

ction criteria. Select the

required inspection plan and scroll horizontally to your right.

Generated by Jive on 2016-07-26Z

15

Stability Study with SAP Quality Management

You scroll horizontally to your right till you get see the column for Strategy l

ike below screen. Enter/choose the

same maintenance strategy (e.g. QSTABI) for all the selected inspection plan(s).

Generated by Jive on 2016-07-26Z

16

Stability Study with SAP Quality Management

Now Follow the menu path Task List >> Maintenance Packages like below screen.

Generated by Jive on 2016-07-26Z

17

Stability Study with SAP Quality Management

The system will navigates to below screen in which you can assign the required p

ackages. You can assign and

navigate to other selected inspection plans using navigation buttons on the tran

saction tool bar.

Generated by Jive on 2016-07-26Z

18

Stability Study with SAP Quality Management

Generated by Jive on 2016-07-26Z

19

Stability Study with SAP Quality Management

Generated by Jive on 2016-07-26Z

20

Stability Study with SAP Quality Management

Also, dont forget to save and exit from the transaction.

This will add maintenance packages in your inspection plans. That decides the pl

anned stations for the storage

condition for which the inspection plan is assigned.

3. Stability Study Processing

The standard stability study process flow is as below

Generated by Jive on 2016-07-26Z

21

Stability Study with SAP Quality Management

3.1. Create Quality Notification

Use Transaction QM01 and Notification Type QS-Stability Study with Material

Generated by Jive on 2016-07-26Z

22

Stability Study with SAP Quality Management

In Below screen, Enter notification type QS.

In Below Screen, Enter the material and plant and hit enter key. The system will

open up the batch number

field

Generated by Jive on 2016-07-26Z

23

Stability Study with SAP Quality Management

In below screen, enter the batch number and Save

Generated by Jive on 2016-07-26Z

24

Stability Study with SAP Quality Management

Notification is created

Generated by Jive on 2016-07-26Z

25

Stability Study with SAP Quality Management

3.2. Create Initial Sample

Open the notification in change using transaction QM02

Generated by Jive on 2016-07-26Z

26

Stability Study with SAP Quality Management

In Below screen, enter the notification number and enter

In below screen, in Action Box, Click on Action Create Initial Sample

The system should show a pop-up dialog box for initial sample. On the pop-up dia

log box, Enter Primary

Packaging, Sample Container and the sample quantity (the total sample quantity f

or the stability study i.e. total

Generated by Jive on 2016-07-26Z

27

Stability Study with SAP Quality Management

of all the storage condition sample). Storage Condition and Storage Location is

optional as this is the initial

sample. If the product required to be kept in particular storage condition (e.g.

product need refrigeration) then

you must define the same as the product need to be kept inside the refrigerator

before placing into the stability

chamber.

Click on Save and change notification. This will create the initial sample for t

he stability study.

Note: You must create initial sample when you decide to do stability study as th

e system do not allow

to start the study in back date.

3.3. Confirm Initial Sample

In below screen, in Action Box, Click on Action Confirm Initial Sample

Generated by Jive on 2016-07-26Z

28

Stability Study with SAP Quality Management

The system should show a pop-up dialog box for the sample confirmation with all

the details.

Generated by Jive on 2016-07-26Z

29

Stability Study with SAP Quality Management

Click on save and change notification button. The system should show another pop

-up dialog box for physical

sample drawing confirmation

Click on continue to confirm the sample

Generated by Jive on 2016-07-26Z

30

Stability Study with SAP Quality Management

3.4. Create Initial Inspection Lot

In below screen, in Action Box, Click on Action Initial test Inspection lot

The system shows a pop-up dialog box for specification selection. Enter the Grou

p and Group

counter and put Initial Inspection lot as Short Text and click on Create Inspectio

n lot.

Generated by Jive on 2016-07-26Z

31

Stability Study with SAP Quality Management

The System show another pop-up dialog box for flexible specification selection s

creen where you can select

the required test as well as change the specification of the test as per the req

uirement and click on copy to

create inspection lot. Alternatively, you can click on copy all button to copy a

ll the specification if you are using

the required inspection plan.

The system should create the inspection lot. You need to process the inspection

lot separately.

