Académique Documents

Professionnel Documents

Culture Documents

FT.V 3200S

Transféré par

tamasraduCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

FT.V 3200S

Transféré par

tamasraduDroits d'auteur :

Formats disponibles

! '() '" "!" ( !

!"

#" !

"!" $ % &

* + ,-$

Descriere Produsele EPOMID V 3200S sunt vopsele bicomponente, pe baza de rasini epoxidice si

Description fosfat de zinc.Prezinta rezistenta buna la actiunea factorilor de mediu, buna rezistenta la

petrol, ulei mineral, solutii saline 28%, solutie de NaOH 3%, rezistenta buna la apa,

rezistenta buna la temperaturi ridicate (100 - 150C), rezistenta buna la variatii de

temperatura, caracteristici mecanice ridicate (duritate, soc mecanic, flexibilitate), aderenta

foarte buna la diverse tipuri de suport, usor de reacoperit.

EPOMID V 3200S products are two- component paints, based on epoxy resins and zinc phosphate.

Good weather resistance, good resistance to petroleum, mineral oil, salt solutions 28%, 3% solution

of NaOH , good resistance to water, good resistance to high temperature (100 - 150C), good

resistance to temperature variations, high mechanical characteristics (hardness, mechanical shock,

flexibility), very good adherence to different substrates, easy to re-coat.

Utilizare Vopselele V 3200S sunt utilizate ca strat primar sau intermediar pentru:

Recommended use -protectia suprafetelor din otel, a reperelor de metal expuse la diverse conditii favorabile

coroziunii;

-in domeniul constructiei si reparatiei navelor si platformelor marine, pentru protectia

tancurilor de produse lichide, punti interioare si exterioare, instalatii din compartimentul

masinilor, magazii frigorifice, motoare principale, pompe, filtre etc.;

-protectia interioara si exterioara a rezervoarelor de ape reziduale si produse petroliere

(uleiuri minerale, benzina, motorina, hidrocarburi etc.);

-protectia utilajelor din industria chimica, alimentara, farmaceutica, constructii de masini,

vagoane si diverse utilaje;

-protectia constructiilor metalice diverse: poduri, macarale, s.a.;

-protectia elementelor de rezistenta ale constructiilor din otel.

Sunt recomandate pentru climatele: TH, TA, MT, F, N, M.

V 3200S series paints are used as primary or intermediate coat for:

-protection of steel surfaces, metal parts exposed to different corrosion conditions;

-within the field of ships and marine platforms construction and repairing, for protecting of liquids

storage tanks, inside and outside decks, equipment from engines room, cold rooms, main motors,

pumps, filters, etc.;

-inside and outside protection of tanks of waste water and petroleum products (mineral oils, petrol,

gas oil, hydrocarbons, etc.);

-protection of equipment from chemical, food , pharmaceutical industry, mechanical engineering,

waggons and different outfits;

-protection of different metallic constructions: bridges, cranes, etc.;

-protection of strength parts of steel structures.

They are recommended for TH, TA, MT, F, N, M climates.

Temperatura de lucru 150C max.

Service temperature

Sortimente -rosu oxid V 3273SFZ -red oxide

Assortments -gri V 3282SFZ -green

-negru V 32900SFZ -black

Alte culori conform cartelelor RAL sau KBER.

Other assortments in accordance with RAL or KBER colour cards.

! "#$ % & ' ()**+++&$ % &

! '() '" "!" ( !

!"

#" !

"!" $ % &

* + -$

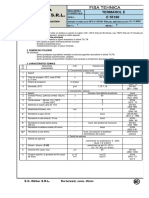

CARACTERISTICI TEHNICE

TECHNICAL DATA

Aspect V 32900SFZ Alte culori

Finish Other colours

Mat Semilucios vizual

Mat Semiglossy visual

Luciu, 60 SRENISO 2813:2003

Gloss , 60 < 20% 40 - 70%

Volum de solide 40% approx. 48% approx. -

Volume solids

Densitate 1,14 kg/l approx. 1.26 kg/l approx. SREN ISO 2811-1:2002

Specific gravity (at 23 C) (at 23 C)

