Académique Documents

Professionnel Documents

Culture Documents

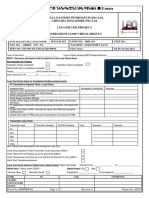

PC-J-95 Instrument Loop Check (Analogue Inputs)

Transféré par

Memyhu Mahmudah0 évaluation0% ont trouvé ce document utile (0 vote)

89 vues1 page123

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce document123

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

89 vues1 pagePC-J-95 Instrument Loop Check (Analogue Inputs)

Transféré par

Memyhu Mahmudah123

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

PC Inspection Test & Record

PC-J-95 Instrument Loop Check (Analogue Inputs)

Tag No. :

Subsystem :

Item Description OK N/A PL Comments

1. PRE-POWERING UP CHECKS

1.01 Check that all loop components on the loop diagram are calibrated ie: calibration certificates

included in loop package.

1.02 Check that the process root valve is isolated and tagged.

1.03 Check that process element is correct.

1.04 Carry out visual check for damage.

1.05 Ensure Pre-commissioning Work package contains sufficient information to proceed with the

Loop Test.

1.06 Ensure all outputs indicated on C and E's are Inhibited and logged in the Inhibit and Jumper

Register.

1.07 Check with System Responsible Comm Engineer that associated equipment is ready for

testing.

1.08 If packaged device (serial connection) ensure that system interface PC-I-10 has been

completed.

2. RECORD DETAILS and PARAMETERS

2.01 Confirm and Record Signal Type.

2.02 Instrument Range Min / Max.

2.03 Instrument Span Min / Max.

2.04 Engineering Units.

2.05 Close knife terminals and verify that loop is healthy (not in fault condition).

2.06 Verify engineering data on top of PCL and datasheet. Note: if any of above data is not in

accordance with the design, an Engineering Query is to be raised to clarify the discrepancy.

3. LOOP CHECK (ANALOGUE INPUT)

3.01 Carry out loop test I.A.W approved Procedure. Record Procedure Number.

3.02 Ensure test equipment is calibrated. Record details below.

4. LOOP CHECK (ANALOGUE INPUT RISING)

4.01 0% -Record Input Value:______Record Output ______ mA.

4.02 25% -Record Input Value:______Record Output ______ mA.

4.03 50% -Record Input Value:______Record Output ______ mA.

4.04 75% -Record Input Value:______Record Output ______ mA.

4.05 100% -Record Input Value:______Record Output ______ mA.

5. LOOP CHECK (ANALOGUE INPUT FALLING)

5.01 75% -Record Input Value:______Record Output ______ mA.

5.02 50% -Record Input Value:______Record Output ______ mA.

5.03 25% -Record Input Value:______Record Output ______ mA.

5.04 0% -Record Input Value:______Record Output ______ mA.

6. RECORD ALARM SETTINGS and RESULTS

6.01 Verify correct graphic display on HMI screen.

6.02 Record alarm LL value.

6.03 Record alarm L value.

6.04 Record alarm H value.

6.05 Record alarm HH value.

6.06 Record alarm HHH value.

6.07 Record alarm priority (Low, High or Urgent

Prepared By Checked By Accepted By Witness By Data Input

Company/Dept: Contractor QA/QC COPI Disc. QA/QC COPI Ops/Comms CCMS Coord./Oprt

Print Name:

Signature:

Date:

Rev: 1, (ID= 24023) - ConocoPhillips PIMS Printed by: Tangkilisan, Yannick Y, 6 -Jul-2015 09:37 Page : 1 of 1

Vous aimerez peut-être aussi

- PC-J-94 Instrument Loop Check (Analogue Inputs)Document1 pagePC-J-94 Instrument Loop Check (Analogue Inputs)Memyhu MahmudahPas encore d'évaluation

- I11c Instrument Close Loop Check PG 1Document1 pageI11c Instrument Close Loop Check PG 1Momo ItachiPas encore d'évaluation

