Académique Documents

Professionnel Documents

Culture Documents

Sharp Edge 2010

Transféré par

PaulCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sharp Edge 2010

Transféré par

PaulDroits d'auteur :

Formats disponibles

thesharpedge

issue seven 2010

MX7 The next generation machine

Rigibore Punching to the top

ToolRoom RN31 A must-have release

Southern Saw Soaring into a new venture

Special Projects Customised engineering

Punch Grinding A complete software solution

FastGrind An affordable CNC machine

contents

2 Welcome to the Sharp Edge 2010

3 Get Lean

Implementation of the Kanban philosophy

4 MX7

The next generation of tool grinding machine

8 Punching to the Top

Rigibore: A class above the rest

10 Broach Resharpening

Toyotas customised resharpening package

11 Global Commitment

ANCAs expansion into the BRIC markets

12 ToolRoom RN31

Industry leading software just got better

Cover image: ANCA's new MX7 machine

14 Special Projects

ANCAs customised engineering solutions

17

See the story on page 4 about the new MX7 equipped with ANCA's

latest innovative technology

Southern Venture

Southern Saw soared into a new venture

The Sharp Edge is published by ANCA Pty Ltd

18 Punch Grinding

A complete punch grinding solution

25 Gatwick Road, Bayswater North

19

Victoria 3153 Australia

www.anca.com FastGrind

Executive Editor: Duncan Thompson

An affordable entry-level CNC machine

Editor: Andrew Ritchie

Got some comments? Ideas for articles?

Please send your feedback to productsupport@anca.com

Know someone who would like their own copy of The Sharp Edge?

20 Technical Specifications

An overview of the FastGrind and MX7

Please advise us and well send them a copy.

Dont want to receive The Sharp Edge?

Please advise us and well remove you from the mailing list. 21 ANCA Worldwide

Find your nearest ANCA dealer

thesharpedge issue seven 2010 1

welcome

Welcome to the Sharp Edge 2010.

Last years economic turbulence proved to be a challenging time for businesses

around the world. At ANCA, we decided to use the downturn as an opportunity

to look inwards and build a stronger company.

ANCAs name has always been synonymous with high quality. Our commitment

to the highest standard possible was affirmed by the installation of the new

Dixi DHP80 Jig Borer at the Bayswater plant in Melbourne. The DHP80, which

is regarded as the most accurate machine tool in the world, adds to our

existing Dixi installation ensuring capacity for across the board precision in our

machines critical components.

In addition to plant improvement, we had a close look at our manufacturing

process to find ways to work smarter. Our production team industriously

adopted the Kanban lean philosophy in targeted machine production areas

such a spindle build and machine base manufacture, to achieve a more efficient

process and increase production capabilities.

Tough times can also create new opportunities. To accommodate our

customers needs for more cost-effective CNC machines, our Research &

Development team recently launched the MX7 and the FastGrind. The two

machines, were built in response to different customer needs. MX7 for

customers seeking efficient, high volume production, while the FastGrind offers

an extremely affordable entry level CNC tool grinder.

Additionally, our Software Development team also unveiled ToolRoom

Release 31, which again raised the industrys benchmark in tool design and

manufacturing software.

As we look forward to new challenges in 2010, which is anticipated to be a

year of strong economic recovery, ANCA remains committed to providing our

customers with world-class machines, services and support, and being the

worlds best at what we do.

Pat Boland

CEO

2 thesharpedge issue seven 2010

get lean

The spindle room after ANCA implemented

its kanban manufacturing process, using a

visual signalling system to trigger actions.

ANCAs endeavour for continual Kanban is now implemented

production improvement means throughout ANCAs production

our customers can reap the including the machine base

rewards from our efforts to work mould section and sub assembly

smarter. areas. Further refinements have

been made to each production

Last year, ANCA implemented area for ongoing improvement.

the first phase of its lean

manufacturing process called Since then, ANCA has seen

Kanban. The Japanese words, significant improvement in

where Kan means visual and its production

ban means card or board, is output. Inventory In the machine

a term associated with lean which used to base mould

production. Kanban basically be stored in one shop section,

the inventory

indicates a visual signalling system large facility is is stored within

used to trigger actions. In the now stored within the area for easy

lean production process, Kanban each assembly access and visual

reminder when

enables the continuous supply of section. This inventory is low.

components so assemblers can not only allows

have what they need, where they visible, quick and

need it, and when they need it. To easy access to components but

control the downstream activities, also provides visual indication

Kanban or the visual signalling when inventory is low.

system is used to activate the

upstream activities. ANCAs implementation of

Kanban has placed great

The spindle assembly room was emphasis on ensuring the

chosen for the Kanban pilot right amount of components

program at ANCA since the are always in stock and

area was less critical and could the production output can

be temporarily taken off-line be achieved on time. The

from the production process. leaner process and increased

The result was encouraging production capabilities will

with around 25% reduction prepare ANCA for the demanding

in production time and 30% times ahead.

reduction in inventory.

thesharpedge issue seven 2010 3

The MX7s

automatic wheel

pack changer

(cover removed

for clarity) offers

10-second wheel

change time and

accurate, rigid

mounting.

MX7 The Next Generation

Greg Perry and Andrew Ritchie report how ANCA MX7 becomes the

Next Generation machine in Precision Tool Grinding.

Following strong customer demand up to 16 mm (5/8). Optimising The 20kW (constant power-S1)

and extensive market research, the machine elements for this permanent magnet HSK wheel

ANCAs research and development tool size range has enabled ANCA spindle delivers outstanding

team has delivered another first to minimise not only the machine performance across the entire

class CNC Tool and Cutter Grinding footprint but also the price. 10,000 RPM range. This spindle

machine that offers versatility with type provides high torque at low

maximum productivity. What makes the MX7 so unique RPM, which is highly desirable

is that it offers the power and for carbide grinding. The wheel

The ANCA MX7 is the next flexibility of a large machine for spindle also includes a special

generation machine, specifically the price of a small machine and feature where it can be used as

designed and built with the latest still includes all the innovative an axis (Q axis), enabling its

technology to suit the demanding features and benefits ANCAs rotary position to be accurately

needs of tool manufacturers. The customers have come to expect controlled. This feature precisely

MX7 design is based on the ANCA over the last 35 years. matches the orientation of the

TX7 machine structure, which wheel arbor to the spindle every

over the past 10 years has been During the MX7 concept stage, time the wheel is changed,

regarded as the ideal production ANCA undertook extensive market resulting in accurate and

design. Proven TX7 qualities that research to ensure that current repeatable wheel runout.