VOC 550g/l (45%)- pentru negru SRENISO 11890-1:2002

Volatile organic compound 515g/l (41%) - alte culori

Timp de curgere 30 - 70s IL-DC-09

Flow time (at 20 C, cup, 4 mm)

Duritate Persoz, min. 140 s SRENISO 1522:2002

Persoz hardness, minimum

Aderenta, grila de 1 mm 1 SREN ISO 2409:2003

Adherence to substrate, 1 mm grid

Uscare, approx. (at 23 C, 50 5% rel. hum.) ASTMD 1640:2003

Dry- to- touch (Tip B) 3 hours

Dry- to- handle (Tip D) 8 hours

Fully cured 7 days

Valabilitate in ambalaj 6 luni de la data fabricatiei, in conditiile respectarii prevederilor de ambalare si

Shelf life depozitare. In functie de conditiile de depozitare, inaintea utilizarii se recomanda

amestecarea produsului.

6 months from the production date, with the observance of the storage and packing

provisions.

Depending on the storage conditions, it is recommended to stir the product before use.

DETALII DE APLICARE

APPLICATION DETAILS

Raport de amestecare Vopsea V 3200S : Intaritor I 322 100p : 20p masic (75p : 25p volumic)

Mixing ratio Base V 3200S : Curing agent I 322 100p : 20p by weight (75p : 25p by volume)

Timp de prereactie 30 min. -

Pre-reaction time (at 23 C)

Interval de utilizare 16 hours SRENISO 9514 : 1997

Pot life (at 23 C)

Metoda de aplicare pensulare pulverizare aer pulverizare airless

Application method brushing( touch up) air spraying airless spraying

Diluant utilizat / Dilutie - - -

Thinner / Thinning ( optional : max. 3% D 302) ( optional : max. 3% D 302) ( optional : max. 3% D 302)

Presiune - 3 - 4 atm 140 - 160 atm

Pressure

Diametru duza - 1.8 - 2.2 mm 0.028 - 0.053

Nozzle orifice

Curatare instrumente KBER CLEANER DKC 003-02S

Cleaning of tools

! "#$ % & ' ()**+++&$ % &

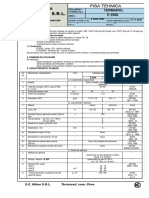

! '() '" "!" ( !

!"

#" !

"!" $ % &

pag.3/5

Grosime strat umed V 32900SFZ Alte culori SRENISO 2808: 2002

Typical wet film thickness Other colour

125 m approx. 105 m approx.

Grosime strat uscat

Typical dry film thickness 50 m approx. 50 m approx. SRENISO 2808: 2002

Interval de reacoperire Vezi mai jos REACOPERIRE

Re-coating interval See RE-COATING below

2 2

Consum teoretic 140 g/m approx - 50m 130 g/m approx - 50m

Theoretical spreading rate 2

8,0 m /l approx - 50m

2

9,6 m /l approx - 50m

Consum practic Consumul practic este functie de conditiile de aplicare (geometria suprafetei, metoda de

Practical spreading rate aplicare, conditiile de mediu) si poate fi 1.2 - 1.5 x consumul teoretic.

Practical spreading rate depends on the application conditions (surface geometry, application

method, environmental conditions) and can be 1.2 - 1.5 x theoretical spreading rate.

Observatie Nu se recomanda amestecarea produselor seria V 3200S cu alte produse.

Remark (alte produse = intaritori, diluanti, agenti de curatare- altele decat cele recomandate de

producator).

Mixing V 3200S series products with other products is not recommended.

(other products = curing agents, thinners, cleaners - others than those recommended by producer)

PREGATIREA Gradul de pregatire a suportului este determinant in obtinerea performantelor sistemului

SUPRAFETEI de protectie. Suportul nu trebuie sa aiba defecte de suprafata (suprapuneri de material,

SURFACE fisuri, stropi de sudura, etc.).

PREPARATION Suprafete metalice noi: sablare la gradul Sa 2 in conformitate cu SRENISO 8501-1:2002

sau 2 conform STAS 10166 / 1- 77, pregatirea suprafetei realizandu-se in conformitate cu

SREM ISO 8504-1:2002, SREN ISO 8504-2:2002, SREN ISO 8504-3:2002.

Se desprafuieste apoi suprafata cu aer comprimat.

