Académique Documents

Professionnel Documents

Culture Documents

BE Mechanical Syllabus Final

Transféré par

sabnisnileshCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BE Mechanical Syllabus Final

Transféré par

sabnisnileshDroits d'auteur :

Formats disponibles

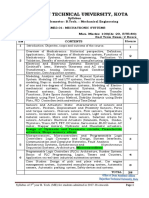

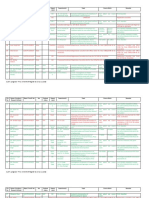

Shivaji University Kolhapur

B. E. (MECHANICAL) Semester- VIII

MECHATRONICS

Teaching Scheme: Examination Scheme:

Lecturers: 3 Hrs/ Week Theory: 100 Marks

Practicals: 2 Hrs/ Week Term work: 25 Marks

Oral Exam: 25 marks

SCOPE OF THE SUBJECT

Mechatronics emphasizes the necessity of integration and interaction among different branches of

engineering. Mechatronics philosophy challenges traditional engineering thinking and practices.

Mechatronics implementation involves a team activity and crossing boundaries between conventional

engineering disciplines.

PREREQUISITES

Knowledge of Mechanical, Electronic, IHP and measurement systems.

COURSE OBJECTIVES

1. To produce competent Mechanical engineers with comprehensive knowledge of Mechatronics to

enable them to apply the relevant knowledge and technologies for the design and realization of

innovative systems and products.

2. To supply qualified personnel to meet the requirement of specialist in Mechatronics.

3. To prepare Mechanical Engineering students for advanced graduate studies in Mechatronics,

Manufacturing engineering and related field.

LEARNING OBJECTIVES

1. Understand the importance of integration of Mechanical, Electronics and Control in the design of

Mechatronics system.

2. Understand key elements of sensors and transducers and interfacing the same with problem under

consideration through PLC.

UNIT 1: Introduction (8)

Introduction to Mechatronics, Mechatronics systems, Measurement systems, multi discipline scenario

Transducers & Sensors:-Position Sensors: Limit switch, photoelectric switches, proximity sensors,

pneumatic limit valves and backpressure sensors, pressure switches, resolvers, incremental & absolute

encoders, decoders & relays. Displacement: Potentiometer sensors, LVDT, capacitive displacement

sensors. Velocity sensors: Tachogenerator, use of encoders, introduction to VFD.

UNIT 2: Signal Conditioning (8)

Signal conditioning process, Operational amplifier (inverting amplifier, non-inverting amplifier,

summing, integrating amplifier, differtianting amplifier, logarithmic amplifier), protection, filtering, data

acquisition, multiplexer, analog to digital converter (ADC), digital to analog converter (DAC). Oscillators

to generator sinusoidal, square, triangular and impulse waveforms, 555 timer, sample and hold,

demultiplexing. Interfacing input output ports, serial and parallel interfacing requirements, buffers,

handshaking, polling and interrupts.

UNIT 3: Digital circuits, Microprocessor and Microcontroller: (6)

Digital logic, number systems, logic gates, Boolean algebra, application of logic gates, sequential logic,

flip flop, D flip flop, JK flip flop, Master slave flip flop.

Microcontroller: Comparison between microprocessor and micro controller, organization of a

microcontroller system, architecture of MCS 51 /ATMEL /PIC controller, pin diagram of 8051,

addressing modes, instruction types and set, Selection and Applications of Microcontroller

UNIT 4: Programmable Logic Controllers (PLC) (6)

Introduction, definition, PLC system and components of PLC input output module, PLC advantages and

disadvantages. Ladder diagram & PLC programming fundamentals:

Basic components and other symbols, fundamentals of ladder diagram, machine control terminology,

update solve ladder update, physical components Vs. program components, light control example,

internal relays, disagreement circuit, majority circuit, oscillator, holding (sealed or latches) contacts,

always ON always OFF contacts, Nesting of ladders.

UNIT 5: PLC programming: (6)

PLC input instructions, outputs, coils, indicators, operational procedures, contact and coil input output,

programming example, fail safe circuits, simple industrial applications. PLC Functions

PLC timer functions Introduction, timer functions, industrial applications, industrial process

Timing applications, PLC control functions PLC counters and its industrial applications, Introduction to

SCADA and MEMS.

UNIT 6: Mechatronics systems: (6)

Traditional Vs Mechatronic Design, Case studies of Mechatronic systems designs, like piece counting

system, pick and place manipulator, simple assembly task involving a few parts, part loading / unloading

system, automatic tool and pallet changers etc. Fault finding and troubleshooting.

