Académique Documents

Professionnel Documents

Culture Documents

Cebex Cable Grout-1

Transféré par

depi_rachmanDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cebex Cable Grout-1

Transféré par

depi_rachmanDroits d'auteur :

Formats disponibles

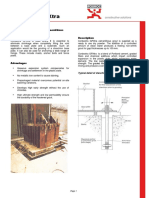

Cebex Cable Grout* constructive solutions

Pre-bagged, non-shrink cementitious grout admixture for

post tensioned cables

Uses Specification

For pumped or free flow grouting, it can be used in a wide Performance specification

range of applications:

All grouting, where shown on the drawing, must be carried

! Post tensioned bridge deck ducts out with a specialised grout admixture which is iron-free

and chloride-free. It shall be mixed with clean water and

! Prestressed structural element cables ducts

cement to the required consistency. The plastic grout must

! Slip form silo tendon ducts not bleed or segregate.

A positive volumetric expansion of up to 4% shall occur.

Advantages

The compressive strength of the grout must exceed 44 N/mm2

! Expansion system compensates for shrinkage and

at 7 days and 60 N/mm2 at 28 days.

settlement in the plastic state

! Develops high early strength without the use of chlorides The storage, handling and placement of the grout must be in

strict accordance with the manufacturer's instructions.

! High ultimate strength and low permeability ensure the

durability of the hardened grout Supplier specification

! Compatible with ordinary Portland Cements complying All grouting where shown on the drawing must be carried out

to BS 12 and ASTM C150 using Cebex Cable Grout manufactured by Fosroc and used

in accordance with the manufacturers current data sheet.

Standards compliance

Cebex Cable Grout complies to BS8110 Part1: 1985 Sec. 8. Properties

The following properties were achieved using OPC cement

Description at a 0.36 w/c ratio.

Cebex Cable Grout is supplied as a dry powder requiring Compressive strength : 24 N/mm2 @ 1 day

only the addition of a controlled amount of clean water and BS 8110 part 1 1985 44 N/mm2 @ 3 days

cement to produce a free flowing non-shrink grout. (flowable consistency) 60 N/mm2 @ 7 days

85 N/mm2 @ 28 days

Cebex Cable Grout is an all fines admixture containing Fresh wet density : Approximately 2000 kg/m3

expansive cement which impart controlled expansion in the depending on actual

plastic state whilst minimising water demand. The material consistency used.

is designed to allow uniform mixing, and eliminates Chloride content : Nil to BS5075

unwanted segregation and bleeding. Expansion : A positive expansion of

characteristics up to 4%

Note : It is recommended that trials be conducted prior

to use, to ascertain the best source of OPC for the

application.

Cebex Cable Grout

Cebex Cable Grout*

Instructions for use Curing

Preparation Any exposed areas should be thoroughly cured. This should

be done by the use of Concure* curing membrane.

Several hours prior to grouting, the area should be flooded

with fresh water. Immediately before grouting takes place any Cleaning

free water should be removed.

Cebex Cable Grout should be removed from tools and

All cable ducts must be thoroughly cleaned. Those ducts equipment with clean water immediately after use. Cured

formed without metal sheaths should be flushed with water material can be removed mechanically, or with Fosroc Acid

after which all surplus water must be removed. Cable Etch*.

anchorages should be sealed before the duct grouting is

Sampling procedure

carried out.

All sampling procedures for Cebex Cable Grout are to be

Mixing and placing - Application

conducted within the confines of a temperature controlled

Mixing laboratory. The reactive agents within Cebex Cable Grout do

not permit site sampling and transport. The procedure for

For best results a mechanically powered grout mixer should

sampling is to be as follows:

be used. When quantities of up to 60 kg are used, a slow

speed drill fitted with a high shear mixer is suitable. Larger 1) A full and unopened bag of Cebex Cable Grout to be

quantities will require a high shear vane mixer. Do not use a selected from the batch allocated for site use and

colloidal impeller mixer, if sands/aggregates are being utilised. despatched to the testing laboratory.

