Académique Documents

Professionnel Documents

Culture Documents

Geogird Types and Properties PDF

Transféré par

Santhoshkumar RayavarapuTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Geogird Types and Properties PDF

Transféré par

Santhoshkumar RayavarapuDroits d'auteur :

Formats disponibles

Geogrid Material & Installation Specification for Permanent Steep Slope

and Wall Construction

Installation Procedure

1. Pre-cut the geogrids, shape the steel mesh formworks and prepare both the hooked bars. After the

levelling and compaction of the foundation soil, place and line up the formworks connecting each other

by mean of a steel or plastic wire. Steel mesh shall be minimum 8.00 mm, 200 x 200 mm mesh size.

2. Place the Tenax reinforcement geogrids in horizontal layers perpendicular to the face and along the

internal face of the steel formworks, anchor the grids to the soil by means of U shaped staples and

temporarily leave the last portion of the grids outside the formworks. The last portion of the grid shall

correspond to the total wrapping length (about 1.5 m). Place the hooked bars to fix the formworks.

Place a pre-planted cow grass or the selected species on the internal side of the steel mesh formwork

against the geogrid.

3. Place suitable thickness of soil on the geogrids & compact it until reaching a compaction effort not

lower than 90% of Standard Proctor. Compaction of fill material about 1,00 m close to the face shall be

carried out using light hand-held compactors, like plate vibrating compactors, while the other part of

the reinforced block may be compacted with heavy rollers.

4. Repeat phase 3 to reach the required geogrid spacing. Wrap the final portion of the grids, previously

kept outside the formworks, toward the inner slope & slightly stretch it and anchor it to the soil by

means of U shaped staples .

5. Repeat the phases 1 - 4 until completion of the work.

Material Specification

The reinforcing element shall be a geogrid manufactured from extrusion and longitudinal drawing of high-

density polyethylene polymer of the highest quality, under strict Quality Control procedures.

The geogrid, when unrolled, shall be a plane monolithical structure, with a uniform distribution of long

shaped apertures, which identify longitudinal ribs and transversal bars.

The longitudinal ribs shall have gone through a process of molecular orientation for increasing the

mechanical characteristics and for ensuring a high long-term resistance under sustained loading.

The junctions between the longitudinal ribs and the transversal bars shall be an integral part of the

geogrid structure. The geogrid shall be inert to all chemicals naturally found in soils and shall have no

solvents at ambient temperature. It shall be susceptible to hydrolysis, shall be resistant to aqueous

solutions of salts, acids and alkalis, shall be non-biodegradable and shall have a suitable content of

carbon black to inhibit attack by ultra violet light.

The geogrid shall be supplied in rolls, with labels that allow a total traceability with reference to the

Quality Assurance System, according to the requirements of ISO Standard.

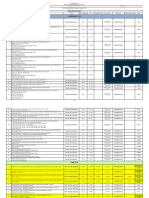

Geogrid type A (TT160)

The geogrid shall comply in full with the following specification:

- Quality Control: The geogrid shall be manufactured in accordance with the Quality Assurance

requirements ISO 9002:94. If required the manufacturing lot shall be certified to conform with ISO 9002

by an external QC/QA firm approved by the Department of Trade and Industry in the Country of the

manufacturer.

- Polymer: High Density Polyethylene.

- Colour: black.

- U.V. protection: carbon black.

- Unit weight: 1000 g/m.

- Tensile Strength: expressed as the 95% confidence limit value, shall be 160.0 kN/m with a peak strain

of around 13.0 % approximately, when tested according to GRI-GG1 at an extension rate of 50

mm/minute at 20 . The tensile strength at 2% strain, obtained from the same test, shall be 45.0 kN/m

minimum.

- Junction strength: shall be not less than 80% of the Tensile Strength in accordance with test method

GRI-GG2.