are now part of the MX7 include: market trends and customer

Outstanding rigidity and demands were met. As a result, As with all ANCA machines,

strength of machine axes the MX7 comes standard with a the MX7 comes standard with

Designed for heavy production 6 wheel-pack changer, offering direct-drive technology, which

grinding maximum production capability. means no belts or pulleys,

Thermal stability allowing it to deliver superior

Optimised axis travel for Since precise coolant delivery positioning, accuracy and

reduced cycle times plays a key part in the grinding reliability. With speeds up to

operation, each wheel pack 3000 RPM, the direct-drive

Even though the MX7 is capable has its own dedicated coolant headstock (A-axis) can also

of grinding a wide range of tools manifold. The wheel pack and be used as a wheel dresser.

varying in diameter and length, the coolant manifold are mounted Dressing operations can be

it is designed to focus specifically together within 10 seconds, called up within the grinding

on the tool sizes that are in ensuring optimum coolant pipe program for truing or dressing

greatest demand covering tools set-up. the grinding wheel.

4 thesharpedge issue seven 2010

For companies looking to optimise compensation without having to

their production output, the MX7 remove the tool from the machine.

has a wide variety of machine

accessories to help automate ANCAs industry renowned

the manufacturing process. The and user-friendly ToolRoom

integrated and flexible MLX loader software also offers a host of

provides high capacity storage programming options from

allowing hours of unmanned grinding standard end mills to

operation. Pallet capacity ranges unique and specialised tools. See

from 840 tools for 3 mm (1/8) Page 12 for more information

to 154 tools for 16mm (5/8). about ANCAs newly released

The loader uses only one gripper ToolRoom RN31 software.

to take the tool from the pallet

to the machine work holding. In light of challenging economic

The loader is integrated into the conditions, and an ever pressing

MX7 machine structure, providing need to remain competitive,

a very rigid assembly. This the MX7 is meeting the needs

structural rigidity along with the of todays tool manufacturers.

single grip tool loading ensures Superior levels of productivity,

accurate and reliable loading accuracy and technology are

every time. The 10-second tool ensuring the MX7 takes its place Windows built into the loader ensure full view

change time ensures the MX7 as the next generation of CNC of its operation from the front of the MX7

machine.

spends more time grinding over grinding machine.

production runs.

When it comes to the grinding

set-up and preparation, ANCAs

CIMulator3D allows the MX7

operator to simulate the

programmed tool path exactly as it

would be ground on the machine.

New tool programs can be verified

for size, shape, machine collisions

and even cycle time estimates.

CIMulator3D allows continuous

work flow through the machine by

reducing development time and

trial grinding.

ANCAs innovative iView is

a precise tool measurement

system that is ideal for precision

The micro pop-up steady offers optimum tool The 20kW power rating of the permanent

tool grinding. It can be set-up support and setting control providing vertical, magnet spindle provides high torque at lower

for profile measurement and axial and yaw adjustment for excellent accuracy. RPM, particularly suited for carbide grinding.

MX7 at a glance (See Page 20 for technical specifications)

10-second tool change

10-second wheel change

Production ready

Wheel changer that stores 6 HSK 50 wheel

packs for increased productivity and flexibility

MLX loader for unmanned operation

Permanent magnet spindle delivers constant

torque across the entire 10,000 RPM range

Off-line tool design and development using

ANCAs ToolRoom and CIMulator3D software

Supported by ANCAs worldwide team of

technical specialists from training right through

to maintenance

thesharpedge issue seven 2010 5

Filtration for

Precision Machining Applications

Ebbco inc. is a full design/ cartridges. Each Cartridge is For more information,

build manufacturer of capable of holding up to 30

filtration systems and filter pounds of carbide sludge. A Contact

vessels focusing on the chiller incorporates a digital Fred Poppe or an Ebbco

metalworking industry since temperature controller representative direct at

1983. which keeps the oil or 001 586 716-5151

coolant through out the

Ebbco offers a large line machine tool at a consistent Or email

of filtration equipment temperature. fpoppe@ebbcoinc.com

for precision machining

applications. Ebbco systems Systems come standard You can also find us on the

are custom designed with Ebbcos patented web at www.ebbcoinc.com.

to OEM manufacturers extended area filter

specifications. baskets which serve as a

prefilter or the optional

The Ebbco Evolution high volume magnetic pre-

Series is a metalworking filter for high speed steel

filtration system designed applications. This system

for precision machining and also incorporates a heavy-

cutter grinding applications duty seal-less filter pump

of carbide, tool steel, to avoid costly seal

surgical metals, PCD and replacement and

ceramics. This system downtime.

conditions coolants and

oils down to 0.5 micron,

while maintaining constant

temperature, avoiding

thermal distortion.

The Ebbco filtration

systems offers a high-

capacity cartridge filter

housing, with an easy to

use hydraulic lid opening

device, to accommodate up

to eight-micron rated filter

The Sharp Edge sent David Arnesen to Wisconsin to find out how Rigibore has used

ANCA machines to help grind inserts to the highest of tolerances.

Rigibore Inc is a precision boring the software is user friendly, finishing wheels, the company

tool producer with an edge. remarked Anthony. And thats grinds the periphery of the piece

Located in Mukwonago, Wisconsin, saying a lot because Rigibore and the chipbreakers for specific

the US branch of UK-based develops much of its own software applications on its boring tools.

Rigibore, has recently developed a for manufacturing.

very special capability. The RX7 is robot-loaded, providing

We thought we could grind Rigibore the ability to operate

Our boring tools can be adjusted inserts in a different way than unattended. During the course

to the micron, so we wanted to be they had been before. We had of the process development, we

able to create very high accuracy developed a range of inserts for and ANCA learned quite a bit

inserts for them, said Anthony the North American market, the automating the production of very

Bassett, Rigibore Inc president. production of which we had been small pieces, from fixturing to robot

The closer tolerance the inserts outsourcing, Anthony explained. handling, Anthony pointed out.

can be the less adjustment With the ANCA grinder, we could

necessaryits almost like having bring the work in-house and Originally developed by ANCA

a brazed tool. assure ourselves that we could for grinding punches used

market ISO standard H tolerance in metalworking and tablet

Rigibores customers include (+/- 13 microns) inserts, one of production, iPunch intelligently

second tier automotive suppliers, the highest tolerances that can be handles multiple steps by knowing

small engine producers, and large ground. the material already removed from

off-road engine builders. For the the previous operation. By spiraling

larger users, we produce special Today, with ANCAs application in from the initial shape to the final

shapes and forms to do very assistance, we are grinding shape, iPunch ensures the wheel

specific things, Anthony added. consistently within 1 to 2 microns is always in contact with the part

with our versatile ANCA RX7 and which eliminates any wasted time

We needed a machine that can the iPunch software, Anthony spent grinding air. Reversal marks

produce small quantities quickly noted. Its amazing how the are eliminated during finishing.

and which can operate unattended machine is holding that tolerance Different back tapers are easily

for larger batches. We approached around the center of the piece. produced by using the C axis to

ANCA for this project because With superabrasive roughing and pivot the wheel position.

