Académique Documents

Professionnel Documents

Culture Documents

User Manual EM, EX

Transféré par

Sergio E. Marchetti Newco S. A.Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

User Manual EM, EX

Transféré par

Sergio E. Marchetti Newco S. A.Droits d'auteur :

Formats disponibles

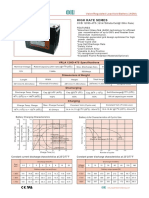

ISO9001:2000, ISO14001:2004 Lubri-Cup EM & EM-X (125/250cc Automatic Lubricator)

Global Solutions, Local Service.

The New Generation of Single Point Lubricators

Rev. 01 Specification Safety instructions

This is the safety alert symbol. It is used to alert you to potential personal

Specification Lubri-Cup EM Lubri-Cup EM-X injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or

Grease pouch 125 or 250cc (replaceable) Same as death.

DC 4.5 Volt (BATTERY PACK)

DC 4.5 Volt (BATTERY PACK)

Power Standard: Alkaline Battery

Standard: Alkaline Battery 1. Please read and save all notices, warnings and safety instructions included

LUBRI-CUP

Option: Lithium Battery

with equipment.

EMUSER

& MANUAL

EM-X

TM Temperature

Standard Battery: 5F~140F (-15C~+60C) Standard Battery:

Lithium Battery: -40F~140F (-40C~+60C) 14F ~ 122F(-10 C~50 C)

2. Battery Safety Instructions

- Store battery at temperatures between 40 F and 80 F for best results.

Working - Do not expose BATTERY PACK to direct sunlight or high heat for extended

Under 280 psi (20kgf/) Under 200 psi (15kgf/) periods of time.

Pressure

- Keep battery within 20 F and 150 F when transporting or temporarily

125cc : 3.6in(91mm) x 7.2in(183mm)

Size Same as storing BATTERY PACK.

250cc : 3.6in(91mm) x 8.2in(210mm)

- Keep BATTERY PACK away from flammable materials.

Weight

125cc : 1.90 Ib (860g)

Same as

- Exposing BATTERY PACK at temperatures greater than 170 F for extended

250cc : 12.32 Ib (1.050g) periods of time(more than 2 hours) may cause damage to BATTERY PACK

and cause possible fire.

Thread size NPT 3/8" Same as

3. Warning

Dispensing Same as

1/2, 1, 2, 3, 6, 12 Months (6 different mode) Do not install lubricator in areas where the unit may be exposed to flames

Period

and or excessive heat.

Multi point Up to 8 points

These conditions may cause the BATTERY PACK to burst thereby putting

Single point

Models people in danger due to the presence of noxious fumes.

Lubri-Cup EM (125, 250cc Grease Lubricator) Main unit Service pack

Lubri-Cup EM-X (125, 250cc Grease Lubricator) 4. Product Warranty

Package Same as

4 units packed in 1 box Individually packed Product warranty is limited to original defects in material and workmanship.

1 case (2 boxes; 8 units) 1 case (20 units) Warranty does not cover collateral damage due to mishandling, abuse,

Before Use

incorrect charging and or any other inappropriate use of this product.

Thank you for purchasing the Lubri-Cup EM, EM-X the new and unique electro-mechanical, single-

point automatic grease dispenser from Chesterton. To ensure the safe operation and proper

installation of the Lubri-Cup EM, EM-X we strongly recommend that you read the following Technical information is subject to change without notice.

instructions carefully before use. If you require further information, please contact your local supplier.

LCD Display - Function Buttons Components Service Pack

Name Display Function Name Display Function

Dispensing

Select any of the six different dispensing rates available..

(1/2, 1, 2, 3, 6, 12 Months)

[125cc]

Indicates period of time the unit has been set for.

Period Set Note: The dispensing rate can be changed during operation.