To enable the grouting operation to be carried out continuously, 2) The Cebex Cable Grout shall be mixed in the laboratory

it is essential that sufficient mixing capacity and labour are following the instructions listed on the product data sheet.

available. The use of a grout holding tank with provision to

3) All sampling shall be conducted using 50 mm cube

gently agitate the grout may be required.

moulds, any other size is not permissible.

32 to 42 litres of clean water (depending on nature of cement)

4) When mixed, the Cebex Cable Grout shall be poured into

and 100 kg of cement are required to be added per 6 kg bag to

50 mm cube moulds, treated with release agent, in two

achieve the correct consistency.

lifts of 25 mm each with a 60 second interval between

The water should be accurately measured into the mixer. The pours. The Cebex Cable Grout shall not be tamped, but

total contents of the Cebex Cable Grout bag should be slowly gentle tapping of the cube mould is permitted to promote

added with the cement and continuous mixing should take the release of air.

place for 5 minutes. This will ensure that the grout has a

5) Fill three 50 mm cube moulds with the Cebex Cable Grout

smooth even consistency.

for each curing time interval specified. Mould filling should

Placing be completed within 15 minutes of the end of the mixing

cycle. The filled moulds should be stacked three high on

Place the grout within 20 minutes of mixing.

top of each other to provide conditions of restraint. The top

Cebex Cable Grout can be placed in annular gaps of up to mould should be restrained either with a weighted metal

60mm in thickness. plate or an empty cube mould.

Pumping should be from a single point to eliminate any air or 6) The cubes should be stored at a 20C+ 2C temperature

entrapment of water used for presoaking. for 24 hours in the laboratory. After 24 hours the cubes are

to be demoulded and placed in a water curing tank

A heavy duty diaphragm pump is recommended for pumping.

maintained at a 20C+ 2C temperature. The cubes are

Screw feed and piston pumps may also be suitable.

then to be cured in accordance with BS1881.

7) Cubes are to be crushed in calibrated compression testing

apparatus with a rate of loading not exceeding 180KN per

minute. Types of cube fracture are to be recorded. Three

cubes are to be crushed for each curing time interval

specified. Results are to be calculated and issued as an

average.

Cebex Cable Grout - Page 2 of 4

Cebex cable Grout*

Limitations Estimating

Low temperature working Supply

Cebex Cable Grout : 6 kg bags

For ambient temperatures below 10C the formwork should

be kept in place for at least 36 hours. Yield

When the air or contact surface temperatures are 5C or below Cebex Cable Grout : approx. 68 litres when mixed

on a falling thermometer, warm water (30-40C) is with 100 kg cement and 34

recommended to accelerate strength development. litres of water

Normal precautions for winter working with cementitious Note: Allowance should be made for wastage when

materials should then be adopted. estimating quantities required.

High temperature working Storage

It is suggested that, for temperatures above 35C, the following Cebex Cable Grout has a shelf life of 12 months if kept in a dry

guidelines are adopted as good working practice: store in sealed bags. If stored in high temperature and high

(i) Store unmixed material in a cool (preferably temperature humidity locations the shelf life will be reduced.

controlled) environment, avoiding exposure to direct

sunlight. Precautions

(ii) Keep equipment cool, arranging shade protection if Health and safety

necessary. It is especially important to keep cool those Cebex Cable Grout is alkaline and should not come into contact

surfaces of the equipment which will come into direct with skin and eyes. Avoid inhalation of dust during mixing.

contact with the material itself. Gloves, goggles and dust mask should be worn. If contact

(iii) Try to eliminate application during the hottest times of the with skin occurs, wash with water. Splashes to eyes should

day. be washed immediately with plenty of clean water and medical

advice sought.

(iv) Make sufficient material, plant and labour available to

ensure that application is a continuous process. Fire

(v) Water (below 20C) should be used for mixing the grout Cebex Cable Grout is non-flammable.

prior to placement.

