Académique Documents

Professionnel Documents

Culture Documents

Levcon Jaykay: Licensee of Bonetti S. .A. Italy

Transféré par

Pankaj PandeyDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Levcon Jaykay: Licensee of Bonetti S. .A. Italy

Transféré par

Pankaj PandeyDroits d'auteur :

Formats disponibles

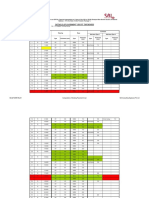

METAL DOCTOR BLADES

MARK MATERIAL DESCRIPTION & THICKNESS "T" (mm) SPECIFIC POINTS

LMO MONEL Monel K500, grade D, artificially aged. Total absence of sparks combined with high

HRC 3943 resistance to wear: ideal for the granite rolls

0.8 mm < T < 1.2 mm at press section.

L13 HTSS Hardened and tempered stainless steel AISI 420 Hardened and tempered stainless steel with

( Cr =10%content).HRC 45 49 generous mechanical characteristics. Ideal

0.8 mm < T < 1.2 mm for 1st group driers and some press rolls.

LST HARDENED Hardened and tempered carbon steel (C=0.75%). Top mechanical characteristics, especially

STEEL HRC 49 52 regarding elasticity and the most effective

0.8 mm < T < 1.2 mm material for MG Take Off ,Creping and some

soft calendars

LBZ BRONZE Top quality hard laminated Bronze, Hardness

HV 200

0.8 mm < T < 1.2 mm

Metal doctor blade with the lowest coefficient

of Friction. LEVCON JAYKAY

LICENSEE OF BONETTI S.P.A. ITALY

APPLICATIONS OF DOCTOR BLADES IN PAPER MACHINES

MARK MATERIAL BLADE WORKING Advisable blade pressure N/m

ANGLE

Normal Maximum

Wire Section Rubber (4 20 P&J) LA1-LA3- LB7 20o 25o 80 100

& Hard Rubber (0 3 P&J) LA1-LA3-LB7-LB1 25o 80 120-200

Couch Rubber (21 45 P&J) LA3-LB5 20o 60 80

Bronze and Steel LA3-LB7-LB1 25o 180 200

Wire Rolls & Hard Rubber(0 3 P&J) LA1-LA3-LB7 25o 100 200

Felt Rolls Black Diamond LB5-LB7-LA3 25o 80 180

Press Rolls Dynarock LB7-LB3-LB1 25o 30o 200 240

Rubber (4 20 P&J) LA1-LB7 20o 25o 110 130

Hard Rubber (01 P&J) L13-LB1 25o 250 300

Granite L13-LMO-LC1-LB1 25o 200 320

Hard Rubber (0 3 P&J) LB7-LB3-LB1 25o 110 130

Microrock LB7-LB3-LB1 25o 90 110

Ceramic LB4-LC1-LCR-TC 27o 300 350

Stonite LB3-LB1 25o 200 260

Grooved Rubber (0 3 P&J) LB7-LB1 25o 200 250

Venta-Nip Steel LB7-LB1 25o 250 300

PU LB7-LB1 25o 250 300

Dryers Cast Iron L13-LBR-LB7-LST 30o 180 250

Chrome LB7-LBZ-LB1 30o 140 250

MG Cylinder Steel LB7-LBZ 30o 140 250

Hard Rubber(0 3 P&J) LB3-LB7 15o 20o 90 160

Size-Press Teflon 15o 90 110

Calender Cast Iron/Steel LB1-LMO-LHR-LB1 25o 180 250

Rubber -compound LST 16o 30 60

Tungsten carbide coated LB1-LHR - 25o 150 200

Reel Drum Cast Iron /Steel LB7-LBZ 30o 180 250

The selection of doctor blade quality is closely linked with the speed of the machine and the presence of lubrication, if

any. For the proper use of the table (that can be modified) we request you to consult us.