8 thesharpedge issue seven 2010

We are grinding consistently within

1 to 2 microns with our versatile

ANCA RX7 and its iPunch software

The iPunch software can grind simulate the process to be sure we that with the RX7, iPunch and our

in three axes so we can grind will produce what the customer is special fixtures, Anthony said. It

any shape we need to, said Ken asking for, he added. has opened up new possibilities for

Kasten, Rigibore Precision Grinding us in grinding inserts. Any insert

specialist, and we can control it With the implementation of we have on our shelf whether it

easily within 1 micron. That was iPunch, Rigibore has reduced cycle is CBN, diamond or carbide, is

it for us. Plus, the software was times 30-40%. iPunch operations ground to H tolerance. And we can

easy to learn, he added. iPunch can be integrated in to iGrind do it confidently with the RX7 and

software moves the wheel in applications, offering Rigibore iPunch software. The combination

and out and up and down and it complete flexibility in grinding its gets us where we want to be,

controls the C axis. This gives us a inserts. grinding special forms on inserts.

flatter edge. Going outside for this kind of

For Rigibore, iPunch opened the service would be unacceptable

Most customer parts come in as door to production of extreme in terms of time and quality, he

drawings, Ken explained. We tolerance inserts that other concluded.

design the parts in SolidWorks sources simply cant touch.

and then save it as a CAD file For an in-depth look at the iPunch

and import directly into iPunch. Our goal is to do more special software, see page 19.

From there we can tweak it and inserts, and we feel we can do

iPunch can grind in three axes so we can grind

any shape we want to... easily within 1 micron

thesharpedge issue seven 2010 9

RX7 regrinding a cylindrical

broach which is held between

centres for total precision.

broach

resharpening

ANCA's solution for a local automotive manufacturer and

global exporter. Greg Perry reports the benefits.

To further enhance the RX7s regardless of the broachs

capabilities, ANCA has released condition and type.

a new versatile and easy-to-use

Broach Resharpening package. The digitising operation can be

This complete package consists performed by digitising one tooth

of specifically designed software only, and then each subsequent

and tooling for the resharpening of tooths position is determined by Specific work-holding has been

both flat and round broaches. an operator manually inputting the designed for both the flat and round

pitch into a user table. broaches. Cylindrical or round

broaches are held between centres

Alternatively, the operator can to provide the rotation. The flat

choose to digitise all teeth on the broach is mounted onto a fixture

broach to determine their true and supported by the same tailstock

position. This approach is ideal for used to hold the round broach.

broaches with uneven wear. The

OD and core depth of the teeth The maximum length broach that

can also be digitised so the data can be ground on the RX7 is:

can be used to ensure each tooth 400mm for a flat broach

is ground to the correct depth. 385mm for a round broach

This data is very useful since

During the Research & the core depth is

Development process, ANCA continually increasing

engineers worked closely with over the length of a

Toyota Motor Corporation Australia broach.

to ensure that the software

had the required parameters to Once the broach

maintain all the important features geometry is digitised,

and geometry of the broach. the data is fed

into the grinding

The software comprises of two operation page to

distinct operations: digitising and set-up reference

grinding. The digitising operation parameters such as

ensures that the teeth geometry depth of cut, number

is precisely identified and their of passes, speeds,

position is accurately determined feeds and spark out.

10 thesharpedge issue seven 2010

global

commitment

ANCAs further expansion into the BRIC markets is marked by the opening of offices in

Brazil and India. By Andrew Ritchie.

ANCAs further expansion into the ANCAs newest office located in

fast-growing developing markets Bangalore, India, was opened in

has seen the opening of two new May 2008. Guruprasad Prashanth,

offices in Brazil and India. This ANCA Indias Sales Manager

represents ANCAs ongoing global believed the new office was well

commitment, in particular to the positioned to support the countrys

BRIC countries (Brazil, Russia, growing demand for CNC tool

India and China). grinding machines.

Both Brazil and India have Bangalore has a strong

shown increasing demands for manufacturing and industrial

ANCAs Tool and Cutter Grinding base including numerous heavy

technology. It is therefore vital for industries, aerospace, engineering Guruprasad Prashanth (RIGHT), ANCA

ANCA to establish regional offices and defence organisations. We Indias Sales Manager demonstrating RX7s

capabilities at the IMTEX Tradeshow in

with dedicated sales staff and certainly see a robust growth in Bangalore.

support engineers to serve the the CNC market here, commented

increased demands and long-term Guruprasad.

needs of our customers.

As the BRIC countries develop,

The ANCA Brazil office, located in ANCAs regional offices will

Sorocaba, So Paulo, was opened continue to grow alongside its

in February 2006. Currently, ANCA customers. ANCAs commitment

Brazil services over 50 machines to be the world leader in CNC Tool

for more than 20 customers and Cutter Grinding technology

around the South America region. is evident by its continued

Most of our customers supply global investment and strategic

cutting tools and equipment expansion, not only with todays

to various industries including established markets, but also the

automotive, manufacturing, developing and emerging markets Giuliano Gisoldi (LEFT), ANCA Brazils

Application Engineer conducting a training

engineering and medical, said of tomorrow. session on the TX7+.

Giuliano Gisoldi, ANCA Brazils

Application Engineer.

ANCA offices in BRIC countries

ANCA Brazil ANCA Russia ANCA China ANCA India

Rua Francisco Ferreira ZAO Rosmark-Steel West Wing, 1/F., Building 4, No. 598/18-1, 2nd Floor

Leo 377 Business Center McTower 475 Fu Te No.1 Road (W) 3rd Main, 11th Cross

Sorocaba 18040 330 Chelieva St., 13 Waigaoqiao FTZ Sadashivnagar

So Paulo 193230 St. Petersburg Shanghai Bangalore - 560 080

Brasil Russia China India

Tel (+55) 15 3221 5512 Tel (+7) 812 336 27 27 Tel (+86) 21 5868 2940 Tel (+91) 80 6546 2152

Fax (+55) 15 3221 5512 (+7) 812 322 96 97 Fax (+86) 21 5868 2921 Fax (+91) 80 4123 6497

Fax (+7) 812 336 27 00

Email brinfo@anca.com Email mozgov@rosmark.ru Email chinfo@anca.com Email indiainfo@anca.com

thesharpedge issue seven 2010 11

ANCAs latest industry leading ToolRoom software offers a host of new features and

enhancements to boost productivity and improve usability. By Paul Bocchi.

