Académique Documents

Professionnel Documents

Culture Documents

Inconel 112-Datasheet

Transféré par

robertTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Inconel 112-Datasheet

Transféré par

robertDroits d'auteur :

Formats disponibles

10

Ni-Cr-Mo Welding Electrode

www.specialmetalswelding.com

INCONEL Welding Electrode 112

INCONEL Welding Electrode 112

INCONEL Welding Electrode 112 is used for shielded-metal-arc welding of INCONEL

alloy 625, INCOLOY alloy 825, INCOLOY alloy 25-6MO, and other molybdenum-contain-

ing stainless steels. It is also used for surfacing of steel and for welding various corrosion-

resistant alloys such as alloy 20. The weld metal has high strength at room and elevated tem-

peratures and has exceptional corrosion resistance, including resistance to pitting, crevice

corrosion, and polythionic acid stress-corrosion cracking. INCONEL Welding Electrode 112 is

useful for many dissimilar joints involving INCONEL alloys, INCOLOY alloys, stainless steels,

low-alloy steels, and carbon steels.

The electrodes provide excellent operability for groove and fillet welding in the downhand

position and the smaller diameter electrodes are also suitable for all position welding. Power

supply: direct current, electrode positive.

Specifications

AWS A5.11 ENiCrMo-3 (UNS W86112)

ASME II C SFA-5.11, ENiCrMo-3 (UNS W86112)

ASME IX, F-No.43

*DIN 1736 EL-NiCr20Mo9Nb (2.4621)

*(EN) ISO 14172 ENi6625 (NiCr22Mo9Nb)

*Supply to these specifications available upon request

For manufacture to ASME III (NCA3800, NB2400), MIL and other specifications

please refer your inquiry to the Technical Department prior to order placement.

Approvals

Canadian Welding Bureau

VdTUV 4450.00

Other approvals may be applicable. Please confirm details of current scope of

approvals with the Technical Department prior to order placement.

Limiting Ni+Co .................... 55.0 min. Si ............................ 0.75 max.

Chemical C .............................. 0.10 max. Cr .......................... 20.0-23.0

Composition Mn .............................. 1.0 max. Nb+Ta .................... 3.15-4.15

Fe .............................. 7.0 max. Mo ............................ 8.0-10.0

S .............................. 0.02 max. P ............................ 0.03 max.

Cu .......................... 0.50 max. Others ................ 0.50 max.

Minimum Tensile Strength, psi 110,000

Mechanical MPa 758

Properties Elongation, (4d) % 30

Available Product Forms Supplied in 10lbs (4.54kg) hermetically sealed containers

Diameter mm 2.4 3.2 4.0 4.8

in 3/32 1/8 5/32 3/16

Length mm 229 356 356 356

in 9 14 14 14

Current (DC+) A 40-65 65-90 90-125 125-160

Vous aimerez peut-être aussi

- Inconel 82 PDFDocument1 pageInconel 82 PDFMiguel MorenoPas encore d'évaluation

- fm82 1Document1 pagefm82 1harikrishnanPas encore d'évaluation

- High Temperature Brazing AlloysDocument0 pageHigh Temperature Brazing AlloysvkmsPas encore d'évaluation

- Westermann Table 8Document1 pageWestermann Table 8muhd.qasimPas encore d'évaluation

- Welding Consumables For Hydro Power StationsDocument16 pagesWelding Consumables For Hydro Power StationsMohamed FaragPas encore d'évaluation

- Monel K500 PDFDocument6 pagesMonel K500 PDFOZAIRTRADELINKPas encore d'évaluation

- Pinnacle Alloys ENiCrFe 3 12.16Document2 pagesPinnacle Alloys ENiCrFe 3 12.16satnamPas encore d'évaluation

- Product Data Sheet: Afrox 7018-1Document2 pagesProduct Data Sheet: Afrox 7018-1Gervasio AndradePas encore d'évaluation

- The Australian Welding Guide PDFDocument220 pagesThe Australian Welding Guide PDFThành Nguyễn XuânPas encore d'évaluation

- KuVa - MFI01 101ENDocument20 pagesKuVa - MFI01 101ENmichel92748Pas encore d'évaluation

- 12 - Vdmee E69 4Document10 pages12 - Vdmee E69 4el_tirano_regresa7359100% (1)