Suprafete vechi: indepartare vopsea veche, degresare cu detergent, indepartarea sarii

sau a altor contaminanti prin curatare cu apa (la presiune ridicata), sablare la minim Sa 2

sau curatare mecanica la gradul St 3 (periere energica in directii perpendiculare),

desprafuire. Se evita lustruirea suprafetelor.

The degree of substrate preparation is decisive for the protective system performance.

The substrate should not present surface defects (material overlapping, cracks, welding drops, etc.).

New metallic surfaces: abrasive blasting Sa 2 in accordance with SRENISO 8501-1:2002 or 2 in

accordance with STAS 10166 / 1 -77, surface preparation is achieved in accordance with SREN ISO

8504-1:2002, SREN ISO 8504-2:2002, SEN ISO 8504-3:2002. Then the surface is dedusted with

compressed air.

Old metallic surfaces: removal of the old paint, degreasing with detergent, removal of salt or other

contaminants by high pressure fresh water cleaning, abrasive blasting minimum Sa 2 or mechanical

cleaning at St3 (strong brushing in perpendicular directions), dedusting. The surfaces polishing

should be avoided.

CONDITII DE Vopselele seria V 3200S se vor aplica pe suprafete curate si uscate, ce vor avea

APLICARE temperaturi peste temperatura punctului de roua pentru evitarea condensarii umiditatii pe

APPLICATION suport.Umiditatea relativa va fi de max. 70%. Aplicarea decurge in conditii optime daca se

CONDITIONS asigura o temperatura a mediului ambiant si a amestecului de 10 - 30C.

V 3200S series paints should be applied only on dry and clean surfaces with temperatures above

the dew point temperature in order to avoid condensation. The relative humidity should be of max.

70%. Application is made under optimal conditions if is ensured a temperature of the ambient

environment and mixture of 10 - 30C.

! "#$ % & ' ()**+++&$ % &

! '() '" "!" ( !

!"

#" !

"!" $ % &

pag.4/5

Observatie Vopselele seria V 3200S sunt destinate acoperirilor profesionale.

Remark

V 3200S series primers are destined to professional uses.

INSTRUCTIUNI DE Se conditioneaza componentii la temperatura de 10 - 30C, se omogenizeaza bine si apoi

APLICARE se prepara amestecul: 100 parti (masic) component A + 20 parti (masic) component B. Pe

APPLICATION durata timpului de prereactie (30 minute) se continua amestecarea prin agitare. Dupa

INSTRUCTIONS prereactie si inainte de aplicare amestecul se dilueaza in proportiile recomandate sau in

proportiile necesare pentru a obtine grosimile de pelicula cerute. Astfel pregatite produsele

seria V 3200S se pot aplica:

-direct pe suprafata metalica pregatita corespunzator sau peste grunduri bogate in zinc

(de ex.: grund epoxidic G 3202-1, grund pe baza de etilsilicat G 4101)

-ca strat primar sau intermediar peste care se pot aplica sisteme de acoperire: epoxidice,

epoxi-gudron, poliuretanice, alchidice.

Straturile succesive de vopsea seria V 3200S se pot aplica dupa uscarea la aer

(min. 4 ore la 20C) a stratului anterior, sau in sistem ud-ud, aplicat prin pulverizare la

15-20 minute de la aplicarea primului strat.

The components should be conditioned at 10-30C, well homogenized and then the mixture is

prepared as follows: 100 parts (weight) component A + 20 parts (weight) component B. During pre-

reaction time (30 minutes) keep on mixing by stirring. . After pre-reaction time and before application

the mixture is thinned in recommended proportions or in necessary proportions for obtaining the

required thickness of the film.

Thus prepared the V 3200S paints can be applied:

-directly on the metallic surface properly prepared or over zinc rich primers (e.g.: epoxy primer

G 3202-1, ethylsilicate primer G4101);

-as primary or intermediate coat over which can be applied coating systems: epoxy, epoxy- tar,

polyurethanes, alkydes.

Successive coats of V 3200S paint can be applied after air drying (min. 4 hours at 20C) of the

previous coat, or in wet- on- wet system, applied by spraying 15 -20 minutes after the application of

the first coat.