Generated by Jive on 2016-07-26Z

32

Stability Study with SAP Quality Management

I hope everyone on this forum for Quality Management must be aware of the inspec

tion lot result recording and

Usage Decision. So, I will not describe the same in details.

3.5. Complete Initial Inspection Lot

You need not to perform the this action from the Quality Notification action box

if you use the standard UD code

provided for making usage decision for stability study as those UD code contains

the follow up action to do this.

You can see the same in the below screen shots.

Generated by Jive on 2016-07-26Z

33

Stability Study with SAP Quality Management

Generated by Jive on 2016-07-26Z

34

Stability Study with SAP Quality Management

If you use custom UD codes without follow up action, you need to click on the ac

tion box for Complete Initial

Test as per below screenshot

Generated by Jive on 2016-07-26Z

35

Stability Study with SAP Quality Management

3.6. Define Storage Conditions

In below screen, in Action Box, Click on Action Specify Storage Conditions

The System shows a pop-up dialog box for defining the storage conditions. Select

the required Storage

Conditions and distribute the sample quantity for the selected storage condition

s. Click on save and change

notification button to save the same.

Generated by Jive on 2016-07-26Z

36

Stability Study with SAP Quality Management

3.7. Create Testing Schedule

In below screen, in Action Box, Click on Action Create Testing Schedule

Generated by Jive on 2016-07-26Z

37

Stability Study with SAP Quality Management

The system shows a pop-up dialog box for create test schedule. Select the Mainte

nance Strategy and Define

the Scheduling period and Click on create Testing schedule, save and change the

notification button to create

the testing schedule.

Note: You must define the scheduling period greater than last station. E.g. If y

ou are planning for 3, 6,

9, 12, 18, 24, 36, 48, 60 Months then you must put value greater than 60 Months.

In this case I am putting 72 Months (I always ask the client for the maximum per

iod for stability study

and ask them to standardize a fixed value to be defined as scheduling period to

avoid any confusion)

E.g. if client say that they do stability maximum up to 60 Months, I tell them t

o standardize 72 Months. If

they say 36 Months then I tell to standardize 48 Months.

Generated by Jive on 2016-07-26Z

38

Stability Study with SAP Quality Management

Now, you should be have a question in your mind Why????

Because, if you are using time-key date in maintenance strategy then system will

not create last station

in maintenance schedule.

E.g. If you have 3, 6, 9, 12, 18, 24, 36, 48, 60 months stations and if you defi

ne the scheduling period as

60 Months. The System will create the test schedule till 48 months and will not

show 60 Months station.

Because the system consider 1 month = 30 days and if you calculate 30 days x 60

Months = 1800 days.

So, if your start date is 12.07.2016 then you are scheduling up to 1800 days i.e

. till date 16.06.2021.

But as per the time-key date strategy it should be 12.07.2021 which is greater t

han 16.06.2021. So, the

system do not create schedule for 60 months station. Although, the system will g

enerate the inspection

lot for 60 Months when 12.07.2021 date is reached. So, it is up to you to follow

the same or not.

But, I recommend to use my suggestion if you are using the scheduling data for r

eporting purpose.

3.8. Change Testing Schedule (Assign Inspection Plan)

In below screen, in Action Box, Click on Action Change Testing Schedule (here I

have changed the

text for the action to fit to my clients requirement)

The system shows a pop-up dialog box asking for Do you want to edit the testing s

chedule for

the study and return to the study? click on Yes.

Generated by Jive on 2016-07-26Z

39

Stability Study with SAP Quality Management

The system navigates to Change Maintenance Plan screen.

Here, you select the Maintenance Item (each maintenance item represents a storag

e conditions selected in

previous step) and click on Item Tab

Generated by Jive on 2016-07-26Z

40

Stability Study with SAP Quality Management

In below screen, you can see the details of the maintenance item.

Click on Cycle Item, you will see nothing in that tab.

Generated by Jive on 2016-07-26Z

41

Stability Study with SAP Quality Management

Come back to Item tab. Enter Group and Group Counter (basically assign the inspe

ction plan to a storage

condition) then navigate to cycle item tab to see the assigned time points

Generated by Jive on 2016-07-26Z

42

Stability Study with SAP Quality Management

Generated by Jive on 2016-07-26Z

43

Stability Study with SAP Quality Management

Now, use the Navigation buttons to navigate between items.