- Pre-Loop Check ProcedureDocument1 pagePre-Loop Check ProceduresithulibraPas encore d'évaluation

- Loop Checking Procedure IdeasDocument2 pagesLoop Checking Procedure IdeasJonatas13Pas encore d'évaluation

- 3BCN8 15026 A01 G01 DCS Operation and Maintenance ManualDocument58 pages3BCN8 15026 A01 G01 DCS Operation and Maintenance Manualramses mantillaPas encore d'évaluation

- Instrument Loop CheckDocument3 pagesInstrument Loop Checknayum100% (1)

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979D'EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonPas encore d'évaluation

- Anti Surge ControllerDocument5 pagesAnti Surge ControllerInter Tung100% (1)

- Axxon Next 4.1 Architectural and Engineering SpecsDocument21 pagesAxxon Next 4.1 Architectural and Engineering SpecsNiamat TribakPas encore d'évaluation

- Loop Check Sheet Sol ValveDocument2 pagesLoop Check Sheet Sol Valveshanks263100% (1)

- (EMERSON) Loop CheckingDocument29 pages(EMERSON) Loop CheckingDavid Chagas80% (5)

- Converting PLC-5 or SLC 500 Logic To Logix-Based LogicDocument82 pagesConverting PLC-5 or SLC 500 Logic To Logix-Based LogicSoy JahPas encore d'évaluation

- T315C-08 Exercise 8.1 - RevFDocument14 pagesT315C-08 Exercise 8.1 - RevFMarco RojasPas encore d'évaluation

- DCS Commisioning StepsDocument7 pagesDCS Commisioning StepsJoven BabieraPas encore d'évaluation

- I Et 6000.67 0000 800 Pdy 001 eDocument178 pagesI Et 6000.67 0000 800 Pdy 001 epitucha_hs100% (1)

- Partial Stroke Testing Implementing For The Right ReasonsDocument10 pagesPartial Stroke Testing Implementing For The Right ReasonsOrkhan SeyidovPas encore d'évaluation

- API 610 Vertical Turbine Pump VS6 (Can Type) VS1 (Sump Type)Document22 pagesAPI 610 Vertical Turbine Pump VS6 (Can Type) VS1 (Sump Type)Magico NinoPas encore d'évaluation

- Instr Loop CheckDocument3 pagesInstr Loop CheckMiko Quijano100% (1)

- Logic Check Function Check ProcedureDocument15 pagesLogic Check Function Check ProcedureArjun Shantaram Zope100% (1)

- Icl 009 PLC PanelDocument2 pagesIcl 009 PLC Panelsamwel kariukiPas encore d'évaluation

- Spi FFDocument17 pagesSpi FFjose_johnPas encore d'évaluation

- DPT Smart Pressure TransmitterDocument15 pagesDPT Smart Pressure Transmitterprasanta_bbsrPas encore d'évaluation

- Ignition SCADA Training-1-1Document1 pageIgnition SCADA Training-1-1Nikhil WakchaurePas encore d'évaluation

- Cold Loop CheckingDocument1 pageCold Loop CheckingZulkernain Omer TariqPas encore d'évaluation

- Instrumentation Procedure ISODocument12 pagesInstrumentation Procedure ISOAhmad Adel El Tantawy100% (1)

- SIP-SOP02-R0-2017 SOP Differential Pressure Transmitter CalibrationDocument3 pagesSIP-SOP02-R0-2017 SOP Differential Pressure Transmitter CalibrationDwi Mulyanti Dwimulyantishop100% (1)

- Instrument Engineer/Construction/commissioning/startupDocument6 pagesInstrument Engineer/Construction/commissioning/startupapi-77872275Pas encore d'évaluation

- Quick Start Guide Rosemount 700xa Gas Chromatograph en 7052512Document68 pagesQuick Start Guide Rosemount 700xa Gas Chromatograph en 7052512Zts MksPas encore d'évaluation

- Loop Check and ValveDocument1 pageLoop Check and ValveMohd A IshakPas encore d'évaluation