REACOPERIRE In conditiile unei ventilatii suficiente, intervalele optime de reacoperire pentru vopselele

RE-COATING seria V 3200S, la temperatura de 20C, sunt urmatoarele (pentru o grosime de strat uscat

de 50 m):

Under conditions of sufficient ventilation the optimum re-coating intervals for V 3200S series paints

(50 m dry film thickness), at 20C temperature, are as follows:

E 3200 ES 5400V E 3900

Min. Max. Min. Max. Min. Max.

24 h 30 zile 18 h 48 zile 48 h 72 h

24 h 30 days 18 h 48 days 48 h 72 h

! "#$ % & ' ()**+++&$ % &

! '() '" "!" ( !

!"

#" !

"!" $ % &

* + $-$

Observatii Inainte de reacoperire, dupa expunerea in medii contaminate, suprafetele vor fi bine

Remarks curatate prin spalare cu jet de apa la presiune ridicata, urmata de uscare. In cazul

depasirii intervalului maxim de reacoperire, se va proceda la o asperizare a suprafetei

pentru a se asigura o buna aderenta pentru straturile urmatoare.

Atingerea intervalelor maxime de reacoperire, asigurarea unei bune aderente, precum si

bune proprietati mecanice implica asigurarea urmatoarelor:

-vopseaua trebuie aplicata intr-o grosime de strat uscat in jurul valorii de 50 m;

-stratul de vopsea obtinut trebuie sa fie uniform, de buna calitate si fara urme de

pulverizare uscata;

-conditiile de uscare si intarire vor fi conform celor specificate la punctul CONDITII DE

APLICARE pana la intarirea completa;

-suprafetele TREBUIE sa fie perfect curate inaintea reacoperirii.

Suprafetele vopsite pot fi expuse doar pentru scurte perioade de timp direct la lumina

solara (UV), altfel intervalele de reacoperire maxime nu mai sunt valabile.

Before re-coating, after exposure in contaminated environment, clean the surface thoroughly by

(high pressure) fresh water jetting and let it dry. If the maximum re-coating interval is exceeded,

roughening of the surface is necessary to ensure good intercoat adhesion to following coats.

For reaching the maximum re-coating intervals, ensuring a good adherence as well as good

mechanical properties the following conditions should be ensured:

-the paint has a dry film thickness as near as possible to 50 m;

-the film formed is uniform, qualitative and "dry spray- free";

-the drying and curing conditions are according to the APPLICATION CONDITIONS until full cure is

obtained;

-the surfaces MUST be completely clean before re-coating.

The coated surfaces can be exposed only for short periods, directly to sunlight (ultra-violet light),

otherwise the maximum re-coating intervals are not valid.

AMBALARE Vopselele seria V 3200S: bidoane metalice de 22l (20 kg).

PACKING Intaritor I 322: cutii de 6.5 l (4 kg), bidoane metalice de 22l(15kg).

V 3200S series paints: metallic buckets of 22l (20 kg).

Curing agent I 322: metallic cans of 6.5l (4 kg), metallic buckets of 22l(15kg).

SECURITATEA MUNCII Toate operatiile de manipulare, transport, depozitare, utilizare se vor realiza respectand cu

WORK SAFETY strictete normele de prevenire a incendiilor, normele de protectia muncii si igiena sanitara.

Se interzice: prezenta oricaror surse de foc, vopsirea in spatii fara o ventilatie

corespunzatoare, contactul direct al pielii cu produsul respectiv, inhalarea prelungita a

vaporilor, ingerarea produsului.

All the operations of handling, transport, storage and use should be accomplished in strict

compliance with the fire prevention, safety and health norms. The presence of any fire source,

painting in areas without adequate ventilation, direct contact of skin with the respective product,

prolonged inhalation of vapors and ingestion of the product should be forbidden.

NOTA Toate aceste date au caracter general privind performantele si utilizarea produsului, de

NOTE aceea recomandam testarea produsului in conditiile propriei tehnologii de aplicare a

beneficiarului.

Rugam consultati producatorul pentru lamuriri suplimentare.

All these data have a general character regarding the performance and use of the product; therefore

we recommend the testing of the product under conditions specific to the application technology of

the beneficiary.

Please contact the producer for further information.