Generated by Jive on 2016-07-26Z

44

Stability Study with SAP Quality Management

Generated by Jive on 2016-07-26Z

45

Stability Study with SAP Quality Management

Generated by Jive on 2016-07-26Z

46

Stability Study with SAP Quality Management

Now, Click on Save on below screen.

The System saves the maintenance plan and navigates back to the notification scr

een.

Generated by Jive on 2016-07-26Z

47

Stability Study with SAP Quality Management

3.9. Store Stability Samples

In below screen, in Action Box, Click on Action Store Stability Sample

Generated by Jive on 2016-07-26Z

48

Stability Study with SAP Quality Management

The system shows a pop-up dialog box for Store stability Sample. Select all the

storage conditions and choose

the sample location and click on save and change the notification button to stor

e the sample.

Generated by Jive on 2016-07-26Z

49

Stability Study with SAP Quality Management

3.10. Complete Test Scheduling

In below screen, in Action Box, Click on Action Complete Test Scheduling

Generated by Jive on 2016-07-26Z

50

Stability Study with SAP Quality Management

The System shows a pop-up dialog box asking for Do you want to set the status "Te

st Scheduling

Completed" and return to the stability study? click on yes.

The system perform the action of completion of test scheduling.

3.11. Define Start Date of Study

In below screen, in Action Box, Click on Action Define Start Date of Study

Generated by Jive on 2016-07-26Z

51

Stability Study with SAP Quality Management

The system shows a pop-up dialog box for defining start of cycle. Check / Change

date and click on Save and

Change notification button to complete the action.

Note: The dates are very important for the stability study. Below is the order f

or the different dates. If

you deviate from the order then you will mess up the stability study notificatio

n and you may need to

close the same and create new one for the same.

Initial Sample Creation Date <= Initial Sample Confirmation Date <= Store Stabil

ity Sample Date <= Start

Date of Study.

You cannot define the start date of the study as back date (if initial sample is

created on current date) /

Future date

3.12. Deadline Monitoring for Due Stations

You need to schedule a daily background Job with Transaction IP30 with proper va

riant to create inspection lot

for the stability.

You need to process the generated inspection lot for Result recording and Usage

Decision.

Generated by Jive on 2016-07-26Z

52

Stability Study with SAP Quality Management

I hope everyone on this forum for Quality Management must be aware of scheduling

a background job as well

as inspection lot processing. So, I will not describe the same in details.

3.13. Complete Study and Reporting

Once all the stations are completed, you can use action box item. Complete Stabi

lity Study to complete the

study.

Also, you can Use Actions Display Objects for Study to see the object linked to

the stability study notification.

It shows Quality Notification, Initial Physical Sample, Initial Inspection lot,

Physical Samples for Storage

Conditions and Their inspection lots and Maintenance Plan.

You can use the action Display Stability History to display all the result recor

ding history till date for the

stability study. This action is also available while result recording of the sta

bility study inspection lot. There is a

command button below the sample.

There are many other things that you can customize as per your requirements.

I hope this document will be helpful. There are many possibility in the stabilit

y study with SAP QM. You can

explore the same.

Regards,

Dipeshkumar Bhavsar

Generated by Jive on 2016-07-26Z

53

Vous aimerez peut-être aussi

- Stability Study With SAP Quality ManagementDocument53 pagesStability Study With SAP Quality ManagementSandeep89% (9)

- Stability StudyDocument18 pagesStability StudyPramod ShettyPas encore d'évaluation

- Sap PP SyllabusDocument4 pagesSap PP SyllabusZaheer AhamedPas encore d'évaluation

- SAP Quality Management Course SyllabusDocument3 pagesSAP Quality Management Course Syllabusyash50% (2)

- Production Kitting Using WM-PP Interface: Setting Up SAP WM PP Interface Is Covered in This Online SAP WM Training CourseDocument6 pagesProduction Kitting Using WM-PP Interface: Setting Up SAP WM PP Interface Is Covered in This Online SAP WM Training Courseanon_672875766Pas encore d'évaluation