Technical support

Fosroc offers a comprehensive technical support service to

specifiers, end users and contractors. It is also able to offer

on-site technical assistance, an AutoCAD facility and dedicated

specification assistance in locations all over the world.

Cebex Cable Grout - Page 3 of 4

Cebex Cable Grout*

Additional Information

Fosroc manufactures a wide range of complementary

products which include :

! waterproofing membranes & waterstops

! joint sealants & filler boards

! cementitious & epoxy grouts

! specialised flooring materials

Fosroc additionally offers a comprehensive package of

products specifically designed for the repair and

refurbishment of damaged concrete. Fosrocs Systematic

Approach to concrete repair features the following :

! hand-placed repair mortars

! spray grade repair mortars

! fluid micro-concretes

! chemically resistant epoxy mortars

! anti-carbonation/anti-chloride protective coatings

! chemical and abrasion resistant coatings

For further information on any of the above, please consult

your local Fosroc office - as below.

* Denotes the trademark of Fosroc International Limited

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard

Conditions for the Supply of Goods and Service

Head Office

Al Gurg Fosroc telephone: (+9714) 2858606 fax: (+9714) 2859649 email: agf@fosroc.com

LLC Regional offices

Dubai, Al Gurg Fosroc telephone: 285 8787 fax: 285 2023 email: dubai@fosroc.com

Post Box 657, Dubai Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

United Arab Emirates Bahrain, YBA Kanoo telephone: 17735454 fax: 17732828 email: bahrain@fosroc.com

Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

www.fosroc.com

Oman, Al Amana telephone: 771 5080 fax: 771 7554 email: oman@fosroc.com

Qatar, Tadmur telephone: 413628 fax: 440812 email: qatar@fosroc.com

UAE/0357/03/E

Vous aimerez peut-être aussi

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Cebex Cable GroutDocument4 pagesCebex Cable GroutMohamed SalamaPas encore d'évaluation

- Cebex Cable Grout PlusDocument13 pagesCebex Cable Grout PlustalatzahoorPas encore d'évaluation

- Fosroc Cebex Cable Grout Plus: Constructive SolutionsDocument4 pagesFosroc Cebex Cable Grout Plus: Constructive SolutionsVincent JavatePas encore d'évaluation

- Fosroc Cebex Cable Grout: Constructive SolutionsDocument4 pagesFosroc Cebex Cable Grout: Constructive SolutionsVan Chuong VoPas encore d'évaluation

- Fosroc Cebex Cable Grout: Pre-Bagged, Non-Shrink Cementitious Grout Admixture For Post Tensioned CablesDocument3 pagesFosroc Cebex Cable Grout: Pre-Bagged, Non-Shrink Cementitious Grout Admixture For Post Tensioned CablesKRISHNA PRASATH SPas encore d'évaluation

- Conbextra Cable GroutDocument4 pagesConbextra Cable Groutm.elsanee.cubicPas encore d'évaluation

- Conbextra PDocument4 pagesConbextra Pm.elsanee.cubicPas encore d'évaluation

- Cebex Cable Grout - FosrocDocument4 pagesCebex Cable Grout - FosrocIrshadYasinPas encore d'évaluation

- Fosroc Conbextra P: Constructive SolutionsDocument4 pagesFosroc Conbextra P: Constructive SolutionsVincent JavatePas encore d'évaluation

- Concrete Repair MaterialDocument4 pagesConcrete Repair MaterialJeikor J128Pas encore d'évaluation

- Conbextra STDDocument2 pagesConbextra STDPritha DasPas encore d'évaluation

- Fosroc Conbextra Cable Grout: Constructive SolutionsDocument4 pagesFosroc Conbextra Cable Grout: Constructive SolutionsVincent JavatePas encore d'évaluation

- Conbextra STDDocument2 pagesConbextra STDm.elsanee.cubicPas encore d'évaluation