The 125 / 250cc lubricator comes with a unique automatic

Day Till Indicates the # of days remaining until the units' Service "Locking system" to prevent any possible accidental 125cc Pouch

For Setting

Replacement pack must be replaced (days until lubricant expiry) Dispensing Period re-programming of the unit after it has been set. The EM, Spring

& EM-X unit automatically locks the keypad 30 seconds after it Sticker

Days after dispensing cycle completion (Expiry) To deactivate has been programmed, and will display a lock icon ( ) on

Days After St-XX indicates the number of days since the lube cycle has the LCD. You cannot reprogram the unit once the locking

Dispensing lock

been completed or the grease pouch has become empty. system has been activated. To unlock, simply press the Housing

Completion "St" denotes "Stop" "Mode/Lock" button on the unit's keypad for two seconds or

until the Lock icon disappears. You may re-program the unit

# of days on standby mode due to excessive backpressure once the locking system has been deactivated.

Ch-XX indicates the number of days since the unit has

Check Lube Line stopped due to excessive lube line backpressure.

(All functions will stop except TEST MODE to protect unit) Power ON/OFF Press this button for 2 seconds to turn unit on or off. Battery Pack

Test Indicates that the test mode is activated.

The test function is provided to make sure that the unit is 125cc Dust Cover

working properly prior to installation or after changing the Pouch

Indicates that the unit is in lock mode. The unit cannot be

Auto Locking service pack.

reprogrammed in this mode.

IMPORTANT: To activate the test mode, depress the test Battery pack

Battery Indicates low battery power

Test 125/250

TEST

button for 2 seconds. The word "test" will start blinking on the

LCD and the unit will begin to dispense grease during a

[250cc]

Backpressure Backpressure sensing capability function. 2minute cycle. To deactivate test mode, depress the test 250cc Pouch

Sensing Indicates to check bearing zerk and grease feed line button again. The unit will stop the testing cycle within 20

Capability To clear this icon, just press the "Test" Button for 2 seconds. seconds; otherwise it will continue testing for the remainder LCD Display Main Body

of the 2 minutes. If the unit does not operate in Test Mode, it

Empty grease level should be returned to your supplier for inspection. Reset Button

Replacement Sticker

Indicates that the lube cycle has been completed and that

Service Pack Use to reset the unit back to its original default setting if: Control panel

the grease pouch is empty. Select Button

Grease Volume - There exists an abnormal display on LCD screen.

125 / 250 Indicates grease pouch size (volume 125 / 250cc). - The unit malfunctions, or if the Power Button is not

Selection Reset

responding. Test Button

CAUTION! Pressing the reset button will eliminate all

Power Button

The Red LED will blink periodically when low battery power,

Singnal Lamp excessive backpressure, or low grease levels exist. previous settings and preprogrammed data in memory. i.e.

counter

Warning Battery Pack

- The enclosure does not comply with the requirements of resistance to light (ISO 4892). Nozzle Protector

- Explosion Hazard-Do not removes or replaces batteries unless power has been disconnected DO NOT EXPOSE IN SUNLIGHT DIRECTLY

or the area is known to be free of ignitable concentrations of flammable gases or vapors. - This product does not submit the shock test (EN 60068-2-27). 250cc Dust Cover

- This equipment is suitable for use in Class I, Division 2, Groups C and D Hazardous Locations AVOID MECHANICAL SHOCK OR DAMAGE TO PRODUCT

OR non-hazardous locations only. - DO NOT OPEN WHEN ENERGIZED.

SUBSTITUTION OF MOTOR AND REED SWITCH MAY IMPAIR SUITABILITY FOR DIVISION - DO NOT USE ANY OTHER TYPE OF BATTERY EXCEPT STANDARD BATTERY.

Lubri-Cup EM & EM-X (125/250cc Automatic Lubricator)

Installation & Service Pack Replacement TROUBLESHOOTING GUIDELINE

Lubri-Cup EM & EM-X

A. First Installation

Display Function Trouble Cause Remedy

1. Before installing the Lubri-Cup EM, EM-X the lubrication point (bearing and passage) should be manually lubricated using a LCD SCREEN DISPLAYS - Possible electrical malfunction of CPU or circuitry. - Utilize standard manufacturers battery

grease gun to ensure that the bearing has a clear passage. It is recommended that this procedure be conducted using either FAULT OR RED LIGHT - BATTERY PACK missing, incorrectly installed, or may faulty. - The BATTERY PACK must be replaced with each service pack relacement.

