Académique Documents

Professionnel Documents

Culture Documents

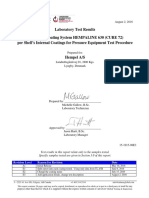

Plasite 4500 S Pds 10-14 - Marine

Transféré par

Achraf BoudayaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Plasite 4500 S Pds 10-14 - Marine

Transféré par

Achraf BoudayaDroits d'auteur :

Formats disponibles

PLASITE 4500 S

PRODUCT DESCRIPTION PHYSICAL CHARACTERISTICS

Plasite 4500 S is a 100% solids, flake-filled, premium epoxy coating

designed for internal steel and concrete tanks and pipe lining. It is a two

component system consisting of 4-parts by volume of Part A resin and Tensile Strength.... 7,000 psi

one part by volume of Part B hardener. It is applied by plural component (ASTM D-638)

or single component spray equipment, in a one-coat application (20-60 Flexural Strength..... 10,800 psi

mils) for internal lining applications. It also meets AWWA C210

specification. (Formerly known as Plasite 140 S) (ASTM D-790)

6

Flexural Modulus of Elasticity.... 5.9 psi x 10

USES/APPLICATIONS (examples)

(ASTM D-790)

Chemical storage tanks

Wastewater clarifiers Hardness...... 75

Equipment supports (ASTM D-2240 Shore D)

Oil storage tanks Weight per Mixed Gallon. 10 lbs

Immersion Service for Jet Fuel Pot-life@75F/24C: 45-60 min.

Catwalks

Concrete exposures in wastewater applications Cure Time (Approx.)

Potable water tanks and pipelines meets or exceeds ANSI/NSF Dry To Touch.. @ 75F/24C: 12 hrs

Std. 61 for tanks larger than 1000 gallons or pipe with 42 diameter Firm.. @ 75F/24C: 24 hrs

or greater.*

Cure for Immersion Service (min 50F)

*Valid if manufactured at a certified location. Crude oil or aliphatic hydrocarbons . @ 75F/24C: 36 hrs

All Others .................................. @ 75F/24C: 7 days

PRODUCT ADVANTAGES

Potable water service7 days @ 75F

High impact resistance

Superior adhesion to steel and concrete Bond Strength (Steel).....1700 psi

Resistance to a broad range of chemicals

Can be applied in a one-coat application up to 60 mils STORAGE CONDITIONS

Can be sprayed using single component airless equipment Keep Plasite 4500 S products tightly sealed in their original containers

VOC compliant until ready for use. Store at 50-85F/10-29C, out of direct sunlight.

Properly stored, Plasite 4500 S products have a shelf life of six months.

CHEMICAL RESISTANCE To ensure maximum film build, Plasite 4500 S should be used within

In addition to excellent water immersion resistance, Plasite 4500 S is three months of the manufacture date. Proper jobsite storage of Plasite

resistant to a broad range of chemicals such as fuels, salts, alkalies, 4500 S is essential to its performance. Follow these general procedures

many acids, and some solvents. for storage at the jobsite:

COLORS Store components (Part A and Part B) unopened, in a dry place, at 50-

Light gray, light blue, and white. Use light grey for potable water service. 85F/10-29C, out of direct sunlight, and protected from the elements.

Keep away from heat and flame.

PACKAGING

Plasite 4500 S is offered in one gallon and five gallon units. For the 24-48 hours just prior to use, narrow the storage temperature to

One gallon unit includes: 70-85F/21-29C to facilitate ease of mixing.

1 gallon (partial) can of Part A (resin)

1 quart can of 4500S/4550S Part B (hardener) SUBSTRATE PREPARATION

Steel

Five gallon unit includes: Immediately prior to application of the coating or lining, the steel

5 gallon (partial) pail of Part A (resin) substrate must be clean of all oil, grease, dirt, dust, mill scale, rust, flash

1 gallon can of 4500S/4550S Part B (hardener) rust, corrosion products, salts, solvents, chlorides, other chemicals, and

existing coatings.

FILM THICKNESS

Depends on service, typically applied at 30-40 mil/1 mm in a one coat All welds must be smooth and continuous; no skip welds. All weld

application. Do not exceed 60 mils for ANSI/NSF Std. 61 use. splatter, buckshot, laminations, and slivers must be removed and

ground smooth; undercuts and pinholes must be ground smooth and

COVERAGE filled with weld metal. All projections, sharp edges, high points and fillets

The theoretical coverage of PLASITE 4500 S is 1,604 mil sq. ft./gal. For must be ground smooth to a radius of at least 1/8 in./0.32 cm and all

estimating purposes, one gallon will cover 32 sq. ft./gal. at 40 mil/1 mm corners must be likewise rounded.

