Académique Documents

Professionnel Documents

Culture Documents

31 40 DM45spurhd Rev001

Transféré par

whmidi7331Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

31 40 DM45spurhd Rev001

Transféré par

whmidi7331Droits d'auteur :

Formats disponibles

Atlas Copco Drilling Solutions DM30/45/L/ T4 Spur Rotary Head

STEP 68

68. Install the motor adapter and attach to the housing with socket screw (item 41,

95055216). Care should be taken not to damage the oring. Repeat this step for the 2nd

motor adapter.

STEP 69

69. Lightly coat with grease the oring groove and machined surface of the motor adapter

(item 26, 57368052), then insert oring (item 12, 95086724). Repeat this step for the

2nd motor adapter.

STEP 70

70. Heat wear sleeve (item 36, 50822097) on the induction heater or oil bath to 100F.

Assembly/Rebuild Page 31 57788853

Atlas Copco Drilling Solutions DM30/45/L/ T4 Spur Rotary Head

STEP 71

71. With insulated gloves (57788093), insert the wear sleeve with the bevel edge pointing

down, using wear sleeve tool (57512410). Carefully drive the wear sleeve down

evenly until it contacts the shoulder on the spindle just above the keyway.

STEP 72

72. Place the cup of the upper spindle bearing (item 33, 95434569) into the cover. Use a

small steel hammer and bronze bar (57788713) to evenly and fully seat the cup. Take

care not to strike the bearing surface.

STEP 73

73. Heat the upper spindle bearing cone (item 33) to 300F using the induction heater or

hot oil bath.

Assembly/Rebuild Page 32 57788853

Atlas Copco Drilling Solutions DM30/45/L/ T4 Spur Rotary Head

STEP 74

74. With insulated gloves, lower the bearing onto the spindle tapered end down. Tap the

inner race of the bearing with a hammer and bar (57788713) to seat it properly.

Proceed to the next step while the bearing is still warm.

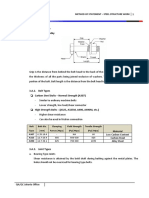

SETTING SPINDLE BEARING PRELOAD - ROLLING TORQUE

Note: Setting proper preload for the spindle bearings is the most important process within

the assembly. Special tools required are listed in the following assembly steps.

STEP 75

75. Lightly coat with grease (item 119) the exposed spindle threads. Verify the spindle

(item 1) is supported so that the cup and cone of the spindle lower bearing are pressed

tightly together. Install the bearing adjusting nut (item 24, 57291304) and tighten

against the upper bearing cone, inner race.

Assembly/Rebuild Page 33 57788853

Atlas Copco Drilling Solutions DM30/45/L/ T4 Spur Rotary Head

STEP 76

76. With the input pinion tool (57791766) attached and the ratchet (57791717) located in

the motor adapter spline, two angles (57788788), located 180 degrees apart and

connected to the rotary housing, 2 screws (95934659) and flat washers (95972238),

and adjustment locking ring tool (57788796) are required for the setting from the kit.

STEP 77

77. Install the adjustment locking ring (57512436) in the grooves on the adjusting locking

nut (item 24, 57291304) as shown. The wings on item 24 will contact the surfaces of

the angles (57788788) to prevent spindle rotation, therefore increasing preload on the

spindle bearing when the input pinion tool is rotated. Tighten the 2 screws and

lockwashers to hold the angles after alignment to the wings as shown. Tighten the

locknut (item 24) by turning (counter-clockwise) the gear train through the input

shaft. Use input pinion tool (57791766) to turn the input pinion shaft. The 15:1 gear

reduction makes tightening the locking nut easier. Strike the inner race of the upper

bearing with a steel hammer and bronze drift a couple of times 180 degrees opposing

points. The rolling torque will drop-off by less resistance through the input pinion

tool.

Assembly/Rebuild Page 34 57788853

Atlas Copco Drilling Solutions DM30/45/L/ T4 Spur Rotary Head

STEP 78

78. Lower the jack (57791865) supporting under the spindle. Repeat tightening the lock

nut, turning the input pinion tool. Repeat striking the inner race process.

STEP 79

79. Periodically remove the adjustment locking ring tool (57788796) and measure the

rolling torque through the spindle. Use the spindle rotation tool (57788804) and dial

type torque wrench (57788812) to measure the preload. Continue tightening through

the input shaft until torque required to turn the spindle reaches 100-150 ft-lbs.

Measure rolling torque through the spindle not through the input shaft.

As the rolling torque measured approaches the required setting, strike the inner

race of the upper bearing with a hammer and bronze drift a couple of times 180

degrees opposing points. Repeat these steps until the torque value remains constant

at 120-130 ft-lb after striking the race.