BLINKING OR BLANK - Old Battery pack was not replaced during service pack replacement.

the same or a compatible lubricant with what is contained in the grease pouch of the Lubri-Cup EM, EM-X. - Store BATTERY PACK in a cool, dry area to prevent damage.

SCREEN. - Battery leakage occurred.

If any doubts exist in regards to a clear lubrication flow, test the backpressure of the bearing with a grease gun connected to

a pressure gauge. Ensure that the break - off pressure is below 500 psi (approx. 35 kg-f/cm2, or 34.5 bar). It is always best to

keep the constant delivery pressure as low as possible. - BATTERY PACK missing, faulty or incorrectly installed. - The BATTERY PACK must be replaced with each changeover.

UNIT WON'T OPERATE

- Old BATTERY PACK not replaced during changeover - Ensure BATTERY PACK is correctly installed.

2. Remove the grease nipple. Check for hardened grease in bearing zerk.

If hardened grease exists, clean zerk before mounting the unit on bearing. - BATTERY PACK expired (Low Battery) - Replace BATTERY PACK

- An unusual storage condition may be encountered - Store BATTERY PACK in a cool and dry place prevent impact damage

LOW BATTERY (Temperature or Humidity) - Ensure operating environment meets requirements.

INDICATION - Damaged BATTERY PACK

3. Insert the BATTERY PACK into the battery compartment of the main unit. - Extreme environment

(Make sure that the battery is locked in place after insertion by turning the metal clip on top) (e.g. exceeds -15C ~ +60C : 5~140F)

- Confirm correct dispensing rate

- Check lube line and bearing history

- Over lubrication occurring - Determine cause and rectify.

BACKPRESSURE - Grease blockage

SENSING CAPABILITY - Excessive back pressure IMPORTANT :

4. Place the pointed open end of the grease pouch To clear I-con for the Backpressure sensing capability, press TEST

5. And turn top housing clockwise until you hear the - Extreme operating temperature

over the lubricators' top check valve. button for 2 seconds. If not clear I-con, then please contact local

top housing "click". (e.g. exceeds -15C ~ +60C : 5~140F)

suppliers.

- GREASE POUCH incorrectly fitted - Fit GREASE POUCH correctly

UNIT WON'T - GREASE POUCH empty - Replace GREASE POUCH and BATTERY PACK

DISPENSE GREASE - Loose spring or pressure plate Refit spring or pressure plate

6. Install an appropriate 3/8" NPT or BSP adaptor and make sure that the adaptor is well tightened to the unit. The 3/8" brass - Grease hardening due to cold temperature or high oil bleeding. - Use appropriate quality grease for operating environment

tip of the unit is vibration proof. In other words it ensures that the fitting will not snap off at the nose even under severe

vibration or shock load.

For installations that involve extreme vibration, excessive heat, or service location that is considered dangerous, use the

remote mounting bracket (clamping device) and 1/4" hose no longer than 10ft.

7. Turn the Lubri-Cup EM, EM-X unit ON by depressing the POWER button for 2 seconds. To confirm that the LCD is working,

make sure that the Red LED blinks once as soon as you press the "power" button. The unit is working as long as the LCD

Explosion Proof Certification

displays information.

Next, press the TEST button for 2 seconds. The unit will start to dispense grease. The unit will operate continuously in Purge Certification UL ATEX KTL Remark

mode and go through an entire cycle of (approximately 2 min). Rating ClassDivision 2 Groups - C, D EEx nL IIB T5 IP54 Ex nC IIB T5 IP54 -

To deactivate the TEST MODE FUNCTION, press the TEST button again. The unit will stop testing within the next 20 seconds.

Depress the MODE button to set the dispensing rate. Each time the MODE button is depressed, the dispensing rate changes D-C1 I Div 1/2 IIA IIA Propane

in ascending order Gas groups Typical Gas

D-C1 I Div 1/2 IIB IIB Ethylene

i.e. 1 2 3 6 12 H. Note: (H = Half month.)