- Automatic Batch Determination Shelf LifeDocument18 pagesAutomatic Batch Determination Shelf LifeKhalil EL KARAMAPas encore d'évaluation

- Global Sap Kanban ProcessDocument52 pagesGlobal Sap Kanban ProcessAbhijitPas encore d'évaluation

- Active Ingredient Management and Batch BalancingDocument24 pagesActive Ingredient Management and Batch Balancingmrivo100% (1)

- Implementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesD'EverandImplementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesPas encore d'évaluation

- SAP PP Serial Number ManagementDocument14 pagesSAP PP Serial Number Managementhoney50% (2)

- Handling Unit Management in SAP MMDocument15 pagesHandling Unit Management in SAP MMRULER KINGSPas encore d'évaluation

- LO710-V46c-En Problem Processing With Quality NotificationsDocument318 pagesLO710-V46c-En Problem Processing With Quality NotificationsWinston Kong Gao100% (1)

- Planning With Shelflife in PPDSDocument3 pagesPlanning With Shelflife in PPDSJintasit HearPas encore d'évaluation

- SAP PP REM Profile AssistanceDocument19 pagesSAP PP REM Profile AssistanceKanapon GunpromPas encore d'évaluation

- Sap PP Vijay ResumeDocument2 pagesSap PP Vijay Resumesonu87000% (1)

- Name of Candidate SAP - PP Functional Consultant Professional SummaryDocument5 pagesName of Candidate SAP - PP Functional Consultant Professional SummaryVasuPas encore d'évaluation

- Notification - Sending Mail Process FlowDocument14 pagesNotification - Sending Mail Process FlowshafisfjPas encore d'évaluation

- QM-WM Interface IssuesDocument28 pagesQM-WM Interface IssuesJagannadh Pradeep Ivaturi100% (2)

- Multilevel Subcontracting Process in SAP S4 HANADocument15 pagesMultilevel Subcontracting Process in SAP S4 HANASiva Thunga100% (1)

- MRP With HanaDocument9 pagesMRP With HanaNeeraj KumarPas encore d'évaluation

- Sap QM CFR Audit Management PDFDocument28 pagesSap QM CFR Audit Management PDFAnywhere100% (1)

- Key Data Structure List (KDS) : PurposeDocument8 pagesKey Data Structure List (KDS) : PurposeAditya100% (2)

- SAP Batch Derivation-Bath DeterminationDocument27 pagesSAP Batch Derivation-Bath Determinationrakesh1618Pas encore d'évaluation

- EHP6 for SAP ERP 6.0 MRP LIVE Process DocumentationDocument18 pagesEHP6 for SAP ERP 6.0 MRP LIVE Process Documentationrahul shendage100% (1)

- HUMDocument35 pagesHUMPranaya Barik100% (1)

- Batch Specific Active Ingredient ManagementDocument35 pagesBatch Specific Active Ingredient Managementrakeshp73Pas encore d'évaluation

- Sample SD BBPDocument30 pagesSample SD BBProlsonlewisPas encore d'évaluation

- Restrictions For SAP CWM in SAP S/4HANADocument11 pagesRestrictions For SAP CWM in SAP S/4HANATuấn Nguyễn Khắc MinhPas encore d'évaluation

- Stock Transfer Between Same PlantDocument25 pagesStock Transfer Between Same PlantamitjpPas encore d'évaluation

- New SAP Manufacturing ERP Features and Functions For Discrete Manufacturers - Execution StepsDocument34 pagesNew SAP Manufacturing ERP Features and Functions For Discrete Manufacturers - Execution Stepsliram299188Pas encore d'évaluation

- PP BBPDocument20 pagesPP BBPSiva Sankar Mohapatra100% (1)

- Batch Determination PPDocument13 pagesBatch Determination PPrvk386Pas encore d'évaluation

- QM OverviewDocument79 pagesQM OverviewRakesh MusalePas encore d'évaluation

- SAP Handling Unit Management Integration With Production PlanningDocument23 pagesSAP Handling Unit Management Integration With Production Planningsjobsvn100% (1)

- Sap PP Enterprise Structure 1Document24 pagesSap PP Enterprise Structure 1NASEER ULLAHPas encore d'évaluation