(20% loss included).

All pitting, gouges, scratches, and other defects must be repaired either

THINNERS (No thinner is recommended ) by welding or by filling with repair materials that are compatible with the

Clean up: Thinner #2 coating or lining system and suitable for the intended service conditions.

VOC CONTENT Coating as Supplied All surfaces to be coated or lined must be readily accessible.

Color Lbs./Gal. g/L

Lt. Gray 0.00 0.00

October 2014 replaces December 2013 118P

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company to

verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE,

EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline and Plasite are

registered trademarks of Carboline Company. Page 1 of 3

PLASITE4500 S

The steel must be blasted to a Near White Metal Finish (NACE No. 2, this requirement. Use a surface thermometer to frequently monitor the

SSPC SP 10) with a minimum 3 mil (75 micron) dense, sharp anchor temperature of the steel substrate.

profile free of peening, as measured by ASTM D 4417.

EQUIPMENT

Defects exposed by blasting must be repaired. Single Component Airless Spray

All pumps and hoses must be in proper working order, clean and free

Refer to Plasite Bulletin PA-3. of foreign matter. Use air motor with an air ratio of 45:1 or larger such

as Graco King airless spray pump.

Concrete

Immediately prior to application of coating, concrete substrate must All filters should be removed from the pump. Use a minimum 3/8

be: in./0.95 cm spray hose from pump to gun, not to exceed 100 ln. ft./30.5

Adequately cured (generally, at least 28 days; check with ln. m. It is best to bring the material directly to the gun body and not go

Carboline if concrete has cured less than 28 days). through a tube in the handle.

Structurally sound.

Free of all dirt, dust, debris, oil, grease, fats, chemical The size of airless spray tip will depend on the area being sprayed, the

contamination, salts, solvents, surface hardeners, incompatible viscosity, and the temperature of the materials. Use sizes from 0.19 -

curing compounds and form release agents, laitance and 0.35 in. If using an inline filter, use a 60-mesh screen size.

efflorescence.

Concrete surface must be dry. The mixed material temperature should be 75-85F/ 24-38C for best

spraying.

And must have:

Tensile strength of at least 300 psi. Note: Ambient temperature above 85F/29C will shorten pot life.

pH in the range of 7 to 11.

All fins, projections and splatter removed. To prepare the material for spraying, mix Part A with a jiffy type

All defects repaired using patching as described herein. mechanical mixer for two minutes, mix Part B until color is well

Failed or otherwise incompatible old coatings removed. blended, then mix Part A and Part B together for two minutes using the

A surface texture similar to medium sandpaper (40 to 60 grit). jiffy mixer.

Refer to Carbolines separate document Surface Preparation When using a 45:1, set the mixed material under the pump (it is best to

Concrete for further instruction in the preparation of concrete surfaces. remove the siphon tube and pump directly from the bottom of the

pump) and start spraying. The air pressure required will vary between

Locate all expansion joints, control joints, floor drains, equipment base 55-65 lbs.

plates, and mid-floor termination points. Handle them as per

Carbolines separate document Construction Details. When spraying is completed, solvent purge the lower unit and spray

gun, then remove the bottom ball valve and clean thoroughly.

Degraded concrete on horizontal surfaces should be restored using

Carboguard 510 Concrete Repair Mortar or specified restoration Plural Spray

materials. Use a fixed ratio (4:1 by volume) plural component spray rig such as:

Graco King Hydro-Cat, Graco XTR or equal Extreme Machine with

Honeycombs or any form voids in vertical surfaces must be filled. Use heated hoppers, heated hoses to a mixer manifold through a static

a putty made with Carboguard 510 Concrete Repair Mortar. mixer to a 50 ft whip hose followed by a silver gun (Binks 1M or equal)

utilizing self-cleaning reverse-a-tips from 0.19 to 0.35 inches. See

Concrete is a very porous material. As it warms during the day it equipment specifications for more details.

expels air, or outgasses. A coating applied while the concrete is

outgassing likely will develop bubbles and pinholes. Note: The A side should be at a minimum of 110F/43C and the

the B side at 90-100F/32-38C. This will ensure proper spraying

To avoid this, the material should be applied when the temperature of of PLASITE 4500 S.

the concrete is falling. Usually this is from late afternoon into the night.