- The Long Term Design Strength, at a strain not exceeding 10% in 120 years, shall be 65.0 kN/m at a

mean temperature of 20 when tested in accordance with test method ASTM D 5262.

Geogrid type B (TT120)

The geogrid shall comply in full with the following specification:

- Polymer: High Density Polyethylene.

- Colour: black.

- U.V. protection: carbon black.

- Unit weight: 800 g/m.

- Tensile Strength expressed as the 95% confidence limit value, shall be 120.0 kN/m with a peak strain

of around 13.0 % approximately, when tested according to GRI-GG1 at an extension rate of 50

mm/minute at 20 . The tensile strength at 2% strain, obtained from the same test, shall be 36.0 kN/m

minimum.

- Junction strength: shall be not less than 80% of the Tensile Strength in accordance with test method

GRI-GG2.

- The Long Term Design Strength, at a strain not exceeding 10% in 120 years, shall be 48.0 kN/m at a

mean temperature of 20 when tested in accord ance with test method ASTM D 5262.

Geogrid type C (TT090)

The geogrid shall comply in full with the following specification:

- Quality Control: The geogrid shall be manufactured in accordance with the Quality Assurance

requirements ISO 9002:94. If required the manufacturing lot shall be certified to conform with ISO 9002

by an external QC/QA firm approved by the Department of Trade and Industry in the Country of the

manufacturer.

- Polymer: High Density Polyethylene.

- Colour: black.

- U.V. protection: carbon black.

- Unit weight: 600 g/m.

- Tensile Strength: expressed as the 95% confidence limit value, shall be 90.0 kN/m with a peak strain

of around 13.0 % approximately, when tested according to GRI-GG1 at an extension rate of 50

mm/minute at 20 . The te nsile strength at 2% strain, obtained from the same test, shall be 26.0 kN/m

minimum.

- Junction strength: shall be not less than 80% of the Tensile Strength in accordance with test method

GRI-GG2.

- The Long Term Design Strength, at a strain not exceeding 10% in 120 years, shall be 37.0 kN/m at a

mean temperature of 20 when tested in accordance with test method ASTM D 5262.

Geogrid type D (TT060)

The geogrid shall comply in full with the following specification:

- Quality Control: The geogrid shall be manufactured in accordance with the Quality Assurance

requirements ISO 9002:94. If required the manufacturing lot shall be certified to conform with ISO 9002

by an external QC/QA firm approved by the Department of Trade and Industry in the Country of the

manufacturer.

- Polymer: High Density Polyethylene.

- Colour: black.

- U.V. protection: carbon black.

- Unit weight: 400 g/m.

- Tensile Strength: expressed as the 95% confidence limit value, shall be 60.0 kN/m with a peak strain

of around 13.0 % approximately, when tested according to GRI-GG1 at an extension rate of 50

mm/minute at 20 . The tensile strength at 2% strain, obtained from the same test, shall be 17.0 kN/m

minimum.

- Junction strength: shall be not less than 80% of the Tensile Strength in accordance with test method

GRI-GG2.

- The Long Term Design Strength, at a strain not exceeding 10% in 120 years, shall be 25.0 kN/m at a

mean temperature of 20 when tested in accordance with test method ASTM D 5262.

Geogrid type E (TT045)

The geogrid shall comply in full with the following specification:

- Quality Control: The geogrid shall be manufactured in accordance with the Quality Assurance

requirements ISO 9002:94. If required the manufacturing lot shall be certified to conform with ISO 9002

by an external QC/QA firm approved by the Department of Trade and Industry in the Country of the

manufacturer.

- Polymer: High Density Polyethylene.

- Colour: black.

- U.V. protection: carbon black.

- Unit weight: 300 g/m.

- Tensile Strength: expressed as the 95% confidence limit value, shall be 45.0 kN/m with a peak strain

of around 11.5 % approximately, when tested according to GRI-GG1 at an extension rate of 50

mm/minute at 20 . The tensile strength at 2% strain, obtained from the same test, shall be 11.0 kN/m

minimum.