Assembly/Rebuild Page 35 57788853

Atlas Copco Drilling Solutions DM30/45/L/ T4 Spur Rotary Head

STEP 80

80. After properly setting rolling torque, install the tongued lock washer (item 31,

57291288). Additional tightening through the input shaft maybe required for

alignment of holes in items 24 and 31.Insert the tongue into the keyway of the

spindle.

STEP 81

81. Lightly coat with loctite (56784267) onto 6 screws (item 25, 95270815) to secure the

tongued washer to the preload lock nut. If the bolt holes do not line up, tighten the

preload slightly until the holes align.

Note: Sufficient preload is critical. Insufficient preload will allow the upper spindle-

bearing race to slip under the lock nut during drilling and breakout operations.

This slipping of the race will quickly wear away the bottom of the locknut. Any

existing preload will be lost resulting in endplay. Endplay in the spindle assembly

is harmful to bearings and other components. Life expectancy of the rotary head

will be shortened.

Historical root causes: Repeated problems with the swivel packing assembly i.e. water

leaks, missing packing rings, etc may be an indication of loss of preload of the main

bearing / spindle assembly.

Assembly/Rebuild Page 36 57788853

Atlas Copco Drilling Solutions DM30/45/L/ T4 Spur Rotary Head

STEP 82

82. Lightly coat the spindle threads with grease (item 119), install oil seal (item 35,

52164282) into the upper seal housing (item 32, 52248150), to hold dirt out and tap

the seal to secure flush to top surface of the housing. Refer to oil seal design and

selection for proper installation and function.

STEP 83

83. Install and tighten lube fitting (item 69, 95201547), insert silicone (item 120,

50700731) around the housing machined surface, then insert the upper seal housing

(item 32, 52248150) over the spindle and align the holes. Care should be taken not to

damage or deform the seal during installation. Insert 2 screws (item 51, 95104204),

180 degrees apart to secure the seal housing for the following steps.

STEP 84

84. Inspect the thread in spindle cap (item 39, 57347379) to remove any dirt, rust or

damage threads, prior to inserting ring thread (item 42, 50610971) and lightly coat

with grease.

Assembly/Rebuild Page 37 57788853

Atlas Copco Drilling Solutions DM30/45/L/ T4 Spur Rotary Head

STEP 85

85. Insert slinger (item 38, 52187804) over the spindle and onto the top surface of the

seal housing. Use flat head screwdriver, if required for installation.

STEP 86

86. Place o-ring (item 154, 95086625) into spindle groove, prior to connecting spindle

cap (item 39, 57347379).

STEP 87

87. Attach modified input pinion tool (57791766) to the ratchet (57791717) and insert

into the motor adapter input spline. Connect a 48 pipe wrench to the flats on the

spindle cap (item 39, 57347379) and secure against the rotary housings anchor guide.

Tighten item 39 by rotating the ratchet clock wise.

Assembly/Rebuild Page 38 57788853

Atlas Copco Drilling Solutions DM30/45/L/ T4 Spur Rotary Head

STEP 88

88. Insert swivel (item 37, 52248176), align swivel flange hole to upper seal housing,

insert 6 screws and lockwashers (item 51, 95104204; item 6, 95934733), then tighten

with impact wrench.

STEP 89

89. Invert swivel cap (item 50, 57183329), insert one packing (item 43, 50694876) and

lightly lubricate with grease (item 119, 57818221) the packing top surface and the

swivel cap machined surface.

STEP 90

90. Insert the 2nd packing supplied with item 43 inside the spindle cap (item 39) and

lightly lubricate with grease (item 119) the packing surfaces as shown.

Assembly/Rebuild Page 39 57788853

Atlas Copco Drilling Solutions DM30/45/L/ T4 Spur Rotary Head

STEP 91

91. Insert wear bushing (item 43) in the groove of item 39 on top of the 2nd packing.

STEP 92

92. Screw 2 threaded rods (57788820) into swivel (item 37, 52248176) for shim set (item

46, 52210317) and swivel cap (item 50, 57183329) for installation and alignment.

STEP 93

93. Shim to 0.125 (57788838) clearance between machined surfaces of items 37 and 50

for swivel packing proper preload. Insert screws and lockwashers (items 5 and 6,

95934451 and 95934733) and torque to requirement.