Term Work

1. Trial on sensors (minimum four)

2. Assignment on Microprocessor and Microcontroller.

3. PLC programming on Industrial Applications based on Timers, Counters, internal relays

(Minimum 4 applications)

4. Fabrication of Simple Mechatronics working project by a group of 4/5 students using hardware

and suitable software.

5. Assignment on PLC Data handling and Fault finding

6. Assignment on SCADA and MEMS

7. Industrial visit to study Mechatronic system application & submission of visit report.

Note: Mechatronics Laboratory is expected to have a simple 8 input 8 output PLC

Reference Books

1. Mechatronics W. Bolton, Pearson education

2. Mechatronics Mahalik, TATA McGraw Hill

3. Microprocessor 8085 Gaokar

4. Mechatronics Appu Kuttam, Oxford publications

5. Automated Manufacturing systems, S. Brain Morris, McGraw Hill

6. Introduction to PLC programming, NIIT, P

7. Programmable logical controller, Hackworth % Hackworth, Pearson Education

8. Programmable logical controller, Reis Webb, Prentice Hall

9 Mechatronics and Microprocessor by Ramchandran Willey India

10 Mechatronics: Integrated Mechanical Electronic System by Ramchandran Willey India

11. Programmable logical controller,3e Gary Dunning Cengage Learning

12. Mechatronics Source Book by N C Braga Cengage Learning

13. SCADA, Stuart A. Boyer, ISA Publication.

14. MEMS & Microsystems, HSU Tairan, TMH publication

Vous aimerez peut-être aussi

- GTU MECHATRONICS SYLLABUSDocument2 pagesGTU MECHATRONICS SYLLABUSpmagrawalPas encore d'évaluation

- 1.unit 1 MechatronicsDocument63 pages1.unit 1 MechatronicsSolcastic SoulPas encore d'évaluation

- ME8791 SyllabusDocument2 pagesME8791 SyllabusAnonymous mRBbdopMKfPas encore d'évaluation

- Industrial Instrumentation and AutomationDocument3 pagesIndustrial Instrumentation and AutomationArya RahulPas encore d'évaluation

- Mechatronics ME5007Document5 pagesMechatronics ME5007Kalum ChandraPas encore d'évaluation

- ME8791 SyllabusDocument2 pagesME8791 SyllabusMr.G.Chandrasekar mechanicalstaffPas encore d'évaluation

- Course Objectives:: Me3254: MechatronicsDocument7 pagesCourse Objectives:: Me3254: Mechatronicsgiriaj kokarePas encore d'évaluation

- Industrial AutomationDocument2 pagesIndustrial AutomationmaheshPas encore d'évaluation

- Be Electrical Engg 2008 SyllabusDocument40 pagesBe Electrical Engg 2008 SyllabusGaurav sPas encore d'évaluation

- Pias 2020-18earc302Document23 pagesPias 2020-18earc302Deepak KumarPas encore d'évaluation

- Control Systems: Government Polytechnic Channapatna Department of Mechanical EngineeringDocument39 pagesControl Systems: Government Polytechnic Channapatna Department of Mechanical EngineeringJunaid Ulla KhasimPas encore d'évaluation

- Mechatronics & AutomationDocument9 pagesMechatronics & AutomationAnandababuPas encore d'évaluation

- CDM ME 407 Mechatronics - 2021Document15 pagesCDM ME 407 Mechatronics - 2021Tony K PaulPas encore d'évaluation

- HIT PLC Programming Course Covers Control, NetworksDocument7 pagesHIT PLC Programming Course Covers Control, NetworksTanaka dzapasi100% (1)

- Electro-Hydraulic Systems. Development of Circuits For Industrial,-/automationDocument3 pagesElectro-Hydraulic Systems. Development of Circuits For Industrial,-/automationAmeya GanpatyePas encore d'évaluation

- PLCs and AutomationDocument2 pagesPLCs and AutomationKhaja JamalPas encore d'évaluation

- 29 MT242 ElectroHydraulic and ElectroPneumatic SystemsDocument2 pages29 MT242 ElectroHydraulic and ElectroPneumatic SystemsLeonidas PerezPas encore d'évaluation

- MechatronicsDocument8 pagesMechatronicsJeslet JoyPas encore d'évaluation

- Mechatronics Systems DesignDocument1 pageMechatronics Systems DesignKannan MuthusamyPas encore d'évaluation

- PLC and SCADA ApplicationsDocument4 pagesPLC and SCADA ApplicationsShreemanti RokadePas encore d'évaluation

- ME407 MechatronicsDocument2 pagesME407 MechatronicsVivek SivaramanPas encore d'évaluation