Since its beginning, ANCA has parameter values are changed. operation now supports grinding of

been committed to providing In addition, RN31 will promptly an eccentric OD and a facet relief

the most advanced and flexible provide feedback on any potential ballnose in one continuous blended

tool design and manufacturing geometrical errors or grinding move.

software packages on the market. limitations during the design

ToolRoom RN31 resolutely process. ToolRoom RN31 also makes

continues ANCAs commitment. it easier to achieve complex

With many new features and The OD-finish eccentric relief tool geometries with its new

enhancements, it is undoubtedly a grinding option has been improved Tool Segments feature, which

must-have release. to produce an accurate eccentric essentially allows one tool to be

relief form using a new relief modelled as a combination of

The design and manufacture definition. For ballnose tools, the two or more separate tools. This

of complex tool geometries

demand software flexibility and

ease of use, which have always

been synonymous with ANCAs

products. As tool designs become

increasingly sophisticated, it is

vital to have software that is up to

the job. ToolRoom RN31 expands

the softwares capabilities to define

and grind custom tool geometries

with several new features. This

includes a new custom walk editor

that enables users to enter custom

defined geometry to achieve

special or complex end-face

features.

Ballnose tool manufacturers will

greatly benefit from RN31s new

layouts, 3D design-time graphics,

and enhanced functionality for

designing ballnose tools. Instant

visual verification is achieved

through the new 3D graphics

which are dynamically updated as The new Custom Walk Editor in ToolRoom RN31 opens up a new range of end-face possibilities.

12 thesharpedge issue seven 2010

feature provides a perfect balance

of flexibility and ease of use,

allowing complex tools containing

several diameter segments to be

easily designed.

In todays high technology

manufacturing environment,

cutting-edge preparation has

increasingly become a necessity,

and subsequently, an important

ingredient in the successful design

of cutting tools. ToolRoom

RN31 expands the cutting-

Left: A new tool to add to the toolbox. Tool Segments allows tools with distinct

edge preparation capability by segments to be created easily, eliminating the complexity of breaking parameter links.

introducing many new K-Land Right: The enhanced Ballnose operation now features 3D design-time graphics and

grinding features for drill points. geometry checking for instant verification.

Additionally, new operations have

been included to grind a K-Land preview image dialogs, parameter assured that RN31 is the most

edge on the rolled-chamfer and change event logs incorporating feature-rich software upgrade

step sections on step tools. The an Undo feature, improved menu ANCA has released to date. This

new K-Land cycles for rolled- structures and new P-Axis set-up article only highlights a few major

chamfer and step sections require options, just to name a few. developments. To discover RN31s

no digitising. The geometry extensive options and functional

is calculated automatically to ToolRoom RN31 is sure to capabilities, please contact your

produce accurate K-Land edges. please existing and new ANCA local ANCA branch for further

customers alike. Customers who information, demonstrations or

Cycle time can be reduced via the are looking to upgrade can be trial licenses.

new Auto-Approach feature, which

uses a smarter and more consistent

approach moves between iGrind

operations, eliminating the need

to specify end-of-operation stop

positions. For tools with several

operations, the Auto-Approach

feature can provide significant

cycle-time savings.

Usability has also been a major

consideration for RN31, which

features a wide range of new

interface enhancements including

tool search utilities, tool-file

One of the many new developments in RN31 is the introduction of

the new Compression Router software into iGrind.

The new software reaps all the benefits of the iGrind interface and

significantly simplifies tool design by taking a smarter approach

towards compression router geometry. For example, important

geometric parameters such as overlap width and distance are

specified directly. The fluting operations can then calculate the

required parameters to achieve these targets.

Existing Compression Router users will find the new iGrind software

a tremendous leap forward, benefitting from features such as

design-time geometry displays within the operations, help images for

New K-Land grinding operations allow all parameters, in-built calculators to achieve important geometric

accurate K-Land edges to be ground on the dimensions, and much more.

rolled step and chamfer sections of a step

drill. Geometry is calculated automatically,

regardless of flute shape, eliminating the The new software takes all the guess-work out of the tool design

need to digitise. process and is guaranteed to cut design times dramatically.

thesharpedge issue seven 2010 13

special projects

ANCAs customised engineering

ANCA CNC grinders are now being used to provide solutions to many processes.

As Duncan Thompson reports, the solution was a combination of several factors.

At ANCA, we understand that engineers can ensure that automation extend beyond using

todays businesses seek greater our customers requirements robots to load odd shaped work

production flexibility and are completely understood. pieces. Additional benefits can

capacity. As a result, ANCA Particularly in more complex be gained by adding peripheral

engineers have been working applications, ANCA engineers equipment to the robot station,

closely with our customers to often visit the customers sites to allowing it to perform other

design an increasingly broad understand existing processes, tasks. Washing stations, laser

range of precision grinding where improvements can be etchers, vision systems, polishing

applications for ANCA machines achieved and how to integrate stations and interchangeable

beyond standard cutting tool these solutions to the ANCA tool heads have been added to

grinding. machine. extend the robots functionality

and eliminate the need for these

processes to be performed on

Special Engineering Projects Areas for Special Engineering

another machine. This simplifies

Projects

ANCA engineers can undertake production planning and

special engineering projects to There are three key areas enhances flexibility.

help customers find innovative where ANCA engineers can work

and specialised grinding solutions with our customers on special Tooling

for their manufacturing needs. engineering projects. More often than not, a

Every project is different with customised automation where

unique requirements and Automation a part is to be loaded with a

machinery set-up. Therefore, While ANCAs standard loaders robot will require special tooling,

the key to the project success can handle regular cylindrical which can be as simple as special

comes from the close working tools, a special solution may be grippers and pallets, or can be

relationship between ANCA needed for over dimensional or extended to more complicated

engineers and our customers. odd shaped work pieces. options such as special headstock

ANCA engineers deliver tailored tooling or work piece holding.

By developing an intimate automation designs to suit

knowledge of our customers specific customer needs. The ANCA engineers can design

production process, ANCA advantages of customised specialised tooling to

14 thesharpedge issue seven 2010

accommodate our customers

requirements ensuring seamless

integration into the automated

solution.