- Cebex 200Document2 pagesCebex 200Anonymous XVEucVMsEPas encore d'évaluation

- TDS Cebex 200 India2 PDFDocument2 pagesTDS Cebex 200 India2 PDFKamal KumarPas encore d'évaluation

- HK Conbextra UW PDFDocument4 pagesHK Conbextra UW PDFtin aungtunPas encore d'évaluation

- Conbextra HF - Grout For Tank Gaps PDFDocument4 pagesConbextra HF - Grout For Tank Gaps PDFEngr.Mohammed KhaledPas encore d'évaluation

- Cebex 200Document2 pagesCebex 200reshmitapallaPas encore d'évaluation

- Conbextra HFDocument4 pagesConbextra HFm.elsanee.cubicPas encore d'évaluation

- Conbextra HESEDocument4 pagesConbextra HESEm.elsanee.cubicPas encore d'évaluation

- CONBEXTRA GP - JordanDocument4 pagesCONBEXTRA GP - JordanShabbir HussainPas encore d'évaluation

- Conbextra HFDocument4 pagesConbextra HFThrtThrthPas encore d'évaluation

- X-Mix CableGrout AdditiveDocument2 pagesX-Mix CableGrout AdditiveKRISHNA PRASATH SPas encore d'évaluation

- Conbextra Cable Grout : Constructive SolutionsDocument4 pagesConbextra Cable Grout : Constructive SolutionsAnonymous uNhWGqNzPas encore d'évaluation

- Datasheet File Conbextra - HFDocument4 pagesDatasheet File Conbextra - HFandikaPas encore d'évaluation

- Fosroc Supercast EPTDocument2 pagesFosroc Supercast EPTArun KumarPas encore d'évaluation

- Conbextra EP10TG PDFDocument2 pagesConbextra EP10TG PDFAcho SupraholicPas encore d'évaluation

- Conbextra EP: T T T T T TDocument4 pagesConbextra EP: T T T T T TFeri Oktara IrawanPas encore d'évaluation

- Conbextra EP10Document2 pagesConbextra EP10m.elsanee.cubicPas encore d'évaluation

- Expanse Al 600Document4 pagesExpanse Al 600raza102Pas encore d'évaluation

- Conbextra UWDocument2 pagesConbextra UWm.elsanee.cubicPas encore d'évaluation

- Fosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutDocument2 pagesFosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutVincent JavatePas encore d'évaluation

- Conbextra EP40 UAEDocument2 pagesConbextra EP40 UAEjasonPas encore d'évaluation

- Fosroc Conbextra UW: Constructive SolutionsDocument2 pagesFosroc Conbextra UW: Constructive SolutionsVincent JavatePas encore d'évaluation

- Conbextra Ep40Document3 pagesConbextra Ep40talatzahoorPas encore d'évaluation

- (PDS) Conbextra GPDocument4 pages(PDS) Conbextra GPSheena GardnerPas encore d'évaluation

- Nitobond EP 0608Document2 pagesNitobond EP 0608James PittsPas encore d'évaluation

- Fosroc Conbextra BB80: Constructive SolutionsDocument4 pagesFosroc Conbextra BB80: Constructive SolutionsVincent JavatePas encore d'évaluation

- TDS - Conbextra BB72 IN - IndiaDocument2 pagesTDS - Conbextra BB72 IN - IndiaVikas Singh ChandelPas encore d'évaluation

- Conbextra UW: Constructive SolutionsDocument4 pagesConbextra UW: Constructive SolutionstalatzahoorPas encore d'évaluation

- Conbextra GP PDFDocument4 pagesConbextra GP PDFPrabowo SandiPas encore d'évaluation

- CEBEX300Document2 pagesCEBEX300talatzahoorPas encore d'évaluation

- Expangrout GP: General Purpose Non-Shrink Cementitious Grout UsesDocument4 pagesExpangrout GP: General Purpose Non-Shrink Cementitious Grout UsesZaid AhmedPas encore d'évaluation