- ME401 Design of Machine Elements - I.image - MarkedDocument2 pagesME401 Design of Machine Elements - I.image - MarkedShino BabuPas encore d'évaluation

- VI TH Sem MechanicalDocument15 pagesVI TH Sem MechanicalNabeel KhanPas encore d'évaluation

- Vidyavardhaka College Mechatronics Microprocessor Class NotesDocument3 pagesVidyavardhaka College Mechatronics Microprocessor Class NotesAkash AkuPas encore d'évaluation

- Form 1 Course OutlineDocument5 pagesForm 1 Course OutlineMuhammad SumeetPas encore d'évaluation

- ME8791 Mechatronics 01 - by WWW - Learnengineering.inDocument125 pagesME8791 Mechatronics 01 - by WWW - Learnengineering.inLAKKANABOINA LAKSHMANARAOPas encore d'évaluation

- 2171103Document4 pages2171103narayanPas encore d'évaluation

- Unit 1Document184 pagesUnit 1KANISHKAR Hem SankarPas encore d'évaluation

- Industrial AutomationDocument4 pagesIndustrial AutomationmeghasugauliPas encore d'évaluation

- Module Information Module Title Electric Drives and Control Module Code MMD2511Document4 pagesModule Information Module Title Electric Drives and Control Module Code MMD2511Ashley KaPas encore d'évaluation

- MEE1045 - MECHATRONICS-SYSTEMS-DESIGN - EPJ - 1.0 - 49 - MEE1045 Mechatronics Systems Design PDFDocument2 pagesMEE1045 - MECHATRONICS-SYSTEMS-DESIGN - EPJ - 1.0 - 49 - MEE1045 Mechatronics Systems Design PDFSathish SatPas encore d'évaluation

- Project On PLC For Color Mixer ConveyorDocument37 pagesProject On PLC For Color Mixer ConveyorJunaid Ulla KhasimPas encore d'évaluation

- Notes MechaDocument41 pagesNotes MechaashPas encore d'évaluation

- TECP3851-Microprocessor and Programmable Logic ControllersDocument1 pageTECP3851-Microprocessor and Programmable Logic ControllersStevePas encore d'évaluation

- Rajasthan Technical University, Kota: Syllabus 3 Year - V Semester: B.Tech.: Mechanical EngineeringDocument1 pageRajasthan Technical University, Kota: Syllabus 3 Year - V Semester: B.Tech.: Mechanical Engineeringsharad pareekPas encore d'évaluation

- MechatronicsDocument59 pagesMechatronicslki06343Pas encore d'évaluation

- Bangalore Universty: University Visvesvaraya College of EngineeringDocument8 pagesBangalore Universty: University Visvesvaraya College of Engineeringsaurav bsPas encore d'évaluation

- AAI SyllabusDocument6 pagesAAI SyllabusKrishna DwivediPas encore d'évaluation

- Lec1 PLCDocument67 pagesLec1 PLCmayarm802Pas encore d'évaluation

- Engineering Mathematics - Iv CODE: 10 MAT 41 IA Marks: 25 Hrs/Week: 04 Exam HRS: 03 Total HRS: 52 Exam Marks:100 Part-A Unit-I: Numerical Methods - 1Document14 pagesEngineering Mathematics - Iv CODE: 10 MAT 41 IA Marks: 25 Hrs/Week: 04 Exam HRS: 03 Total HRS: 52 Exam Marks:100 Part-A Unit-I: Numerical Methods - 1HmmTell TellPas encore d'évaluation

- IPS Academy Offers Minor in Robotics EngineeringDocument9 pagesIPS Academy Offers Minor in Robotics EngineeringajayPas encore d'évaluation

- Course Title: Industrial Automation & Mechatronics Course Code: 6025 Course Category: E Periods/Week: 5 Periods/Semester: 75 Credits: 5Document6 pagesCourse Title: Industrial Automation & Mechatronics Course Code: 6025 Course Category: E Periods/Week: 5 Periods/Semester: 75 Credits: 5VaisakVenugopalPas encore d'évaluation

- MECHATRONICS LABORATORY MODULE 1Document104 pagesMECHATRONICS LABORATORY MODULE 1Nandha KumarPas encore d'évaluation

- MT221 Control Engineering Course OverviewDocument2 pagesMT221 Control Engineering Course OverviewHanover PedroPas encore d'évaluation

- 259 - Lecturer NotvfvvervrevDocument81 pages259 - Lecturer NotvfvvervrevBijay KumarPas encore d'évaluation

- MECHATRONICS Notes PDFDocument69 pagesMECHATRONICS Notes PDFsivakrishna nadakuduru100% (1)