Stop applying the material well before dawn, so it has time to set up Take care to prevent the mixed material from setting up in your hoses.

firm to the touch before outgassing begins. This may be anywhere For best results, keep your hoses as short as possible, purge them

from 1 to 6 hours, depending upon the weather conditions. In addition, immediately if work is interrupted, keep them out of direct sunlight and

it is a good idea to shade the work area from direct sunlight. Do not insulated from hot surfaces.

apply material when temperature will fall within 5F/3C of the dew

point. APPLICATION

Mixing

Priming may be required in situations where outgassing could be a For Single Component Spray

problem. Consult Carboline for primer recommendations. Use Jiffy type mixers for all mixing and stirring. When operating the

mixer avoid plunging it up and down in the bucket, this can fold air into

the resin, which may cause bubbles to form in the coating after it has

MASKING & PROTECTION been applied. Individually stir each separate Part A and Part B

Mask or remove adjacent surfaces and equipment that are not to be component to a smooth, uniform consistency and color. Any sediment

lined. Once applied, PLASITE 4500 S is difficult to remove. Protect in the container must be thoroughly scraped up and redispersed.

nearby pumps, motors and other equipment from spent abrasive

venting from the tank during blasting. Spray: Immediately before applying a spray coat, stripe all continuous

welds and edges with a brush-coat to assure adequate protection of

APPLICATION GUIDELINES these areas.

Before mixing and applying any material, make sure environmental

conditions are satisfactory for application. Weather conditions, and Brush/Roll: Normally recommended for touch-up or repair areas.

especially dew point, should be constantly monitored in light of the Consult Technical Service or your local representative for specific

work being done. Final blast cleaning and application of the lining guidelines and procedures.

system must only be performed when it is clear the temperature of the

steel substrate will not fall within 5F/3C of the dew point.

Dehumidification and/or temperature control may be necessary to meet

October 2014 replaces December 2013

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company to

verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE,

EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline and Plasite are

registered trademarks of Carboline Company. Page 2 of 3

PLASITE 4500 S

All spray equipment should be clean and in proper working order. Application and curing times are dependent upon ambient

Contact Carboline Technical Service for start-up and clean-up conditions. Consult Carbolines Technical Service Department if

procedures. Adjust pressure to 50-70 psi and open the valves at the conditions are not within recommended guidelines.

manifold and purge materials at the spray gun. Attach spray tip and

PRECAUTIONS

begin to spray. Dependent upon tip size, each pass will be 8-14

mil/200-350 microns per pass. Apply material to specified thickness. Before handling and application of this material consult the MSDS

sheets. As with any product, those handling PLASITE 4500 S

Apply criss-cross multi-passes, moving gun at a fairly rapid rate, materials should employ proper safety practice. Hypersensitive

maintaining a wet appearing film. Use a wet film thickness gauge to persons should wear protective clothing, gloves, and use

monitor film build. protective cream on any exposed areas.

Note: Force curing may be desirable in certain circumstances. NOTES

Check with Carbolines Technical Service Department. Material Safety Data Sheets on PLASITE 4500 S are available

upon request.

CURING

Specific information regarding the chemical resistance of

PLASITE 4500 S can be found by contacting Carboline Technical

PLASITE 4500 S will be dry to the touch in 12-18 hours at 75F/24C, Service.

36-48 hours at 50F, will be firm to the touch in 24 hours at

75F/24C or 48-72 hours at 50F, and will be suitable for limited

A staff of technical service engineers is available to assist with

product application, or to answer questions related to Carboline

chemical service in 36 hours at 75F/24C or 4-5 days at 50F. For

products.

most service final cure time for immersion is 7 days at 75F/24C or

14 days at 50F. Consult Carboline Technical Service for specific

Requests for technical literature or service can be made through

local sales representatives and offices worldwide.

chemical service.

SAFETY

Note: All linings used for potable water service must be cleaned to

READ THIS NOTICE

local specifications to meet potable water standards. There are

SAFETY AND MISCELLANEOUS EQUIPMENT

several methods to disinfect and prepare a tank for service. The

following is a synopsis of Method 2 of ANSI/AWWA Standard (C652)

For tank lining work or enclosed spaces, it is recommended that the

for Disinfection of Water-Storage Facilities.

operator provide himself with clean coveralls and rubber soled shoes

1. Thoroughly rinse the entire tank.

and observe good personal hygiene. Certain personnel may be

2. Apply a solution of Sodium Hypochlorite (household bleach) of

sensitive to various types of resins which may cause dermatitis.

