Académique Documents

Professionnel Documents

Culture Documents

IM Turbo Nozzle 2750 2950

Transféré par

Faithrul RijalCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

IM Turbo Nozzle 2750 2950

Transféré par

Faithrul RijalDroits d'auteur :

Formats disponibles

Turbo-Nozzle 2750 B, EN 15182-2, No.

20208833 12/10

Turbo-Nozzle 2950 B, EN 15182-2, No. 60617533

Hollow jet nozzle with shut-off for emission of

extinguishing water by means of full and angle-variable spray jet

Operating and indicating elements:

Shut-off:

The control lever is used to turn the nozzle off or on. Lever forwards: OFF, lever backwards: ON.

Flow rate adjustment using the pointer and flushing function:

The flow rate can easily be pre-selected by turning one of the knurled adjustment collars:

360 550 750 LPM, resp. 550 750 950 LPM at 6 bar.

The position in the middle is marked by an additional button (pointer) and is located on top,

at the small flow rate to the right (3 oclock position), at the great flow rate to the left

(9 oclock position).

By turning the knurled adjustment collar anti-clockwise beyond the position 750, resp.

950 the cleaning position is adjusted. Then the pointer is located at the bottom (7 oclock).

In case the knurled adjustment collar is turned into the cleaning position, dirt particles up to 10 mm

diameter are flushed out. All flow rate positions are fixed by means of rasters.

The flushing function is shown by chattering.

Using the pointer to adjust the shape of the jet:

By turning the red head of the nozzle/jet forming sleeve it can be switched from full to spray jet.

The pointer is located on the jet forming sleeve and at a spray jet of 45on top: By turning the jet

forming sleeve anti-clockwise it is switched into the maximum spray jet 120, clockwise into full jet.

Thus the pointer is in position 11 oclock resp. 2 oclock.

All adjustable jet shapes are fixed by a raster.

Throw distance of full jet:

Flow rates:

Weight and dimension: With adaptor Storz B: 3600 g, 405x245x126 mm

Mode of operation:

The especially marked position 45-spray angle (poi nter on top) on the red head of the nozzle

produces a spray cone which can be used effectively in case of danger of flash-over.

The turbo-nozzle 2750/2950 produces a focus full jet and a spray jet up to 120 maximum. The

pressure at the inlet of the turbo-nozzle influences the sizes of the droplets. Higher pressures and/or

less flow rate reduce the size of the droplets. The teeth at the water outlet of the rubber head reflect

water droplets into the center of the spray jet and thus produce a spray cone which is partly filled up.

High throw distances are achieved in focus full jet by means of a corresponding mechanical striking

force of the water stream.

Repulsion Forces:

During operation the nozzle produces a repulsion force which depends on the pressure and the water

flow rate. Therefore the shut-off always has to be opened and closed slowly.

Attention: High repulsion forces are caused physically for the turbo-nozzle 2750 (2950) in position

750 (950) l/min at 6 bar at approx. up to 450 (550) ! Newton, requiring caution and practice, especially

during operation in unstable grounds.

We recommend our branchpipe holder B DIN 14368 and handling by 2 men generally.

Extinguishing fires in electrical equipment:

A full jet of water of the turbo-nozzle 2750 (2950) provides sufficient resistance according to VDE

0132 to prevent a high voltage flashover up to 30 kV provided that the clearance distances according

to VDE 0132 are observed. For the turbo-nozzle 2750 14,5 m (tip diameter 22), for turbo-nozzle

2950 16 m (tip diameter 24).

Service instructions:

After having worked with foam, the turbo-nozzle has to be flushed with water after use.

The turbo-nozzle should be drained after use by uncoupling from the hose and repeated switching

ON - OFF.

The turbo-nozzle 2750/2950 can be disassembled and assembled with standard tools, provided that

the user disposes of knowledge in function and some experience. It is a fact that the flow rates have

to be readjusted correctly for all hollow jet nozzles in case of repair we recommend to return the

turbo-nozzle to the factory.