Programming

For custom programming for

special engineering projects,

ANCA iGrind software is

specifically designed to allow

easy implementation of special

cycles that can run within a

customised user interface.

Additionally, for parts which

are defined as 3D CAD models,

ANCA engineers use a specially Automation: A vision detection system was installed on a Fanuc robot loader to detect and

orientate the internal coolant holes of the blanks. By removing the need to digitise in the

developed post processer for machine, overall cycle times were reduced.

UG-NX CAM, allowing ultimate

programming flexibility.

The Broach Resharpening

Package, which was developed

by ANCA engineers in conjunction

with Toyota Motor Corporation

(see the story on page 10), is just

one example of ANCA engineers

forming a strong partnership and

collaboration with our customers

to deliver a comprehensive

solution to their special needs.

ANCA prides itself on facing the

new challenges presented by

industry. By working closely with

you, our customer, ANCA draws

on its depth of experience and

expertise to deliver innovative

outcomes that result in a

stronger bottom line for your

business. Tooling: Special headstock tooling was designed by ANCAs engineers to hold multiple tools at

the same time to reduce load cycle time and increase productivity.

Programming: ANCA software engineers work with customers to develop

specialised grinding programs and user interfaces for cutting tools and 3D

components.

By importing a 3D part model into UG-

NXCAM, engineers can use ANCAs post

processor software to develop the grinding

path, which is then implemented on the

ANCA machine. This technique has been

successfully applied to production of medical tools such as bone rasps (above)

and prosthetic knee joints, turbine blades as well as development of unique

cutting tools.

In the bone rasp example above, the TX7+ machine reduced production time of

these components from 4 hours to less than 50 minutes.

thesharpedge issue seven 2010 15

Manufacturers of cutting tools While it is understood that Savings can also be realised by

such as end mills and drills are shorter cycle times result in applying the right parameters

under constant pressure to better economy, it is rarely to utilise the full potential of the

produce at lower costs, yet at stated what this economy means machine tool. WTG engineers

ever higher quality. The users in numbers. If we shorten the have the knowledge, and the

of those same tools are under cycle time of a solid carbide end software tools, to optimize

similar pressures. Hence, we mill by just one minute, from customer processes on the shop

need grinding wheels that grind 15 to 14 minutes, for example, floor. On request, for internal

economically and efficiently. into what cost savings would operator training, a DVD showing

this translate? Using the WTG the optimal preparation and

The NaxoForce grinding wheel Total Cost Calculation Program, use of NaxoForce diamond and

range made by the Winterthur a program available to calculate CBN wheels is also available in a

Technology Group (WTG) meets costs, shows that this one variety of languages.

these demands: from grinding minute would save 1.50 per

wheels for high material removal workpiece. Given a large lot For further information, please

rates combined with excellent size, this would translate into contact our representatives

form holding, down to polishing substantial savings, making below.

wheels that guarantee mirror the tool manufacturer more

finishes. competitive and profitable.

southern venture GX7 helped Southern Saw soar into a new business venture.

Greg Perry reports.

Purchasing your first CNC grinding Following several months of expand their business to other

machine can be a daunting research, Southern Saw settled states of Australia.

decision as it represents a major on the ANCA GX7. We were

turning point in your business. really impressed with the Southern Saws machine is fitted

This was particularly true for an performance of the machine, with the compact CLX loader

Australian company, Southern the quality of the demonstration which provides the capability

Saw Service. For them, investing by ANCA staff and the facilities for unattended operation. We

in the ANCA GX7 also meant at ANCAs headquarters in have certain jobs that we run

venturing into a completely new Melbourne said Kevin. This, in on a weekly basis now. Theres

business direction. the end, made it a pretty easy nothing better than coming in first

decision for us to buy the ANCA thing in the morning and knowing

Southern Saw Service is located machine. that our machine has been

in Hobart, the capital city of making money while we sleep

Australias most southern state, Once they had the machine, all said Kevin.

Tasmania. Originally called Van they needed was the work. After

Diemens Land, Tasmania was we had the machine on order, we Southern Saw Service now

one of the earliest settlements started promoting it, said Kevin. services and manufactures a

in Australia. Now it is well known It was amazing really. People range of metal cutting tools as

for tourism, gourmet food, started knocking on our door with well as wood working cutters

wine and breweries, and timber boxes of tools asking if we can and profile blades. At the time,

industry. sharpen this or if we can make it might have seemed like a bold

that. Work was coming to us. step to invest in the ANCA GX7,

For two generations, Southern By promoting the ANCA machines Kevin happily testifies that despite

Saw has been servicing saw capabilities, Southern Saw found a few sleepless nights initially, he

blades and band saws for the local that it not only helped generate now sits back and thinks about

timber industry in Hobart and the new business in Tasmania, but his next ANCA machine.

surrounding area. Comfortable in also created opportunities to

their market sector, proprietors

Kevin and Andrew Scott decided

to branch out and investigate new Theres nothing better than...

business possibilities. After careful

consideration, they concluded that knowing that our machine

cutting tools would be their next has been making money

venture.

while we sleep.

thesharpedge issue seven 2010 17

punch grinding

ANCAs new software that offers a complete solution

for any punch grinding application by Andrew Ritchie.

ANCA has recently released a templates or imported via a DXF to grind tools to any customised

comprehensive punch grinding file. Final tool geometry is defined shapes as required. The tool

software package, which is a by the number of physical steps geometry can be specified by

significant addition to ANCAs on the tool, which may include any using one of the 24 library

existing range of Tool and of the following: templates or can be imported via a

Cutter Grinder software. The Punch form DXF file. The KHP software allows

new software aims to expand Necking section full control over each operation

and enhance punch grinding Cylindrical section sequence for:

capabilities for ANCAs customers. Peel grinding profile Slice roughing

Taper punches Profile finishing

iPunch is designed to be used in Formed wheel grind

conjunction with iGrind, offering iPunch can precisely handle Form generation by oscillation

cycles for grinding standard multiple steps by identifying

(convex) punches. The iPunch the material that has already Grinding is performed with either

software can also be used in been removed from the previous standard (sharp-edge) wheels

combination with ANCAs existing operation. By spiraling inwards or formed wheels, using ANCAs

Key Hole Punch software, from the initial to the final shape, Dressing Software to dress custom

providing complete flexibility in iPunch ensures the wheel is profiles.

punch grinding applications. constantly in contact with the

part. The iPunch software allows ANCAs new punch grinding suite,

iPunch full control over each operation the iPunch and KHP software,

The iPunch software can provide sequence for: allows customers total freedom to

ANCAs customers with new Roughing grind any combination of punch

business opportunities in the areas Finishing geometry and profile. With a

of turret press punch tools as well Sparkout quick and easy set-up through the

as periphery grinding of inserts. Oscillation library templates or via DXF and

Punch geometry can be specified the capacity to store a multiple

using one of the 38 library Key Hole Punch selection of wheels, there has

For programming concave never been a faster and more

punches, ANCA Key Hole Punch flexible approach to grinding

(KHP) software has the ability punches.