- RN Ewm 900 enDocument16 pagesRN Ewm 900 enAakriti ChPas encore d'évaluation

- EWM - Wave Management - SAP BlogsDocument18 pagesEWM - Wave Management - SAP BlogsAadityaa ChintapalliPas encore d'évaluation

- Handling Unit Management in SAP Packing During Outbound ProcessDocument48 pagesHandling Unit Management in SAP Packing During Outbound ProcessManibudh Sankasem0% (1)

- Alternate and Parallel Sequence in RoutingDocument27 pagesAlternate and Parallel Sequence in Routingkrishna100% (1)

- REM ProfilesDocument9 pagesREM ProfilesNishant PatilPas encore d'évaluation

- Warehouse Management With SAP EWMDocument695 pagesWarehouse Management With SAP EWMDurga SPas encore d'évaluation

- WM-QM Interface in SAP WMDocument8 pagesWM-QM Interface in SAP WMsumitjain_25Pas encore d'évaluation

- Sap MM Business Blue Print SampleDocument79 pagesSap MM Business Blue Print SampleNiranjan BeheraPas encore d'évaluation

- Manage QM Data in SAP Material MasterDocument40 pagesManage QM Data in SAP Material MasterRohit shahi100% (1)

- Sap QM End User ManualDocument70 pagesSap QM End User ManualDemoPas encore d'évaluation

- Check for Certificate Receipt in SAP QMDocument1 pageCheck for Certificate Receipt in SAP QMganeshPas encore d'évaluation

- The Up & Away Advisors’ Guide to Implementing and Executing Sap’s Vehicle Management SystemD'EverandThe Up & Away Advisors’ Guide to Implementing and Executing Sap’s Vehicle Management SystemPas encore d'évaluation

- Step by Step Sap QM End User ManualDocument63 pagesStep by Step Sap QM End User ManualAditya DeshpandePas encore d'évaluation

- Calibration CertificateDocument29 pagesCalibration CertificateSrinivasa Rao MullapudiPas encore d'évaluation

- Alert and MacroDocument11 pagesAlert and MacroDennis RoyPas encore d'évaluation

- SAP QM Questionnaire for BlueprintDocument10 pagesSAP QM Questionnaire for BlueprintchameladeviPas encore d'évaluation

- Automotive QM Manual Config GuideDocument342 pagesAutomotive QM Manual Config Guidesureva65Pas encore d'évaluation

- 03.inbound POSCDocument5 pages03.inbound POSCmjPas encore d'évaluation

- SAP Batch Management OverviewDocument70 pagesSAP Batch Management Overviewlibran_15Pas encore d'évaluation

- C Ewm 94 Study Guide and How To Crack Ex PDFDocument5 pagesC Ewm 94 Study Guide and How To Crack Ex PDFmaniPas encore d'évaluation

- SAP Repetitive Manufacturing With Reporting Point BackflushDocument12 pagesSAP Repetitive Manufacturing With Reporting Point BackflushDevidas Karad100% (1)

- Material Quantity CalculationDocument33 pagesMaterial Quantity Calculationbalu4indians100% (1)

- Sap QM IDI Interface With LIMSDocument21 pagesSap QM IDI Interface With LIMSHTE100% (1)

- Warehouse Management Systems A Complete Guide - 2019 EditionD'EverandWarehouse Management Systems A Complete Guide - 2019 EditionPas encore d'évaluation

- EulaDocument3 pagesEulaBrandon YorkPas encore d'évaluation

- UnconsciousnessDocument91 pagesUnconsciousnessFitri Amelia RizkiPas encore d'évaluation

- Fortiap S Fortiap w2 v6.0.5 Release Notes PDFDocument10 pagesFortiap S Fortiap w2 v6.0.5 Release Notes PDFtorr123Pas encore d'évaluation

- Fortiap v6.0.5 Upgrade Table PDFDocument2 pagesFortiap v6.0.5 Upgrade Table PDFtorr123Pas encore d'évaluation

- Management of Unconscious PatientDocument51 pagesManagement of Unconscious PatientEmenike Donald Ejieji50% (2)