- 1.6580, DIN 30CrNiMo8, AISI 4340 Round Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Forging,1.6580, DIN 30CrNiMo8, AISI 4340 Sheet,1.6580, DIN 30CrNiMo8, AISI 4340 Coil,1.6580, DIN 30CrNiMo8, AISI 4340 Flat Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Pipe,LrregularDocument3 pages1.6580, DIN 30CrNiMo8, AISI 4340 Round Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Forging,1.6580, DIN 30CrNiMo8, AISI 4340 Sheet,1.6580, DIN 30CrNiMo8, AISI 4340 Coil,1.6580, DIN 30CrNiMo8, AISI 4340 Flat Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Pipe,Lrregularroberto_perraciniPas encore d'évaluation

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoPas encore d'évaluation

- Stick Electrodes For Welding of Stainless Steels: Part NumberDocument19 pagesStick Electrodes For Welding of Stainless Steels: Part NumberAyman RiyadhPas encore d'évaluation

- Kavish DesaiDocument33 pagesKavish DesaiKavish DesaiPas encore d'évaluation

- Esab DublexDocument8 pagesEsab DublexSuphi YükselPas encore d'évaluation

- Properties and Welding Procedure For Grade 91 Alloy Steel: Siddharth Pant and Swati BhardwajDocument6 pagesProperties and Welding Procedure For Grade 91 Alloy Steel: Siddharth Pant and Swati BhardwajArvind ShuklaPas encore d'évaluation

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerPas encore d'évaluation

- SAF Welding Cutting GuideDocument165 pagesSAF Welding Cutting GuideSelvem0% (1)

- Manufacturers of advanced welding consumables data sheet for cobalt alloy NS-ECo-6Document1 pageManufacturers of advanced welding consumables data sheet for cobalt alloy NS-ECo-6yadi_baePas encore d'évaluation

- Stick electrodes for welding steels and stainless steelsDocument46 pagesStick electrodes for welding steels and stainless steelsAdeKusumahPas encore d'évaluation

- EN19 Alloy Steel Properties GuideDocument5 pagesEN19 Alloy Steel Properties GuideNaiduPas encore d'évaluation

- Welding TrainingDocument87 pagesWelding Trainingeswar100% (1)

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelPas encore d'évaluation

- ENiFe CI 55 1Document2 pagesENiFe CI 55 1akashmalayiPas encore d'évaluation

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakPas encore d'évaluation

- ELT-05-ET-TS-0003 - Specification For Welding Consumable For 9% Ni Steel - R0Document12 pagesELT-05-ET-TS-0003 - Specification For Welding Consumable For 9% Ni Steel - R0jorgekarlosprPas encore d'évaluation

- Arc Welding ElectrodesDocument6 pagesArc Welding ElectrodeswaleedyossefPas encore d'évaluation

- WB56S M.M.A. welding electrode specificationsDocument1 pageWB56S M.M.A. welding electrode specificationslathasri78Pas encore d'évaluation

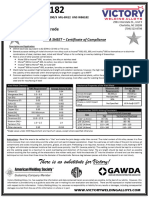

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianPas encore d'évaluation

- 17 4 PHDocument2 pages17 4 PHzaranrajputPas encore d'évaluation

- Creep-Resistant Steels - TWIDocument6 pagesCreep-Resistant Steels - TWIJlkKumarPas encore d'évaluation

- Creep-Resistant Steels - TWI PDFDocument6 pagesCreep-Resistant Steels - TWI PDFFarid Ahmed KhwajaPas encore d'évaluation

- Duplex Stainless Steels: Properties and Welding TechniquesDocument25 pagesDuplex Stainless Steels: Properties and Welding Techniqueskdsenipah6667Pas encore d'évaluation

- Metrode 410NiMo B-11Document4 pagesMetrode 410NiMo B-11Claudia MmsPas encore d'évaluation

- Stellite 21Document2 pagesStellite 21Mohsen ParpinchiPas encore d'évaluation

- Weldability of Cr-Mo SteelsDocument20 pagesWeldability of Cr-Mo SteelsNitin Bajpai100% (2)

- TDS - Nimrod C276KSDocument1 pageTDS - Nimrod C276KSImmalatulhusnaPas encore d'évaluation

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghPas encore d'évaluation

- High Quality Products For Welding and CladdingDocument25 pagesHigh Quality Products For Welding and Claddingsanketpavi21100% (1)

- 11-14%Cr IIW Document - Part 2 PDFDocument21 pages11-14%Cr IIW Document - Part 2 PDFManuel CarreñoPas encore d'évaluation