If you are unable to program a setting and a lock icon is displayed, press the mode button for 2 seconds until the lock The skin temperature shall not exceed the minimum ignition

Maximum

icon disappears. Program your lubricator. The unit will automatically lock 30 seconds after you stop pressing any of temperature of the substances to be found in the hazardous location.

Surface T6(85) T5(100) T5(100)

the 3 programming buttons. The "T" code designations apply to motors and other types of

Temperature

electrical equipment subject to hazardous location classification.

Protection against dust; -IP5X

Dust penetration is not prevented altogether, but dust must not enter

8. Use attached label to note grease type, 9. Use Dust cover to keep the clean. in sufficient quantities to prevent the equipment from operating

Enclosure

installation and date of expiration of lube cycle. satisfactorily, or to impair safety.

protection - IP54 IP54

indices Protection against water spray; -IPX4

Water splashes on to the enclosure from any direction must not have

any harmful effects.

B. Change of Service Pack (Repeat above steps 3 - 9) Classification

CI I Div2 Zone2(gas) Ignitable concentrations not likely to exist under normal operations, or

of hazardous -

Display Function locations

CI I Zone2(gas) Zone22(dust) may exist for a short time only

1. Remove the pouch, then remove the BATTERY PACK from the battery compartment of the main unit. Certificate LCIE 07

E304815 2007-1167-Q1 -

number ATEX 6100X

1) It is highly recommended that you use a factory filled grease pouch.

(Warranty will be void if unit malfunctions due to a problem caused by a customer filled pouch)

2) BATTERY PACK Must Always be replaced along with pouch.

A.W. Chesterton Company

2. Use attached label to record grease type, 9. Use Dust cover to keep the clean.

installation, and date of expiration of lube cycle.

Global Solutions, Local Service.

Vous aimerez peut-être aussi

- M 75 90 115 - FourStroke - 2.1LDocument660 pagesM 75 90 115 - FourStroke - 2.1LAlex Diaz79% (19)

- H-D 2015 Touring Models Parts CatalogDocument539 pagesH-D 2015 Touring Models Parts CatalogGiulio Belmondo100% (1)

- 225/250 3.0 Litre Work: Electronic Fuel InjectionDocument719 pages225/250 3.0 Litre Work: Electronic Fuel InjectionMicka-PrestationsPas encore d'évaluation

- Service Manual E80 Excavator: S/N AETB11001 & Above S/N AET311001 & AboveDocument879 pagesService Manual E80 Excavator: S/N AETB11001 & Above S/N AET311001 & Abovepython78Pas encore d'évaluation

- XL24 SeriesDocument2 pagesXL24 Seriesmario2Pas encore d'évaluation

- Chapter 1 - Introduction To Employee Training and Development - 3Document27 pagesChapter 1 - Introduction To Employee Training and Development - 3Chaudry Adeel100% (1)

- Abc of UccDocument28 pagesAbc of UccCount-Daniel John Fogarty100% (4)

- 02whole PDFDocument313 pages02whole PDFAme Ra100% (1)

- Wabco GuideDocument16 pagesWabco GuideMohd FairusPas encore d'évaluation

- XL2410 Series Emergency Battery Systems: Sealed Lead Acid BatteriesDocument2 pagesXL2410 Series Emergency Battery Systems: Sealed Lead Acid BatteriesJudy LopezPas encore d'évaluation

- 14 Design of Bolted JointsDocument13 pages14 Design of Bolted JointsPRASAD32675% (4)

- Battery SpecificationDocument80 pagesBattery SpecificationMohd Khan100% (1)

- Kobelco Mark 6e Training ManualDocument8 pagesKobelco Mark 6e Training ManualMahmoud SaudyPas encore d'évaluation

- TECDCT-2145 Cisco FabricPathDocument156 pagesTECDCT-2145 Cisco FabricPathWeiboraoPas encore d'évaluation