- Vishnu Priya Anguraj Tsmu Grp-14Document39 pagesVishnu Priya Anguraj Tsmu Grp-14torr123100% (1)

- Dr. Praveen Kumar DoddamaniDocument81 pagesDr. Praveen Kumar Doddamanitorr123100% (2)

- DGFT IndiaDocument33 pagesDGFT IndiaKarthik RedPas encore d'évaluation

- Presented By: Dr. Vishal Bathma Asst. Professor Community Medicine PCMS&RCDocument42 pagesPresented By: Dr. Vishal Bathma Asst. Professor Community Medicine PCMS&RCtorr123Pas encore d'évaluation

- Hypertension: PharmacotherapyDocument23 pagesHypertension: Pharmacotherapytorr123Pas encore d'évaluation

- Understanding Parkinson's DiseaseDocument52 pagesUnderstanding Parkinson's Diseasetorr123Pas encore d'évaluation

- Cranial Osteomyelitis Diagnosis and Treatment OptionsDocument5 pagesCranial Osteomyelitis Diagnosis and Treatment OptionsRajanish Kumar50% (2)

- EEM Best PracticesDocument26 pagesEEM Best Practicestorr123Pas encore d'évaluation

- Neoadjuvant Therapies for Gastric CancerDocument64 pagesNeoadjuvant Therapies for Gastric Cancertorr123Pas encore d'évaluation

- Bonetumoursandprinciplesoflimbsalvagesurgery 140504075940 Phpapp01Document87 pagesBonetumoursandprinciplesoflimbsalvagesurgery 140504075940 Phpapp01torr123Pas encore d'évaluation

- DGFT IndiaDocument33 pagesDGFT IndiaKarthik RedPas encore d'évaluation

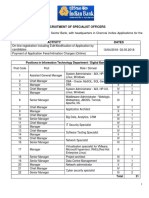

- India Bank Recruitment of Specialist Officers EngDocument25 pagesIndia Bank Recruitment of Specialist Officers Engajay kumarPas encore d'évaluation

- Contactdermatitis 130920140849 Phpapp01Document65 pagesContactdermatitis 130920140849 Phpapp01torr123Pas encore d'évaluation

- Hspowerpoint 140424161028 Phpapp01Document25 pagesHspowerpoint 140424161028 Phpapp01torr123Pas encore d'évaluation

- HaemodialysisDocument98 pagesHaemodialysisKo Zin100% (1)

- CP R75.40VS SmartViewTracker AdminGuideDocument31 pagesCP R75.40VS SmartViewTracker AdminGuidetorr123Pas encore d'évaluation

- Administration Guide: 17 February 2013Document303 pagesAdministration Guide: 17 February 2013torr123Pas encore d'évaluation

- India Bank Recruitment of Specialist Officers EngDocument25 pagesIndia Bank Recruitment of Specialist Officers Engajay kumarPas encore d'évaluation

- Liver Diseases With Pregnancy3603Document138 pagesLiver Diseases With Pregnancy3603torr123Pas encore d'évaluation

- Afib574903profslideshareversiondaspeakerbureauslidedeck10 131017131248 Phpapp02Document31 pagesAfib574903profslideshareversiondaspeakerbureauslidedeck10 131017131248 Phpapp02torr123Pas encore d'évaluation

- CP R75.40VS SmartViewTracker AdminGuideDocument31 pagesCP R75.40VS SmartViewTracker AdminGuidetorr123Pas encore d'évaluation

- Preventing AFib Related Strokes SlideDocument48 pagesPreventing AFib Related Strokes Slidetorr123Pas encore d'évaluation

- Physiological Aspect of Foods & Drugs As Aphrodisiacs: Guided By-Presented byDocument21 pagesPhysiological Aspect of Foods & Drugs As Aphrodisiacs: Guided By-Presented bytorr123Pas encore d'évaluation

- Preventing AFib Related Strokes SlideDocument48 pagesPreventing AFib Related Strokes Slidetorr123Pas encore d'évaluation

- CCNP Work BookDocument94 pagesCCNP Work Booktorr123100% (1)

- 02 CV Tracking SETUPDocument10 pages02 CV Tracking SETUPAbraham SegundoPas encore d'évaluation