- Best Practice in P&ID DrawingDocument42 pagesBest Practice in P&ID DrawingKMAC1230% (2)

- 3210-8550-FS-0008 Foundation Fieldbus Functional RequrementDocument34 pages3210-8550-FS-0008 Foundation Fieldbus Functional Requrementsuhailfarhaan100% (2)

- Control Valve IPF Function Test1Document5 pagesControl Valve IPF Function Test1btjajadiPas encore d'évaluation

- Commissioning Issues and Solutions: Teo Puay Yong Pepperl+Fuchs Pte LTD SingaporeDocument52 pagesCommissioning Issues and Solutions: Teo Puay Yong Pepperl+Fuchs Pte LTD Singaporesolo AdoPas encore d'évaluation

- Transmitter TutorialDocument36 pagesTransmitter Tutorialbillyboxer100% (1)

- Modbus IntroDocument10 pagesModbus IntroArmando GarciaPas encore d'évaluation

- National Oil Corporation: Rev Date Description Checked ApprovedDocument14 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliPas encore d'évaluation

- Loop Checking and Field Instrument Testing ProcedureDocument7 pagesLoop Checking and Field Instrument Testing Procedurecharzree0% (1)

- Dcs SpecificationDocument42 pagesDcs Specificationsina20795Pas encore d'évaluation

- 639-2017 - Forms (ITP)Document9 pages639-2017 - Forms (ITP)george stanley pacetePas encore d'évaluation

- OvationDocument12 pagesOvationeshanrastogiPas encore d'évaluation

- Foundation Fieldbus Segment Drawing (FF Cable Schedule) - ModifDocument721 pagesFoundation Fieldbus Segment Drawing (FF Cable Schedule) - ModifLakshman KaretiPas encore d'évaluation

- Junction Box and Local Control Panel Quality Control and Inspection Report FormDocument1 pageJunction Box and Local Control Panel Quality Control and Inspection Report FormJpa YudiPas encore d'évaluation

- Each Company Has Its Own Procedure and Common Practices: Types of Loop TestDocument3 pagesEach Company Has Its Own Procedure and Common Practices: Types of Loop TestGuthayaBowsalPas encore d'évaluation

- SOP - HMI Upgrade - Rev01 PDFDocument2 pagesSOP - HMI Upgrade - Rev01 PDFhzq1e100% (1)

- Loop Check: Operator's GuideDocument21 pagesLoop Check: Operator's Guidemc_prayerPas encore d'évaluation

- Boiler Control SystemsDocument64 pagesBoiler Control SystemsSridhar DineshPas encore d'évaluation

- HJDocument4 pagesHJShajil VazhakkalilPas encore d'évaluation

- PROJECT STANDARD AND SPECIFICATIONS Instrumentation Specifications Rev01web PDFDocument8 pagesPROJECT STANDARD AND SPECIFICATIONS Instrumentation Specifications Rev01web PDFMohsin AliPas encore d'évaluation

- Control System Specification Energy Equity KeeraDocument42 pagesControl System Specification Energy Equity KeeraIkhtiander IkhtianderPas encore d'évaluation

- Instrumentation Switch ChecklistDocument5 pagesInstrumentation Switch Checklistrenjithv_4Pas encore d'évaluation

- SS04 CH01 - 48V BDT Transducer SAT FormatDocument74 pagesSS04 CH01 - 48V BDT Transducer SAT FormatshameemindiaPas encore d'évaluation

- Automation Check ListDocument9 pagesAutomation Check Listrenjithv_4Pas encore d'évaluation

- MC-J-09 Unit Control Panel, System and Termination CabinetDocument1 pageMC-J-09 Unit Control Panel, System and Termination CabinetMiftah MasrurPas encore d'évaluation

- IPT Test Plan-ProposalDocument16 pagesIPT Test Plan-ProposalOchie RomeroPas encore d'évaluation

- MC-J0-03 Tubing - TemplateDocument4 pagesMC-J0-03 Tubing - TemplatePipin AripinPas encore d'évaluation