Vous aimerez peut-être aussi

- Protective Functions: RPC-F System - L7Document4 pagesProtective Functions: RPC-F System - L7MoodPas encore d'évaluation

- Slam Shut Serie100+brochureDocument4 pagesSlam Shut Serie100+brochureChelito IxPas encore d'évaluation

- Installation and Maintenance of Air Break Vertical Controls for Steam BoilersDocument14 pagesInstallation and Maintenance of Air Break Vertical Controls for Steam Boilerssvkraja007100% (3)

- Hydraulikstanze DSP-120 Hydraulic Punch DSP-120: Bedienungsanleitung / Operation InstructionsDocument13 pagesHydraulikstanze DSP-120 Hydraulic Punch DSP-120: Bedienungsanleitung / Operation InstructionsMasterrPas encore d'évaluation

- Navod Cs Solar 2 A 3 enDocument2 pagesNavod Cs Solar 2 A 3 enTim RobertsPas encore d'évaluation

- Variable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Document8 pagesVariable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Dias EliPas encore d'évaluation

- Instal Leaflet DM920 DM930 Bal Valves PDFDocument6 pagesInstal Leaflet DM920 DM930 Bal Valves PDFMumtaz AhmadPas encore d'évaluation

- ServiceManuals LG Washing WFT902 WF-T902 Service ManualDocument65 pagesServiceManuals LG Washing WFT902 WF-T902 Service Manualobi777100% (3)

- SPM Full Bore Emergency Unloading Valve Manual PDFDocument9 pagesSPM Full Bore Emergency Unloading Valve Manual PDFPablo SotoPas encore d'évaluation

- DW 200 C 0001Document26 pagesDW 200 C 0001Cristea Calin100% (1)

- Maintenance and service manual for elevator control valve EV 100 blainDocument13 pagesMaintenance and service manual for elevator control valve EV 100 blaindragishabl100% (1)

- Maintenance and Service Manual For Elevator Control Valve: EV 100 BlainDocument13 pagesMaintenance and Service Manual For Elevator Control Valve: EV 100 Blainsuk2010Pas encore d'évaluation

- Rotary Evaporators EYELA JapanDocument12 pagesRotary Evaporators EYELA Japanard_caballeroPas encore d'évaluation

- thermCA en Stand 2013 03 18Document56 pagesthermCA en Stand 2013 03 18mohamed ghareebPas encore d'évaluation

- Pressure Controller Application Guide: ModelDocument2 pagesPressure Controller Application Guide: ModelSIVAM81Pas encore d'évaluation

- Tools MaunalDocument86 pagesTools MaunalAbrar HussainPas encore d'évaluation

- Turbine & Its Governing and Turbo Generator AlokDocument143 pagesTurbine & Its Governing and Turbo Generator AlokSHAMSIK2002100% (3)

- Abovegroundhydrants Dropdownpillar 84-25-27 P7 PDFDocument4 pagesAbovegroundhydrants Dropdownpillar 84-25-27 P7 PDFLimhot SitanggangPas encore d'évaluation

- SV10-20 Poppet, 2-Way, Normally Closed: Solenoid ValvesDocument2 pagesSV10-20 Poppet, 2-Way, Normally Closed: Solenoid ValvesMartin Andrew TugadePas encore d'évaluation

- Adjusting The Hydraulic PumpDocument6 pagesAdjusting The Hydraulic PumpSugeng Ciko Darminto90% (10)

- Variable Vane Pump VDCDocument14 pagesVariable Vane Pump VDCDian PramadiPas encore d'évaluation

- NIMCO CV3000sDocument16 pagesNIMCO CV3000sBruno SamaeianPas encore d'évaluation

- Automatic Flocculant Plant Control PhilosophyDocument8 pagesAutomatic Flocculant Plant Control PhilosophyBebel VillarPas encore d'évaluation