- SUZUKI DF200 225 250 Service Man 2Document49 pagesSUZUKI DF200 225 250 Service Man 2Candido IsazaPas encore d'évaluation

- Digital Filter DesignDocument102 pagesDigital Filter Designjaun danielPas encore d'évaluation

- XL246A Emergency Battery Systems: Sealed Lead Acid BatteriesDocument2 pagesXL246A Emergency Battery Systems: Sealed Lead Acid BatteriesFernando CarmonaPas encore d'évaluation

- CBSU SAE PaperDocument8 pagesCBSU SAE PaperSanjeev MahajanPas encore d'évaluation

- Smile Bat 10.3 Data Sheet PDFDocument2 pagesSmile Bat 10.3 Data Sheet PDFFaridoon AhmedPas encore d'évaluation

- Willard GuideDocument46 pagesWillard GuideBronwynne OctoberPas encore d'évaluation

- LK-1-Eko SaputroDocument7 pagesLK-1-Eko SaputroEko SaputroPas encore d'évaluation

- MODEL: TM180, TM181 AC: 100 - 240VAC 50-60Hz DC: 60W 5A at 12V Thermally AdjustedDocument44 pagesMODEL: TM180, TM181 AC: 100 - 240VAC 50-60Hz DC: 60W 5A at 12V Thermally AdjustedtracePas encore d'évaluation

- LK 1 - Perawatan BusiDocument3 pagesLK 1 - Perawatan BusiA Firdaus, S.TPas encore d'évaluation

- Securaplane Vrla Emergency Battery Certification List Powered by CyclonDocument2 pagesSecuraplane Vrla Emergency Battery Certification List Powered by CyclonJudy LopezPas encore d'évaluation

- Fusion Magic Fuel Usage and Contributions (Version 1)Document2 pagesFusion Magic Fuel Usage and Contributions (Version 1)myinves00Pas encore d'évaluation

- Battery TesterDocument1 pageBattery TesterDaniel Trujillo RiveraPas encore d'évaluation

- Bike Katalog Englisch PDFDocument257 pagesBike Katalog Englisch PDFAnonymous Wyb8Y1Pas encore d'évaluation

- Yamaha CLP 635 - ManuelDocument144 pagesYamaha CLP 635 - ManuelPascalPas encore d'évaluation

- LK 1 - A Firdaus - Perawatan BusiDocument4 pagesLK 1 - A Firdaus - Perawatan BusiA Firdaus, S.TPas encore d'évaluation

- Supplemental Inflatable Restraints (Sir)Document7 pagesSupplemental Inflatable Restraints (Sir)David Wise-MannPas encore d'évaluation

- Product Flyers Pulsarlube EX EnglishDocument2 pagesProduct Flyers Pulsarlube EX EnglishJhon Antonio Quiliche CanoPas encore d'évaluation

- Manual Eletrico Apc Back Ups 1200Document4 pagesManual Eletrico Apc Back Ups 1200walter souza0% (1)

- COVER TYPE FIXTURE (15w)Document2 pagesCOVER TYPE FIXTURE (15w)FrancisPas encore d'évaluation

- Owner's Manual & Safety Instructions: InverterDocument28 pagesOwner's Manual & Safety Instructions: InverterbowcoastiePas encore d'évaluation

- Sta-Rite ManualDocument40 pagesSta-Rite ManualcarlosPas encore d'évaluation

- Agus Rahmat Hidayat - Tugas KP2Document5 pagesAgus Rahmat Hidayat - Tugas KP2Agus Rahmat HidayatPas encore d'évaluation

- UPS Battery SizingDocument8 pagesUPS Battery SizingAhmed FaragPas encore d'évaluation

- ACCU Recharge MAXI Charger: European Region Product DetailDocument1 pageACCU Recharge MAXI Charger: European Region Product DetailgibarboudisPas encore d'évaluation

- Downloaded From Manuals Search EngineDocument28 pagesDownloaded From Manuals Search EngineJaime Lozano MaciasPas encore d'évaluation