Assembly/Rebuild Page 40 57788853

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Shop Manuel WA900-3Document1 589 pagesShop Manuel WA900-3whmidi7331100% (2)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- CAT 345 B AGS 01 Up Hydraulic SchematicDocument7 pagesCAT 345 B AGS 01 Up Hydraulic SchematicGanapati Hegde100% (6)

- Heat King HK-400 and HK-400Ho PDFDocument45 pagesHeat King HK-400 and HK-400Ho PDFBolivarPas encore d'évaluation

- BS 13460 - Maintenance-Documents For Maintenance PDFDocument28 pagesBS 13460 - Maintenance-Documents For Maintenance PDFavmr100% (7)

- BS En-15341 PDFDocument28 pagesBS En-15341 PDFroben1979100% (8)

- The Complete Guide To Simple OEEDocument26 pagesThe Complete Guide To Simple OEEWan Sek Choon100% (2)

- BS en 60300 3 11 2009Document52 pagesBS en 60300 3 11 2009whmidi7331100% (4)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Yamaha XTZ 750 ST Service ManualDocument425 pagesYamaha XTZ 750 ST Service ManualAmigosek80% (5)

- Electrical System D10T2 Track-Type Tractor: Volume 1 - Component LocationDocument6 pagesElectrical System D10T2 Track-Type Tractor: Volume 1 - Component Locationwhmidi7331Pas encore d'évaluation

- B124 PM 1 (250 Hour Interval) - 2019-12-25Document1 pageB124 PM 1 (250 Hour Interval) - 2019-12-25whmidi7331Pas encore d'évaluation

- 416F2 Hyd UENR3748UENR3748-01 SISDocument9 pages416F2 Hyd UENR3748UENR3748-01 SISMaury Barrales100% (1)

- Hydraulic System D10T2 Track-Type Tractor: Machine Component LocationsDocument2 pagesHydraulic System D10T2 Track-Type Tractor: Machine Component Locationswhmidi7331Pas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document14 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768whmidi7331Pas encore d'évaluation

- 789C Off-Highway Truck, Powered by 3516 Engine (SEBP2790-223) - PM 2F METRIC (500 HOUR INTERVAL)Document1 page789C Off-Highway Truck, Powered by 3516 Engine (SEBP2790-223) - PM 2F METRIC (500 HOUR INTERVAL)whmidi7331Pas encore d'évaluation

- 11 - 8 Steps To Success in Maintenance Planning and Scheduling PDFDocument42 pages11 - 8 Steps To Success in Maintenance Planning and Scheduling PDFmsaad19103564100% (2)

- 789C Off-Highway Truck, Powered by 3516 Engine (SEBP2790-223) - PM 1 Metric (250 HOUR Interval)Document1 page789C Off-Highway Truck, Powered by 3516 Engine (SEBP2790-223) - PM 1 Metric (250 HOUR Interval)whmidi7331Pas encore d'évaluation

- 789C Off-Highway Truck, Powered by 3516 Engine (SEBP2790-223) - PM 1F METRIC (250 HOUR INTERVAL)Document1 page789C Off-Highway Truck, Powered by 3516 Engine (SEBP2790-223) - PM 1F METRIC (250 HOUR INTERVAL)whmidi7331Pas encore d'évaluation

- FEN03960-01 Volume2Document808 pagesFEN03960-01 Volume2whmidi7331Pas encore d'évaluation

- Previous Screen Welcome: m400rs: Truck 789D Truck SPD 789D Off-Highway Truck SPD00001-UP (MACHINE) POWERED BY 3516 EngineDocument2 pagesPrevious Screen Welcome: m400rs: Truck 789D Truck SPD 789D Off-Highway Truck SPD00001-UP (MACHINE) POWERED BY 3516 Enginewhmidi7331Pas encore d'évaluation

- Maintenance Key Performance IndicatorsDocument15 pagesMaintenance Key Performance Indicatorswhmidi7331100% (3)

- Modern Approach To Overall Equipment Effectiveness (Oee)Document36 pagesModern Approach To Overall Equipment Effectiveness (Oee)Kailas Sree Chandran100% (1)

- Moradizadeh Hasan 200309484 MASC ISE Fall2014Document129 pagesMoradizadeh Hasan 200309484 MASC ISE Fall2014whmidi7331Pas encore d'évaluation

- Standards Related To Maintenance November 2012Document17 pagesStandards Related To Maintenance November 2012whmidi7331100% (1)

- Overall Equipment EffectivenessDocument27 pagesOverall Equipment EffectivenessMarciano ZanottoPas encore d'évaluation

- ECN0215 Dash CompletedDocument8 pagesECN0215 Dash Completedwhmidi7331Pas encore d'évaluation

- OEEDocument23 pagesOEEkayumanggiPas encore d'évaluation

- Maintenance Reaility CheckDocument3 pagesMaintenance Reaility Checkwhmidi7331100% (1)

- 11 - 8 Steps To Success in Maintenance Planning and Scheduling PDFDocument42 pages11 - 8 Steps To Success in Maintenance Planning and Scheduling PDFmsaad19103564100% (2)

- Sustainability 05 00338 v3Document19 pagesSustainability 05 00338 v3whmidi7331Pas encore d'évaluation

- General Standards in Physical Asset ManagementDocument54 pagesGeneral Standards in Physical Asset ManagementMazin Al-Ghamdi100% (1)