- Piston Pumpa Za BačveDocument24 pagesPiston Pumpa Za Bačvesealion72Pas encore d'évaluation

- Municipal Water Supply Pump CatalogueDocument23 pagesMunicipal Water Supply Pump CatalogueMandisa Sinenhlanhla NduliPas encore d'évaluation

- Manual Balancing Valves CIM 727: Technical InformationDocument10 pagesManual Balancing Valves CIM 727: Technical InformationblindjaxxPas encore d'évaluation

- Клапан На 180 НасосDocument4 pagesКлапан На 180 Насосanon_757712831100% (1)

- Shuttle Series PDFDocument40 pagesShuttle Series PDFIvan IvanovicPas encore d'évaluation

- Butterfly Valves PDFDocument6 pagesButterfly Valves PDFjasedPas encore d'évaluation

- Spreader Training - EH5U & EH170UDocument43 pagesSpreader Training - EH5U & EH170UDavid Adeola Ogunyemi100% (3)

- Operating Manual for Self-Priming PumpDocument9 pagesOperating Manual for Self-Priming PumpAPas encore d'évaluation

- Manual for Prestopress-3 Hydraulic Embedding PressDocument23 pagesManual for Prestopress-3 Hydraulic Embedding PressnarutomoviePas encore d'évaluation

- TZ, TZE, TZB Desiccant Compressed Air Dryer Technicians GuideDocument30 pagesTZ, TZE, TZB Desiccant Compressed Air Dryer Technicians GuideJoel100% (1)

- Oral Candy Meo Class 4Document32 pagesOral Candy Meo Class 4deepanck0% (2)

- Spreader Training Eh5u Amp Eh170u PDF FreeDocument43 pagesSpreader Training Eh5u Amp Eh170u PDF FreeMoez KarouiPas encore d'évaluation

- Fill Rite Fuel MeterDocument12 pagesFill Rite Fuel MeterriobmPas encore d'évaluation

- LPR-N Tester Valve Funcionamiento 1Document33 pagesLPR-N Tester Valve Funcionamiento 1Александр КинтероPas encore d'évaluation

- Solenoid Controlled Pilot Operated Directional Valves Specifications and RatingsDocument50 pagesSolenoid Controlled Pilot Operated Directional Valves Specifications and RatingsphaindikaPas encore d'évaluation

- Needles Restrictor Hk66k102Document16 pagesNeedles Restrictor Hk66k102seaqu3stPas encore d'évaluation

- Del 1 E 180-195-VD250 General DescriptionDocument8 pagesDel 1 E 180-195-VD250 General DescriptionManuel Morales TorresPas encore d'évaluation

- Additel 918 ManualDocument2 pagesAdditel 918 ManualAnonymous ffje1rpaPas encore d'évaluation

- 873 400 Regulator Operation and Maintenance ManualDocument2 pages873 400 Regulator Operation and Maintenance ManualHassan KhattabPas encore d'évaluation

- Be Butterfly Valves PB VFB PDFDocument14 pagesBe Butterfly Valves PB VFB PDFYogiePas encore d'évaluation

- 302032-1 Stroke Balancing - Test Gauge KitDocument4 pages302032-1 Stroke Balancing - Test Gauge KitAntonio SanchezPas encore d'évaluation

- Direct Acting Excess Pressure ValvesDocument8 pagesDirect Acting Excess Pressure ValvescartarPas encore d'évaluation

- Zinex Hydraulic TroubleshootingGuideDocument14 pagesZinex Hydraulic TroubleshootingGuideSecoteloPas encore d'évaluation

- Viking Series 90 Operating & Maintenance Instructions: FiltersDocument15 pagesViking Series 90 Operating & Maintenance Instructions: FiltersninatenaPas encore d'évaluation

- SMART Accumax USER MANUAL - SINGLE CHANNELDocument22 pagesSMART Accumax USER MANUAL - SINGLE CHANNELYessica PinedaPas encore d'évaluation