- TUF4D1: Hard Case Lantern™ SpecificationsDocument1 pageTUF4D1: Hard Case Lantern™ SpecificationsdiscoverthedarkPas encore d'évaluation

- Single RelaysDocument5 pagesSingle RelaysNelson ValenciaPas encore d'évaluation

- Microtek Ups 600va 30kvaDocument14 pagesMicrotek Ups 600va 30kvaHarpinder SinghPas encore d'évaluation

- Service Manual: HammondDocument33 pagesService Manual: HammondPrincePas encore d'évaluation

- High Rate Series: CCB 12HD-475Document1 pageHigh Rate Series: CCB 12HD-475orunmila123Pas encore d'évaluation

- Liulce00 01Document16 pagesLiulce00 01John Fredy Palacio G.Pas encore d'évaluation

- CompresorDocument68 pagesCompresorgabyPas encore d'évaluation

- 758 sc1309Document23 pages758 sc1309Samsung BarryPas encore d'évaluation

- Cub Cadet Trimmer Model CC 2000 Operators ManualDocument20 pagesCub Cadet Trimmer Model CC 2000 Operators Manualelvisandmick100% (1)

- Tipe / Type Vega R New 2008 Nomor Identifikasi Kendaraan / MH34D70028j903504 No. Mesin / Engine No. 4D7.903528 Nomor Plat / License No. KT 2701 KG 60Document7 pagesTipe / Type Vega R New 2008 Nomor Identifikasi Kendaraan / MH34D70028j903504 No. Mesin / Engine No. 4D7.903528 Nomor Plat / License No. KT 2701 KG 60DidinMuhtadinPas encore d'évaluation

- 1994 Chevrolet 1500 PDFDocument404 pages1994 Chevrolet 1500 PDFOmerPas encore d'évaluation

- Deka SpecificationsDocument2 pagesDeka SpecificationsMohd NB MultiSolarPas encore d'évaluation

- Repair Manual: ChassisDocument29 pagesRepair Manual: ChassisJerzy LisowskiPas encore d'évaluation

- Contoh/Example Tipe / Type Yamaha N Max Nomor Identifikasi Kendaraan / T 5035 RV No. Mesin / Engine No. - Nomor Plat / License No. T 5035 RV 11033 KMDocument5 pagesContoh/Example Tipe / Type Yamaha N Max Nomor Identifikasi Kendaraan / T 5035 RV No. Mesin / Engine No. - Nomor Plat / License No. T 5035 RV 11033 KMAgus Rahmat HidayatPas encore d'évaluation

- 2010 07 Teach Me Time ManualDocument8 pages2010 07 Teach Me Time ManualBrian C. HagertyPas encore d'évaluation

- A1289QSGDocument1 pageA1289QSGCesar QPas encore d'évaluation

- Alphacell Smu-F: Valve Regulated Lead Acid BatteryDocument20 pagesAlphacell Smu-F: Valve Regulated Lead Acid BatteryMatthew TowerPas encore d'évaluation

- Catalogue CarAccProd enDocument12 pagesCatalogue CarAccProd enCristiana LaviniaPas encore d'évaluation

- clp430 PDFDocument96 pagesclp430 PDFKezia Marissa WetsemaPas encore d'évaluation

- Axial Wraith Poison Spyder Jeep Wrangler ManualDocument52 pagesAxial Wraith Poison Spyder Jeep Wrangler Manualccamargo_engcivilPas encore d'évaluation

- Delphi Metri Pack SeriesDocument106 pagesDelphi Metri Pack Seriescontrax8Pas encore d'évaluation

- Service Manual: 19990220-99800 Hamamatsu, JapanDocument51 pagesService Manual: 19990220-99800 Hamamatsu, JapanSantiago JacoboPas encore d'évaluation

- InvertecV205 PDFDocument109 pagesInvertecV205 PDFyako1511Pas encore d'évaluation

- Solarni PovratakDocument42 pagesSolarni Povratakmax2smith-7Pas encore d'évaluation

- S8254a Battery ProtectionDocument29 pagesS8254a Battery ProtectionPierDonneePas encore d'évaluation