LEVCON JAYKAY MACHINERY PVT. LTD

Regd. Office : 81/2, Palm Avenue, Kolkata 700 019

Phone : (033) 2283 3074, (033) 2280 3810, Fax : (033) 2287 0548,

Email : Levconjaykay@Ljaykay.com

Website : www.Ljaykay.com

DOCTOR BLADES DOCTOR BLADE MATERIAL

Levcon Jaykay Machinery, a Licensee of Choice of Blade material for various applications involve the following criteria

Bonetti S.p.A, Italy an ISO company, Dimensional Stability of the blade under load Flexibility

specializes in manufacturing Doctor Blades.

Withstand temperature variations and temperature Machining accuracy and Mechanical Strength

Levcon Jaykay Doctor Blades are finished in

India with Rivets and Doctor Materials imported Water absorption Blade burst formation

from Bonetti S.p.A, Italy. Tolerances are Friction value (sparks) Condition of roll Surface

maintained as per International standards and

norms with a perfect square edge and smooth

SYNTHETIC DOCTOR BLADES

machined bevel, tested with fastest paper

machines. We manufacture Doctor Blades MARK MATERIAL DESCRIPTION & THICKNESS "T" (mm) SPECIFIC POINTS

suitable for all applications tailor-made for your HDPE AND COTTON FIBER BLADES

requirements and satisfaction. LA3 BLUE A special groove allows introduction in most

UHMaW Virgin polyethylene Maximum

POLYSET temperature : 90oC common holders, rivets can be fitted in other

T = 5 mm cases. Ideal for wire and press rolls.

LA1 RED UHMW Polyethylene identical to but Low coefficient of friction combined with

SUPERPOLYSET reinforced with glass fibers. superior resistance to wear , recommended

T = 5 mm for speeds over 600 m/min, for wire and

some press rolls.

TECHNICAL AUDIT LB5 BROWN Woven Cotton laminate bonded with Phenolic Thermosetting doctor blade with the low

PHENOSET resin. Maximum temperature:130C. coefficient of friction. The best solution, for

2.3 mm < T < 3.2 mm example at copper coated cooling cylinders.

Levcon Jaykay has been trained by Bonetti in

Europe to support the Indian customers and FIBER GLASS AND ABRASIVE BLADES

find specific solutions to all doctoring problems .

LB7 GREEN Fiberglass layers bonded with Epoxy resin. Most commonly used fiberglass doctor blade

We have trained resources for conducting EPOXY Maximum temperature :170 C. for a wide range of applications. Outstanding

1.5 mm < T < 2.8 mm performance on some types of presses,

detailed on site technical audit , analysis and calendars and on dryer cylinders.

troubleshooting of your existing doctoring LHR HOT EPOXY Fiberglass layers bonded with special Epoxy Similar to LB7, but specially made for heated

resin. Maximum temperature:250 C. roll in calendars.

system utilising your used blades to identify and 1.5 mm < T < 1.9 mm

preempt doctoring problems. Call us for LB3 RED Fiberglass layers specially arranged to obtain With exceptional mechanical characteristic

Technical Audit or any assistance required SUPEREPOXY high resistance to wear bonded with Epoxy allowing blade pressure of 220 N/m, grants

resin.Maximum temperature:180C. perfect cleaning during its lifetime.

for alignment and fine tuning of your 1.5 mm < T < 1.9 mm

existing Doctoring System. LBR ABRASIVE Fiberglass with abrasive materials 120GRIT Fiberglass doctor blade with best Cleaning

bonded with Epoxy Resin. Maximum action: to be used under the most severe

operating temperature:180C. cleaning conditions at MG and 1st Group

The audit also involves the followings checks at site :- 1.5 mm < T < 2 mm driers.

Stability of the Doctoring System No turning Moment Fiberglass , carbon fiber layers with the

LCR CARBO Specially designed for usage in 2nd Position

Loading mechanism ABRASIVE addition of abrasive materials 180 GRIT in Ceramic press rolls, to ensure that the

Alignment vis a vis working angle bonded with Epoxy Resin. Maximum roll surface porosity, critical for sheet release

operating temperature:180C. remains unchanged.