- 1 Introduction 10 Jul 2018 - Reference Material I - Day 1Document11 pages1 Introduction 10 Jul 2018 - Reference Material I - Day 1Adarsh RajPas encore d'évaluation

- Embedded System SyllabusDocument3 pagesEmbedded System SyllabusVishnu PradeepPas encore d'évaluation

- B.E. 6th Sem MechatronicsDocument3 pagesB.E. 6th Sem MechatronicsSantosh AlonePas encore d'évaluation

- Study & Evaluation Scheme Three Year Diploma Course in Instrumentation and Control Engineering (2014 Scheme) Semester - VDocument15 pagesStudy & Evaluation Scheme Three Year Diploma Course in Instrumentation and Control Engineering (2014 Scheme) Semester - VVarun RanaPas encore d'évaluation

- Third Year Sem A Sem B UpdatedDocument40 pagesThird Year Sem A Sem B UpdatedArpitPas encore d'évaluation

- ME4447-ME6405 Course OutlineDocument13 pagesME4447-ME6405 Course OutlineAnonymous qTKCWlxPas encore d'évaluation

- Instrumentation and ControlDocument2 pagesInstrumentation and ControlKrista JacksonPas encore d'évaluation

- B Tech (EE) SemDocument31 pagesB Tech (EE) SemUtkarshPas encore d'évaluation

- 30 MN423 Instrumentation Measurement and ControlDocument2 pages30 MN423 Instrumentation Measurement and ControlLeonidas PerezPas encore d'évaluation

- Saya Suka AwakDocument6 pagesSaya Suka AwakNazif JaafarPas encore d'évaluation

- Mechatronics Notes PDFDocument188 pagesMechatronics Notes PDFharish100% (1)

- ME 475 Mechatronics: Semester: July 2015Document22 pagesME 475 Mechatronics: Semester: July 2015ফারহান আহমেদ আবীরPas encore d'évaluation

- New Trends in Observer-Based Control: An Introduction to Design Approaches and Engineering ApplicationsD'EverandNew Trends in Observer-Based Control: An Introduction to Design Approaches and Engineering ApplicationsOlfa BoubakerPas encore d'évaluation

- Practical Control of Electric Machines: Model-Based Design and SimulationD'EverandPractical Control of Electric Machines: Model-Based Design and SimulationPas encore d'évaluation

- Potential FlowDocument3 pagesPotential FlowsabnisnileshPas encore d'évaluation

- Flow Over A Circular CylinderDocument19 pagesFlow Over A Circular CylindersabnisnileshPas encore d'évaluation

- National Board of Accreditation: Pro-Forma For Pre-Qualifiers TIER-I InstitutionsDocument9 pagesNational Board of Accreditation: Pro-Forma For Pre-Qualifiers TIER-I InstitutionssabnisnileshPas encore d'évaluation

- Environment and Sustainability (OE4BW) - 5) Enrollment Certificate 3905Document1 pageEnvironment and Sustainability (OE4BW) - 5) Enrollment Certificate 3905sabnisnileshPas encore d'évaluation

- What Is The Lowdown On Faulty Plane Engines?: Aditya AnandDocument3 pagesWhat Is The Lowdown On Faulty Plane Engines?: Aditya AnandsabnisnileshPas encore d'évaluation

- Certificate For Completion of Latex TrainingDocument1 pageCertificate For Completion of Latex TrainingsabnisnileshPas encore d'évaluation

- PDocument13 pagesPsabnisnileshPas encore d'évaluation

- National Board of Accreditation: Pro-Forma For Pre-Qualifiers TIER-I InstitutionsDocument9 pagesNational Board of Accreditation: Pro-Forma For Pre-Qualifiers TIER-I InstitutionssabnisnileshPas encore d'évaluation

- Zade Abhilash Mallikarjun: Fluid Mechanics-A Successful Enrollment To The CourseDocument1 pageZade Abhilash Mallikarjun: Fluid Mechanics-A Successful Enrollment To The CoursesabnisnileshPas encore d'évaluation

- Certificate For Completion of Latex TrainingDocument1 pageCertificate For Completion of Latex TrainingsabnisnileshPas encore d'évaluation

- 02.automated Assembly SystemsDocument27 pages02.automated Assembly SystemssabnisnileshPas encore d'évaluation

- FM LabDocument21 pagesFM LabsabnisnileshPas encore d'évaluation

- 51 Types of DOSADocument51 pages51 Types of DOSAGulnaz Hasmani100% (7)

- Introduction To Ho'OponoponoDocument2 pagesIntroduction To Ho'OponoponosabnisnileshPas encore d'évaluation