- 10 Conbextra EP10Document2 pages10 Conbextra EP10ahmad wildaanPas encore d'évaluation

- Conbextra EP10 : High Strength, Epoxy Resin GroutDocument1 pageConbextra EP10 : High Strength, Epoxy Resin GroutminedataPas encore d'évaluation

- TDS Conbextra GP VNDocument4 pagesTDS Conbextra GP VNShahanis NabilaPas encore d'évaluation

- Conbextra EP10: High Strength, Epoxy Resin GroutDocument3 pagesConbextra EP10: High Strength, Epoxy Resin GroutR.ThangarajPas encore d'évaluation

- Conbextra GPDocument4 pagesConbextra GPm.elsanee.cubicPas encore d'évaluation

- Conbextra GPDocument4 pagesConbextra GPMuhammad ShoaibPas encore d'évaluation

- Conbextra HF: Shrinkage Compensated Cementitious Precision GroutDocument4 pagesConbextra HF: Shrinkage Compensated Cementitious Precision GroutbinodPas encore d'évaluation

- Conbextra BB80Document4 pagesConbextra BB80m.elsanee.cubicPas encore d'évaluation

- Conbextra GPXtraDocument4 pagesConbextra GPXtraJoshua EkoPas encore d'évaluation

- Brochure 28Document2 pagesBrochure 28Jong Dollente Jr.100% (1)

- Fosroc Conbextra EP10: Constructive SolutionsDocument2 pagesFosroc Conbextra EP10: Constructive SolutionsVincent JavatePas encore d'évaluation

- Pile Caping Head Treatment PDFDocument2 pagesPile Caping Head Treatment PDFLimbert Rodriguez Pinto100% (1)

- Conbextra Cable GroutDocument4 pagesConbextra Cable GroutVenkata RaoPas encore d'évaluation

- Sewage Disposal Works: Their Design and ConstructionD'EverandSewage Disposal Works: Their Design and ConstructionPas encore d'évaluation

- Geotextiles and Geomembranes HandbookD'EverandGeotextiles and Geomembranes HandbookT.S. IngoldÉvaluation : 5 sur 5 étoiles5/5 (1)

- Crawler Crane Technical Manual: Add: No. 613, 3 Section of Middle Fu Rong RD Changsha City, Hunan Province, ChinaDocument10 pagesCrawler Crane Technical Manual: Add: No. 613, 3 Section of Middle Fu Rong RD Changsha City, Hunan Province, Chinadepi_rachmanPas encore d'évaluation

- GFRC Admix Mix DesignDocument5 pagesGFRC Admix Mix Designdepi_rachmanPas encore d'évaluation

- (PDS) Lokfix EpDocument2 pages(PDS) Lokfix Epdepi_rachman100% (1)

- LTM1200 en PDFDocument10 pagesLTM1200 en PDFdepi_rachmanPas encore d'évaluation

- SF Marina English Brochure 2015-04-30Document16 pagesSF Marina English Brochure 2015-04-30depi_rachmanPas encore d'évaluation

- Steel Bars: High Yield DeformedDocument1 pageSteel Bars: High Yield Deformeddepi_rachmanPas encore d'évaluation

- Sheet and Plate - Steel DataDocument1 pageSheet and Plate - Steel Datadepi_rachmanPas encore d'évaluation

- Method Statement - Sikagard 670 W MYDocument1 pageMethod Statement - Sikagard 670 W MYdepi_rachman100% (1)

- NeoResin DTM Presentation 9-01Document22 pagesNeoResin DTM Presentation 9-01idreesgisPas encore d'évaluation

- Recommended Practice For Corrosion Management of Pipelines in Oil & Gas Production and TransportationDocument123 pagesRecommended Practice For Corrosion Management of Pipelines in Oil & Gas Production and Transportationsaifoa100% (2)

- Product Term and ConditionsDocument50 pagesProduct Term and Conditionsain2Pas encore d'évaluation