- Eservice - ReportDocument5 pagesEservice - ReporthamidiPas encore d'évaluation

- Modbus Check Sheet ExampleDocument2 pagesModbus Check Sheet ExampleGuston SupriyadiPas encore d'évaluation

- MC-B-01 MC Inspection & Test Record BuildingDocument1 pageMC-B-01 MC Inspection & Test Record BuildingMemyhu MahmudahPas encore d'évaluation

- Commissioning Procedure EngrDocument11 pagesCommissioning Procedure EngrkumarPas encore d'évaluation

- Tooo': oOO OO.Document28 pagesTooo': oOO OO.ediasianagriPas encore d'évaluation

- Supra Fit Type Supra Fit New (Hitam)Document3 pagesSupra Fit Type Supra Fit New (Hitam)Memyhu MahmudahPas encore d'évaluation

- MC L 04 Pipework ReinstatementDocument1 pageMC L 04 Pipework ReinstatementMemyhu MahmudahPas encore d'évaluation

- MC-L-01B Pipework Before TestDocument1 pageMC-L-01B Pipework Before TestMemyhu MahmudahPas encore d'évaluation

- MC-L-02 Pipework After TestDocument1 pageMC-L-02 Pipework After TestMemyhu MahmudahPas encore d'évaluation

- Supra Fit Type Supra Fit New (Hitam)Document3 pagesSupra Fit Type Supra Fit New (Hitam)Memyhu MahmudahPas encore d'évaluation

- MC L 01A Pre Hydrotest LinewalkDocument1 pageMC L 01A Pre Hydrotest LinewalkMemyhu MahmudahPas encore d'évaluation

- MC Inspection & Test Report: Mc-N-04 Grouting Mc-N-04 GroutingDocument1 pageMC Inspection & Test Report: Mc-N-04 Grouting Mc-N-04 GroutingMemyhu MahmudahPas encore d'évaluation

- SIMAK Pascasarjana S1 Ekstensi 2013 ENGLISH Kode 202Document38 pagesSIMAK Pascasarjana S1 Ekstensi 2013 ENGLISH Kode 202Ulfi KhabibahPas encore d'évaluation

- Latihan AnisahDocument3 pagesLatihan AnisahMemyhu MahmudahPas encore d'évaluation

- MC-B-01 MC Inspection & Test Record BuildingDocument1 pageMC-B-01 MC Inspection & Test Record BuildingMemyhu MahmudahPas encore d'évaluation

- Sket RumahDocument12 pagesSket RumahMemyhu MahmudahPas encore d'évaluation

- 5605 10893 1 SMDocument7 pages5605 10893 1 SMMemyhu MahmudahPas encore d'évaluation

- Lagu Barat TerbaruDocument3 pagesLagu Barat TerbaruMemyhu MahmudahPas encore d'évaluation

- Sop Print ScreenDocument21 pagesSop Print ScreenMemyhu MahmudahPas encore d'évaluation

- Lagu Barat TerbaruDocument3 pagesLagu Barat TerbaruMemyhu MahmudahPas encore d'évaluation

- 5605 10893 1 SMDocument7 pages5605 10893 1 SMMemyhu MahmudahPas encore d'évaluation

- Jurnal EtaDocument3 pagesJurnal EtaMemyhu MahmudahPas encore d'évaluation

- 1713 BP 1Document17 pages1713 BP 1api-3698598Pas encore d'évaluation

- BTICINO Catalog Matix PDFDocument80 pagesBTICINO Catalog Matix PDFsokolobanPas encore d'évaluation

- Manufacturing Systems-Fleximble Manufacturing Application-Case Study of ZimbabweDocument5 pagesManufacturing Systems-Fleximble Manufacturing Application-Case Study of Zimbabwejosphat muchatutaPas encore d'évaluation