- National Conference on Interdisciplinary Trends in EngineeringDocument45 pagesNational Conference on Interdisciplinary Trends in EngineeringsabnisnileshPas encore d'évaluation

- Jean Piaget's Cognitive Theories of DevelopmentDocument44 pagesJean Piaget's Cognitive Theories of DevelopmentDominic RiveraPas encore d'évaluation

- Math Patterns: Determining Missing Terms in Repeating SequencesDocument5 pagesMath Patterns: Determining Missing Terms in Repeating SequencesFranchescaLoisa Fuga100% (1)

- Media LiteracyDocument16 pagesMedia LiteracyRLM100% (2)

- Las Week1 - Math5-Q3Document3 pagesLas Week1 - Math5-Q3Sonny Matias100% (2)

- 5E Lesson Plan Template: TeacherDocument6 pages5E Lesson Plan Template: Teacherapi-515949514Pas encore d'évaluation

- Guidelines For The USC Vol CorpsDocument3 pagesGuidelines For The USC Vol CorpsAngeli GuadalupePas encore d'évaluation

- Resume of Sahed AhamedDocument2 pagesResume of Sahed AhamedSahed AhamedPas encore d'évaluation

- Frame CorrectionDocument32 pagesFrame CorrectionsahayaPas encore d'évaluation

- Moma Catalogue - Tadao AndoDocument329 pagesMoma Catalogue - Tadao AndodinaPas encore d'évaluation

- Keep It Local Jan 2013Document32 pagesKeep It Local Jan 2013Talkabout PublishingPas encore d'évaluation

- A Proficiency Oriented Approach To Listening - Omagio, AliceDocument14 pagesA Proficiency Oriented Approach To Listening - Omagio, AliceEmilse IñigoPas encore d'évaluation

- Pack Your Bags: Activity TypeDocument3 pagesPack Your Bags: Activity TypeBurak AkhanPas encore d'évaluation

- Solar Energy Course on Fundamentals & ApplicationsDocument1 pageSolar Energy Course on Fundamentals & ApplicationsPradeep NairPas encore d'évaluation

- Frameworks For Technological IntegrationDocument9 pagesFrameworks For Technological IntegrationInjang MatinikPas encore d'évaluation

- Coach Fundamentals CertDocument4 pagesCoach Fundamentals CertCarmen MoraruPas encore d'évaluation

- Cognitive and Metacognitive ProcessesDocument45 pagesCognitive and Metacognitive ProcessesjhenPas encore d'évaluation

- ANA StandardsDocument1 pageANA Standardsointeriano100% (1)

- Resume of MD - Rayhanur Rahman Khan: ObjectiveDocument3 pagesResume of MD - Rayhanur Rahman Khan: ObjectiveRayhanPas encore d'évaluation

- Ph.D. Enrolment Register As On 22.11.2016Document35 pagesPh.D. Enrolment Register As On 22.11.2016ragvshahPas encore d'évaluation

- Grade 6 Food Preservation Weekly LessonDocument67 pagesGrade 6 Food Preservation Weekly Lessonchona redillasPas encore d'évaluation

- 0,,BBA 305, Business Values and EthicsDocument2 pages0,,BBA 305, Business Values and EthicsKelvin mwaiPas encore d'évaluation

- Tuitionfees 2 NdtermDocument3 pagesTuitionfees 2 NdtermBhaskhar AnnaswamyPas encore d'évaluation

- English: Cambridge AssessmentDocument23 pagesEnglish: Cambridge AssessmentDiegoPas encore d'évaluation

- Start Up Guide - How To Become A Truck Dispatcher eDocument12 pagesStart Up Guide - How To Become A Truck Dispatcher eDragan LovricPas encore d'évaluation

- Unpacking and Combining The Most Essential Learning CompetenciesDocument17 pagesUnpacking and Combining The Most Essential Learning CompetenciesJulie Ann RiveraPas encore d'évaluation

- Micro TeachingDocument14 pagesMicro TeachingChanlin ChackoPas encore d'évaluation

- EQ2410 (2E1436) Advanced Digital CommunicationsDocument11 pagesEQ2410 (2E1436) Advanced Digital CommunicationsdwirelesPas encore d'évaluation

- IntIntellectual Property Rightsellectual Property RightsDocument3 pagesIntIntellectual Property Rightsellectual Property RightsJosephine TorresPas encore d'évaluation

- La Comunicación Médico - PacienteDocument8 pagesLa Comunicación Médico - PacienteHugo SanchezPas encore d'évaluation

- 44th Biennial Convention Program PDFDocument180 pages44th Biennial Convention Program PDFEnrique TrvjilloPas encore d'évaluation