! "#$ % & ' ()**+++&$ % &

Vous aimerez peut-être aussi

- FT.G 3202-1Document5 pagesFT.G 3202-1tamasraduPas encore d'évaluation

- Profile MetaliceDocument65 pagesProfile Metalicecornel_bucur_2Pas encore d'évaluation

- Manual RAZOR RCS Z-100 Z-200 RO v1.5Document13 pagesManual RAZOR RCS Z-100 Z-200 RO v1.5Cristi Schipor100% (1)

- Catalog - Sudarea Cu Arc Electric4920026195069149795 PDFDocument93 pagesCatalog - Sudarea Cu Arc Electric4920026195069149795 PDFRobert TeodorescuPas encore d'évaluation

- SR en 1943Document114 pagesSR en 1943Vasi ChiriacPas encore d'évaluation

- Regimuri Sudare - RelatiiDocument3 pagesRegimuri Sudare - RelatiiAlexandru DascalitaPas encore d'évaluation

- Manual Instalare SontecDocument11 pagesManual Instalare SontecDan DanubiusPas encore d'évaluation

- Indicatii Proiectare Chiller MideaDocument90 pagesIndicatii Proiectare Chiller Mideageorgianconstantin100% (1)

- Fisa Tehnica Radiator Otel Ferroli 22 PKKPDocument2 pagesFisa Tehnica Radiator Otel Ferroli 22 PKKPcosmin_crys83Pas encore d'évaluation

- Otel de Scule - 1 - 2379Document3 pagesOtel de Scule - 1 - 2379Petrus UngureanuPas encore d'évaluation

- Motor Asincron Trifaza in ColivieDocument3 pagesMotor Asincron Trifaza in ColivieFlorin PavelPas encore d'évaluation

- Tipuri de Tevi - MAironDocument2 pagesTipuri de Tevi - MAironBravooo8344Pas encore d'évaluation

- Indrumar Tehnician Prelucrari MecaniceDocument33 pagesIndrumar Tehnician Prelucrari MecanicevintiloiusPas encore d'évaluation

- GHIDDocument18 pagesGHIDCatalin StanPas encore d'évaluation

- Caiet de Sarcini Paratrasnet StadionDocument3 pagesCaiet de Sarcini Paratrasnet StadionvizanteaPas encore d'évaluation

- Camin Tragere Cabluri - Fisa Tehnica-1Document2 pagesCamin Tragere Cabluri - Fisa Tehnica-1Sorin StanPas encore d'évaluation

- Statie PECO - Terasament f3Document1 pageStatie PECO - Terasament f3Luciana LePas encore d'évaluation

- Proiect TSP: Student: Andon Alis-GheorgheDocument25 pagesProiect TSP: Student: Andon Alis-GheorgheBogdan DumitrascuPas encore d'évaluation

- Camin Debitmetru 09-09-2015Document1 pageCamin Debitmetru 09-09-2015Rada IoanPas encore d'évaluation

- Indicativ C-133-1982 Imbinari Cu SIRPDocument24 pagesIndicativ C-133-1982 Imbinari Cu SIRPilepadatuPas encore d'évaluation

- F PI AW CAW 145 05 Ed01 Rev5 Cklist MOEDocument47 pagesF PI AW CAW 145 05 Ed01 Rev5 Cklist MOEoniPas encore d'évaluation

- PAFSIN-Conducte Flowtite PT ApaDocument40 pagesPAFSIN-Conducte Flowtite PT Apabik3ruPas encore d'évaluation

- Particularități În Fabricația Unei Matrițe Experimentale.Document27 pagesParticularități În Fabricația Unei Matrițe Experimentale.Ilie_Andreea100% (1)

- REFLEX C InstalareDocument24 pagesREFLEX C InstalareAnghel DumitriuPas encore d'évaluation

- Buderus SC20Document18 pagesBuderus SC20Razvan DragneaPas encore d'évaluation

- Alegerea Materiale, Dimens, VerificareDocument52 pagesAlegerea Materiale, Dimens, VerificareAlex FilipPas encore d'évaluation

- Instructiuni Montaj Tubulatura Buderus Logamax Plus GB 162Document28 pagesInstructiuni Montaj Tubulatura Buderus Logamax Plus GB 162Nicolae Chiriac100% (1)

