Académique Documents

Professionnel Documents

Culture Documents

Industrial Engineering

Transféré par

Jon West0 évaluation0% ont trouvé ce document utile (0 vote)

6 vues2 pagesIndustrial Engineering

Copyright

© © All Rights Reserved

Formats disponibles

TXT, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentIndustrial Engineering

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme TXT, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

6 vues2 pagesIndustrial Engineering

Transféré par

Jon WestIndustrial Engineering

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme TXT, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

Industrial engineering

From Wikipedia, the free encyclopedia

This article includes a list of references, but its sources remain unclear becau

se it has insufficient inline citations. Please help to improve this article by

introducing more precise citations. (January 2017) (Learn how and when to remove

this template message)

Industrial engineering is a branch of engineering which deals with the optimizat

ion of complex processes, systems or organizations. Industrial engineers work to

eliminate waste of time, money, materials, man-hours, machine time, energy and

other resources that do not generate value. According to the Institute of Indust

rial and Systems Engineers, they figure out how to do things better, they engine

er processes and systems that improve quality and productivity.[1]

Industrial engineering is concerned with the development, improvement, and imple

mentation of integrated systems of people, money, knowledge, information, equipm

ent, energy, materials, analysis and synthesis, as well as the mathematical, phy

sical and social sciences together with the principles and methods of engineerin

g design to specify, predict, and evaluate the results to be obtained from such

systems or processes.[2] While industrial engineering is a longstanding engineer

ing discipline subject to (and eligible for) professional engineering licensure

in most jurisdictions, its underlying concepts overlap considerably with certain

business-oriented disciplines such as operations management.

Depending on the sub-specialties involved, industrial engineering may also be kn

own as, or overlap with, operations research, systems engineering, manufacturing

engineering, production engineering, management science, management engineering

, ergonomics or human factors engineering, safety engineering, or others, depend

ing on the viewpoint or motives of the user.

Contents [hide]

1 Overview

2 History

2.1 Origins

2.1.1 Industrial Revolution

2.1.2 Specialization of labor

2.1.3 Interchangeable parts

2.2 Pioneers

2.3 Modern practice

2.4 Compared to other engineering disciplines

3 Education

3.1 Undergraduate curriculum

3.2 Graduate curriculum

4 Salaries and workforce statistics

4.1 United States

4.2 Norway

5 See also

6 Notes

7 Further reading

Overview[edit]

This section does not cite any sources. Please help improve this section by addi

ng citations to reliable sources. Unsourced material may be challenged and remov

ed. (October 2014) (Learn how and when to remove this template message)

While originally applied to manufacturing, the use of "industrial" in "industria

l engineering" can be somewhat misleading, since it has grown to encompass any m

ethodical or quantitative approach to optimizing how a process, system, or organ

ization operates. Some engineering universities and educational agencies around

the world have changed the term "industrial" to broader terms such as "productio

n" or "systems", leading to the typical extensions noted above.

The various topics concerning industrial engineers include:

Process engineering: design, operation, control, and optimization of chemical, p

hysical, and biological processes.

Systems engineering: an interdisciplinary field of engineering that focuses on h

ow to design and manage complex engineering systems over their life cycles.

Safety engineering: an engineering discipline which assures that engineered syst

ems provide acceptable levels of safety.

Data science: the science of exploring, manipulating, analyzing, and visualizing

data to derive useful insights and conclusions

Machine learning: the automation of learning from data using models and algorith

ms

Analytics and data mining: the discovery, interpretation, and extraction of patt

erns and insights from large quantities of data

Cost engineering: practice devoted to the management of project cost, involving

such activities as cost- and control- estimating, which is cost control and cost

forecasting, investment appraisal, and risk analysis.

Value engineering: a systematic method to improve the "value" of goods or produc

ts and services by using an examination of function.

Quality engineering: a way of preventing mistakes or defects in manufactured pro

ducts and avoiding problems when delivering solutions or services to customers.

Project management: is the process and activity of planning, organizing, motivat

ing, and controlling resources, procedures and protocols to achieve specific goa

ls in scientific or daily problems.

Management engineering: a specialized form of management that is concerned with

the application of engineering principles to business practice

Supply chain management: the management of the flow of goods. It includes the mo

vement and storage of raw materials, work-in-process inventory, and finished goo

ds from point of origin to point of consumption.

Ergonomics: the practice of designing products, systems or processes to take pro

per account of the interaction between them and the people that use them.

Operations research, also known as management science: discipline that deals wit

h the application of advanced analytical methods to help make better decisions

Operations management: an area of management concerned with overseeing, designin

g, and controlling the process of production and redesigning business operations

in the production of goods or services.

Job design: the specification of contents, methods and relationship of jobs in o

rder to satisfy technological and organizational requirements as well as the soc

ial and personal requirements of the job holder.

Financial engineering: the application of technical methods, especially from mat

hematical finance and computational finance, in the practice of finance

Industrial plant configuration: sizing of necessary infrastructure used in suppo

rt and maintenance of a given facility.

Facility management: an interdisciplinary field devoted to the coordination of s

pace, infrastructure, people and organization

Engineering design process: formulation of a plan to help an engineer build a pr

oduct with a specified performance goal.

Logistics: the management of the flow of goods between the point of origin and t

he point of consumption in order to meet some requirements, of customers or corp

orations.