200 mg/liter (0.02% solution) for a period of 30 minutes.

3. Thoroughly rinse with clean water.

THE SOLVENT IN THIS COATING IS FLAMMABLE AND CARE

4. Check the surface with pH paper.

AS DEMANDED BY GOOD PRACTICE, OSHA, STATE AND

5. The pH should be 6.8 to 7.2.

LOCAL SAFETY CODES, ETC. MUST BE FOLLOWED CLOSELY.

Keep away from heat, sparks and open flame and use necessary

safety equipment, such as, air mask, explosion-proof electrical

Plasite 4500 S does have a propensity to blush during its cure cycle.

equipment, non-sparking tools and ladders, etc. Avoid contact with

The blush is to be removed before top-coating or placing this material

skin and breathing of vapor or spray mist. When working in tanks,

into potable water service.

rooms and other enclosed spaces, adequate ventilation must be

provided. Refer to PLASITE Bulletin PA-3. Keep out of the reach of

LINING REPAIR

children.

Before any touch-up or recoat material can be applied, the first coat

must be properly prepared for intercoat adhesion. CAUTION - Read and follow all caution statements on this product

data sheet, material safety data sheet and container label for this

The first coat must be cured firm to the touch. Coating on floors must product.

be able to support foot traffic.

If the first coat cures more than 24-hours, lightly sand or mechanically This data sheet provides standard information on the coating and

abrade the surface after scrubbing it down with soap and water. application procedure. Since varying conditions may not be covered,

consult with your local sales representative or Carboline Technical

Any surface to be touched up or recoated should be protected. When Service Department for further information.

the recoat material is applied, the surface must be dry and free of all

dirt, dust, debris, oil, grease and other contamination.

INSPECTION

Degree of surface preparation shall conform to appropriate

specifications as outlined in SURFACE PREPARATION section. Film

thickness of each coat and total dry film thickness of the coating

system shall be determined with a non-destructive magnetic gauge

properly calibrated.

RECOMMENDATIONS

Apply only on a clean, sound, properly prepared substrate.

Minimum ambient or substrate temperature is 50F/10C. Optimal

temperature is 75F/24C.

Maximum substrate temperature is 100F/38C at the time of

application.

Relative humidity should be between 0-90%.

Substrate temperature should be 5F/3C above the dew point.

October 2014 replaces December 2013

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company to

verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE,

EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline and Plasite are

registered trademarks of Carboline Company.` Page 3 of 3

Vous aimerez peut-être aussi

- Interseal 670HS+Br+EngDocument2 pagesInterseal 670HS+Br+Engrajauae2008100% (1)

- Design of Welded Connections: Submitted To Prof. Berlanty Iskander byDocument17 pagesDesign of Welded Connections: Submitted To Prof. Berlanty Iskander byاحمد حمديPas encore d'évaluation

- Concrete Moisture Testing Guide 1-15Document2 pagesConcrete Moisture Testing Guide 1-15soutrick BaruiPas encore d'évaluation

- Saudi Aramco Inspection Checklist: Receiving Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2003 30-Apr-13 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2003 30-Apr-13 Mechpookkoya thangalPas encore d'évaluation

- Interzinc 52: Epoxy Zinc-RichDocument4 pagesInterzinc 52: Epoxy Zinc-RichKrishna VachaPas encore d'évaluation

- Chevron Pre-Inspection ChecklistDocument2 pagesChevron Pre-Inspection ChecklistosersPas encore d'évaluation

- Icorr Certification Scheme: Icorr Training Courses (Itc)Document5 pagesIcorr Certification Scheme: Icorr Training Courses (Itc)sheikbbaPas encore d'évaluation

- ATEX Ex-Proof Jargon Buster For MOTOR UsersDocument28 pagesATEX Ex-Proof Jargon Buster For MOTOR Usersdpee27619438Pas encore d'évaluation

- A High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingDocument15 pagesA High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingpaimpillyPas encore d'évaluation

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947Pas encore d'évaluation

- Meccoct18 12573Document9 pagesMeccoct18 12573Malik Ansar HayatPas encore d'évaluation

