Académique Documents

Professionnel Documents

Culture Documents

Operations Manual

Transféré par

winarnobCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Operations Manual

Transféré par

winarnobDroits d'auteur :

Formats disponibles

3601 48 Street

Wetaskiwin, Alberta T9A 3N9

Phone: (780) 361-2350

Toll Free: (866) ANNUGAS

Fax: (780) 361-2355

Email: info@annugas.com

ANNUGAS PRODUCTION ENHANCER

OPERATIONS AND MAINTENANCE MANUAL

Contents

Operation of Annugas Production Enhancer ............................................................................ 3

Normal Operations ................................................................................................................. 3

Pressure Regulated Bypass ................................................................................................... 3

Manually Bypass the Compressor .......................................................................................... 3

Isolating Compressor.............................................................................................................. 3

Without a Pressure Regulator ................................................................................................. 4

Shutting the Pumping Unit Down ............................................................................................ 4

Starting up the Pumping Unit .................................................................................................. 4

Operations in Temperatures Below 5C (40F) ....................................................................... 5

Maintenance of Annugas Production Enhancer ....................................................................... 5

Figure 1: Valve Positions in Typical Normal Operations ............................................................ 6

Figure 2: Valve Positions in Manual Bypass Mode ..................................................................... 7

Figure 3: Valve Positions to Isolate the Compressor .................................................................. 8

Figure 4: Valve Positions in Normal Operations without Pressure Regulator .............................. 9

Page 1 Document: AE-008 Rev 0

Revision Date: 12 Feb 2015

3601 48 Street

Wetaskiwin, Alberta T9A 3N9

Phone: (780) 361-2350

Toll Free: (866) ANNUGAS

Fax: (780) 361-2355

Email: info@annugas.com

ANNUGAS PRODUCTION ENHANCER

OPERATIONS AND MAINTENANCE MANUAL

The Annugas Production Enhancer is an engineered Walking Beam Compressor for mounting

to the pumping unit of an oil well. As such, only Annugas Compression Consulting Ltd. Service

Technicians are trained and qualified to service this equipment.

Modifying parts, not using the proper bolts, nuts, and washers, and unauthorized service will

void your warranty and may cause equipment damage and/or personal injury.

Maximum working pressures are:

AG600 series: 400 psi

AG800 series: 225 psi

AG1000 series: 135 psi

Fuel Gas Scrubber: 600 psi

The working pressures for the AG600, AG800, and AG1000 series compressors are determined

so that the forces generated by the piston rod of the compressor are limited. Excessive piston

rod loads can cause damage to the pumping unit, including but not limited to the walking beam,

bearings and gear box.

If the compressor is not required in the field, it should be removed and examined by an Annugas

Compression Consulting Ltd. Service Technician. Afterwards, it should be stored in a dry

location.

Recommended Components

Pressure Regulator; a pressure regulator can be used to prevent the casing from going

into a vacuum or to prevent excessive rod load which can cause damage to the pumping

unit, compressor, or both,

Fuel Gas Scrubber; a fuel gas scrubber can be used to separate fluids from the gas and

prevent fluids from getting into the compressor,

High Level Shutdown; a high level shutdown sensor is installed on the fuel gas scrubber

and used to shut down the pumping unit and compressor before fluids can enter the

compressor.

What Not To Do

Do not leave the suction valve open when the pumping unit is shut down. Well pressure

can build up and flow gas and liquids through the compressor,

Do not lengthen the stroke of the pumping unit, increase pressure relief valve settings, or

modify the installation without calling Annugas Compression Consulting Ltd.,

Do not oil or grease any bearings or the piston rod,

Do not heat trace or insulate the compressor cylinder,

Do not remove the compressor by taking the cross pins out of the top or bottom bearing

or clevis.

Page 2 Document: AE-008 Rev 0

Revision Date: 12 Feb 2015

3601 48 Street

Wetaskiwin, Alberta T9A 3N9

Phone: (780) 361-2350

Toll Free: (866) ANNUGAS

Fax: (780) 361-2355

Email: info@annugas.com

Operation of Annugas Production Enhancer

Normal Operations

For normal operations, the gas flow and valve positions on a typical installation with a regulator

are shown in Figure 1. The gas will flow through the fuel gas scrubber to the compressor and

then to the production flow line as below:

1. From the casing through the suction line,

2. Into the fuel gas scrubber manifold piping,

3. Into the fuel gas scrubber,

4. Out of the fuel gas scrubber to the suction of the compressor,

5. Out of the compressor discharge to the fuel gas scrubber manifold,

6. Out of the fuel gas scrubber manifold to the discharge line,

7. From the discharge line into the production flow line.

8. The first valve coming off the fuel gas scrubber on the drain line is to remain open to

allow fluids to flow back to the wellhead.