- Junction strength: shall be not less than 80% of the Tensile Strength in accordance with test method

GRI-GG2.

- The Long Term Design Strength, at a strain not exceeding 10% in 120 years, shall be 21.2 kN/m at a

mean temperature of 20 when test ed in accordance with test method ASTM D 5262.

TENAX Secondary Reinforcement (LBO 220 SAMP Geogrid)

The reinforcing element shall be a geogrid manufactured from extrusion and longitudinal plus transversal

drawing of polypropylene polymer of the highest quality, under strict Quality Control procedures.

The geogrid, when unrolled, shall be a plane monolithical structure, with a uniform distribution of

rectangular apertures which identify longitudinal and transversal ribs.

The longitudinal and transversal ribs shall have gone through a process of molecular orientation for

increasing the mechanical characteristics and for ensuring a high long term resistance under sustained

loading. The junctions between the longitudinal and the transversal ribs shall be an integral part of the

geogrid structure and shall in no case be obtained by weaving, knitting or bonding single threads or other

tensile elements.

The geogrid shall be inert to all chemicals naturally found in soils and shall have no solvents at ambient

temperature. It shall be susceptible to hydrolysis, shall be resistant to aqueous solutions of salts, acids

and alkalis, shall be non-biodegradable and shall have a suitable content of carbon black to inhibit attack

by ultra violet light.

The geogrid shall comply in full with the following specification:

- Quality Control:

The geogrid shall be manufactured in accordance with the Quality Assurance requirements ISO

9002:94. If required the manufacturing lot shall be certified to conform with ISO 9002 by an external

QC/QA firm approved by the Department of Trade and Industry in the Country of the manufacturer.

- Polymer: Polypropylene.

- Standard colour: black.

- U.V. protection: carbon black.

- Unit weight: 230 g/m.

- Tensile Strength: expressed as the 95% confidence limit value, shall be 20 kN/m and 20kN/m with a

peak strain of 11.0 % and 10.0 % approximately in the longitudinal and transverse directions

respectively, when tested according to GRI-GG1 at an extension rate of 50 mm/minute at 20 . The

tensile strength at 5% strain, obtained from the same test, shall be 14 kN/m in both the longitudinal

and transverse directions.

The geogrid shall be supplied in rolls, with labels which allow a full traceability with reference to the

Quality Assurance System, according to the requirements of ISO 10320 Standard.

Vous aimerez peut-être aussi

- Elem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Document18 pagesElem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Santhoshkumar RayavarapuPas encore d'évaluation

- Elem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Document18 pagesElem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Santhoshkumar RayavarapuPas encore d'évaluation

- Elem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Document41 pagesElem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Santhoshkumar RayavarapuPas encore d'évaluation

- Elem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Document18 pagesElem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Santhoshkumar RayavarapuPas encore d'évaluation

- Elem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Document41 pagesElem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Santhoshkumar RayavarapuPas encore d'évaluation

- Elem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Document18 pagesElem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Santhoshkumar RayavarapuPas encore d'évaluation

- Format For IRC 83 2014 (Part IV) Clause 5.5Document1 pageFormat For IRC 83 2014 (Part IV) Clause 5.5Gobinder Singh VirdeePas encore d'évaluation

- Elem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Document18 pagesElem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Santhoshkumar RayavarapuPas encore d'évaluation

- Elem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Document18 pagesElem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Santhoshkumar RayavarapuPas encore d'évaluation

- Elem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Document18 pagesElem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Santhoshkumar RayavarapuPas encore d'évaluation

- Elem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Document18 pagesElem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Santhoshkumar RayavarapuPas encore d'évaluation

- GtipiuoiklDocument4 pagesGtipiuoiklSanthoshkumar RayavarapuPas encore d'évaluation