Oscillations

1.5 mm < T < 2 mm

Blade wear Geometry

Strength & Deflection of the system and blades under load FIBER GLASS AND CARBON FIBER BLADES

Vibrations of the system

LB1 GREY Fiberglass, carbon fiber layers bonded with Most commonly used carbonfiber doctor

Choice of blade material CARBOSET Epoxy resin. Excellent chemical resistance. blade for a wide range of applications.

Threading Maximum operating temperature: 190C. Outstanding performance on some types of

Roll Surface Condition 1.5 mm < T < 2.0 mm presses, calendars and on dryer cylinders.

LC1 BLACK SUPER 1 0 0 % sp e ci a l ca rb o n fi b e r re i n fo r c e d & Doctor Blade of the new generation with

CARBOSET b o n d e d w i th e p o xy re si n .M a x i m u m highest resistance to wear and best self

o p e r a ti n g te mp e r a tu r e : 19 0 C . lubricating grade, capable to work even at

1.5 mm < T < 2 mm 500N/m. Best Chemical and wear resistance.

Vous aimerez peut-être aussi

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Rev. 0 Release All MaterialDocument2 pagesRev. 0 Release All MaterialHery SaputraPas encore d'évaluation

- Pavement Crust ThicknessDocument10 pagesPavement Crust ThicknessHarsh DeepPas encore d'évaluation

- Ilovepdf MergedDocument9 pagesIlovepdf MergedRajashree PawarPas encore d'évaluation

- Arklite Specialty Lamps, Limited - Pune: Department:-Dta Uvq Job Sheet For Gph178T5Vh 200 Nos (So 103)Document1 pageArklite Specialty Lamps, Limited - Pune: Department:-Dta Uvq Job Sheet For Gph178T5Vh 200 Nos (So 103)gaurav tathePas encore d'évaluation

- Bill of Material For A01200B163434EW1NANA-F A01, DN200, PN03, AL, SS304, SS304, EPDM WHITE, BARE Shaft Butterfly ValveDocument1 pageBill of Material For A01200B163434EW1NANA-F A01, DN200, PN03, AL, SS304, SS304, EPDM WHITE, BARE Shaft Butterfly Valvesachin sabalePas encore d'évaluation

- ATV RUS LIM RCT 001 - MergedDocument5 pagesATV RUS LIM RCT 001 - MergedNaam Ka KyaPas encore d'évaluation

- Valvula de Retencion A Clapeta Oscilante Din pn16 dn50 300Document2 pagesValvula de Retencion A Clapeta Oscilante Din pn16 dn50 300JOHNNY CALEROPas encore d'évaluation

- Essemm Ind.Document2 pagesEssemm Ind.Maan SaabPas encore d'évaluation

- IntercambiosDocument8 pagesIntercambiosjaviervbPas encore d'évaluation

- Electrode Booklet F Web 97Document1 pageElectrode Booklet F Web 97satnamPas encore d'évaluation

- 2 X 150 GBV-170207Document1 page2 X 150 GBV-170207Debasis Pattnaik DebaPas encore d'évaluation

- Evermark LTDDocument9 pagesEvermark LTDRakibul islamPas encore d'évaluation

- Form Stok OpnameDocument20 pagesForm Stok Opnameiduy emailsPas encore d'évaluation

- BOP and Door Components: Specifications and Parts ListsDocument2 pagesBOP and Door Components: Specifications and Parts ListsDandi ZulkarnainPas encore d'évaluation

- Hindustan Copper Limited Pricing Summary of CC Rod 8mm As OnDocument1 pageHindustan Copper Limited Pricing Summary of CC Rod 8mm As OnNavin ChaudhariPas encore d'évaluation

- Bulk Material StockDocument8 pagesBulk Material StockAshanmugam SunfacePas encore d'évaluation

- Chinese Specification For Cast Iron and S. G. IronDocument1 pageChinese Specification For Cast Iron and S. G. IronRahul KhoslaPas encore d'évaluation

- No. Item Code Item NameDocument29 pagesNo. Item Code Item NameThenut PaisantaraPas encore d'évaluation