Far Left: Examples of key hole punches ground on the TX7 Left: iPunch library of standard

shapes Right: Grinding wheel path can be graphically displayed

18 thesharpedge issue seven 2010

FastGrind

ANCA's latest FastGrind is an affordable entry-level resharpening tasks as well as

CNC resharpening machine, reports Greg Perry. some light manufacturing.

The FastGrind is not limited to first

Taking the first step into CNC The FastGrind Advantages time or small-scale CNC users.

grinding technology can be a The FastGrind is designed to meet Large tool producers are investing

major investment, which requires the requirements of resharpening in the FastGrind as an additional

careful consideration. ANCAs or small-batch manufacturing. resource for special tooling

newest entry-level CNC grinding By removing unnecessary high or small quantity jobs. Since

machine, the FastGrind, may production orientated options interrupting production machines

help make the decision-making such as auto loading and for a small batch or one-off task

process a little bit easier. automated clamping, we have can be costly, the FastGrind

been able to reduce build costs has proven to be an attractive

What is FastGrind? and deliver the most affordable option for quick turnaround

Built on the highly successful RX7 ANCA CNC grinding machine yet. projects. Large machine shops

platform, the FastGrind delivers or manufacturing companies with

proven machine design, quality Designed with regrinding high tool consumption can also

and precision for which ANCA is capability in mind, the FastGrinds realise a significant cost saving

renowned. 3.7Kw/5HP (8kW/10HP peak) by using the FastGrind to provide

offers sufficient power for inhouse resharpening capability.

ANCAs latest entry-level machine

uses the same machine elements FastGrind at a glance (See Page 20 for technical specifications)

as the RX7 with the only

significant differences being the Resharpening machine with some

reduced spindle power and the manufacturing capabilities

visual appearance.

Unbeatable price/performance ratio

The FastGrind includes all ANCA ANCAs proven accuracy and reliability

innovations such as direct drive

technology, polymer concrete The very latest in CNC grinding technology

base, MPG feed and Cim3D. Most Double ended HSK wheel spindle

importantly, ANCAs ToolRoom Polymer ANCAcrete base

suite allows you an unlimited

access to the full range of tool MPG feed

and cutter grinding software. Direct-drive technology

User friendly and industry leading software

thesharpedge issue seven 2010 19

MX7 technical specifications

CNC-Data

ANCA 5DX, Intel Core 2 Duo, min. 1GB RAM, 15 Touch Screen, Ethernet port, 56kbps modem, Two USB ports, UPS

Mechanical axes

X-axis Y-axis Z-axis C-axis A-axis Q-axis

0.0001 mm 0.0001 mm 0.0001 mm

Position feedback resolution 0.0001 deg 0.0001 deg 0.03 deg

0.0000039 0.0000039 0.0000039

0.001 mm 0.001 mm 0.001 mm

MX7

Programming resolution 0.001 deg 0.001 deg 0.3 deg

0.000039 0.000039 0.000039

Software axes (patented): B, V, U, W

The ANCA MX7 machine

is the "next generation" Work piece

in precision CNC grinding. Maximum tool diameter / Maximum tool grind length / Maximum weight: 100 mm (4) / 250 mm (9 3/4") / 20 kg (44 lbs)

With innovative features

Drive system

built in as standard,

ANCA Digital (SERCOS) / Linear axes direct drive ballscrew / Rotary axes direct drive

this machine has the

speed, flexibility and Machine data

performance for any high- Grinding spindle: ANCA Bi-directional 20 kW (S1) 29Nm / 10,000 RPM / Permanent magnet / Position controlled axis (Q-axis) / Integral

production environment. direct drive / HSK 50F Taper

Grinding wheels: Max. diameter 150mm (6) / Wheel bore: 31.75mm (1.250), 32mm, 20mm / Six wheel packs with max. four wheels each.

Other data

Electrical power 25 KVA

Probe system Renishaw

Coolant system External

Machine base ANCACrete (polymer concrete)

Colour RAL 7035 / RAL 5014

Weight Approximately 5,500 kg (12,125 lbs)

Width Depth Height

Floor plan (including loader) 2320 mm 2240 mm 2130 mm

92 88 80

ANCA reserves the right to alter or amend specifications without prior notice

FastGrind technical specifications

CNC-Data

ANCA 5DX, Intel Core 2 Duo, min. 1GB RAM, 15 Screen, One USB port, Network port

Mechanical axes

X-axis Y-axis Z-axis C-axis A-axis

0.0001 mm 0.0001 mm 0.0001 mm

Position feedback resolution 0.0001 deg 0.0001 deg

0.0000039 0.0000039 0.0000039

0.001 mm 0.001 mm 0.001 mm

Programming resolution 0.001 deg 0.001 deg

FastGrind

0.000039 0.000039 0.000039

Software axes (patented): B, V, U, W

The ANCA FastGrind is an

Work piece

affordable entry-level CNC

Maximum tool diameter / Maximum weight: 220 mm (8.6) / 20 kg (44 lbs)

resharpening machine

with some manufacturing Drive system

capacity. ANCA Digital (SERCOS) / Linear axes direct drive ballscrew / Rotary axes direct drive

Machine data

Grinding spindle: ANCA Bi-directional 3.7 kW (S1) / 10,000 RPM / Integral direct drive / HSK40F taper

Grinding wheels: Max. diameter 202mm (8) / Wheel bore: 31.75 mm (1.250), 32 mm, 20 mm / Two wheel packs with max. four wheels each.