- Shwerwin Williams Internal Lining PresentationDocument42 pagesShwerwin Williams Internal Lining PresentationPaolo VisentinPas encore d'évaluation

- Cte Ongc SpecDocument21 pagesCte Ongc SpecMohamed HushainPas encore d'évaluation

- PPL Su 2005 PDFDocument11 pagesPPL Su 2005 PDFresp-ect100% (1)

- ChemicalDocument5 pagesChemicalisaac2408Pas encore d'évaluation

- NewbuildingUniversalPrimers WhitePaperDocument4 pagesNewbuildingUniversalPrimers WhitePapermkccm100% (1)

- AGA - Embrittlement Galvanized Stainless SteelDocument1 pageAGA - Embrittlement Galvanized Stainless SteelMarcelo Hayashi NeyPas encore d'évaluation

- JPCL Transpipe EbookDocument82 pagesJPCL Transpipe Ebookvincent.w.stone6724Pas encore d'évaluation

- PROJECT STANDARD and SPECIFICATIONS Fire Proofing Vessels and Supports Rev01webDocument4 pagesPROJECT STANDARD and SPECIFICATIONS Fire Proofing Vessels and Supports Rev01webAzeem50% (2)

- FireProofing SpecificationDocument10 pagesFireProofing SpecificationSalman ShaikhPas encore d'évaluation

- Underground Insulation Specification Data SheetDocument2 pagesUnderground Insulation Specification Data Sheetadoptvn100% (1)

- InspectThis 2015-Fall PDFDocument16 pagesInspectThis 2015-Fall PDFKhalida Muddasser100% (1)

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988D'EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockPas encore d'évaluation

- Interseal 670HDocument2 pagesInterseal 670Hmadmax_mfpPas encore d'évaluation

- Abrasive BlastingDocument52 pagesAbrasive Blastinglwin_oo2435100% (1)

- USA Map PowerPoint SlidesDocument10 pagesUSA Map PowerPoint SlidesJota Gomez CdlmPas encore d'évaluation

- Tech Coating SelectionDocument8 pagesTech Coating SelectionKarthikeyan Shanmugavel100% (1)

- The Journal of Protective Coatings & Linings - Why Surface Preparation Is ImportantDocument5 pagesThe Journal of Protective Coatings & Linings - Why Surface Preparation Is ImportantSergio Daniel Barea Nuñez100% (1)

- Zinc Silicate PrimersDocument9 pagesZinc Silicate PrimersminhnnPas encore d'évaluation

- Corrosion Application Library ManualDocument230 pagesCorrosion Application Library ManualMiguel Angel Holguin MontañoPas encore d'évaluation

- CH 04.02 Coating ConcreteDocument7 pagesCH 04.02 Coating ConcreteNgô Trung NghĩaPas encore d'évaluation

- Executive Summary:: International Maritime OrganizationDocument6 pagesExecutive Summary:: International Maritime Organizationtudormoraru100% (1)

- Fouling-Repellent Coating For Shell-And-Tube Heat ExchangersDocument3 pagesFouling-Repellent Coating For Shell-And-Tube Heat Exchangersزيد عدنان عبد الحسين100% (1)

- Conventional AirsprayDocument218 pagesConventional AirspraylambtranPas encore d'évaluation

- Challenging The Organic "Zinc Rich" Primer StandardDocument9 pagesChallenging The Organic "Zinc Rich" Primer Standardaliabdulhamid100% (2)

- CuiDocument6 pagesCuiأحمد صبحىPas encore d'évaluation

- FireproofingDocument3 pagesFireproofingarki_emmanPas encore d'évaluation

- Comparison of Fireproofing SpecificationDocument9 pagesComparison of Fireproofing SpecificationKwan-Rin Ratchaneeya100% (2)

- Saic B 2001 WasitDocument6 pagesSaic B 2001 WasitAnonymous 4e7GNjzGWPas encore d'évaluation

- Corrosion Under InsulationDocument21 pagesCorrosion Under InsulationRenan Soares KieferPas encore d'évaluation

- Ballast TK HempelsDocument15 pagesBallast TK HempelsGeorgios PapakostasPas encore d'évaluation

- Pa 3 PDFDocument0 pagePa 3 PDFNageswara Rao BavisettyPas encore d'évaluation

- MarineLine784 Protective CoatingsDocument8 pagesMarineLine784 Protective CoatingsTimuçin ÇolakelPas encore d'évaluation