- Mahlepi270 GBDocument5 pagesMahlepi270 GBHassanPas encore d'évaluation

- P/N 6700-0494-000 Rev 2 06/2015 Oxygen Blender ManualDocument32 pagesP/N 6700-0494-000 Rev 2 06/2015 Oxygen Blender ManualEdmund S Maputi100% (1)

- Gilson PipetDocument24 pagesGilson Pipetroyfang2293Pas encore d'évaluation

- DV 04 2014 PDFDocument55 pagesDV 04 2014 PDFJuliana Thibes MartiniPas encore d'évaluation

- PUMPEX Service Instructions Sp20 80Document19 pagesPUMPEX Service Instructions Sp20 80Teodor BochevPas encore d'évaluation

- Belimo valves and actuators guide for shut-off and butterfly valvesDocument12 pagesBelimo valves and actuators guide for shut-off and butterfly valves윤병택Pas encore d'évaluation

- Насосы FagDocument24 pagesНасосы FagMasterrPas encore d'évaluation

- Operation and Maintenance: Model 873-400 RegulatorDocument2 pagesOperation and Maintenance: Model 873-400 Regulatorilham rusdyPas encore d'évaluation

- Water Pump Pressure Control Switch Adjustment Nut Direction1Document12 pagesWater Pump Pressure Control Switch Adjustment Nut Direction1ver_at_workPas encore d'évaluation

- Akron 3491 Installation ManualDocument13 pagesAkron 3491 Installation ManualDercio CostaPas encore d'évaluation

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementD'EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementPas encore d'évaluation

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGD'EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGPas encore d'évaluation

- McMaster-Carr 316 Stainless Steel BSPT to NPT Pipe Fitting AdapterDocument2 pagesMcMaster-Carr 316 Stainless Steel BSPT to NPT Pipe Fitting AdapterFaithrul RijalPas encore d'évaluation

- Edge Protection ProfilesDocument6 pagesEdge Protection ProfilesFaithrul RijalPas encore d'évaluation

- DIN-3570-U Bolt PDFDocument2 pagesDIN-3570-U Bolt PDFvictoraghi100% (1)

- MALE STUD CONNECTOR - FLOpdfDocument1 pageMALE STUD CONNECTOR - FLOpdfFaithrul RijalPas encore d'évaluation

- Alfaflex - AlfacierDocument2 pagesAlfaflex - AlfacierrijalharunPas encore d'évaluation

- MALE STUD CONNECTOR - FLOpdfDocument1 pageMALE STUD CONNECTOR - FLOpdfFaithrul RijalPas encore d'évaluation

- BRD - Klee-Datablad DIN 6330Document2 pagesBRD - Klee-Datablad DIN 6330LaviPas encore d'évaluation

- Pnmlo PlugDocument1 pagePnmlo PlugFaithrul RijalPas encore d'évaluation

- Stra Union OrfsDocument1 pageStra Union OrfsrijalharunPas encore d'évaluation

- Bolt Torque Guide HagueDocument1 pageBolt Torque Guide HagueFaithrul RijalPas encore d'évaluation

- MaleStraightAdapterThreadBSPParallelMetricParallel PDFDocument1 pageMaleStraightAdapterThreadBSPParallelMetricParallel PDFFaithrul RijalPas encore d'évaluation

- 8 DS2X6 PDFDocument1 page8 DS2X6 PDFFaithrul RijalPas encore d'évaluation

- MaleStraightAdapterThreadBSPParallelMetricParallelDocument1 pageMaleStraightAdapterThreadBSPParallelMetricParallelFaithrul RijalPas encore d'évaluation

- StraightAdapterWithDoubleSwivelNutThreadMetricParallel PDFDocument1 pageStraightAdapterWithDoubleSwivelNutThreadMetricParallel PDFFaithrul RijalPas encore d'évaluation