Other data

Electrical power 15 KVA (including coolant system)

Probe system Renishaw

Coolant system External

Machine base ANCACrete (polymer concrete)

Colour RAL 7035 / RAL 5014

Weight Approximately 4,500 kg (9,920 lbs)

Width Depth Height

Floor plan (including coolant system) 2075 mm 1450 mm 1990 mm

82 55 78

ANCA reserves the right to alter or amend specifications without prior notice

20 thesharpedge issue seven 2010

ANCA worldwide

Asia Pacific

ANCA Pty Ltd, Melbourne Australia +61 3 9751 8200

ANCA Machine Tool (Shanghai) Co. Ltd Shanghai China +86 21 5868 2940

ANCA Japan Nagoya Japan +81 561 53 8543

ANCA India Bangalore India +91 80 6546 2152

ANCA Thailand Ltd Rayong Thailand +66 3 895 9252

ANCA Motion Taichung Taiwan +886 4 2336 4386

Sahamit Machinery Bangkok Thailand +66 2 295 1000

CKB Hiroshima Japan +81 82 227 3211

Nagoya Japan +81 52 776 4832

Osaka Japan +81 6 6442 3270

Tokyo Japan +81 3 3498 2131

Allied Chase Shanghai China +86 21 6284 2166

Leeport (Holdings) Limited Hong Kong China +852 2427 7991

SH International Seoul South Korea +82 2 3413 2147

Europe

ANCA GmbH Mannheim Germany +49 621 338 100

ANCA Italia Vicenza Italy +39 0444 341 642

ANCA (UK) Ltd Coventry United Kingdom +44 24 7644 7000

Christophe Chaumet ANCA Bourg Saint Christophe France +33 675 186 395

ALBA Precision sro Brno Czech Republic +420 548 214 098

ALBA Precision sro Bansk Bystrica Slovakia +421 48 414 8627

CNC leri Teknoloji ve Tic. Ltd. ti Istanbul Turkey +90 212 786 6200

Aitor Epelde Delteco Eibar Spain +34 943 70 70 07

KR Trading Juelsminde Denmark +45 75 69 01 35

MAVIS VS Impex srl Bucaresti Romania +40 745 385 917

Ravema AB Varnamo Sweden +46 370 488 00

Ravema AS Oslo Norway +47 66 85 90 10

SGM Machine Technology Grimbergen Belgium +32 2 466 34 40

Slawomir Antoszczyk ANCA Welekie Drogi Poland +48 668 150 552

Soumen Hiontakone OY Mikkeli Finland +358 40 5055 159

TECNO team Eisenstadt Austria +43 05 9010 28460

Tek Team Ltd Yehud Israel +972 3 632 3576

Tool Man SARL Veyrier-Geneve Switzerland +41 22 890 0405

ZAO Rosmark Steel St. Petersburg Russia +7 812 336 2727

North America

ANCA Inc. Wixom, MI USA +1 248 926 4466

Beckman Precision Inc. Greer, SC USA +1 864 801 8181

Earth Falcon Lauderdale-by-the-sea, FL USA +1 945 202 9090

Innovative Machine Solutions Inc. Watertown, WI USA +1 414 333 1343

Machine Tool Marketing Inc. Tulsa, OK USA +1 918 369 7065

Machines & Methods Inc. Bellevue, WA USA +1 425 746 1656

Beaverton, OR USA +1 503 617 1992

McDaniel Machinery Inc. Pelham, AL USA +1 205 403 9900

Metalworking Technologies Limited Arlington Heights, IL USA +1 847 818 5800

Modern Tools Inc. Stoneham, MA USA +1 781 438 3211

Productivity Inc. Minneapolis, MN USA +1 763 476 8600

Cedar Rapids, IA USA +1 319 632 4288

Omaha, NE USA +1 402 330 2323

Smith Industrial Machine Sales Rochester, NY USA +1 585 738 8323

Smith Machinery Salt Lake City, UT USA +1 801 263 6403

SMS Machine Tools Rexdale, Ontario Canada +1 416 675 7300

Tornquist Machinery Brea, CA USA +1 714 572 6830

Phoenix, AZ USA +1 602 470 0334

Grinding Solutions S.C. San Pedro Garza /NL Mexico +52 811 776 5851

South America

ANCA do Brasil So Paulo Brasil +55 15 3221 5512

Online

Email us at info@anca.com or visit our website at www.anca.com.

thesharpedge issue seven 2010 21

MX7

The Next

Generation

The next generation in precision grinding

has now arrived with ANCAs new MX7.

With a list of innovative features that are built in

standard for improved performance and production;

this is the one grinding machine that the industry

has long been waiting for.

High torque spindle with

HSK taper.

6 pack wheel-changer

standard.

Integrated loader.

Intelligent design and

engineering.

Industry renowned software.

Speed, flexibility, ANCA reliability

and optimum precision are just

some of the benefits with

the machine that has it all.

Precision

Versatility

www.anca.com Productivity

Confidence

For your nearest ANCA branches, see page 21.

Or email us at info@anca.com

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- SOLIDWORKS Educational Product. For Instructional Use OnlyDocument1 pageSOLIDWORKS Educational Product. For Instructional Use OnlyPaulPas encore d'évaluation

- Aerofly RC 7 Manual English PDFDocument46 pagesAerofly RC 7 Manual English PDFPaulPas encore d'évaluation

- Coffee-Cup 2Document1 pageCoffee-Cup 2PaulPas encore d'évaluation

- Coffee-Cup 1Document1 pageCoffee-Cup 1PaulPas encore d'évaluation

- Manual Ez 220Document60 pagesManual Ez 220Anonymous l33pKnPas encore d'évaluation

- Harp Buying GuideDocument16 pagesHarp Buying GuidePaulPas encore d'évaluation

- Gradual Tap HSSDocument1 pageGradual Tap HSSGinoPas encore d'évaluation

- Topografi E I NGI Nereasca & Scanare 3DDocument16 pagesTopografi E I NGI Nereasca & Scanare 3DPaulPas encore d'évaluation

- Rotoles 400 by Ledinek Deu EngDocument3 pagesRotoles 400 by Ledinek Deu EngPaulPas encore d'évaluation

- DW5000Document2 pagesDW5000PaulPas encore d'évaluation

- Master Volume Master Tone Blender Pot: Modified HSS Stratocaster® Wiring DiagramDocument1 pageMaster Volume Master Tone Blender Pot: Modified HSS Stratocaster® Wiring DiagramPaulPas encore d'évaluation

- The Chord Symbol Guide PDFDocument2 pagesThe Chord Symbol Guide PDFKazunyAnime PianoPas encore d'évaluation

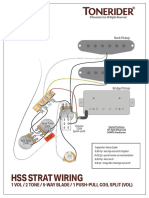

- Hss Strat Wiring: 1 Vol / 2 Tone / 5-Way Blade / 1 Push-Pull Coil Split (Vol)Document1 pageHss Strat Wiring: 1 Vol / 2 Tone / 5-Way Blade / 1 Push-Pull Coil Split (Vol)PaulPas encore d'évaluation