Pressure Regulated Bypass

When the compressor flow rate is larger than the gas production of the well, the compressor will

draw the casing into a vacuum. In this case, the pressure regulator will open and allow gas

from the discharge lines to enter the suction lines of the compressor to make up for any gas

shortage. This will keep the compressor from drawing the casing into a vacuum.

To verify that the pressure regulator is functioning as required, close the valve from the suction

line to the casing. With the compressor operating normally, the pressure gauge on the suction

line at the wellhead will show the pressure drop and hold at the set point of the regulator. The

set point for the pressure regulator is set on installation based on well parameters and could

vary from well to well.

Manually Bypass the Compressor

In order to manually bypass the compressor, refer to Figure 2 to show the valve position for the

bypass valve. If the compressor is to be left running, leave the automatic drain line and the

drain connection to wellhead valves open so that fluids will continue to drain.

It is important to remember that with the compressor in manual bypass; well gas, well oil,

chemicals, and other well fluids can still get into the compressor. For chemical injections,

circulating the well, and other interventions, the compressor must be isolated.

Isolating Compressor

In order to isolate the compressor from the wellhead refer to Figure 3 and follow the steps

below:

1. Open the manual bypass valve on the fuel gas scrubber manifold piping,

2. Close the valve that connects the suction line to the casing and the valve connecting the

discharge line to the production flow line.

3. Close the drain connection to wellhead valve to isolate the fuel gas scrubber.

Page 3 Document: AE-008 Rev 0

Revision Date: 12 Feb 2015

3601 48 Street

Wetaskiwin, Alberta T9A 3N9

Phone: (780) 361-2350

Toll Free: (866) ANNUGAS

Fax: (780) 361-2355

Email: info@annugas.com

4. The compressor can be left operating with the pumping unit running or the pumping unit

can be shut down.

Without a Pressure Regulator

If there is no pressure regulator on the piping system for the Annugas Production Enhancer,

the typical normal operation of the valves is illustrated in Figure 4. To isolate the compressor

with this system, follow the same procedures as outlined above in the Manual Bypass section.

Shutting the Pumping Unit Down

If the pumping unit is to be shut down for any reason, the following procedure is to be followed:

1. The pumping unit must be shut down so that the piston rod and piston are at bottom on

the compressor. To clarify, the piston rod will have the least amount of rod showing

above the packing. For example, on a conventional pumpjack with the compressor

installed between the center (saddle or pivot) bearing and the equalizer (tail) bearing the

pumpjack will be stopped so that the horses head is at the highest point. This is the

point when the crank arm and the pitman arm are inline and not necessarily when the

weights are at the lowest point.

2. Isolate the compressor using the procedure above for Isolating Compressor. Ensure

that the drain connection to wellhead valve is closed.

3. With the manual bypass valve open and the drain connection to wellhead valve closed,

slowly open the manual drain valve to bleed down the pressure and drain any fluids that

might have accumulated and prevent any fluids from accumulating above or below the

piston of the compressor.

4. If the compressor is to be shut down for long periods, it is strongly recommended that

an Annugas Service Technician take down the compressor and prepare it for storage.

This will limit the amount of corrosion from occurring.

This shut down position is critical when the ambient temperatures are below 5C (40F) as any

fluids in the compressor could freeze. Failure to shut down the pumping unit in the

recommended position could result in equipment damage and/or personal injury.

Starting up the Pumping Unit

When starting up the pumping unit after the unit has been shut down, the following procedure

should be used:

1. Bump (quickly turn pumping unit motor on and off) pumping unit motor switch for the first

couple turns of the crank arm. Use these cycles to watch the compressor to ensure that

the compressor moves freely and is not binding.

2. Slowly open the suction line valve to allow the casing gas to fill the compressor,

scrubber and all lines.

3. Slowly open the discharge line valve.

4. Open the drain connection to wellhead valve.

5. Turn on the pumping unit for normal operations.

6. Close the bypass valve and make sure that the compressor is working.

7. Once proper operation is confirmed, the valves on the scrubber manifold should be

returned to normal operations as shown in Figure 1.