- Bateria CCB 12HD-37Document1 pageBateria CCB 12HD-37Hector CardosPas encore d'évaluation

- High Bay Food Processing Fixture For Surface or Pendant MountingDocument1 pageHigh Bay Food Processing Fixture For Surface or Pendant Mountingapi-15065309100% (2)

- Computer 1Document8 pagesComputer 1marce1909Pas encore d'évaluation

- Name: Amir Bin Rossaifuddin Id: 2016307153 Group: Emd2M2ADocument2 pagesName: Amir Bin Rossaifuddin Id: 2016307153 Group: Emd2M2AamirossaifuddinPas encore d'évaluation

- Pellets Burner 6 00 Manual EnglishDocument22 pagesPellets Burner 6 00 Manual EnglishTasos KachpanisPas encore d'évaluation

- Soichiro HondaDocument5 pagesSoichiro HondaVeronika YsPas encore d'évaluation

- Information: Reading Images - The Grammar of Visual DesignDocument5 pagesInformation: Reading Images - The Grammar of Visual DesignAndang Prasetya Adiwibawa BernardusPas encore d'évaluation

- Leadership and Management 2003Document46 pagesLeadership and Management 2003Ciella Dela Cruz100% (1)

- Datapipe Fact SheetDocument1 pageDatapipe Fact SheetDeneme Deneme AsPas encore d'évaluation

- Brochure Otis Gen360 enDocument32 pagesBrochure Otis Gen360 enshimanshkPas encore d'évaluation

- Y y Y Y Y: Design of Machinery 86Document1 pageY y Y Y Y: Design of Machinery 86Star GlacierPas encore d'évaluation

- Hfe Panasonic Sa-Akx50 PH PN Service enDocument132 pagesHfe Panasonic Sa-Akx50 PH PN Service enJohntec nuñezPas encore d'évaluation

- Ma 500TRDocument3 pagesMa 500TRBoban ButrićPas encore d'évaluation

- BH MobileDocument6 pagesBH MobileleostojcicPas encore d'évaluation

- 연대경제대학원 석사학위논문 학술정보원등록 최종본Document121 pages연대경제대학원 석사학위논문 학술정보원등록 최종본0514bachPas encore d'évaluation

- Technical Data: An Innovative & Cutting-Edge Digital Radiography SystemDocument12 pagesTechnical Data: An Innovative & Cutting-Edge Digital Radiography SystemJacques GamelinPas encore d'évaluation

- Specialty Lubricants Molykote®: 44MA GreaseDocument2 pagesSpecialty Lubricants Molykote®: 44MA GreasefadhlidzilPas encore d'évaluation

- B-Trees and B+-Trees: Jay Yim CS 157B Dr. LeeDocument34 pagesB-Trees and B+-Trees: Jay Yim CS 157B Dr. LeemaskplyPas encore d'évaluation

- Aggregate Planning and Master Scheduling: Mcgraw-Hill/IrwinDocument15 pagesAggregate Planning and Master Scheduling: Mcgraw-Hill/IrwinKushal BhatiaPas encore d'évaluation

- Basic Ship Design PhasesDocument1 pageBasic Ship Design PhasesJhon GreigPas encore d'évaluation

- Anothr System Definition FacilityDocument90 pagesAnothr System Definition FacilityllllllluisPas encore d'évaluation

- Advanced Power ElectronicsDocument4 pagesAdvanced Power ElectronicsLinkan PriyadarsiniPas encore d'évaluation

- Project 1 - Nimisha AgrawalDocument13 pagesProject 1 - Nimisha AgrawalNimisha AgrawalPas encore d'évaluation

- 1St Flr. Reflected Ceiling Plan 2Nd Flr. Reflected Ceiling PlanDocument1 page1St Flr. Reflected Ceiling Plan 2Nd Flr. Reflected Ceiling PlanMac KYPas encore d'évaluation

- Overheat Freeze Mechanisms of Solar CollectorsDocument5 pagesOverheat Freeze Mechanisms of Solar CollectorsJuli HasanajPas encore d'évaluation