- 4480 B59 Komatsu To ParkerDocument23 pages4480 B59 Komatsu To Parkerwhmidi7331Pas encore d'évaluation

- H D B I, S, M M: Ydraulic ISC Rake Nstallation Ervice Aintenance AnualDocument9 pagesH D B I, S, M M: Ydraulic ISC Rake Nstallation Ervice Aintenance AnualOsscar Charlee PahpahPas encore d'évaluation

- W26 358 9004Document29 pagesW26 358 9004MROstop.comPas encore d'évaluation

- Installation Instructions Overhead Volleyball System by DraperDocument2 pagesInstallation Instructions Overhead Volleyball System by DraperAmr GadPas encore d'évaluation

- Planos Del Manual ZARANDAS (Error Hojas 43 y 14)Document52 pagesPlanos Del Manual ZARANDAS (Error Hojas 43 y 14)Jesùs Amèsquita0% (1)

- Whirlpool 7mwt9601ww0 Manual de UsuarioDocument12 pagesWhirlpool 7mwt9601ww0 Manual de UsuarioMARTIN CABRERAPas encore d'évaluation

- Special Price Bulletin (April - June.18)Document68 pagesSpecial Price Bulletin (April - June.18)Mae D. Turn0% (1)

- Beta Positioners PDFDocument20 pagesBeta Positioners PDFEvandro Amaral RodriguesPas encore d'évaluation

- APV VRA UK tcm11-63414Document22 pagesAPV VRA UK tcm11-63414RicardoPas encore d'évaluation

- Hyundai Accent 2003 Wheel AlignmentDocument4 pagesHyundai Accent 2003 Wheel AlignmentRodrigo SandovalPas encore d'évaluation

- AI. Griptec Assembly InstructionsDocument26 pagesAI. Griptec Assembly InstructionsAditya DubewarPas encore d'évaluation

- Catálogo D257axDocument736 pagesCatálogo D257axKeler AraujoPas encore d'évaluation

- Workshop Manual: Technical DataDocument36 pagesWorkshop Manual: Technical DataNaing Min HtunPas encore d'évaluation

- Assembly - Manual - FELIX - 3 - 0 - Eng - V3 - B PDFDocument45 pagesAssembly - Manual - FELIX - 3 - 0 - Eng - V3 - B PDFAnonymous JDHMOvPas encore d'évaluation

- Bolted Connection: Structural Design - 2 CE 524Document35 pagesBolted Connection: Structural Design - 2 CE 524Kenneth GutierrezPas encore d'évaluation

- Gestra Pa46 Mpa46 Pa47 Mpa47 Installation..Document32 pagesGestra Pa46 Mpa46 Pa47 Mpa47 Installation..cadhoaPas encore d'évaluation

- Volvo Tad1250 Electric ManualDocument235 pagesVolvo Tad1250 Electric ManualMouloud DerrahiPas encore d'évaluation

- Fig.981 Fast Attacj Universal Swivel Sway Brace Attachment - TOLCODocument1 pageFig.981 Fast Attacj Universal Swivel Sway Brace Attachment - TOLCOEdwin G Garcia ChPas encore d'évaluation

- MOS SS-HTB Tightening PartDocument9 pagesMOS SS-HTB Tightening PartjimdabrondPas encore d'évaluation

- Assembly Bolt ListDocument2 pagesAssembly Bolt ListFair MutasaPas encore d'évaluation

- Pressure Part Method StatementDocument49 pagesPressure Part Method StatementSerkan Yaşa67% (3)

- Gantrail Bolted Fixing: Specifications: Bolt Grade 8.8 10.9Document2 pagesGantrail Bolted Fixing: Specifications: Bolt Grade 8.8 10.9Borislav StoychevPas encore d'évaluation

- Barrett 98B Operators ManualDocument36 pagesBarrett 98B Operators ManualThallusrhamesPas encore d'évaluation

- Attachment 3 - Bolt Tensioning Task PlanDocument4 pagesAttachment 3 - Bolt Tensioning Task Planchancele nguepdjopPas encore d'évaluation

- Front Suspension: Group 33Document22 pagesFront Suspension: Group 33Toponari MedvePas encore d'évaluation

- British Standards and Codes of Practice Relating To Steel ConstructionDocument23 pagesBritish Standards and Codes of Practice Relating To Steel ConstructionChris LiuPas encore d'évaluation

- 50215-104 - Quincy 325Document41 pages50215-104 - Quincy 325Jose AntonioPas encore d'évaluation

- BS 03288 2 2009Document98 pagesBS 03288 2 2009André Ferreira100% (1)

- Copia de Copia de AMC 2Document3 pagesCopia de Copia de AMC 2MarioPas encore d'évaluation