Académique Documents

Professionnel Documents

Culture Documents

DS PM0212 en Co 3730 (Datasheet)

Transféré par

Anonymous FZs3yBHh7Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DS PM0212 en Co 3730 (Datasheet)

Transféré par

Anonymous FZs3yBHh7Droits d'auteur :

Formats disponibles

Mechanical

pressure measurement

Bourdon tube pressure gauge

Model 213.53, liquid filling, stainless steel case

WIKA data sheet PM 02.12

for further approvals

see page 2

Applications

For measuring points with high dynamic pressure loads or

vibrations

For gaseous and liquid media that are not highly viscous

or crystallising and will not attack copper alloy parts

Hydraulics

Compressors, shipbuilding

Special features

Vibration and shock resistant

Especially sturdy design

NS 63 and 100 with German Lloyd and Gosstandart

approval

Scale ranges up to 0 ... 1,000 bar Bourdon tube pressure gauge, model 213.53.100,

lower mount

Description Pressure limitation

NS 50, 63: Steady: 3/4 x full scale value

Design Fluctuating: 2/3 x full scale value

EN 837-1 Short time: Full scale value

NS 100: Steady: Full scale value

Nominal size in mm Fluctuating: 0.9 x full scale value

50, 63, 100 Short time: 1.3 x full scale value

Accuracy class Permissible temperature

NS 50, 63: 1.6 Ambient: -20 ... +60 C

NS 100: 1.0 Medium: +60 C maximum

Scale ranges Temperature effect

NS 50: 0 ... 1 to 0 ... 400 bar When the temperature of the measuring system deviates

NS 63, 100: 0 ... 0.6 to 0 ... 1,000 bar from the reference temperature (+20 C):

or all other equivalent vacuum or combined pressure and Max. 0.4 %/10 K of the span

vacuum ranges

Ingress protection

IP 65 per EN 60529 / lEC 60529

WIKA data sheet PM 02.12 03/2015 Page 1 of 3

Data sheets showing similar products:

Standard version with liquid filling; model 113.53; see data sheet PM 01.08

Standard version Options

Process connection Other process connection

Copper alloy, Sealings (model 910.17, see data sheet AC 09.08)

lower mount (LM) or back mount (BM), Measuring system and movement from stainless steel

NS 50, 63: G B (male), 14 mm flats (model 233.53)

NS 100: G B (male), 22 mm flats NS 100: Zero adjustment (in front)

Increased medium temperature with special soft solder

Pressure element - NS 50, 63: 100 C

NS 50: - NS 100: 150 C

Copper alloy, C-type or helical type Ambient temperature resistant -40 ... +60 C with silicone

oil filling

NS 63: NS 50: Higher scale ranges up to 0 ... 1,000 bar

400 bar: Copper alloy, C-type or helical type Panel mounting flange, stainless steel, for back connection

> 400 bar: Stainless steel 316L, helical type Surface mounting flange, stainless steel (not NS 50)

Mounting clamp (for back connection)

NS 100:

< 100 bar: Copper alloy, C-type

100 bar: Stainless steel 316L, helical type

Movement

Copper alloy CE conformity

Dial

Pressure equipment directive

NS 50, 63: Plastic ABS, white, with pointer stop pin

97/23/EC, PS > 200 bar, module A, pressure accessory

NS 100: Aluminium, white, black lettering

Pointer

NS 50, 63: Plastic, black

Approvals

NS 100: Aluminium, black

GL, ships, shipbuilding (e.g. offshore), Germany

EAC, import certificate, customs union Russia/Belarus/

Window

Plastic, crystal-clear Kazakhstan

GOST, metrology/measurement technology, Russia

KBA, automotive, European Community

Case

CRN, safety (e.g. electr. safety, overpressure, ...), Canada

Natural finish stainless steel, with blow-out device with

NS50: in case back, 12 oclock

NS 63, 100: at case circumference, 12 oclock Certificates 1)

O-ring seal between case and connection.

Scale ranges 0 ... 16 bar with compensating valve to vent 2.2 test report per EN 10204 (e.g. state-of-the-art

case. manufacturing, material proof, indication accuracy)

3.1 inspection certificate per EN 10204 (e.g. indication

Bezel ring accuracy)

Crimp ring, glossy finish stainless steel, triangular bezel

Filling liquid 1) Option

Glycerine

Approvals and certificates, see website

Page 2 of 3 WIKA data sheet PM 02.12 03/2015

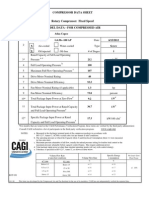

Dimensions in mm

Standard version

Lower mount (LM)

1224557.01

NS 50, 63, centre back mount (CBM) NS 100, lower back mount (LBM)