- Activities Pm.Document13 pagesActivities Pm.jona llamasPas encore d'évaluation

- 8.4.2 Detecting The Presence/Absence of Paper: Pickup RollerDocument2 pages8.4.2 Detecting The Presence/Absence of Paper: Pickup RollerHERL NEIL BilbaoPas encore d'évaluation

- 3.1 Turbine and GoverningDocument90 pages3.1 Turbine and GoverningYudo Heru PribadiPas encore d'évaluation

- Be Katalog-Grabenfr 2013 Engl RZ KleinDocument36 pagesBe Katalog-Grabenfr 2013 Engl RZ Kleincherif100% (1)

- Company CFODocument602 pagesCompany CFOgouravbhatia200189Pas encore d'évaluation

- Best Answer For Each Conversation. You Will Hear Each Conversation TwiceDocument4 pagesBest Answer For Each Conversation. You Will Hear Each Conversation TwiceQuang Nam Ha0% (1)

- Internship Opportunities PDFDocument2 pagesInternship Opportunities PDFMD MoizPas encore d'évaluation

- Behringer FX2000-Product InfoDocument10 pagesBehringer FX2000-Product Infogotti45Pas encore d'évaluation

- Is 15462 2004 Modified Rubber BItumen PDFDocument16 pagesIs 15462 2004 Modified Rubber BItumen PDFrajeshji_000100% (3)

- Performance of Trinidad Gas Reservoirs PDFDocument11 pagesPerformance of Trinidad Gas Reservoirs PDFMarcus ChanPas encore d'évaluation

- Booz Allen - Strategy & BusinessDocument18 pagesBooz Allen - Strategy & BusinessPaul AllenPas encore d'évaluation

- Operating Instructions Back Pressure Regulator Series: BPR: Holter RegelarmaturenDocument19 pagesOperating Instructions Back Pressure Regulator Series: BPR: Holter Regelarmaturenamin100% (2)

- 20140630-A2384 ALTRONIXDocument30 pages20140630-A2384 ALTRONIXRicardo MercadoPas encore d'évaluation

- McGraw-Hill (Level 1) PDFDocument41 pagesMcGraw-Hill (Level 1) PDFDarpan GajjarPas encore d'évaluation

- Astm A325mDocument8 pagesAstm A325mChitra Devi100% (1)

- Personal Data Sheet: Criminology Intern UnitDocument1 pagePersonal Data Sheet: Criminology Intern UnitJoseph RychePas encore d'évaluation

- Tjibau Cultural CentreDocument21 pagesTjibau Cultural CentrepoojaPas encore d'évaluation

- Utilisation of Electrical Energy May 2008Document8 pagesUtilisation of Electrical Energy May 2008rajaniramPas encore d'évaluation

- Fundamentals and History of Cybernetics 2Document46 pagesFundamentals and History of Cybernetics 2izzul_125z1419Pas encore d'évaluation

- Troubleshooting: Fully Automated Urine Particle AnalyzerDocument108 pagesTroubleshooting: Fully Automated Urine Particle Analyzerjw lPas encore d'évaluation

- 0811 IndiadxerDocument6 pages0811 IndiadxerAlexander WiesePas encore d'évaluation

- Pre-Disciplinary and Post-Disciplinary Perspectives: Bob Jessop & Ngai-Ling SumDocument13 pagesPre-Disciplinary and Post-Disciplinary Perspectives: Bob Jessop & Ngai-Ling SumMc_RivPas encore d'évaluation

- PCD 2 MarksDocument23 pagesPCD 2 MarksVignesh VickyPas encore d'évaluation

- EV 10 Best Practice - Implementing Enterprise Vault On VMware (January 2012)Document31 pagesEV 10 Best Practice - Implementing Enterprise Vault On VMware (January 2012)TekkiePas encore d'évaluation

- LabVIEW Project Report Complete HPK Kumar DetailedDocument62 pagesLabVIEW Project Report Complete HPK Kumar DetailedDanny Vu75% (4)

- Abuyog 2018 PDFDocument503 pagesAbuyog 2018 PDFJackelyn Fortaliza RosquettesPas encore d'évaluation