- 028120-SPL-004 Pipeline Weight Coating Rev. CDocument11 pages028120-SPL-004 Pipeline Weight Coating Rev. CRokan Pipeline100% (1)

- Antifire PaintDocument2 pagesAntifire PaintAli ZaibPas encore d'évaluation

- Zinc Silicate or Zinc Epoxy As The Preferred High Performance PrimerDocument10 pagesZinc Silicate or Zinc Epoxy As The Preferred High Performance Primerbabis1980100% (1)

- Osmotic Blisters in Coatings and Adhesives - Metal FinishingDocument2 pagesOsmotic Blisters in Coatings and Adhesives - Metal FinishingMaulana Mufti MuhammadPas encore d'évaluation

- Insulating Gaskets & Its Practical DifficultiesDocument6 pagesInsulating Gaskets & Its Practical Difficulties4A28Sparsh JainPas encore d'évaluation

- 15-1915-08e3-Hempaline Defend 630 (Cure 72)Document28 pages15-1915-08e3-Hempaline Defend 630 (Cure 72)ashishpearlPas encore d'évaluation

- Challenges With Using Ethyl Silicate Inorganic Zinc-Rich PrimerDocument43 pagesChallenges With Using Ethyl Silicate Inorganic Zinc-Rich PrimerMOHAMEDPas encore d'évaluation

- Corrosion - by DR - Kallol Mondal, Department of Metallurgy and Material Science, IIT KanpurDocument3 pagesCorrosion - by DR - Kallol Mondal, Department of Metallurgy and Material Science, IIT KanpurEddie TaiPas encore d'évaluation

- GraceMonokoteZ106HY PDFDocument2 pagesGraceMonokoteZ106HY PDFJovanni RodriguezPas encore d'évaluation

- Angels and Demons in The Realm of Protective CoatingsDocument26 pagesAngels and Demons in The Realm of Protective Coatingsaliabdulhamid100% (1)

- Plasite 4550SDocument3 pagesPlasite 4550SMuhammad RizwanPas encore d'évaluation

- Plasite 4550Document4 pagesPlasite 4550canakyuzPas encore d'évaluation

- Plasite 4550 S PDSDocument3 pagesPlasite 4550 S PDSluisbaPas encore d'évaluation

- 5 Star GroutDocument2 pages5 Star Groutchong pak limPas encore d'évaluation

- CS3204 Rev 01 07Document2 pagesCS3204 Rev 01 07rafa.twanderleyPas encore d'évaluation

- PR 1776 BDocument4 pagesPR 1776 BAznil aznilPas encore d'évaluation

- Series LFII Residential, NFPA 13 Optimized Horizontal Sidewall Sprinklers 5.6 K-FactorDocument6 pagesSeries LFII Residential, NFPA 13 Optimized Horizontal Sidewall Sprinklers 5.6 K-FactorAchraf BoudayaPas encore d'évaluation

- Series LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Document8 pagesSeries LFII Residential Pendent Sprinklers 4.9 K-Factor: Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Achraf BoudayaPas encore d'évaluation

- Series LFII Residential Concealed Pendent Sprinklers, Flat Plate 4.2 K-FactorDocument4 pagesSeries LFII Residential Concealed Pendent Sprinklers, Flat Plate 4.2 K-FactorAchraf BoudayaPas encore d'évaluation

- Series LFII Residential Flush Pendent Sprinklers 4.2 K-FactorDocument8 pagesSeries LFII Residential Flush Pendent Sprinklers 4.2 K-FactorAchraf BoudayaPas encore d'évaluation

- Series LFII Residential Horizontal Sidewall Sprinklers 4.2 K-FactorDocument8 pagesSeries LFII Residential Horizontal Sidewall Sprinklers 4.2 K-FactorAchraf BoudayaPas encore d'évaluation

- Style 10, 20, 30, 40, and 50 Recessed Escutcheons & Protective Paint Caps For Automatic Sprinkler Recessed InstallationDocument4 pagesStyle 10, 20, 30, 40, and 50 Recessed Escutcheons & Protective Paint Caps For Automatic Sprinkler Recessed InstallationAchraf BoudayaPas encore d'évaluation

- Model G1 & G4 Sprinkler Guards Model G1/S1 & G4/S3 Guards With Shields Series TY-B, TY-FRB, TY-L, and TY-FRL SprinklersDocument4 pagesModel G1 & G4 Sprinkler Guards Model G1/S1 & G4/S3 Guards With Shields Series TY-B, TY-FRB, TY-L, and TY-FRL SprinklersAchraf BoudayaPas encore d'évaluation