- F 2005011Document8 pagesF 2005011Faithrul RijalPas encore d'évaluation

- Flomatic Corp, 15 Pruyn's Island, Glens Falls, New York 12801Document2 pagesFlomatic Corp, 15 Pruyn's Island, Glens Falls, New York 12801Faithrul RijalPas encore d'évaluation

- M1003F02!02!0515 AWG Turbo Nozzles Brochure en 01Document4 pagesM1003F02!02!0515 AWG Turbo Nozzles Brochure en 01Faithrul RijalPas encore d'évaluation

- MaleStraightAdapterThreadBSPParallelMetricParallelDocument1 pageMaleStraightAdapterThreadBSPParallelMetricParallelFaithrul RijalPas encore d'évaluation

- Your Paint Guide PDFDocument27 pagesYour Paint Guide PDFFaithrul RijalPas encore d'évaluation

- 2683 Fall 2015 CH Catalog Xsect Guide WDocument4 pages2683 Fall 2015 CH Catalog Xsect Guide WFaithrul RijalPas encore d'évaluation

- 10 Fire FittingsDocument10 pages10 Fire FittingsFaithrul RijalPas encore d'évaluation

- Appliance Cross SectionsDocument1 pageAppliance Cross SectionsFaithrul RijalPas encore d'évaluation

- 2013103094257.SH-hanging Bin ShelvingDocument1 page2013103094257.SH-hanging Bin ShelvingFaithrul RijalPas encore d'évaluation

- 201310309569.professional Customization PDFDocument2 pages201310309569.professional Customization PDFFaithrul RijalPas encore d'évaluation

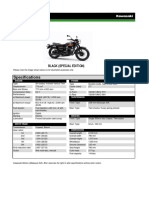

- Specifications: Black (Special Edition)Document1 pageSpecifications: Black (Special Edition)Faithrul RijalPas encore d'évaluation

- TNF WB Window Box SpecificationsDocument4 pagesTNF WB Window Box SpecificationsFaithrul RijalPas encore d'évaluation

- 2013103095642.MHB-storage BinDocument1 page2013103095642.MHB-storage BinFaithrul RijalPas encore d'évaluation

- 201310309569.professional CustomizationDocument2 pages201310309569.professional CustomizationFaithrul RijalPas encore d'évaluation

- Ansul 102Document145 pagesAnsul 102Kadiri OlanrewajuPas encore d'évaluation

- Bathroom Units: Marine & Offshore Interior SystemsDocument7 pagesBathroom Units: Marine & Offshore Interior SystemsFaithrul RijalPas encore d'évaluation

- Product Catalog: Ductless Mini-Splits, Light Commercial and Multi-Zone SystemsDocument72 pagesProduct Catalog: Ductless Mini-Splits, Light Commercial and Multi-Zone SystemsFernando ChaddadPas encore d'évaluation

- HetNet Solution Helps Telcos Improve User Experience & RevenueDocument60 pagesHetNet Solution Helps Telcos Improve User Experience & RevenuefarrukhmohammedPas encore d'évaluation

- Lesson 3 - Materials That Undergo DecayDocument14 pagesLesson 3 - Materials That Undergo DecayFUMIKO SOPHIA67% (6)

- Software Engineering Modern ApproachesDocument775 pagesSoftware Engineering Modern ApproachesErico Antonio TeixeiraPas encore d'évaluation

- Hollow lateral extrusion process for tubular billetsDocument7 pagesHollow lateral extrusion process for tubular billetsjoaopedrosousaPas encore d'évaluation

- Wheat as an alternative to reduce corn feed costsDocument4 pagesWheat as an alternative to reduce corn feed costsYuariza Winanda IstyanPas encore d'évaluation

- Warranty Information Emea and CisDocument84 pagesWarranty Information Emea and CisHenriques BrunoPas encore d'évaluation

- FC Bayern Munich Marketing PlanDocument12 pagesFC Bayern Munich Marketing PlanMateo Herrera VanegasPas encore d'évaluation

- Anthony Flagg's Complaint Against Eddie LongDocument23 pagesAnthony Flagg's Complaint Against Eddie LongRod McCullom100% (1)