31059155.01

11081163.01

NS Dimensions in mm Weight in kg

a b 0.5 b2 0.5 D1 D2 e f G h 1 SW

50 12 30 55 55 50 5.5 - GB 48 14 0.15

63 13 32 56 68 62 6.5 - GB 54 14 0.21

100 15.5 48 81.5 107 100 8 30 GB 87 22 0.80

Process connection per EN 837-1 / 7.3

Ordering information

Model / Nominal size / Scale range / Connection size / Connection location / Options

2008 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

WIKA data sheet PM 02.12 03/2015 Page 3 of 3

03/2015 EN

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Strae 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

Vous aimerez peut-être aussi

- Operation & Maintenance Best Practice O&MBestPracticesDocument169 pagesOperation & Maintenance Best Practice O&MBestPracticesevrimkPas encore d'évaluation

- Process Design of Compressed Air Systems (Project Standards and Specifications)Document19 pagesProcess Design of Compressed Air Systems (Project Standards and Specifications)Anonymous FZs3yBHh7Pas encore d'évaluation

- Cleanroom Heavy Duty Solid Top WorkstationsDocument1 pageCleanroom Heavy Duty Solid Top WorkstationsAnonymous FZs3yBHh7Pas encore d'évaluation

- Lean Maintenance Pfizer Case StudyDocument6 pagesLean Maintenance Pfizer Case StudydenerspPas encore d'évaluation

- PROJECT STANDARDS AND SPECIFICATIONS Compressed Air Systems Rev01 PDFDocument19 pagesPROJECT STANDARDS AND SPECIFICATIONS Compressed Air Systems Rev01 PDFacas35Pas encore d'évaluation

- Balston Sterile Air Filters For The Food IndustryDocument1 pageBalston Sterile Air Filters For The Food IndustryAnonymous FZs3yBHh7Pas encore d'évaluation

- Mediseal Deep Draw Blister Machines Overview 2015 05 ENGDocument9 pagesMediseal Deep Draw Blister Machines Overview 2015 05 ENGAnonymous FZs3yBHh7Pas encore d'évaluation

- Kartonierer P1600-P3200 ENGDocument6 pagesKartonierer P1600-P3200 ENGAnonymous FZs3yBHh7Pas encore d'évaluation

- Pt-By FacomDocument1 pagePt-By FacomAnonymous FZs3yBHh7Pas encore d'évaluation

- Article 1491629756Document10 pagesArticle 1491629756Anonymous FZs3yBHh7Pas encore d'évaluation

- AutoSave - Storage Waste and Recycling 6Document1 pageAutoSave - Storage Waste and Recycling 6Anonymous FZs3yBHh7Pas encore d'évaluation

- Yaskawa FlyerDocument10 pagesYaskawa FlyerAnonymous FZs3yBHh7Pas encore d'évaluation

- Product Range Overview - ChargePoint Technology, 2013Document18 pagesProduct Range Overview - ChargePoint Technology, 2013Anonymous FZs3yBHh7Pas encore d'évaluation

- Europass Curriculum Vitae: Personal InformationDocument5 pagesEuropass Curriculum Vitae: Personal InformationAnonymous FZs3yBHh7Pas encore d'évaluation

- WC500232814 Pag1Document1 pageWC500232814 Pag1Anonymous FZs3yBHh7Pas encore d'évaluation

- Cahier Technique: LV Protection Devices and Variable Speed Drives (Frequency Converters)Document1 pageCahier Technique: LV Protection Devices and Variable Speed Drives (Frequency Converters)Anonymous FZs3yBHh7Pas encore d'évaluation

- Earthing 173Document24 pagesEarthing 173nicus81Pas encore d'évaluation

- Rotary compressor data sheetDocument1 pageRotary compressor data sheetEnd SoonPas encore d'évaluation

- 2016 Werum B PDFDocument12 pages2016 Werum B PDFAnonymous FZs3yBHh7Pas encore d'évaluation

- Understanding Grounding in NEC and IEC StandardsDocument48 pagesUnderstanding Grounding in NEC and IEC StandardsAnonymous FZs3yBHh7100% (1)

- Current Issues in Aseptic ProcessingDocument45 pagesCurrent Issues in Aseptic ProcessingcesarhdezPas encore d'évaluation

- Oe ReportDocument32 pagesOe ReportAnonymous FZs3yBHh7Pas encore d'évaluation

- System Earthings W ResumeDocument2 pagesSystem Earthings W ResumeAnonymous FZs3yBHh7Pas encore d'évaluation

- Nitrogen Sparging and BlanketingDocument3 pagesNitrogen Sparging and BlanketingAnonymous FZs3yBHh7Pas encore d'évaluation

- Product Range Overview - ChargePoint Technology, 2013Document18 pagesProduct Range Overview - ChargePoint Technology, 2013Anonymous FZs3yBHh7Pas encore d'évaluation