- Cek Piso, Dempul Dan NylonDocument13 pagesCek Piso, Dempul Dan NylonAl MusyafirinPas encore d'évaluation

- Consumbles List Section Wise.Document9 pagesConsumbles List Section Wise.engineeringPas encore d'évaluation

- Consumbles Oct-22Document5 pagesConsumbles Oct-22engineeringPas encore d'évaluation

- Op 1250a (Sa Cs 3 97 Ccrmo Ac)Document1 pageOp 1250a (Sa Cs 3 97 Ccrmo Ac)brunizzaPas encore d'évaluation

- Schedule A Part I (Malli) CorrectedDocument106 pagesSchedule A Part I (Malli) CorrectedshivaprasadmPas encore d'évaluation

- Arklite Specialty Lamps, Limited - Pune: Department:-Dta Uvq JOB SHEET FOR G64T5L Trojen 120 NOS (WSL 1907)Document1 pageArklite Specialty Lamps, Limited - Pune: Department:-Dta Uvq JOB SHEET FOR G64T5L Trojen 120 NOS (WSL 1907)gaurav tathePas encore d'évaluation

- Filler Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysDocument8 pagesFiller Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysimrePas encore d'évaluation

- BWSSB 07-03-2018 SorDocument184 pagesBWSSB 07-03-2018 Sorkathir1965Pas encore d'évaluation

- Tabela VCorte SangrarDocument4 pagesTabela VCorte Sangrarcaeiro60Pas encore d'évaluation

- Compact and Beautiful Design (结构紧凑,外观优美) Explosion Proof (Ex d BT6 and CT6) (高等级隔爆) Many Size and Many Type (多品种,多规格)Document9 pagesCompact and Beautiful Design (结构紧凑,外观优美) Explosion Proof (Ex d BT6 and CT6) (高等级隔爆) Many Size and Many Type (多品种,多规格)Mariam Matamala FarranPas encore d'évaluation

- Simmerring® MSC 01 MSC 02 PDFDocument4 pagesSimmerring® MSC 01 MSC 02 PDFcosta59dac9242Pas encore d'évaluation

- Rates of Material Including Lead and Conveynace Charges For The Year 2021-22Document2 pagesRates of Material Including Lead and Conveynace Charges For The Year 2021-22vamsiPas encore d'évaluation

- Malleable Iron Property Casting QualityDocument1 pageMalleable Iron Property Casting QualityMetal deptPas encore d'évaluation

- Consumbles Aug-22Document5 pagesConsumbles Aug-22engineeringPas encore d'évaluation

- Hindustan Copper Limited Pricing Summary of CC Rod 8mm As OnDocument1 pageHindustan Copper Limited Pricing Summary of CC Rod 8mm As OnJames ValenzuelaPas encore d'évaluation

- Profile Carbide Modular Shrink System Inserts ParametersDocument8 pagesProfile Carbide Modular Shrink System Inserts ParametersLaxman KumarPas encore d'évaluation

- LBMDocument4 pagesLBMmekotechPas encore d'évaluation

- Carpenter I Class Carpenter Ii Class: Item Rates - (Sor: 2022-23)Document89 pagesCarpenter I Class Carpenter Ii Class: Item Rates - (Sor: 2022-23)Sasidhar KatariPas encore d'évaluation

- Hardfacing Electrodes: Brand ISDocument13 pagesHardfacing Electrodes: Brand ISashwini shuklaPas encore d'évaluation

- Kebutuhan Consumable Mesin Las CODocument9 pagesKebutuhan Consumable Mesin Las COBagaz KarmawanPas encore d'évaluation

- Leantec Industry Catalogue PDFDocument11 pagesLeantec Industry Catalogue PDFrudiPas encore d'évaluation

- HWDP 3.5 03Document2 pagesHWDP 3.5 03km1790Pas encore d'évaluation

- Parallel Groove ClampDocument1 pageParallel Groove ClampAnanggadhipa Sedyanto PutroPas encore d'évaluation