- Green Solvents For Chemistry - William M NelsonDocument401 pagesGreen Solvents For Chemistry - William M NelsonPhuong Tran100% (4)

- Business Advantage Pers Study Book Intermediate PDFDocument98 pagesBusiness Advantage Pers Study Book Intermediate PDFCool Nigga100% (1)

- FZ16 9B 1KD2 (Patada) PDFDocument62 pagesFZ16 9B 1KD2 (Patada) PDFPanthukalathil Ram100% (1)

- Current Affairs Q&A PDF June 9 2023 by Affairscloud 1Document21 pagesCurrent Affairs Q&A PDF June 9 2023 by Affairscloud 1Yashika GuptaPas encore d'évaluation

- Capran+980 CM en PDFDocument1 pageCapran+980 CM en PDFtino taufiqul hafizhPas encore d'évaluation

- 34 Annual Report 2019 20Document238 pages34 Annual Report 2019 20Rahul N PatelPas encore d'évaluation

- Role Played by Digitalization During Pandemic: A Journey of Digital India Via Digital PaymentDocument11 pagesRole Played by Digitalization During Pandemic: A Journey of Digital India Via Digital PaymentIAEME PublicationPas encore d'évaluation

- Draft of The English Literature ProjectDocument9 pagesDraft of The English Literature ProjectHarshika Verma100% (1)

- Easyjet Group6Document11 pagesEasyjet Group6Rishabh RakhechaPas encore d'évaluation

- Merlin Gerin Medium VoltageDocument10 pagesMerlin Gerin Medium VoltagekjfenPas encore d'évaluation

- 13 Daftar PustakaDocument2 pages13 Daftar PustakaDjauhari NoorPas encore d'évaluation

- Localization Strategy in Vietnamese Market: The Cases ofDocument25 pagesLocalization Strategy in Vietnamese Market: The Cases ofHồng Thy NguyễnPas encore d'évaluation

- SINGGAR MULIA ENGINEERING HORIZONTAL 2-PHASE SEPARATORDocument3 pagesSINGGAR MULIA ENGINEERING HORIZONTAL 2-PHASE SEPARATORElias EliasPas encore d'évaluation

- Exp19 Excel Ch08 HOEAssessment Robert's Flooring InstructionsDocument1 pageExp19 Excel Ch08 HOEAssessment Robert's Flooring InstructionsMuhammad ArslanPas encore d'évaluation

- Acknowledgment: George & Also To Our Group Guide Asst. Prof. Simy M Baby, For Their Valuable Guidance and HelpDocument50 pagesAcknowledgment: George & Also To Our Group Guide Asst. Prof. Simy M Baby, For Their Valuable Guidance and HelpKhurram ShahzadPas encore d'évaluation

- S4H - 885 How To Approach Fit To Standard Analysis - S4HANA CloudDocument16 pagesS4H - 885 How To Approach Fit To Standard Analysis - S4HANA Cloudwai waiPas encore d'évaluation

- NDU Final Project SP23Document2 pagesNDU Final Project SP23Jeanne DaherPas encore d'évaluation

- Exercise Manual For Course 973: Programming C# Extended Features: Hands-OnDocument122 pagesExercise Manual For Course 973: Programming C# Extended Features: Hands-OnAdrian GorganPas encore d'évaluation

- Syllabus - Mech 3rd YearDocument130 pagesSyllabus - Mech 3rd YearAbhishek AmarPas encore d'évaluation

- Machine Design - LESSON 4. DESIGN FOR COMBINED LOADING & THEORIES OF FAILUREDocument5 pagesMachine Design - LESSON 4. DESIGN FOR COMBINED LOADING & THEORIES OF FAILURE9965399367Pas encore d'évaluation

- A - Bahasa Inggris-DikonversiDocument96 pagesA - Bahasa Inggris-DikonversiArie PurnamaPas encore d'évaluation