- LucentDocument2 pagesLucentAnonymous FZs3yBHh7Pas encore d'évaluation

- Cleanroom ESD Flooring InstallationDocument4 pagesCleanroom ESD Flooring InstallationAnonymous FZs3yBHh7Pas encore d'évaluation

- Frequently Asked Questions ESDDocument8 pagesFrequently Asked Questions ESDAnonymous FZs3yBHh7Pas encore d'évaluation

- Comparison Chart ESD Flooring Footwear Static Sensitive ApplicationDocument11 pagesComparison Chart ESD Flooring Footwear Static Sensitive ApplicationAnonymous FZs3yBHh7100% (1)

- Esd NotionsDocument1 pageEsd NotionsAnonymous FZs3yBHh7Pas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Crochet Captain America PDF Amigurum PatternDocument9 pagesCrochet Captain America PDF Amigurum PatternDayana AraujoPas encore d'évaluation

- Reaction Notes-ChemistryDocument19 pagesReaction Notes-ChemistrySirupyEwe GamerPas encore d'évaluation

- Course Syllabus - Chemistry For EngineersDocument10 pagesCourse Syllabus - Chemistry For EngineersNEALE OLIVER BONBONPas encore d'évaluation

- A Study of Acrylic Dispersions Used in The Treatment of PaintingsDocument12 pagesA Study of Acrylic Dispersions Used in The Treatment of PaintingsMilica Stojanov100% (1)

- SUPA75Document1 pageSUPA75Roxxana Roxxana1990Pas encore d'évaluation

- Hydraulic Seal PDFDocument88 pagesHydraulic Seal PDFharoldPas encore d'évaluation

- IntoScience VOL1 Chem To Print 2Document156 pagesIntoScience VOL1 Chem To Print 2Angela Kocevska100% (1)

- Fisa TehnicaDocument2 pagesFisa TehnicaAlexandru GamanPas encore d'évaluation

- WMM Moisture Correction SheetDocument34 pagesWMM Moisture Correction SheetQuality JamPas encore d'évaluation

- ColaLube 3404Document2 pagesColaLube 3404mndmattPas encore d'évaluation

- Chemistry in Action Note PackageDocument21 pagesChemistry in Action Note Packageapi-235471411Pas encore d'évaluation

- Fr4tg135 UkDocument1 pageFr4tg135 UkAnonymous zBSE9MPas encore d'évaluation

- Monitor Corrosion RatesDocument3 pagesMonitor Corrosion RatesbtjajadiPas encore d'évaluation

- Instructions To Surveyors: Domestic Commercial VesselDocument7 pagesInstructions To Surveyors: Domestic Commercial VesselAnonymous wnCaPNIspPas encore d'évaluation

- Woodturning Issue 312 December 2017Document108 pagesWoodturning Issue 312 December 2017Anonymous PcUOts100% (3)

- Ctdcha 2Document10 pagesCtdcha 2TKPas encore d'évaluation

- Door Glass Installation GuideDocument16 pagesDoor Glass Installation GuideFrancisco HernandezPas encore d'évaluation

- Berat BajaDocument25 pagesBerat BajaAchmad Zaki ZulkarnainPas encore d'évaluation

- مهم٢Document127 pagesمهم٢سجى وليدPas encore d'évaluation

- Anleitung Lesezeichen Utl KWenDocument2 pagesAnleitung Lesezeichen Utl KWenfaomosgirlPas encore d'évaluation

- 3733 ABC of Mineral FertilizersDocument16 pages3733 ABC of Mineral FertilizersmPas encore d'évaluation

- Mathcad - Pile Cap Design2 PDFDocument17 pagesMathcad - Pile Cap Design2 PDFVictorAndresCamposCamposPas encore d'évaluation

- Class 10 Science Notes Chapter 3 Studyguide360Document14 pagesClass 10 Science Notes Chapter 3 Studyguide360Rohan RalliPas encore d'évaluation

- Sugerido Exhibicion Century SCZDocument98 pagesSugerido Exhibicion Century SCZYanel Cuellar FloresPas encore d'évaluation

- Astm A519Document14 pagesAstm A519PrakashPas encore d'évaluation

- Tremie ConcreteDocument3 pagesTremie ConcreteChae Tyng FengPas encore d'évaluation

- Annotated Drawings of Britten Pears ArchiveDocument5 pagesAnnotated Drawings of Britten Pears ArchiveDavid CaetanoPas encore d'évaluation

- Title: Project Report On Polyester Webbing: Subject: Project Management in EngineeringDocument6 pagesTitle: Project Report On Polyester Webbing: Subject: Project Management in EngineeringShahbaz ahmad100% (1)

- CrochetDocument31 pagesCrochetMonstrare Vee75% (4)

- Blue LineDocument2 pagesBlue LineRohan KulkarniPas encore d'évaluation