- 800 kVA CM-2NE6A5-AOD5D1 - SUBCONTDocument3 pages800 kVA CM-2NE6A5-AOD5D1 - SUBCONTibnu01Pas encore d'évaluation

- Toshiba Power MosfetsDocument9 pagesToshiba Power MosfetsmacroendrixPas encore d'évaluation

- En 10139Document2 pagesEn 10139releone11Pas encore d'évaluation

- TL - Genius - Bulb - CTRL - v1 1Document4 pagesTL - Genius - Bulb - CTRL - v1 1gautamkr15Pas encore d'évaluation

- MR030-08-2021 (Modification LCT Tank)Document5 pagesMR030-08-2021 (Modification LCT Tank)Hanhan Jaya MahendraPas encore d'évaluation

- Section 3: Specification Classification Product DescriptionDocument1 pageSection 3: Specification Classification Product DescriptiontamharPas encore d'évaluation

- Earthing MaterialDocument7 pagesEarthing MaterialLeland SharafPas encore d'évaluation

- TDS Material Astm-A193-Grade-B8Document1 pageTDS Material Astm-A193-Grade-B8ASTRID AMPas encore d'évaluation

- 5104-Gala-Silent Check ValveDocument1 page5104-Gala-Silent Check ValveNam ĐỗPas encore d'évaluation

- Types of BronzeDocument1 pageTypes of BronzeSudipta GangopadhyayPas encore d'évaluation

- Lista de Mat Tub Rev.1Document5 pagesLista de Mat Tub Rev.1Ricardo Alberto Zapata BalcazarPas encore d'évaluation

- 31163-NB66 BrevikSpare Parts R01Document1 page31163-NB66 BrevikSpare Parts R01Sergei KurpishPas encore d'évaluation

- Modul Kualifikasi LasDocument1 pageModul Kualifikasi LasDwi Agus YuliyantoPas encore d'évaluation

- MBNNDocument3 pagesMBNNblsmsachivalayamPas encore d'évaluation

- 1 Cement 2 Fe-500 3 Fe-415 0.00 4 Mild Steel 5 Structural SteelDocument687 pages1 Cement 2 Fe-500 3 Fe-415 0.00 4 Mild Steel 5 Structural SteelRK PROJECT CONSULTANTSPas encore d'évaluation

- AW - Datasheet - ALLOY 20 CB 3Document2 pagesAW - Datasheet - ALLOY 20 CB 3.xPas encore d'évaluation

- Reconciliation Sheet PRJS & EFFLUENT STRIPPERDocument1 pageReconciliation Sheet PRJS & EFFLUENT STRIPPERkasvikrajPas encore d'évaluation

- Addendum Analisa TKDN Pekerjaan Rehabilitasi Gedung Madiun Lantai 6Document7 pagesAddendum Analisa TKDN Pekerjaan Rehabilitasi Gedung Madiun Lantai 6imam tarregaPas encore d'évaluation

- Fans-Blowers Detail MillwideDocument7 pagesFans-Blowers Detail MillwidePankaj PandeyPas encore d'évaluation

- Super CellDocument2 pagesSuper CellPankaj PandeyPas encore d'évaluation

- 1 Grub Screw Allen High - Ten 16X25Mm: N.R.Agarwal Industries LTD NO Material DescriptionDocument9 pages1 Grub Screw Allen High - Ten 16X25Mm: N.R.Agarwal Industries LTD NO Material DescriptionPankaj PandeyPas encore d'évaluation

- Intercome List - NEW Jan 2019Document9 pagesIntercome List - NEW Jan 2019Pankaj PandeyPas encore d'évaluation

- Pump Motors 22KW & Above Millwide - JAN 19Document22 pagesPump Motors 22KW & Above Millwide - JAN 19Pankaj PandeyPas encore d'évaluation

- Equipment Upload FormatDocument80 pagesEquipment Upload FormatPankaj PandeyPas encore d'évaluation

- Material For Roll CastingDocument5 pagesMaterial For Roll CastingPankaj PandeyPas encore d'évaluation