- Rust Programming Cheat Sheet: IncludesDocument2 pagesRust Programming Cheat Sheet: IncludesmutecamelPas encore d'évaluation

- 8-Port Spectrum Analyzer with Carrier MonitoringDocument2 pages8-Port Spectrum Analyzer with Carrier MonitoringarzeszutPas encore d'évaluation

- Interfacing LCD With F PgaDocument22 pagesInterfacing LCD With F PgaadityagulkotwarPas encore d'évaluation

- Lab Assignment #1 Introduction To Geographic Data 1. LogisticsDocument16 pagesLab Assignment #1 Introduction To Geographic Data 1. LogisticsIgo CandeeiroPas encore d'évaluation

- Xcams - EBookDocument34 pagesXcams - EBookmerarib342Pas encore d'évaluation

- IBM 3500 M2 User's GuideDocument126 pagesIBM 3500 M2 User's GuidekelvislonghiPas encore d'évaluation

- Week 5 Lecture MaterialDocument97 pagesWeek 5 Lecture MaterialSmita Chavan KhairnarPas encore d'évaluation

- Ramdump Venus 2022-01-04 10-22-26 PropsDocument15 pagesRamdump Venus 2022-01-04 10-22-26 PropsYousles maniaPas encore d'évaluation

- 1 s2.0 S2212017312004604 MainDocument9 pages1 s2.0 S2212017312004604 MainTHAPELO PROSPERPas encore d'évaluation

- AI Technologies Transform Military OperationsDocument20 pagesAI Technologies Transform Military OperationsKady YadavPas encore d'évaluation

- Order 7870856 Post SIEM Implementation FinalDocument19 pagesOrder 7870856 Post SIEM Implementation FinalQuinter WandiaPas encore d'évaluation

- Android SQLite Database TutorialDocument6 pagesAndroid SQLite Database TutorialJean claude onanaPas encore d'évaluation

- Studio 5000: Ordering GuideDocument3 pagesStudio 5000: Ordering Guideluis.chuquimiaPas encore d'évaluation

- Catia V5 Tutorial Work BookDocument17 pagesCatia V5 Tutorial Work Bookavaakayi100% (2)

- Virtuoso Foundation IP Characterization PDFDocument7 pagesVirtuoso Foundation IP Characterization PDFMike CainPas encore d'évaluation

- ml310 Vxworks QuickstartDocument32 pagesml310 Vxworks Quickstartjumbo_hydPas encore d'évaluation

- Mysql Security Excerpt 5.1 enDocument85 pagesMysql Security Excerpt 5.1 enEduardo De AmatPas encore d'évaluation

- Operator ManualDocument84 pagesOperator Manualswoessner1100% (1)

- GridWorld AP CompScienceDocument129 pagesGridWorld AP CompScienceJoseph VandegriftPas encore d'évaluation

- R24 System Diagram: AMD OntarioDocument36 pagesR24 System Diagram: AMD OntarioRicardo SilvaPas encore d'évaluation

- Question 1:-Answer True or False For The Following StatementsDocument5 pagesQuestion 1:-Answer True or False For The Following StatementsMony JosephPas encore d'évaluation

- Oracle SQL Developer VMDocument3 pagesOracle SQL Developer VMKhoa DiepPas encore d'évaluation

- Triconex DocumentDocument51 pagesTriconex DocumentsendutdutPas encore d'évaluation

- Optimal performance internet with Global InternetDocument2 pagesOptimal performance internet with Global InternetDony KurniawanPas encore d'évaluation

- Examen Analista FuncionalDocument7 pagesExamen Analista FuncionalAlexia HaedoPas encore d'évaluation

- DX DiagDocument30 pagesDX DiagPepito Pepon PepoidePas encore d'évaluation

- 928TCDocument116 pages928TCJuan David DiazPas encore d'évaluation

- TTLEdit LicenseDocument2 pagesTTLEdit LicenseTrung DuongPas encore d'évaluation

- Mcq4 Questions on Spring Boot, Spring MVC, Microservices and REST APIsDocument40 pagesMcq4 Questions on Spring Boot, Spring MVC, Microservices and REST APIsAbcdPas encore d'évaluation