- E8018-B6 Data SheetDocument2 pagesE8018-B6 Data SheetMurad AlmoudiPas encore d'évaluation

- Stellite 6 DS01-21708 (S R0808)Document2 pagesStellite 6 DS01-21708 (S R0808)bwv1006Pas encore d'évaluation

- Nihonweld Industrial Welding Corp - High Quality Producer of Steel and Welding Consumables - Stainless Steel Electrodes - NIHONWELD NSS-308 - E308-16 PDFDocument2 pagesNihonweld Industrial Welding Corp - High Quality Producer of Steel and Welding Consumables - Stainless Steel Electrodes - NIHONWELD NSS-308 - E308-16 PDFJohnny Jr TumangdayPas encore d'évaluation

- Electrode Booklet F Web 100Document1 pageElectrode Booklet F Web 100satnamPas encore d'évaluation

- Advances in Wear Resistant Alloys and ApplicationsDocument56 pagesAdvances in Wear Resistant Alloys and ApplicationsMilanWaPas encore d'évaluation

- CuniDocument32 pagesCunikampit100% (1)

- 20NiCrMo2-2 Alloy Steel DIN 1.6523 AISI 8620 SteelDocument5 pages20NiCrMo2-2 Alloy Steel DIN 1.6523 AISI 8620 SteelzhenyupanPas encore d'évaluation

- 02.CARBO - RC 3 Blau eDocument1 page02.CARBO - RC 3 Blau eMario CastilloPas encore d'évaluation

- Nickel Alloy Based Filler MetalDocument1 pageNickel Alloy Based Filler MetaljoehodohPas encore d'évaluation

- Datasheet Sandvik Saf 2205 enDocument15 pagesDatasheet Sandvik Saf 2205 enoctavioPas encore d'évaluation

- Prodcat Exotic MetalsDocument37 pagesProdcat Exotic MetalsMichael ClaphamPas encore d'évaluation

- sdg4 - 9 - STAINLESS STEELDocument3 pagessdg4 - 9 - STAINLESS STEELJian Ming WongPas encore d'évaluation

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantD'EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesD'EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Spot Welding Interview Success: An Introduction to Spot WeldingD'EverandSpot Welding Interview Success: An Introduction to Spot WeldingPas encore d'évaluation

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Probeta FileteDocument1 pageProbeta FileterobertPas encore d'évaluation

- At 400 EquipoDocument2 pagesAt 400 EquiporobertPas encore d'évaluation

- Order Confirmation for Robert Toasa from Northern ToolDocument1 pageOrder Confirmation for Robert Toasa from Northern ToolrobertPas encore d'évaluation

- Ut Med EspesorDocument1 pageUt Med EspesorrobertPas encore d'évaluation

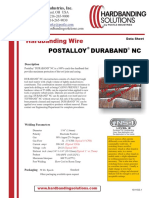

- Duraband PDFDocument1 pageDuraband PDFrobertPas encore d'évaluation

- Zona PanelDocument7 pagesZona PanelrobertPas encore d'évaluation

- LT 7 TractorDocument4 pagesLT 7 TractorsergesxPas encore d'évaluation

- KingpinDocument2 pagesKingpinrobertPas encore d'évaluation

- LT 7 TractorDocument4 pagesLT 7 TractorsergesxPas encore d'évaluation

- Clemco SandbalstingDocument8 pagesClemco SandbalstingrobertPas encore d'évaluation

- Fundamentals of Extrusion: © 2000 ASM International. All Rights Reserved. Aluminum Extrusion Technology (#06826G)Document29 pagesFundamentals of Extrusion: © 2000 ASM International. All Rights Reserved. Aluminum Extrusion Technology (#06826G)robertPas encore d'évaluation

- Aws A5.11Document50 pagesAws A5.11robert100% (1)

- Holland FifthWheelDocument92 pagesHolland FifthWheelrobertPas encore d'évaluation

- Pre Test QuestionsDocument2 pagesPre Test QuestionsAndresNicolasBouvierPas encore d'évaluation

- Caso Codigo 2541 - Asme VDocument1 pageCaso Codigo 2541 - Asme VMiguel Angel Aguilar MenaPas encore d'évaluation

- Weld OverlayDocument3 pagesWeld Overlayrobert100% (1)

- Hard BandingDocument4 pagesHard BandingrobertPas encore d'évaluation

- Uns N06625Document1 pageUns N06625robertPas encore d'évaluation

- Sulzer RTA air start valve operating principleDocument5 pagesSulzer RTA air start valve operating principleHrishikesh More100% (1)