- 118 - Acumulator Apa Rece - Montaj Si UtilizareDocument6 pages118 - Acumulator Apa Rece - Montaj Si UtilizaresebarchieviciPas encore d'évaluation

- Dedurizator Decalux 10 CronoDocument24 pagesDedurizator Decalux 10 CronoTomescu MarianPas encore d'évaluation

- AKL - TPZ ScurtDocument12 pagesAKL - TPZ Scurtbradu09100% (1)

- Agrement Azur VopseaDocument15 pagesAgrement Azur VopseaSárközi Pál-Zoltán100% (1)

- NT I.1 Norme Tehnice de Proiectare-ExecutieDocument92 pagesNT I.1 Norme Tehnice de Proiectare-Executiesorion61Pas encore d'évaluation

- Normativ I 8-78Document23 pagesNormativ I 8-78costinPas encore d'évaluation

- Calculul Grosimii de Proiectar1Document3 pagesCalculul Grosimii de Proiectar1Cosmin BrebeanuPas encore d'évaluation

- Lista Materiale Sanitare InterioareDocument3 pagesLista Materiale Sanitare InterioareMitroKtaPas encore d'évaluation

- Proiectarea Unui BurghiuDocument12 pagesProiectarea Unui BurghiuWillie HollandPas encore d'évaluation

- 3.mecanism de Ridicare 2 Vederi Laterale - MACARADocument1 page3.mecanism de Ridicare 2 Vederi Laterale - MACARAFlorin BuzeaPas encore d'évaluation

- Robinet Rae Actionat ElectricDocument9 pagesRobinet Rae Actionat ElectricDaniel ProncoschiPas encore d'évaluation

- Fisa Tehnica Vibrator Pentru Beton Alfa 50 7004786Document2 pagesFisa Tehnica Vibrator Pentru Beton Alfa 50 7004786Paul PaulPas encore d'évaluation

- Suruburi Pasuire Forma ADocument12 pagesSuruburi Pasuire Forma AAdrian BurlacuPas encore d'évaluation

- Catalog Echipamente SAF-FRO-Baza Tehnica Alfa-Litcud4Document139 pagesCatalog Echipamente SAF-FRO-Baza Tehnica Alfa-Litcud4Mihail MiteaPas encore d'évaluation

- Breviar de Calcul - Instalatii de Detectie Si Alarmare La IncendiuDocument2 pagesBreviar de Calcul - Instalatii de Detectie Si Alarmare La IncendiuRadu ZamfirescuPas encore d'évaluation

- Hilti Ancore Mecanice PDFDocument19 pagesHilti Ancore Mecanice PDFAlexandru PetreaPas encore d'évaluation

- Tabel de Calcul Necesar Racire Vdi2078Document7 pagesTabel de Calcul Necesar Racire Vdi2078Sandor ManesesPas encore d'évaluation

- DiafragmaDocument8 pagesDiafragmaHoria ZecheruPas encore d'évaluation

- Tehnoplus PDFDocument4 pagesTehnoplus PDFDanielRomeo CretuPas encore d'évaluation

- Arcelormittal Panouri Sandwich Arval Accesorii Depozitare TransportDocument8 pagesArcelormittal Panouri Sandwich Arval Accesorii Depozitare TransportIon ChersacPas encore d'évaluation

- Lista Preturi MAX Giurgiu RocastDocument120 pagesLista Preturi MAX Giurgiu RocastDan TararaPas encore d'évaluation

- Vana Amestec 3-CaiDocument5 pagesVana Amestec 3-Caipetre dirstarPas encore d'évaluation

- Ft. GS 5400V PDFDocument5 pagesFt. GS 5400V PDFtamasraduPas encore d'évaluation

- FT.G 3200S Grund EpomidDocument5 pagesFT.G 3200S Grund Epomidm_a_1993Pas encore d'évaluation

- Ft.e 3900Document6 pagesFt.e 3900tamasraduPas encore d'évaluation

- FT.V3300HS Vopsea Epoxi EponimDocument5 pagesFT.V3300HS Vopsea Epoxi Eponimm_a_1993Pas encore d'évaluation