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 pageClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaPas encore d'évaluation

- Sprinkler Spray Patterns Refer To The General Description Section Before Applying The Spray Pattern DataDocument38 pagesSprinkler Spray Patterns Refer To The General Description Section Before Applying The Spray Pattern DataAchraf BoudayaPas encore d'évaluation

- Model G2 Sprinkler Guard, Model WS-2 Shield, and Model WSG-2 Sprinkler Guard With Shield Series ELO-231, ELO-231B, and ELO-231FRB SprinklersDocument4 pagesModel G2 Sprinkler Guard, Model WS-2 Shield, and Model WSG-2 Sprinkler Guard With Shield Series ELO-231, ELO-231B, and ELO-231FRB SprinklersAchraf BoudayaPas encore d'évaluation

- Installer Warning!!! Read The Following Cautions Before Handling or Installing Your SprinklersDocument4 pagesInstaller Warning!!! Read The Following Cautions Before Handling or Installing Your SprinklersAchraf BoudayaPas encore d'évaluation

- Jotashield Flex: Technical Data SheetDocument3 pagesJotashield Flex: Technical Data SheetAchraf BoudayaPas encore d'évaluation

- Flyer TycoDocument8 pagesFlyer TycoAchraf BoudayaPas encore d'évaluation

- Jotun Essence Easy Clean Matt: Technical Data SheetDocument3 pagesJotun Essence Easy Clean Matt: Technical Data SheetAchraf BoudayaPas encore d'évaluation

- Jotashield Extreme: Technical Data SheetDocument3 pagesJotashield Extreme: Technical Data SheetAchraf BoudayaPas encore d'évaluation

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 pageClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaPas encore d'évaluation

- Esab Pipeweld 6010R: Classifications: ApprovalsDocument1 pageEsab Pipeweld 6010R: Classifications: ApprovalsAchraf BoudayaPas encore d'évaluation

- Snubbers Type 31Document1 pageSnubbers Type 31Achraf BoudayaPas encore d'évaluation

- Rigid Struts Type 39Document1 pageRigid Struts Type 39Achraf BoudayaPas encore d'évaluation

- Typical Tensile Properties: Classifications: Welding Current: Diffusible Hydrogen: Alloy Type: Coating TypeDocument1 pageTypical Tensile Properties: Classifications: Welding Current: Diffusible Hydrogen: Alloy Type: Coating TypeAchraf BoudayaPas encore d'évaluation

- Heavy Duty Spring Supports Type 28Document1 pageHeavy Duty Spring Supports Type 28Achraf BoudayaPas encore d'évaluation

- ANVIL PIPE HANGERS & SUPPORTS ContinuedDocument1 pageANVIL PIPE HANGERS & SUPPORTS ContinuedAchraf BoudayaPas encore d'évaluation

- Spring Supports Type 29Document1 pageSpring Supports Type 29Achraf BoudayaPas encore d'évaluation

- Weld-On Brackets Type 35Document1 pageWeld-On Brackets Type 35Achraf BoudayaPas encore d'évaluation

- Snubbers Type 30Document1 pageSnubbers Type 30Achraf BoudayaPas encore d'évaluation

- Anvil Pipe Hangers & SupportsDocument1 pageAnvil Pipe Hangers & SupportsAchraf BoudayaPas encore d'évaluation

- Heavy Duty Spring Hangers Type 22Document1 pageHeavy Duty Spring Hangers Type 22Achraf BoudayaPas encore d'évaluation

- Spring Hangers Type 21Document1 pageSpring Hangers Type 21Achraf BoudayaPas encore d'évaluation

- Spring Hangers Type 25Document1 pageSpring Hangers Type 25Achraf BoudayaPas encore d'évaluation

- ANVIL PIPE HANGERS & SUPPORTS (CTD)Document1 pageANVIL PIPE HANGERS & SUPPORTS (CTD)Achraf BoudayaPas encore d'évaluation

- Chapter - 6 ThermodynamicDocument7 pagesChapter - 6 ThermodynamicManan TyagiPas encore d'évaluation

- Catalogo HaciendaDocument580 pagesCatalogo HaciendajdmhilogisticsPas encore d'évaluation

- Science Fair ChemDocument19 pagesScience Fair Chemapi-506061997Pas encore d'évaluation