Page 4 Document: AE-008 Rev 0

Revision Date: 12 Feb 2015

3601 48 Street

Wetaskiwin, Alberta T9A 3N9

Phone: (780) 361-2350

Toll Free: (866) ANNUGAS

Fax: (780) 361-2355

Email: info@annugas.com

If the compressor appears to bind or jam or if there is unusual noises being generated by the

compressor, the pumping unit should be shut down and Annugas should be called and an

Annugas Service Technician should inspect the compressor and service the compressor if

required.

Operations in Temperatures Below 5C (40F)

It is recommended that the piping manifolds on both the compressor and fuel gas scrubber be

insulated and heat traced. Additional insulation and heat trace are recommended for the fuel

gas scrubber, all hoses and/or piping between the compressor, fuel gas scrubber, and wellhead,

and the drain line from the fuel gas scrubber to the wellhead. The compressor cylinder shall not

be insulated so that additional heat generated by the compression of the gas is dissipated.

Methanol injection may also be required depending on temperature and well conditions.

Generally all installations will have a methanol pot installation at the connection of the suction

line to the wellhead and beside the pressure safety valve (PSV) on the fuel gas scrubber. The

methanol pot is a series of swaged fitting and valves that will allow the operator to safely inject

methanol into the system without being exposed to wellhead pressure or fluids.

Maintenance of Annugas Production Enhancer

The Annugas Production Enhancer is virtually maintenance free. Servicing by Annugas

Compression Consulting Ltd. Service Technicians is strongly recommend at periods not

exceeding twelve (12) month intervals. Please contact Annugas to arrange a service.

Items that should be checked by the well operators are:

The pressure gauges at the wellhead for the suction and discharge pressures should be

checked daily or at an interval not exceeding one (1) week. The suction pressure should

be less than the discharge pressure if the compressor is still operating efficiently. The

pressures will vary from well to well however the suction pressure should remain

constant as long as the well characteristics has not changed.

The manual drain valve should be checked daily to ensure that there is not buildup of

fluids in the fuel gas scrubber. It is the responsibility of the well operator to ensure that

this is performed in a safe and responsible manner.

Page 5 Document: AE-008 Rev 0

Revision Date: 12 Feb 2015

3601 48 Street

Wetaskiwin, Alberta T9A 3N9

Phone: (780) 361-2350

Toll Free: (866) ANNUGAS

Fax: (780) 361-2355

Email: info@annugas.com

Figure 1: Valve Positions in Typical Normal Operations

Page 6 Document: AE-008 Rev 0

Revision Date: 12 Feb 2015

3601 48 Street

Wetaskiwin, Alberta T9A 3N9

Phone: (780) 361-2350

Toll Free: (866) ANNUGAS

Fax: (780) 361-2355

Email: info@annugas.com

Figure 2: Valve Positions in Manual Bypass Mode

Page 7 Document: AE-008 Rev 0

Revision Date: 12 Feb 2015

3601 48 Street

Wetaskiwin, Alberta T9A 3N9

Phone: (780) 361-2350

Toll Free: (866) ANNUGAS

Fax: (780) 361-2355

Email: info@annugas.com

Figure 3: Valve Positions to Isolate the Compressor

Page 8 Document: AE-008 Rev 0

Revision Date: 12 Feb 2015

3601 48 Street

Wetaskiwin, Alberta T9A 3N9

Phone: (780) 361-2350

Toll Free: (866) ANNUGAS

Fax: (780) 361-2355

Email: info@annugas.com

Figure 4: Valve Positions in Normal Operations without Pressure Regulator

Page 9 Document: AE-008 Rev 0

Revision Date: 12 Feb 2015

Vous aimerez peut-être aussi

- Issues No 27 ContentDocument11 pagesIssues No 27 ContentwinarnobPas encore d'évaluation

- 13 Tips Presentasi Efektif - A Madeandi's Life PDFDocument9 pages13 Tips Presentasi Efektif - A Madeandi's Life PDFwinarnobPas encore d'évaluation

- Structural Vibration and Ways To Avoid It - Vibration, Dynamics and Noise PDFDocument3 pagesStructural Vibration and Ways To Avoid It - Vibration, Dynamics and Noise PDFwinarnobPas encore d'évaluation

- Inflow & Outflow Performance Archives - Production TechnologyDocument7 pagesInflow & Outflow Performance Archives - Production Technologywinarnob100% (2)

- Glycol DehydrationDocument1 pageGlycol DehydrationwinarnobPas encore d'évaluation