- Elem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Document18 pagesElem Load Axial (Tonf) Shear-Y (Tonf) Shear-Z (Tonf) Torsion (Tonf M)Santhoshkumar RayavarapuPas encore d'évaluation

- IRC B6 Code General Final Sep 2020 1Document48 pagesIRC B6 Code General Final Sep 2020 1Santhoshkumar RayavarapuPas encore d'évaluation

- 5435454Document6 pages5435454Santhoshkumar RayavarapuPas encore d'évaluation

- Draft Amendment To IRC SP 59 2019 (H-4)Document26 pagesDraft Amendment To IRC SP 59 2019 (H-4)Santhoshkumar RayavarapuPas encore d'évaluation

- Draft Amendment in IRC 6 Fatigue Load Clause 204.6Document4 pagesDraft Amendment in IRC 6 Fatigue Load Clause 204.6Santhoshkumar RayavarapuPas encore d'évaluation

- Midas DiagramsDocument2 pagesMidas DiagramsSanthoshkumar RayavarapuPas encore d'évaluation

- Structure Dwarings PKG 1Document23 pagesStructure Dwarings PKG 1Santhoshkumar RayavarapuPas encore d'évaluation

- Draft Guidelines For Engineering of Natural Slopes (H-4) - CompressedDocument224 pagesDraft Guidelines For Engineering of Natural Slopes (H-4) - CompressedSanthoshkumar Rayavarapu100% (1)

- LJKHJGHFGHDocument12 pagesLJKHJGHFGHSanthoshkumar RayavarapuPas encore d'évaluation

- ErgdfgfghgfnnDocument15 pagesErgdfgfghgfnnSanthoshkumar RayavarapuPas encore d'évaluation

- EwerefdsfsdvdfbfbDocument5 pagesEwerefdsfsdvdfbfbSanthoshkumar RayavarapuPas encore d'évaluation

- B-5 IRC-Final (22-03-21) - CompressedDocument136 pagesB-5 IRC-Final (22-03-21) - CompressedGobinder Singh VirdeePas encore d'évaluation

- LJKHJGHFGHDocument12 pagesLJKHJGHFGHSanthoshkumar RayavarapuPas encore d'évaluation

- FSDFGDFZFBDocument6 pagesFSDFGDFZFBSanthoshkumar RayavarapuPas encore d'évaluation

- FSDFGDFZFBDocument6 pagesFSDFGDFZFBSanthoshkumar RayavarapuPas encore d'évaluation

- Projects SyuyDocument4 pagesProjects SyuySanthoshkumar RayavarapuPas encore d'évaluation

- StandardDocument331 pagesStandardHuan VoPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Technical Conversions - HANDBOOKDocument88 pagesTechnical Conversions - HANDBOOKShishir KoyarePas encore d'évaluation

- BOQ For 5th Utility BuildingsDocument15 pagesBOQ For 5th Utility Buildingssudesh1968Pas encore d'évaluation

- Training Report Himanshu Kumar, Sid 17102103Document55 pagesTraining Report Himanshu Kumar, Sid 17102103Armaan BhatiaPas encore d'évaluation

- Form Work, Reinforcement & Concreting - MethodologyDocument10 pagesForm Work, Reinforcement & Concreting - MethodologyRabnawaz ImamPas encore d'évaluation

- Formwork Based On: Structural ComponentsDocument20 pagesFormwork Based On: Structural ComponentsPatrick Jake DimapilisPas encore d'évaluation

- RCC Building Design Workshop (By Etab & Draftwin Softwares) - 16th & 17th January' 2018Document2 pagesRCC Building Design Workshop (By Etab & Draftwin Softwares) - 16th & 17th January' 2018Dhruv ShahPas encore d'évaluation

- Simplified DesignDocument176 pagesSimplified DesignKofi Daniel100% (2)

- Estimate For RCC StructureDocument8 pagesEstimate For RCC StructureArvind DoraiPas encore d'évaluation