Accounting: the measurement, processing and communication of financial informati

on about economic entities

Capital projects: the management of activities in capital projects involves the

flow of resources, or inputs, as they are transformed into outputs.[3][4] Many o

f the tools and principles of industrial engineering can be applied to the confi

guration of work activities within a project. The application of industrial engi

neering and operations management concepts and techniques to the execution of pr

ojects has been thus referred to as Project Production Management.[5]

Traditionally, a major aspect of industrial engineering was planning the layouts

of factories and designing assembly lines and other manufacturing paradigms. An

d now, in lean manufacturing systems, industrial engineers work to eliminate was

tes of time, money, materials, energy, and other resources.

Examples of where industrial engineering might be used include flow process ch

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- App A For PrintingDocument28 pagesApp A For PrintingJon WestPas encore d'évaluation

- Ise690 Catalog TopicsDocument1 pageIse690 Catalog TopicsJon WestPas encore d'évaluation

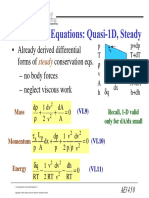

- Already Derived Differential Forms of Conservation Eqs. - No Body Forces - Neglect Viscous WorkDocument3 pagesAlready Derived Differential Forms of Conservation Eqs. - No Body Forces - Neglect Viscous WorkJon WestPas encore d'évaluation

- Solar EngineeringDocument1 pageSolar EngineeringJon WestPas encore d'évaluation

- CocaineDocument3 pagesCocaineJon WestPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- R12 ASCP Training Manual PDFDocument295 pagesR12 ASCP Training Manual PDFFranklin Gomez Romero80% (5)

- Winona Frac Sand Traffic MapDocument1 pageWinona Frac Sand Traffic MapMinnesota Public RadioPas encore d'évaluation

- China Outsourcing Magazine Interview With Mr. Gagan SabharwalDocument7 pagesChina Outsourcing Magazine Interview With Mr. Gagan SabharwalNASSCOMPas encore d'évaluation

- Complete EDM Handbook - 3Document16 pagesComplete EDM Handbook - 3Neil BotesPas encore d'évaluation

- Turning N Milling FormulaDocument2 pagesTurning N Milling FormulaHaris SetiawanPas encore d'évaluation

- Vicat Time of SetDocument16 pagesVicat Time of SetAhmed M AminPas encore d'évaluation

- Logistics Project ReportDocument7 pagesLogistics Project ReportTanmay MiddhaPas encore d'évaluation

- PVC Conduits CatalougeDocument72 pagesPVC Conduits CatalougeS M DineshPas encore d'évaluation

- R.Ramakrishnan.: Ex-Scientist - Merado. Asnt Level IiiDocument21 pagesR.Ramakrishnan.: Ex-Scientist - Merado. Asnt Level IiiMadjid OUCHENE100% (1)

- Me Troll Brochure 2017Document44 pagesMe Troll Brochure 2017KantishPas encore d'évaluation

- FRP Net LiteraturDocument16 pagesFRP Net Literaturvijay10484Pas encore d'évaluation

- Chapter 2-Operations Strategy in A Global Environment Heizer&rDocument10 pagesChapter 2-Operations Strategy in A Global Environment Heizer&rfireflyzzzPas encore d'évaluation

- Imerys Mica in PP 2010Document2 pagesImerys Mica in PP 2010Jedsan LiangphapaipunPas encore d'évaluation

- Inspection of Heat ExchangersDocument20 pagesInspection of Heat Exchangersadel100% (1)

- Container Handbook PDFDocument975 pagesContainer Handbook PDFBaher Saleh0% (1)

- GRE PipeDocument4 pagesGRE PipeMohamed GuezguezPas encore d'évaluation

- Ingersoll Rand07 00Document116 pagesIngersoll Rand07 00texwan_100% (1)

- Draft Daftar Isi SOP Operasional UmumDocument2 pagesDraft Daftar Isi SOP Operasional UmumDoni JVSPas encore d'évaluation

- Tifora PG PDFDocument2 pagesTifora PG PDFOmar Lafuente ZáratePas encore d'évaluation

- ProcurementDocument26 pagesProcurementnkjerseyPas encore d'évaluation

- Electronic Product Development - Manufacturing Cost Estimation PDFDocument21 pagesElectronic Product Development - Manufacturing Cost Estimation PDFDhanus KodiPas encore d'évaluation

- 7-11 Case Solution Section - B - Group 2Document12 pages7-11 Case Solution Section - B - Group 2Prashant ChavanPas encore d'évaluation

- Jaw BrochureDocument12 pagesJaw Brochuremarcosandia1974Pas encore d'évaluation

- Henkel Elastomeric GuideDocument2 pagesHenkel Elastomeric GuideFerdinand A AlbarPas encore d'évaluation

- GICS MethodologyDocument20 pagesGICS MethodologyIvana Yulanda SantosoPas encore d'évaluation

- LABORELEC Conventional Power Plant Materials Course V2 PDFDocument90 pagesLABORELEC Conventional Power Plant Materials Course V2 PDFkatfy1100% (1)

- 8-12-8 Fabrication of Piping PDFDocument7 pages8-12-8 Fabrication of Piping PDFasif rahimPas encore d'évaluation

- Bucket Elevator Project ReportDocument104 pagesBucket Elevator Project ReportTanvi Khurana100% (2)

- Care LabellingDocument26 pagesCare LabellingShashi PrakashPas encore d'évaluation

- Rpt-sales-Fundamentals of Sand ControlDocument8 pagesRpt-sales-Fundamentals of Sand ControlDidier MorenoPas encore d'évaluation