- Chemistry Edexcel RevisionDocument3 pagesChemistry Edexcel RevisionchogoPas encore d'évaluation

- PQ CHM101@MR PossibleDocument3 pagesPQ CHM101@MR PossibleAbraham BanjoPas encore d'évaluation

- 07 UhaDocument15 pages07 UhaMatías GarcíaPas encore d'évaluation

- AIEEEMainPaper Code ADocument37 pagesAIEEEMainPaper Code ArohitrtPas encore d'évaluation

- SA16-0001 Standard Paint SpecificationDocument31 pagesSA16-0001 Standard Paint SpecificationEDANORR NAVALPas encore d'évaluation

- BS en 10181-2019Document16 pagesBS en 10181-2019Federico De Martini100% (1)

- Syllabus Agri 2015Document248 pagesSyllabus Agri 2015parvathivignesh279Pas encore d'évaluation

- GC Training PDFDocument74 pagesGC Training PDFberry Mike100% (1)

- ChaperonsDocument2 pagesChaperonsFabiola Castilla AguilarPas encore d'évaluation

- A1.1.4 Adhesion of Water To Materials That Are Polar or Charged and Impacts For Organisms.Document10 pagesA1.1.4 Adhesion of Water To Materials That Are Polar or Charged and Impacts For Organisms.taiga.aisaka14404Pas encore d'évaluation

- Repsol - RBD Palm Oil SpecsDocument1 pageRepsol - RBD Palm Oil Specskingkongkongking01Pas encore d'évaluation

- Water Chemistry (Dulal Sir) PDFDocument289 pagesWater Chemistry (Dulal Sir) PDFtej94Pas encore d'évaluation

- Recent Developments in Multifunctional Coatings For Solar Panel Applications A Review PDFDocument28 pagesRecent Developments in Multifunctional Coatings For Solar Panel Applications A Review PDFkjjPas encore d'évaluation

- Organometallic ChemistryDocument25 pagesOrganometallic ChemistryKaran RavalPas encore d'évaluation

- Hand Written NotesDocument12 pagesHand Written NotesOne phase 23Pas encore d'évaluation

- Consolidate - Question Paper & Answer Key For The Post of Peon - Advt. No. ENT-04 of 2022Document30 pagesConsolidate - Question Paper & Answer Key For The Post of Peon - Advt. No. ENT-04 of 2022himanshujagga0Pas encore d'évaluation

- Drying Chapter 8 PDFDocument15 pagesDrying Chapter 8 PDFketan sharmaPas encore d'évaluation

- Catálogo de Válvulas de Segurança ApolloDocument1 pageCatálogo de Válvulas de Segurança Apolloarhon berdichPas encore d'évaluation

- Temperature Stability of Oxytocin Ampoules LabelleDocument7 pagesTemperature Stability of Oxytocin Ampoules Labelletoper kiritoPas encore d'évaluation

- Module 7 CytogeneticsDocument37 pagesModule 7 CytogeneticsJash SamaPas encore d'évaluation

- Question PaperDocument16 pagesQuestion PaperAashi AkterPas encore d'évaluation

- Entrance Mark Division: Eligibility Criteria: For Be Civil and Be ElectricalDocument21 pagesEntrance Mark Division: Eligibility Criteria: For Be Civil and Be ElectricalaayushPas encore d'évaluation

- Regulated Imports 2015 04 06 Version 2 Sorted by CategoryDocument6 105 pagesRegulated Imports 2015 04 06 Version 2 Sorted by CategoryMeowthemathicianPas encore d'évaluation

- Experiment 2 Uv-Visible Determination of An Unknown Concentration of Kmno SolutionDocument8 pagesExperiment 2 Uv-Visible Determination of An Unknown Concentration of Kmno SolutionNurul Syafinaz RohizatPas encore d'évaluation

- Atomic Structure Mark Scheme: Science Exams SortedDocument8 pagesAtomic Structure Mark Scheme: Science Exams SortedSaima Usman - 41700/TCHR/MGBPas encore d'évaluation

- Zeolite-Embedded Silver Extends Antimicrobial Activity of Dental AcrylicsDocument6 pagesZeolite-Embedded Silver Extends Antimicrobial Activity of Dental AcrylicsMario Rivera CortesPas encore d'évaluation

- Some Basic Concepts of Chemistry-Exercise With SolutionsDocument24 pagesSome Basic Concepts of Chemistry-Exercise With Solutionssureshgdvm67% (15)