- MOS DrainageDocument16 pagesMOS DrainageMohammad Hadoumi Saldan100% (1)

- Control of Thermal Cracking in Concrete Water Retaining Structures PDFDocument5 pagesControl of Thermal Cracking in Concrete Water Retaining Structures PDFyohannesPas encore d'évaluation

- Gantt ChartDocument4 pagesGantt ChartAbi ConstructionsPas encore d'évaluation

- Catalog StandardDocument23 pagesCatalog Standardproject listPas encore d'évaluation

- Procurement Progress Calculation Report Proyek Pltgu Tanjung Uncang 100-120 MW BatamDocument3 pagesProcurement Progress Calculation Report Proyek Pltgu Tanjung Uncang 100-120 MW BatamDwi Mulyanti Dwimulyantishop100% (1)

- 05 C&S WMS at Super Structure (RC Work)Document10 pages05 C&S WMS at Super Structure (RC Work)Aldi mubaroqPas encore d'évaluation

- Issue Date: Week 1 Submission Date: 18 November 2020 Feedback Date: Week 6Document8 pagesIssue Date: Week 1 Submission Date: 18 November 2020 Feedback Date: Week 6teck yuPas encore d'évaluation

- A Case Productivity Model For Automatic Climbing SystemDocument19 pagesA Case Productivity Model For Automatic Climbing SystemAhmad Dzikri FauzanPas encore d'évaluation

- 3) Method Statement For Formwork Steel & Concrete WorkDocument9 pages3) Method Statement For Formwork Steel & Concrete WorkMukesh PrajapatPas encore d'évaluation

- Built Up Rate: FormworkDocument11 pagesBuilt Up Rate: Formworksyazwan_badboyz100% (2)

- ITT Draft 3Document30 pagesITT Draft 3Stuart Goldsworthy-TrappPas encore d'évaluation

- Work Plan Inspection of Laboratory Structural Work For 01.01.2024 (IHI) Afternoon & Evening ShiftDocument6 pagesWork Plan Inspection of Laboratory Structural Work For 01.01.2024 (IHI) Afternoon & Evening ShiftChina CivilPas encore d'évaluation

- SECTION 03 05 00 Common Work Results For ConcreteDocument44 pagesSECTION 03 05 00 Common Work Results For ConcreteAlexander MasongsongPas encore d'évaluation

- Checklist For Safe Construction of FormworkDocument3 pagesChecklist For Safe Construction of Formworklwin_oo2435100% (1)

- MFE Component Description Oct-12Document33 pagesMFE Component Description Oct-12Shamika Ayre100% (5)

- Method Statement For Construction of Bridge RC Structure at BR 562-Sg. ChenderiangDocument12 pagesMethod Statement For Construction of Bridge RC Structure at BR 562-Sg. ChenderiangMAYMODERN STEELPas encore d'évaluation

- Building With HempDocument72 pagesBuilding With HempStilian DeskovPas encore d'évaluation

- TEC-221300 - MET-DoR-001 (Method Statement For Drainage Sewage Works) (H)Document15 pagesTEC-221300 - MET-DoR-001 (Method Statement For Drainage Sewage Works) (H)Arul SankaranPas encore d'évaluation

- 2022-06-29 Method Statement of Construction of Odor Control System Rev. ADocument71 pages2022-06-29 Method Statement of Construction of Odor Control System Rev. AMeng PamplonaPas encore d'évaluation

- Cast-In Place ConcreteDocument217 pagesCast-In Place ConcreteFarid ObandoPas encore d'évaluation

- IABSE IASS2011 Davis Rippmann Pawlofski BlockDocument8 pagesIABSE IASS2011 Davis Rippmann Pawlofski Blockdenis1808scribdPas encore d'évaluation

- Tentative Road BudgetDocument47 pagesTentative Road BudgetMelissa De La RosaPas encore d'évaluation