- Diagram of 4 Steps in ISO 9001 Risk ManagementDocument1 pageDiagram of 4 Steps in ISO 9001 Risk ManagementJamPas encore d'évaluation

- Horiba Gloss Checker IG-330 - Instruction ManualDocument10 pagesHoriba Gloss Checker IG-330 - Instruction ManualPaulPas encore d'évaluation

- Windows 10 Shortcut Keys GuideDocument3 pagesWindows 10 Shortcut Keys GuideDan Gusarenco100% (1)

- User GuideDocument166 pagesUser GuidePaulPas encore d'évaluation

- Garmin RunDocument38 pagesGarmin RunPaulPas encore d'évaluation

- String ChartDocument14 pagesString ChartRosalie WilsonPas encore d'évaluation

- 13 Troubleshooting Tools To Fix Windows 10Document8 pages13 Troubleshooting Tools To Fix Windows 10PaulPas encore d'évaluation

- TextDocument1 pageTextPaulPas encore d'évaluation

- Top 5 Jazz Endings Sheet MusicDocument1 pageTop 5 Jazz Endings Sheet MusicorlistPas encore d'évaluation

- 5 Things To Know About Network Monitoring in A Cloud-Centric WorldDocument6 pages5 Things To Know About Network Monitoring in A Cloud-Centric WorldPaulPas encore d'évaluation

- A New Technique For The Rapid Measurement of The Acoustic Impedance of Wind InstrumentsDocument8 pagesA New Technique For The Rapid Measurement of The Acoustic Impedance of Wind InstrumentsPaulPas encore d'évaluation

- WIN10 Commands PDFDocument3 pagesWIN10 Commands PDFemil2809Pas encore d'évaluation

- Scales Chords PianoDocument7 pagesScales Chords PianoCarlos Cruz100% (2)

- Moto TypesDocument1 pageMoto TypesPaulPas encore d'évaluation

- 5611 Exploring Windows 10 WSGDocument18 pages5611 Exploring Windows 10 WSGNicu StanPas encore d'évaluation

- Coffee MotoDocument1 pageCoffee MotoPaulPas encore d'évaluation

- The Risk Management Handbook EhsDocument45 pagesThe Risk Management Handbook EhsPaulPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- ASME B16.34-2013 Valves Standard PDFDocument7 pagesASME B16.34-2013 Valves Standard PDFRanganathan SekarPas encore d'évaluation

- Test 3 ReadingDocument29 pagesTest 3 ReadingThinh LePas encore d'évaluation

- Propeller & Propulsion TerminologyDocument4 pagesPropeller & Propulsion TerminologyjmvPas encore d'évaluation

- Experienced NDT engineer CVDocument6 pagesExperienced NDT engineer CVTrung Tinh HoPas encore d'évaluation

- Marley Geareducer: Model 3600 and 4000Document16 pagesMarley Geareducer: Model 3600 and 4000rashm006ranjanPas encore d'évaluation

- Areca Leaf Plate Making MachineDocument21 pagesAreca Leaf Plate Making MachineKumar DiwakarPas encore d'évaluation

- Material Type: Austenitic Steels (TP304, 310, 316, 321, 347)Document1 pageMaterial Type: Austenitic Steels (TP304, 310, 316, 321, 347)MamacintPas encore d'évaluation

- A1104 - Catania Empire DormDocument1 pageA1104 - Catania Empire Dormjaime roblesPas encore d'évaluation

- LNG Industry May 2013Document92 pagesLNG Industry May 2013Edgar Rojas ZAcarias100% (1)

- Grand Stands RequirementsDocument8 pagesGrand Stands RequirementsJonathan Marvin Bacares DuePas encore d'évaluation

- DNV Offshore Installation OperationsDocument37 pagesDNV Offshore Installation OperationsEyoma EtimPas encore d'évaluation

- JFK Moon SpeechDocument4 pagesJFK Moon SpeechViAnne ReyesPas encore d'évaluation

- Estimation and CostingDocument19 pagesEstimation and CostingAditi ShahPas encore d'évaluation

- Travel Buddy - White - PaperDocument14 pagesTravel Buddy - White - PaperAdam WinterfloodPas encore d'évaluation

- Abhishek Nagrare - Salesforce Resume-12SepDocument5 pagesAbhishek Nagrare - Salesforce Resume-12SepAdvertisement AccountPas encore d'évaluation

- Solar Electric Propulsion: Technology DevelopmentDocument23 pagesSolar Electric Propulsion: Technology DevelopmentFlorentDarraultPas encore d'évaluation

- High-Productivity Turning CenterDocument4 pagesHigh-Productivity Turning CenterthyskiePas encore d'évaluation

- 2624 Saipem Sem 13 Ing FiDocument116 pages2624 Saipem Sem 13 Ing FiRoxana ComaneanuPas encore d'évaluation

- Ieema Members' DirectoryDocument26 pagesIeema Members' DirectoryTechnetPas encore d'évaluation

- 2013 Collin Technologies Case StudyDocument81 pages2013 Collin Technologies Case StudyChiPas encore d'évaluation

- Design Fatigue AssessmentDocument15 pagesDesign Fatigue AssessmentIdris SiddiquiPas encore d'évaluation

- Marketing Strategies of Tata NanoDocument59 pagesMarketing Strategies of Tata NanoHitesh Jogani75% (8)

- Specification (GTX-35VS Kaveri) : Afterburning TurbofanDocument18 pagesSpecification (GTX-35VS Kaveri) : Afterburning Turbofanandrw1987Pas encore d'évaluation

- Etom Level 2 PDFDocument2 pagesEtom Level 2 PDFNicolePas encore d'évaluation

- Terminal 3 Beijing - Kailiao PDFDocument21 pagesTerminal 3 Beijing - Kailiao PDFTeja BawanaPas encore d'évaluation

- Used Machinery Expo 2011Document8 pagesUsed Machinery Expo 2011Swati SinghPas encore d'évaluation

- Surigao State College of TechnologyDocument106 pagesSurigao State College of Technologyraymond balitePas encore d'évaluation

- Duplex ConstructionDocument12 pagesDuplex ConstructionMadcat87Pas encore d'évaluation

- ROTORCOMP Company ProfileDocument26 pagesROTORCOMP Company ProfileJose Santos0% (1)

- Technical and Professional Courses Scholarship Scheme DetailsDocument8 pagesTechnical and Professional Courses Scholarship Scheme DetailsIkram RanaPas encore d'évaluation