- Structural Vibration and Ways To Avoid It - Vibration, Dynamics and Noise PDFDocument3 pagesStructural Vibration and Ways To Avoid It - Vibration, Dynamics and Noise PDFwinarnobPas encore d'évaluation

- Barebow Archery NotesDocument11 pagesBarebow Archery NoteswinarnobPas encore d'évaluation

- Pipeline Annual ReportDocument9 pagesPipeline Annual ReportwinarnobPas encore d'évaluation

- Inflow & Outflow Performance Archives - Production TechnologyDocument7 pagesInflow & Outflow Performance Archives - Production Technologywinarnob100% (2)

- Deep Bed Nutshell Filter Evolution English LetterDocument15 pagesDeep Bed Nutshell Filter Evolution English LetterArun GuptaPas encore d'évaluation

- Fax - 600-EP2200-2015-S0 - 64821 - Presentasi Operation Integrity Management For Oil and Gas IndustryDocument2 pagesFax - 600-EP2200-2015-S0 - 64821 - Presentasi Operation Integrity Management For Oil and Gas IndustrywinarnobPas encore d'évaluation

- Risk AssessmentDocument2 pagesRisk AssessmentwinarnobPas encore d'évaluation

- Pipeline Annual ReportDocument9 pagesPipeline Annual ReportwinarnobPas encore d'évaluation

- Commuterline Schedule Update 22 July 2017 Yellow Line Jatinegara BogorDocument40 pagesCommuterline Schedule Update 22 July 2017 Yellow Line Jatinegara BogorBayuPas encore d'évaluation

- Why Compression Ratio Matters PDFDocument10 pagesWhy Compression Ratio Matters PDFwinarnobPas encore d'évaluation

- 2014 Lean Management Enterprise Compendium With LinksDocument164 pages2014 Lean Management Enterprise Compendium With LinksSajid AliPas encore d'évaluation

- Indocita Annual Training Schedule 2017 (Update)Document4 pagesIndocita Annual Training Schedule 2017 (Update)winarnobPas encore d'évaluation

- E 881511 Om GSCTP C P RC GBR 6-A4Document72 pagesE 881511 Om GSCTP C P RC GBR 6-A4winarnobPas encore d'évaluation

- D-PGS3-0-1225-306-C 1 of 2Document1 pageD-PGS3-0-1225-306-C 1 of 2winarnobPas encore d'évaluation

- How To Start Building Your Next-Generation Operating Model - McKinsey & CompanyDocument13 pagesHow To Start Building Your Next-Generation Operating Model - McKinsey & CompanywinarnobPas encore d'évaluation

- Basic Practices in Compressors Selection PDFDocument11 pagesBasic Practices in Compressors Selection PDFwinarnob100% (1)

- Why Compression Ratio Matters2 PDFDocument10 pagesWhy Compression Ratio Matters2 PDFwinarnobPas encore d'évaluation

- An Improved Method For Evaluating Compressor Rod Bushing DesignsDocument5 pagesAn Improved Method For Evaluating Compressor Rod Bushing Designswinarnob100% (1)

- Why Compression Ratio MattersDocument10 pagesWhy Compression Ratio MatterswinarnobPas encore d'évaluation

- How To Start Building Your Next-Generation Operating Model - McKinsey & CompanyDocument13 pagesHow To Start Building Your Next-Generation Operating Model - McKinsey & CompanywinarnobPas encore d'évaluation

- Brochure & Registration Form 13-15 March 2017Document3 pagesBrochure & Registration Form 13-15 March 2017winarnobPas encore d'évaluation

- Process Safety Management Guidelines For ComplianceDocument16 pagesProcess Safety Management Guidelines For CompliancewinarnobPas encore d'évaluation

- D-PGS3-0-1225-306-C 2 of 2Document1 pageD-PGS3-0-1225-306-C 2 of 2winarnobPas encore d'évaluation

- Chevron Business Conduct Ethics CodeDocument31 pagesChevron Business Conduct Ethics CodewinarnobPas encore d'évaluation

- CM Vs GC 7pages PDFDocument7 pagesCM Vs GC 7pages PDFwinarnobPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Liquid Ring Vacuum Pumps: KinneyDocument12 pagesLiquid Ring Vacuum Pumps: KinneyTrang DangPas encore d'évaluation

- List Solo Run + MRTDocument1 pageList Solo Run + MRTveby enandesPas encore d'évaluation