- Application Data Sheet: General InformationDocument5 pagesApplication Data Sheet: General InformationAugusto PenessiPas encore d'évaluation

- Lathe Machine Specifications Specification Unit Specification UnitDocument1 pageLathe Machine Specifications Specification Unit Specification UnitTHIRUMALAIPas encore d'évaluation

- Comparision IS VS EURO PDFDocument7 pagesComparision IS VS EURO PDFRadhaKrishnanTPas encore d'évaluation

- Theory of ElasticityDocument719 pagesTheory of ElasticityAlberto Gaxiola HernándezPas encore d'évaluation

- Bsen 3310 Flow Meter Discharge Coefficient EstimationDocument7 pagesBsen 3310 Flow Meter Discharge Coefficient Estimationapi-300980681Pas encore d'évaluation

- Meniu Skoda PDFDocument5 pagesMeniu Skoda PDFCoso MotoPas encore d'évaluation

- Ashok Leyland In-Plant Training ReportDocument12 pagesAshok Leyland In-Plant Training Reportbalakvit100% (2)

- TECUMSEH Model Number CodesDocument6 pagesTECUMSEH Model Number Codesd3xter0% (1)

- Forging Learning Plan Thors Elearning SolutionsDocument1 pageForging Learning Plan Thors Elearning SolutionsNagaraju MuruguduPas encore d'évaluation

- ID2CNC MachineExplode AllDocument22 pagesID2CNC MachineExplode AllNixonGarcia100% (1)

- ASTM E23-12c PDFDocument25 pagesASTM E23-12c PDFSantiago Oliva100% (2)

- Therm-O-Disc Bimetal-60t-Section-En-Us-5469064Document14 pagesTherm-O-Disc Bimetal-60t-Section-En-Us-5469064Phạm Thiên TrườngPas encore d'évaluation

- Drive Diagram: Total Weight 70 TDocument10 pagesDrive Diagram: Total Weight 70 TAlanPas encore d'évaluation

- Wetted Wall Column Experiment and Set UPDocument4 pagesWetted Wall Column Experiment and Set UPvarun kumarPas encore d'évaluation

- Design and Fabrication of Pneumatic Quick Return MechanismDocument43 pagesDesign and Fabrication of Pneumatic Quick Return MechanismvinothPas encore d'évaluation

- Massey Ferguson Mf4263 Part CatalogueDocument20 pagesMassey Ferguson Mf4263 Part Cataloguescott100% (52)

- 7 - Psy - Chart - XLS Cooling CoilDocument28 pages7 - Psy - Chart - XLS Cooling CoilRanu JanuarPas encore d'évaluation

- r7310306 Heat TransferDocument4 pagesr7310306 Heat TransfersivabharathamurthyPas encore d'évaluation

- Rotary ActuatorDocument4 pagesRotary ActuatorAnderson Luiz GambaroPas encore d'évaluation

- 2017 - Aquaflair Chillers Brochure PDFDocument76 pages2017 - Aquaflair Chillers Brochure PDFJeffPas encore d'évaluation

- Circular Motion, Buoyancy, and DensityDocument13 pagesCircular Motion, Buoyancy, and DensityAshutosh Kumar SinghPas encore d'évaluation

- CDL Test AnswersDocument13 pagesCDL Test AnswersRichard Tod Gould100% (1)

- Tac 07 CsaDocument36 pagesTac 07 CsaWalter TaipePas encore d'évaluation

- TRANE Product Report - ERTAF 355 HE - 5.6 - 11.2Document1 pageTRANE Product Report - ERTAF 355 HE - 5.6 - 11.2ZeeshanPas encore d'évaluation

- Process Design of Distillation ColumnDocument6 pagesProcess Design of Distillation ColumncristianoPas encore d'évaluation

- Solution To Quiz 1 Fluid MechanicsDocument7 pagesSolution To Quiz 1 Fluid MechanicsMark Augusto V. AgusPas encore d'évaluation

- 2.875 P110 8.70ppf PH6-TS6Document1 page2.875 P110 8.70ppf PH6-TS6Giana KoesoemahPas encore d'évaluation

- Nabl 107 PDFDocument29 pagesNabl 107 PDFGurdeep SinghPas encore d'évaluation

- BS 4504-Part 3.2Document31 pagesBS 4504-Part 3.2Simon LawPas encore d'évaluation