- Motor Lubrication Report: SN Status HP SN Status HPDocument2 pagesMotor Lubrication Report: SN Status HP SN Status HPPankaj PandeyPas encore d'évaluation

- Remark SN Particulars: Left TOP Front Left TOP FrontDocument6 pagesRemark SN Particulars: Left TOP Front Left TOP FrontPankaj PandeyPas encore d'évaluation

- Precommissioning ChecklistDocument2 pagesPrecommissioning ChecklistPankaj PandeyPas encore d'évaluation

- Eil RevalidationDocument1 pageEil RevalidationPankaj PandeyPas encore d'évaluation

- Roll Covering Letter LathiaDocument6 pagesRoll Covering Letter LathiaPankaj PandeyPas encore d'évaluation

- Material For Roll CastingDocument5 pagesMaterial For Roll CastingPankaj PandeyPas encore d'évaluation

- Data Sheet: Induction Motor Champion Series Motor Type: 1SE0 319-4NA80 SDocument3 pagesData Sheet: Induction Motor Champion Series Motor Type: 1SE0 319-4NA80 SPankaj PandeyPas encore d'évaluation

- Heat Exchanger SpecificationsDocument1 pageHeat Exchanger SpecificationsPankaj PandeyPas encore d'évaluation

- Fenner Dual Duty Pulley With Taper Lock Bush: A / Spa C / SPC 8V Timing PulleyDocument3 pagesFenner Dual Duty Pulley With Taper Lock Bush: A / Spa C / SPC 8V Timing PulleyPankaj Pandey100% (1)

- V Belt ManualDocument116 pagesV Belt ManualPankaj Pandey100% (1)

- Cost Evalution For Instruments To Be Calibrated (Iso) : SR - NO. Description Total Instruments Rate/Unit Total CostDocument1 pageCost Evalution For Instruments To Be Calibrated (Iso) : SR - NO. Description Total Instruments Rate/Unit Total CostPankaj PandeyPas encore d'évaluation

- Contractor Works For - 2011Document2 pagesContractor Works For - 2011Pankaj PandeyPas encore d'évaluation

- Introduction & Litreture (All)Document63 pagesIntroduction & Litreture (All)Pankaj PandeyPas encore d'évaluation

- PDF 2 BearingDocument1 pagePDF 2 BearingPankaj PandeyPas encore d'évaluation

- Equivalents Chains & BeltsDocument3 pagesEquivalents Chains & BeltsPankaj PandeyPas encore d'évaluation

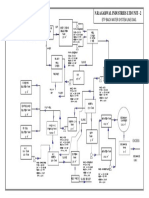

- N.R.Agarwal Industries LTD Unit - 2: Etp Back Water System Line DiagDocument1 pageN.R.Agarwal Industries LTD Unit - 2: Etp Back Water System Line DiagPankaj PandeyPas encore d'évaluation

- Pump Model MEGA-G 32-200Document5 pagesPump Model MEGA-G 32-200Pankaj PandeyPas encore d'évaluation

- Train From Mumbai To VapiDocument1 pageTrain From Mumbai To VapiPankaj PandeyPas encore d'évaluation

- TiwaryjiDocument3 pagesTiwaryjiPankaj PandeyPas encore d'évaluation

- Desai SabDocument5 pagesDesai SabPankaj PandeyPas encore d'évaluation

- TiwaryjiDocument3 pagesTiwaryjiPankaj PandeyPas encore d'évaluation

- 19-PM-2015-16 Gripcoat Coating On Rewinder NR VapiDocument2 pages19-PM-2015-16 Gripcoat Coating On Rewinder NR VapiPankaj PandeyPas encore d'évaluation

- Night Duty ReportDocument1 pageNight Duty ReportPankaj PandeyPas encore d'évaluation

- Positive and Adjustable Choke CatalogueDocument7 pagesPositive and Adjustable Choke CatalogueEsteban Reyes100% (1)

- Aluminium Alloy 5754 Data SheetDocument1 pageAluminium Alloy 5754 Data Sheetprasanth cpPas encore d'évaluation