- Chapter 1Document199 pagesChapter 1Mohd Syafiq AkmalPas encore d'évaluation

- Experimental Studies On Heat Transfer and Pressure Drop Characteristics For New Arrangements of Corrugated Tubes in A Double Pipe Heat ExchangerDocument10 pagesExperimental Studies On Heat Transfer and Pressure Drop Characteristics For New Arrangements of Corrugated Tubes in A Double Pipe Heat ExchangerkumarPas encore d'évaluation

- Optimizing and Troubleshooting Plunger Lift Wells2Document51 pagesOptimizing and Troubleshooting Plunger Lift Wells2henry99Pas encore d'évaluation

- Thermodynamic Properties of Fluids (Chap 3) SmithDocument70 pagesThermodynamic Properties of Fluids (Chap 3) SmithS S S REDDY100% (1)

- With ASME ' U ' StampDocument4 pagesWith ASME ' U ' StampOSWALINFRA HEDPas encore d'évaluation

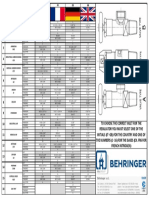

- Cylinder ConnectionsDocument1 pageCylinder ConnectionsВиктор100% (1)

- Selecting Amines For Sweetening Units PDFDocument9 pagesSelecting Amines For Sweetening Units PDFGui Do EspPas encore d'évaluation

- Cargo Operating Manual Grace AcaciaDocument311 pagesCargo Operating Manual Grace Acaciamaronnam75% (4)

- CAGI Data Sheet - 2209 PDFDocument1 pageCAGI Data Sheet - 2209 PDFShiro EmiyaPas encore d'évaluation

- Hyd Int Val 20HM20 Rev 0110Document2 pagesHyd Int Val 20HM20 Rev 0110Malique AdamPas encore d'évaluation

- Lab Name: Performance and Analysis of Kaplan Turbine On Multi Turbine TestDocument11 pagesLab Name: Performance and Analysis of Kaplan Turbine On Multi Turbine TestFarhan EdwinPas encore d'évaluation

- Poseidon Product Range 2021-1-sc811Document29 pagesPoseidon Product Range 2021-1-sc811Урош ypow ypocPas encore d'évaluation

- Gaseous StateDocument12 pagesGaseous StateRaju Singh0% (1)

- Air Pollution Dispersion Modeling PDFDocument6 pagesAir Pollution Dispersion Modeling PDFadcaPas encore d'évaluation

- Ds Fluor BasfDocument4 pagesDs Fluor BasfAnil KumarPas encore d'évaluation

- CFD Module: User's GuideDocument572 pagesCFD Module: User's GuideResul SahinPas encore d'évaluation

- Fluid Transients in Pipeline Systems (1st Edition) - ThorleyDocument264 pagesFluid Transients in Pipeline Systems (1st Edition) - ThorleyMamoon Riaz100% (9)

- Manual Bomba Versa MaticDocument18 pagesManual Bomba Versa Maticregue_g_801719926100% (1)

- Heat NoDocument234 pagesHeat NoDARMAPas encore d'évaluation

- TitusDocument215 pagesTitusJorgePas encore d'évaluation

- Description of Damage: 5.1.1.1 Amine Corrosion 5.1.1.1.1Document5 pagesDescription of Damage: 5.1.1.1 Amine Corrosion 5.1.1.1.1Ajmi HmidaPas encore d'évaluation

- Sizing Pressure RelievingDocument20 pagesSizing Pressure RelievingNuch NapapornPas encore d'évaluation

- Unit 2 Lecture 6 - Energy ConsiderationsDocument9 pagesUnit 2 Lecture 6 - Energy ConsiderationsEstherPas encore d'évaluation

- Cat Acetylene A-40 FillingDocument2 pagesCat Acetylene A-40 FillingJohan Cazon MorenoPas encore d'évaluation

- MY PPT On LNGDocument35 pagesMY PPT On LNGAlekhya Bandaru100% (2)

- Developed Laminar Flow in Pipe Using Computational Fluid DynamicsDocument10 pagesDeveloped Laminar Flow in Pipe Using Computational Fluid Dynamicsyashsaini020Pas encore d'évaluation

- Float Valve Type Hfi Made DanfossDocument12 pagesFloat Valve Type Hfi Made DanfossAngela Viviana ChiquizaPas encore d'évaluation

- Matlab - Equations of StateDocument23 pagesMatlab - Equations of StateMia Beatrice Benavidez MawiliPas encore d'évaluation