- Sikadur 42 HSDocument2 pagesSikadur 42 HSthe pilotPas encore d'évaluation

- Demolition/Removal Permit Application Form: Planning, Property and Development DepartmentDocument3 pagesDemolition/Removal Permit Application Form: Planning, Property and Development DepartmentAl7amdlellahPas encore d'évaluation

- Proposal Semister ProjectDocument7 pagesProposal Semister ProjectMuket AgmasPas encore d'évaluation

- TFU-Risk Assessment RA-11 - Use of Grooving & Threading MachinesDocument1 pageTFU-Risk Assessment RA-11 - Use of Grooving & Threading Machinesarshin wildanPas encore d'évaluation

- 2nd Term Study Guide 4th Grade Feb 2024 Cambridge ObjectivesDocument8 pages2nd Term Study Guide 4th Grade Feb 2024 Cambridge Objectivessofi.cardenas1968Pas encore d'évaluation

- Research Activity #2Document2 pagesResearch Activity #2Shania GualbertoPas encore d'évaluation

- Laboratory Medicine Internship BookletDocument95 pagesLaboratory Medicine Internship BookletMuhammad Attique100% (1)

- Pamet and PasmethDocument4 pagesPamet and PasmethBash De Guzman50% (2)

- The Lion and The AntDocument4 pagesThe Lion and The AntDebby Jean ChavezPas encore d'évaluation

- Intellectual Disability: Definition, Classification, Causes and CharacteristicsDocument12 pagesIntellectual Disability: Definition, Classification, Causes and CharacteristicsRyan RV ViloriaPas encore d'évaluation

- Shoulder Joint Position Sense Improves With ElevationDocument10 pagesShoulder Joint Position Sense Improves With ElevationpredragbozicPas encore d'évaluation

- BottomDocument4 pagesBottomGregor SamsaPas encore d'évaluation

- NT PotentialMiningDevelopmentsDocument13 pagesNT PotentialMiningDevelopmentsho100hoPas encore d'évaluation

- 2015 4-H Show & Sale CatalogDocument53 pages2015 4-H Show & Sale CatalogFauquier NowPas encore d'évaluation

- Region Iii - Central Luzon Padapada National High SchoolDocument2 pagesRegion Iii - Central Luzon Padapada National High SchoolRotipPas encore d'évaluation

- Lesson Plan in Advanced Chemistry AlcohoDocument17 pagesLesson Plan in Advanced Chemistry AlcohoGlaiza Mapute CaringalPas encore d'évaluation

- Governance StructureDocument1 pageGovernance StructureJoydip MukhopadhyayPas encore d'évaluation

- 2016 Uptown Parksuites D3 PDFDocument54 pages2016 Uptown Parksuites D3 PDFArafat Domado100% (1)

- PL00002949Document5 pagesPL00002949Nino AlicPas encore d'évaluation

- Jurnal Gerd PDFDocument6 pagesJurnal Gerd PDFdilaPas encore d'évaluation

- Cataloge ICARDocument66 pagesCataloge ICARAgoess Oetomo100% (1)

- W4. Grade 10 Health - Q1 - M4 - v2Document22 pagesW4. Grade 10 Health - Q1 - M4 - v2Jesmael PantalunanPas encore d'évaluation

- Iso 15011-2-2009Document26 pagesIso 15011-2-2009marcosPas encore d'évaluation

- Uppercut MagazineDocument12 pagesUppercut MagazineChris Finn100% (1)

- Ancamine Teta UsDocument2 pagesAncamine Teta UssimphiwePas encore d'évaluation

- Chemical Analysis and Mechancial Test Certificate: Yield Strength Tensile Strength ElongationDocument1 pageChemical Analysis and Mechancial Test Certificate: Yield Strength Tensile Strength ElongationDigna Bettin CuelloPas encore d'évaluation

- 5070 s14 QP 11Document16 pages5070 s14 QP 11OsamaRahimPas encore d'évaluation