- 83 Deko L 3000 Lac Amorsa - FT 83 Rev 0Document4 pages83 Deko L 3000 Lac Amorsa - FT 83 Rev 0Dan George IIIPas encore d'évaluation

- FT G 3200HS PDFDocument5 pagesFT G 3200HS PDFtamasraduPas encore d'évaluation

- FT Alkigrunt M DTMDocument4 pagesFT Alkigrunt M DTMAlina DimaPas encore d'évaluation

- 1-GE 053-04-Ghid de Executie Privind Protectia Impotriva Coroziunii A Constructiilor Din OtelDocument23 pages1-GE 053-04-Ghid de Executie Privind Protectia Impotriva Coroziunii A Constructiilor Din OtelCuciureanu GheorghePas encore d'évaluation

- Epomid G 3200Hs: Technical Data SheetDocument5 pagesEpomid G 3200Hs: Technical Data SheettamasraduPas encore d'évaluation

- Caiet Sarcini Umpluturi Si Fundatii - DOROSOL C30Document12 pagesCaiet Sarcini Umpluturi Si Fundatii - DOROSOL C30Iulian TabaraPas encore d'évaluation

- PTL 039Document5 pagesPTL 039Virginia Elena IordachePas encore d'évaluation

- Ft. e 55180Document2 pagesFt. e 55180tamasraduPas encore d'évaluation

- Ft. e 5500Document2 pagesFt. e 5500tamasraduPas encore d'évaluation

- Ft. e 3200SMDocument3 pagesFt. e 3200SMtamasraduPas encore d'évaluation

- Grund Anticoroziv in Dispersie Apoasa AutoreticulabilDocument3 pagesGrund Anticoroziv in Dispersie Apoasa AutoreticulabiltamasraduPas encore d'évaluation

- Ft. e 8900Document4 pagesFt. e 8900tamasraduPas encore d'évaluation

- Grund Anticoroziv in Dispersie Apoasa AutoreticulabilDocument3 pagesGrund Anticoroziv in Dispersie Apoasa AutoreticulabiltamasraduPas encore d'évaluation

- Ft. e 5500Document2 pagesFt. e 5500tamasraduPas encore d'évaluation

- Ft. e 3200MDocument3 pagesFt. e 3200MtamasraduPas encore d'évaluation

- Ft. e 2200Document1 pageFt. e 2200tamasraduPas encore d'évaluation

- D391 FTDocument1 pageD391 FTtamasraduPas encore d'évaluation

- Ft. e 3200MDocument3 pagesFt. e 3200MtamasraduPas encore d'évaluation

- Ft. e 2200Document1 pageFt. e 2200tamasraduPas encore d'évaluation

- Ft. e 2200Document3 pagesFt. e 2200tamasraduPas encore d'évaluation

- Ft. C 5000 PDFDocument3 pagesFt. C 5000 PDFtamasraduPas encore d'évaluation

- FT G 3200HS PDFDocument5 pagesFT G 3200HS PDFtamasraduPas encore d'évaluation

- Ft. C 5101C PDFDocument3 pagesFt. C 5101C PDFtamasraduPas encore d'évaluation

- FT V 3200HSDocument5 pagesFT V 3200HStamasraduPas encore d'évaluation

- FT GS 5400VDocument5 pagesFT GS 5400VtamasraduPas encore d'évaluation

- FT.G 5700Document5 pagesFT.G 5700tamasraduPas encore d'évaluation

- Ft. C 320 PDFDocument3 pagesFt. C 320 PDFtamasraduPas encore d'évaluation

- FT G 5700 PDFDocument5 pagesFT G 5700 PDFtamasraduPas encore d'évaluation

- FT Es 5400V - L, SL, SM, M - 2004 PDFDocument6 pagesFT Es 5400V - L, SL, SM, M - 2004 PDFtamasraduPas encore d'évaluation

- FT.V 3300hsmDocument2 pagesFT.V 3300hsmtamasraduPas encore d'évaluation

- Ft.e 3900Document6 pagesFt.e 3900tamasraduPas encore d'évaluation

- E3200Document8 pagesE3200m_bivolaruPas encore d'évaluation

- FT.G 4101Document6 pagesFT.G 4101tamasraduPas encore d'évaluation

- E3200Document8 pagesE3200m_bivolaruPas encore d'évaluation