- Dac BDocument15 pagesDac BArief BudimanPas encore d'évaluation

- PFI ES 24 Pipe BendingDocument24 pagesPFI ES 24 Pipe BendingSrinivas Jasti100% (1)

- Lectut MT 307 PPT MT 307 04 Weld Metallurgy - WYlLE5JDocument25 pagesLectut MT 307 PPT MT 307 04 Weld Metallurgy - WYlLE5Jsachingir100% (1)

- Practical Guidelines Inspect Repair HDG Coatings 2008Document24 pagesPractical Guidelines Inspect Repair HDG Coatings 2008forbeskaPas encore d'évaluation

- Stainless-Steel-1.4301-304 - CopieDocument3 pagesStainless-Steel-1.4301-304 - CopieYoucef KherroubiPas encore d'évaluation

- Sand Casting: Sunil Sutar Mtech (Design Engineering)Document17 pagesSand Casting: Sunil Sutar Mtech (Design Engineering)Prema Latha100% (1)

- GFR CatalogDocument137 pagesGFR CatalogironeousPas encore d'évaluation

- Botellas Acumulador Accumulator Catalog Rev DDocument5 pagesBotellas Acumulador Accumulator Catalog Rev DFrank MoralesPas encore d'évaluation

- Asme b16.25 BW Ends InterpretDocument5 pagesAsme b16.25 BW Ends InterpretIvan OsorioPas encore d'évaluation

- Designation by Standards: Steel Vcmo230 (Mat - No. 1.7707, Din 30crmov9, Aisi 4340)Document5 pagesDesignation by Standards: Steel Vcmo230 (Mat - No. 1.7707, Din 30crmov9, Aisi 4340)janjicbojanPas encore d'évaluation

- Consulting ProposalDocument14 pagesConsulting ProposalKalpesh JainPas encore d'évaluation

- Vulcraft Roof and Floor Deck SystemsDocument116 pagesVulcraft Roof and Floor Deck SystemsTitto8528Pas encore d'évaluation

- Green InhibitorsDocument8 pagesGreen InhibitorsRuben SuarezPas encore d'évaluation

- An Analysis of The Steady State Wire Drawing of STR Hardening MatDocument29 pagesAn Analysis of The Steady State Wire Drawing of STR Hardening Matcoshuk100% (1)

- AASHTO T-250 Thermoplastic Traffic Line Material - Test MethodsDocument13 pagesAASHTO T-250 Thermoplastic Traffic Line Material - Test MethodsAn Trang100% (3)

- Sa268 TP409 PDFDocument8 pagesSa268 TP409 PDFmaheshPas encore d'évaluation

- Wellhead CatalogueDocument78 pagesWellhead CatalogueAminPas encore d'évaluation

- Welding TERMINOLOGY DefinitionDocument33 pagesWelding TERMINOLOGY DefinitionrajuPas encore d'évaluation

- HW 4Document2 pagesHW 4rowen1982Pas encore d'évaluation

- Ko Large Bore PistonsDocument0 pageKo Large Bore PistonsvshalimovPas encore d'évaluation

- Centrifuge Basket DesignDocument9 pagesCentrifuge Basket DesignManoj BendalePas encore d'évaluation

- Unit 2 - Advanced Joining ProcessesDocument49 pagesUnit 2 - Advanced Joining ProcessesVikas MaliPas encore d'évaluation

- New and Revised Code (2009)Document1 pageNew and Revised Code (2009)danielsu87Pas encore d'évaluation

- Shearing MachineDocument36 pagesShearing MachineAntehun MekonnenPas encore d'évaluation

- Selection of NodularizersDocument2 pagesSelection of Nodularizersarnaldorcr8646100% (2)

- ETA 98 0001 HST3 HST Metal Expansion Anchor Approval Document ASSET DOC 5422375Document269 pagesETA 98 0001 HST3 HST Metal Expansion Anchor Approval Document ASSET DOC 5422375Deitie ArkelvPas encore d'évaluation

- Stainless SteelDocument6 pagesStainless Steelkarioke mohaPas encore d'évaluation